Page 1

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

AM-FSpwSWRO2500_EN.doc Jun-13

Flow

Permeate, concentrate,

low pressure ERD inlet,

high pressure ERD outlet

Conductivity/ Temp

Feed, permeate

pH

Feed

Pressure Indicators

Pre-/post-filter, primary,

final, permeate, concen-

trate, pre-/post-ERD, pump

discharge

Pressure Switch

Feed, permeate,

concentrate

Pressure Transmitter

Primary, final

SeaPRO*-210

2500 m3/day Seawater Desalination Machine

General Features

Major components skid-mounted for easy in-

stallation

GE Fanuc QuickPanel 12-inch color display and

VersaMax processor

4-20 mA instruments on touchscreen

Primary and final pressure transmitters

Variable frequency drive (VFD) for high pressure

and boost pump

Stand alone master control enclosure, local

control enclosure with remote I/O

Standard package includes pressure exchanger

type energy recovery device

BASIC option package available including

booster type energy recovery device

Operating Parameters

Figure 1. SeaPRO-210 General Layout (reference only)

Frame ....................................... Painted blue carbon steel

Enclosures ........................................ NEMA 4 carbon steel

Membranes ................................................................. AD-400

Membrane Housing .................... FRP, 1000 PSI (69 bar)

Cartridge Filters ........... 1-micron nominal, ROsave.Zs

Recovery .............................................................................. 35%

Design temp. ........................................................ 25ºC (77F)

Operating range ............................... 15-32C (59-90F) 1

Design Feed TDS .............................................. 47,000 ppm

Nominal rejection ..................................................... 97-99%

Minimum inlet pressure .......................... 30 PSIG (2 bar)

1

Varying the operating temperature may affect permeate rate

Materials of Construction

High-pressure piping .......................... Super Austenitic/

Super Duplex material

Low-pressure piping ............................ Schedule 80 PVC

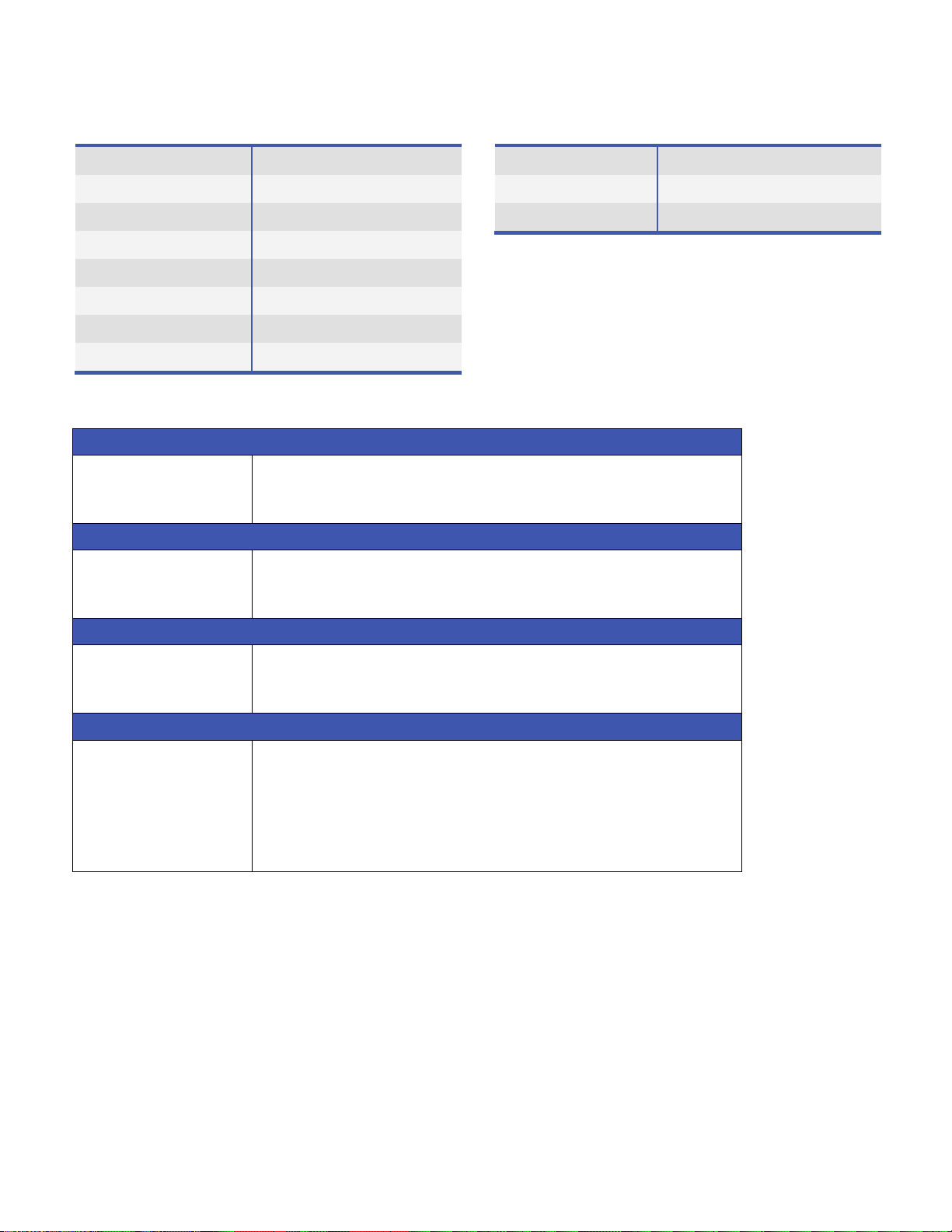

Table 1: Standard Instrumentation

Page 2

Table 2: Pump and Motor

HP Pump Model

MBN80-255

Manufacturer

Sulzer

Quantity

1

HP Pump Motor

315 kW

Boost Pump Model

6x6x8A VHK

Manufacturer

Union Pump

Boost Pump Motor

37 kW

Quantity

1

Model

PX-180

Manufacturer

Energy Recovery, Inc (ERI)

Quantity

5

Permeate rate:

Concentrate Rate:

Feed Rate:

2500 m3/day (460 gpm)

4643 m3/day (850 gpm)

7143 m3/day (1310 gpm)

Membrane Elements and Housings

Membranes Quantity:

Memb. Housing Style:

Banking Arrangement:

210

7 element long, 4 port

30, parallel

Cartridge Filtration

Cartridge Filter:

Filter Length:

Filter Quantity:

RO.Zs 01-50

50” (127 cm)

100 per change out

Installation and Utility Requirements

Inlet:

Permeate:

Concentrate:

Air Pressure:

Power:

Control Circuit:

8” flange

6” flange

8” flange

100 psig, oil-free

380 VAC, 3-phase, 50Hz

220 VAC, 1-phase, 50Hz

Table 4: Model SeaPRO-210 Specifications

Table 3: Energy Recovery

Page 2 AM-FSpwSWRO2500_EN

Loading...

Loading...