Page 1

GE Power & Water

Water & Process Technologies

Analytical Instruments

Fact Sheet

Sievers 500 RL

e

On-Line TOC Analyzer

Advancing the science of ultra low-level TOC

measurement in microelectronics applications

Overview

The Sievers* 500 RLe On-Line TOC Analyzer is the

semiconductor industry’s only on-line, reagentless TOC

analyzer capable of accurately detecting problematic

compounds such as urea, trimethylamine (TMA),

organic acids and organic bases.

An on-line Total Organic Carbon (TOC) analyzer should

be as simple as possible, but not so simple that it

exposes the fabrication operations to unacceptable

risks associated with undetected organic transients.

Recently the leading global semiconductor immersion

tool manufacturer has required all TOC measurements

of the water feeding their tools to include the accurate

measurement of organic nitrogen compounds in the

ultrapure water (UPW).1 Some brands of TOC analyzers

are simply not able to measure commonly present

organic nitrogen compounds such as urea or TMA in

the UPW.

measures them to meet this new TOC performance

requirement.

1,2

The 500 RLe accurately and reproducibly

showed that 91% of all the Instrument-to-Instrument

TOC readings were within ± 0.05 ppb C. Additionally

44,272 LOD analyses were performed on the same ve

analyzers, and 98% of the time the TOC LOD was less

than 0.02 ppb C (see Figures 3 and 4). It is notable that

this performance is achieved automatically without

the need to do manual re-calibration operations or

to send the analyzer osite for special calibrations, as

often required by other TOC sensors.

e

Design enhancements allow the 500 RL

on higher conductivity waters than the PPT while still

delivering the same analytical performance. As a result,

the 500 RLe oers greater versatility and reliability.

Specic attention has been paid to performance on

low dissolved oxygen (DO) water systems, resolving

TOC recovery issues that are problematic for other

reagentless TOC analyzers.

to operate

The 500 RLe uses GE Analytical Instruments’ proprietary

membrane conductometric technology, delivering ultra

low-level accuracy and reliability by eliminating false

positive and false negative readings associated with

other simplied TOC technologies (see Figures 1 and 2).

The 500 RLe automatically exhibits the best-inclass Instrument-to-Instrument matching and the

lowest Limit of Detection (LOD) for reagentless

online semiconductor UPW TOC analyzers. Five

500 RLe Analyzers were placed on the same major

semiconductor companies’ 0.3 ppb C UPW and data

was collected for two months. The large data set

Applications

Microelectronics Ultrapure Process Waters

The 500 RLe Analyzer’s remarkable Instrumentto-Instrument matching allows you to condently

compare TOC results between dierent water loops

in your factory and around the world. The very high

sensitivity, as demonstrated by the LOD, allows you to

see the smallest change in your system before it gets

out of control.

For the most advanced state-of-the-art chip

manufacturing facilities’ requirements, there is never

a question about unmeasured organics that may be

Page 2

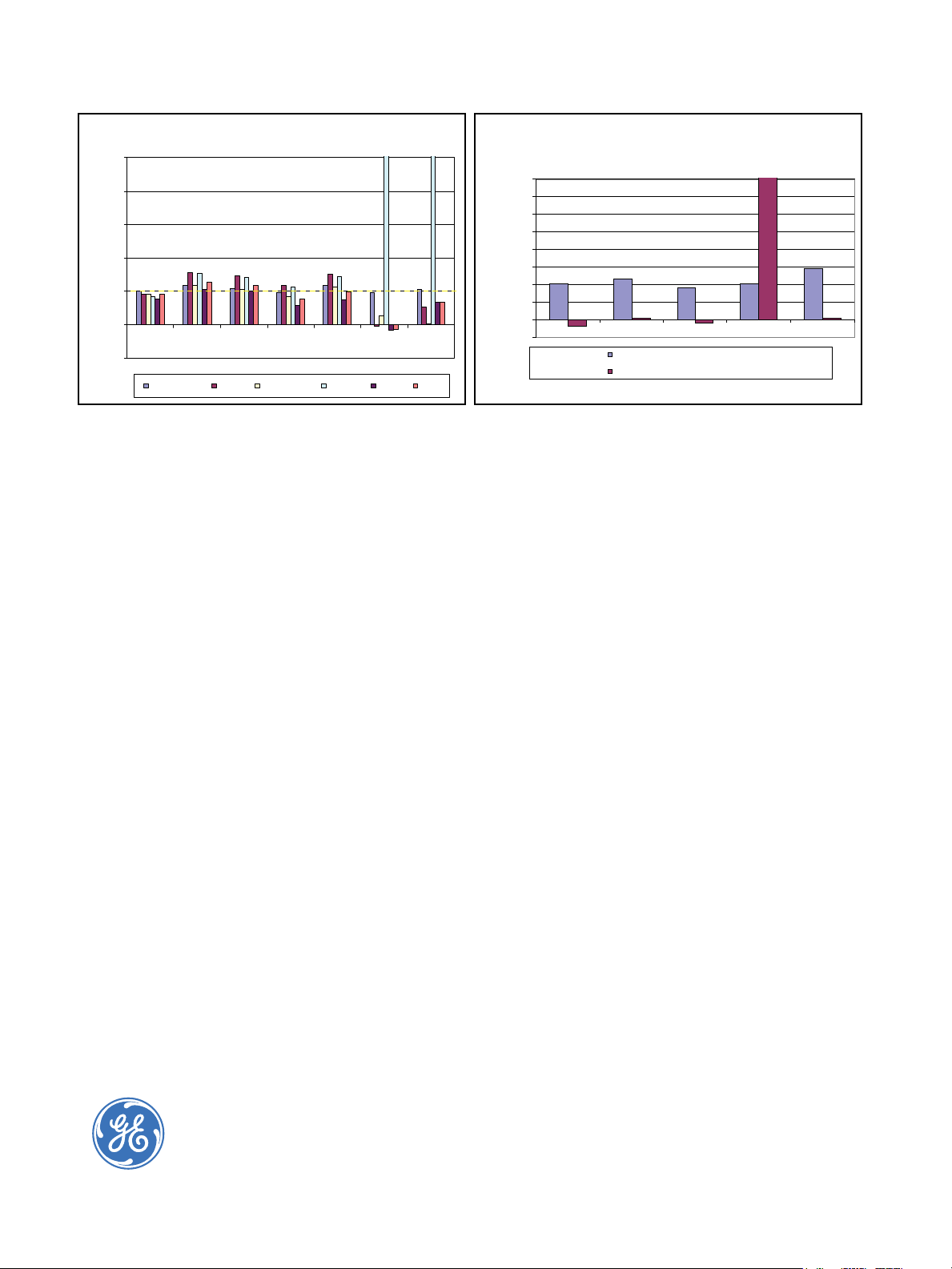

% Recovery on 5 ppb Injections

- Dissolved O

2

< 2 ppb

% Recovery for 5 ppb TOC Injections

500

400

300

200

% Recovery

100

0

900 500-24 500-19 PPT-6 PPT-9 A-1000 5000TOC

-100

2-Propanol Urea Acetic Acid C HCl3TMA TMAH

% Recovery for 5 ppb TOC Injections

% Recovery on 5 ppb Injections - Dissolved O2 < 2 ppb

400

350

300

250

200

150

100

% Recovery

50

0

TMA 2-Propanol Aceti c Acid Chloroform Urea

-50

Sievers (Membrane Conductometric)

Competition (Direct Conductometric)

Figure 1. Recovery comparison of Sievers and other brands

aecting the lithography or another critical process.

Because you are measuring all the organics with the

500 RLe, your facilities engineers are given the best tool

to optimize their processes. The top semiconductor

companies in the world accept no other options for

their critical UPW TOC measurements.

Low DO / Hydrogenated Water Applications

Low DO and hydrogenated water systems are becoming

more common in microelectronics applications. Low DO

systems present a signicant challenge to reagentless

TOC analyzers because all reagentless TOC analyzers

rely on the process water as a source of oxygen for fully

oxidizing the organics in the sample.

In low DO systems, there is insucient oxygen available

to facilitate full oxidation, resulting in articially low TOC

results. If a contamination event occurs, the lack of

oxygen may prevent complete oxidation of the organics.

Consequently, most analyzers will show little or no change

in the TOC value. Only the Sievers 500 RLe incorporates

trace oxygen addition to ensure fully oxidized organics in

low DO and hydrogenated water systems. This gives you

the ability to see important changes in your water system

that other analyzers completely miss (see Figure 2).

Figure 2. Recovery graph for TOC injections

Robust Method

TOC Recovery

The 500 RLe has been extensively tested to demonstrate

comparability to the Sievers PPT Analyzer as well as

superior performance relative to competitive TOC

technologies.

of the 500 RLe in normal and Low DO systems, compared

to the PPT and alternative TOC technologies.

Risk of Simplied TOC Methods

Can you trust the TOC results from your analyzer

to provide your fabrication engineers with the best

measurement tools? Simplied TOC methods used in

other TOC analyzers expose the water system and fab

to contamination risks from compounds that these

simplied technologies can not detect. In numerous

published studies and technical papers,

simplied TOC analyzers have been demonstrated

to be incapable of reliable performance in waters

containing even the simplest organic compounds —

compounds known to exist in UPW systems, introduced

through the feed waters, resins, system materials,

and production processes. The Sievers membrane

technology dramatically enhances the ability to detect

and manage variations in TOC contamination that

can go unnoticed and uncontrolled with older, more

simplied TOC sensors.

1,2,3

Figures 1 and 2 show the performance

1,2,3

these

Page 3

91% of Measurements are within ± 0.05 ppb C

5 Separate 500 RLe On-line TOC Analyzers- Matching on Same 0.3 ppb C UPW

Data Collected for 2 Months n = 155,925 data points

25%

20%

15%

10%

% of Total Readings

5%

14%

0%

Difference Cumulative

100%

99%

96%

91%

79%

62%

47%

34%

Instrument-to-Instrument Matching (ppb C)

100%

100%

120%

100%

80%

60%

40%

20%

0%

98% of LODs are Less that 0.02 ppb C

Five Each On-line 500 RLe TOC Analyzers- Same UPW-32 Days

LODs Calculated Using a 10 PT Moving Average N = 44,272 Separate LOD Analyses

80%

70%

60%

70%

50%

40%

30%

Cumulative %

20%

10%

0%

0-0.01 0.01-0.02 0.02-0.03 0.03-0.04 0.04-0.05 > 0.05

98%

99%

Percent of values Cumulative

99%

LOD (ppb C)

99%

100%

120%

100%

80%

60%

40%

20%

0%

Figure 3. Instrument-to-Instrument study results proving the

± 0.05 ppb C match between ve analyzers

Key Features

Economical Designs

The 500 RLe comes in two models to meet your needs. The

500 RLe with Standard iOS (Integrated On-Line Sampling

System) utilizes the familiar Sievers sample inlet device,

allowing for on-site calibration and running standards

and grab samples. The 500 RLe Base Model utilizes a

simplied sample inlet block, facilitating continuous online operation. On-site calibration may be performed

using an optional iOS accessory. The 500 RLe Base Model

is cost-competitive with even the simplest TOC sensors,

while still providing superior analytical performance and

optional on-site calibration.

Higher Conductivity Limits

The 500 RLe incorporates design elements from the

Sievers 800 and 900 Series that enable reagentless

TOC measurement in waters up to 25 μS/cm at neutral

pH. Equally as important, this design enhancement

means that upsets and abnormal uctuations in UPW

system conductivity from plant transients do not aect

analytical performance.

Figure 4. LOD study results proving the 0.03 limit of detection

for multiple 500 RL

e

Analyzers

the lowest detection limit of any TOC analyzer on the

market — 0.03 ppb — and provides the condence

that all organics are being fully recovered regardless

of chemical composition. The automated advanced

TOC zero function provides world class Instrumentto-Instrument matching of ± 0.05 ppb C, allowing you

to compare critical dierences between water loops

at your site or on the other side of the world. The

combination of analytical sensitivity, Instrument-toInstrument matching, robustness, and stable sub-ppb

performance provides condence that critical UPW

and fabrication processes are controllable and that

even the most subtle trends can be closely monitored

to protect your manufacturing processes.

References

1

Godec, Richard D., “Monitoring and Controlling UPW Organic Nitrogen Contamination to Improve Immersion Photolithography Process Control.” Presented

at ULTRAPURE WATER Conference, Portland, OR, November 2011, Tall Oaks

Publishing, Inc.

2

Godec, Richard D., ”The Performance Comparison of Ultrapure Water TOC

Analyzers using an Automated Standard Addition Apparatus.” Published and

copyrighted by Semiconductor Pure Water and Chemical Conference, 2000

Proceedings.

3

Kauman, Jon S.,Ph.D., “Validating On-Line TOC Analyzers for Real-Time

Release.” Pharmaceutical Manufacturing, Nov/Dec 2006.

Sensitivity, Accuracy, Instrument-to-Instrument

Matching, and Stability

With microelectronic TOC limits being driven ever lower,

it is critical that TOC analyzers operate accurately

and reliably at sub-ppb levels. The 500 RLe achieves

Page 4

System Specications**

Total Organic Carbon

Range 0.03 to 2,500 ppb as C

Accuracy

Precision < 1% RSD or 0.03 ppb as C, whichever is greater

pH Range 5.5 to 8.0 in order to meet accuracy specication

Maximum Sample Conductivity 25 µS/cm at neutral pH

Analysis Modes On-Line, On-Line Averaged, On-Line Timed

Analysis Time Continuous mode: 6 minutes

Average and timed modes: 0.5, 1, 4, 8, or 24 hours

External Flow Rate Minimum 50 mL/min

Sample Temperature 1° C to 95° C (34° F to 203° F)

Sample Pressure Up to 100 psig

Interferences Insensitive to organic heteroatoms and measures

organic nitrogen

Calibration Stability Typically stable for 12 months

Display Readout 3 signicant digits

Instrument

Power 100–240 ±10% VAC, 50 W, 50/60 Hz

Normal Operating Environment Intended for indoor use only

Ambient Temperature 10° C to 40° C (50° F to 104° F)

Maximum Relative Humidity Up to 95%, noncondensing

Maximum Altitude 2,300 m (7,546 ft)

Inputs One isolated binary input

Outputs Three isolated 4-20 mA outputs, one Serial (RS-232), one USB

port, one parallel printer port, four alarm outputs, and one

Ethernet port

Installation/Overvoltage Category II (protects against transients present in Category II power)

Safety Certications ETL, CE

Pollution Degree 2 (normally only non-conductive pollution)

Display Backlit Quarter-VGA touchscreen display

Dimensions H: 41.9 cm (16.5 in); W: 48.3 cm (19 in); D: 27.4 cm (10.8 in)

Weight 16.9 kg (37.2 lb)

IP Rating Environmental enclosure: IP 45

Consumables

UV Lamp 6 months

Pump Tubing (with pump heads) 12 months

DI Water Cartridge Typically 24 months (depends on water quality)

Inline lter Replace as needed (depends on water quality)

DI Water Level Rell As needed (check when replacing other items)

± 0.1 ppb or ± 5% of measurement, whichever is greater

*Trademark of General Electric Company; may be registered in one or more countries.

**Stated analytical performance is achievable under controlled conditions that minimize operator and standards errors.

The Sievers 500 RL TOC Analyzers are protected by one or more of the following US and foreign patents: US 8,003,048; US 5,976,468; US 5,837,203; US 5,443,991; EP

0897530; FR 0897530; GB 0897530; DE 69702516.0-08. Other patents pending.

For more information, visit www.geinstruments.com. Find a sales partner near you through the “Contact Us” Section.

The Americas

GE Analytical Instruments

6060 Spine Road

Boulder, CO 80301-3687 USA

T +1 800 255 6964

T +1 303 444 2009

F +1 303 527 1797

geai@ge.com

www.geinstruments.com

Europe/Middle East/Africa

GE Analytical Instruments

Unit 3, Mercury Way

Urmston, Manchester

UK M41 7LY

T +44 (0) 161 864 6800

F +44 (0) 161 864 6829

geai.europe@ge.com

©2012, General Electric Company. All rights reserved.

Asia Pacic

GE Analytical Instruments

7/F, Building 2, No. 5 Hua Tuo Rd

ZhangJiang Hi-Tech Park, Pudong

Shanghai, China 201203

T +(8621) 38777775

F +(8621) 38777469

geai.asia@ge.com

300 00165 Rev E

ISO

9001:2008

QUALITY

MANAGEMENT

SYSTEM

MC12-043

Loading...

Loading...