Page 1

Water & Process Technologies

Fact Sheet

Sievers 860

Laboratory TOC Analyzer & GE Autosampler RT12

High Performance at an Affordable Cost for

General Pharmaceutical Water Testing Requirements

GE Analytical Instruments, Inc.

www.geinstruments.com/india

Page 2

The Sievers 860 — Affordable, High Performance

The Sievers 860 Laboratory Total

Organic Carbon (TOC) Analyzer

from GE Analytical Instruments was

designed specifically for pharmaceutical applications. Based on the

proven technology used in the bestselling Sievers 900 Laboratory

model, the new Sievers 860 provides excellent analytical performance at an affordable price. It

offers a streamlined feature set

designed to meet general pharmaceutical water testing requirements.

Like other Sievers TOC analyzers,

the Sievers 860 is easy to set up,

operate and maintain, and requires

no special operator training. To

keep cost of ownership low, the Sievers 860 needs no

internal reagents.

The innovative DataPlus software makes the Sievers

860 more than an analyzer. Featuring an intuitive PCbased interface, the software lets you easily manage

the data sample points in your water system and comply with global TOC monitoring requirements, such as

the US, European, Chinese, Indian,

and Japanese Pharmacopeias

(USP, EP, ChP, IP, and JP).

Manufactured by the General

Electric Company (GE), Sievers TOC

Analyzers bring a strong tradition of

innovation, quality, and reliability.

When regulatory compliance and

public safety is critical, partnering

with an established, trusted manufacturer is essential to control

risks. Sievers is the leading pharmaceutical TOC analyzer brand,

and more than 10,000 Sievers TOC

Analyzers have been installed

throughout the world.

Applications

The Sievers 860 TOC Analyzer was designed for general

pharmaceutical water testing, including Water for

Injection (WFI) and Purified Water (PW). It has a linear

range of 0.3 ppb to 1.5 ppm, and offers a more robust

alternative to the direct conductivity method.

Sievers 860 Highlights

Proven Sievers Technology — The Sievers 860 is based

on the industry-leading Sievers 900 Laboratory TOC

Analyzer. It uses the Sievers Membrane Conductometric

TOC technology that provides unsurpassed analytical

performance and reliability.

Regulatory Compliance — The Sievers 860 complies with

the IP, USP, EP ChP, JP, and other major global pharmacopeia requirements.

Affordability —The Sievers 860’s streamlined feature set

was carefully designed to reduce costs, but still offer high

performance for select pharmaceutical applications.

One-Touch Operation — The Sievers 860 can operate

with or without a PC. Using the Analyzer keypad, standard

TOC measurements can typically be run with just a single

push of a button.

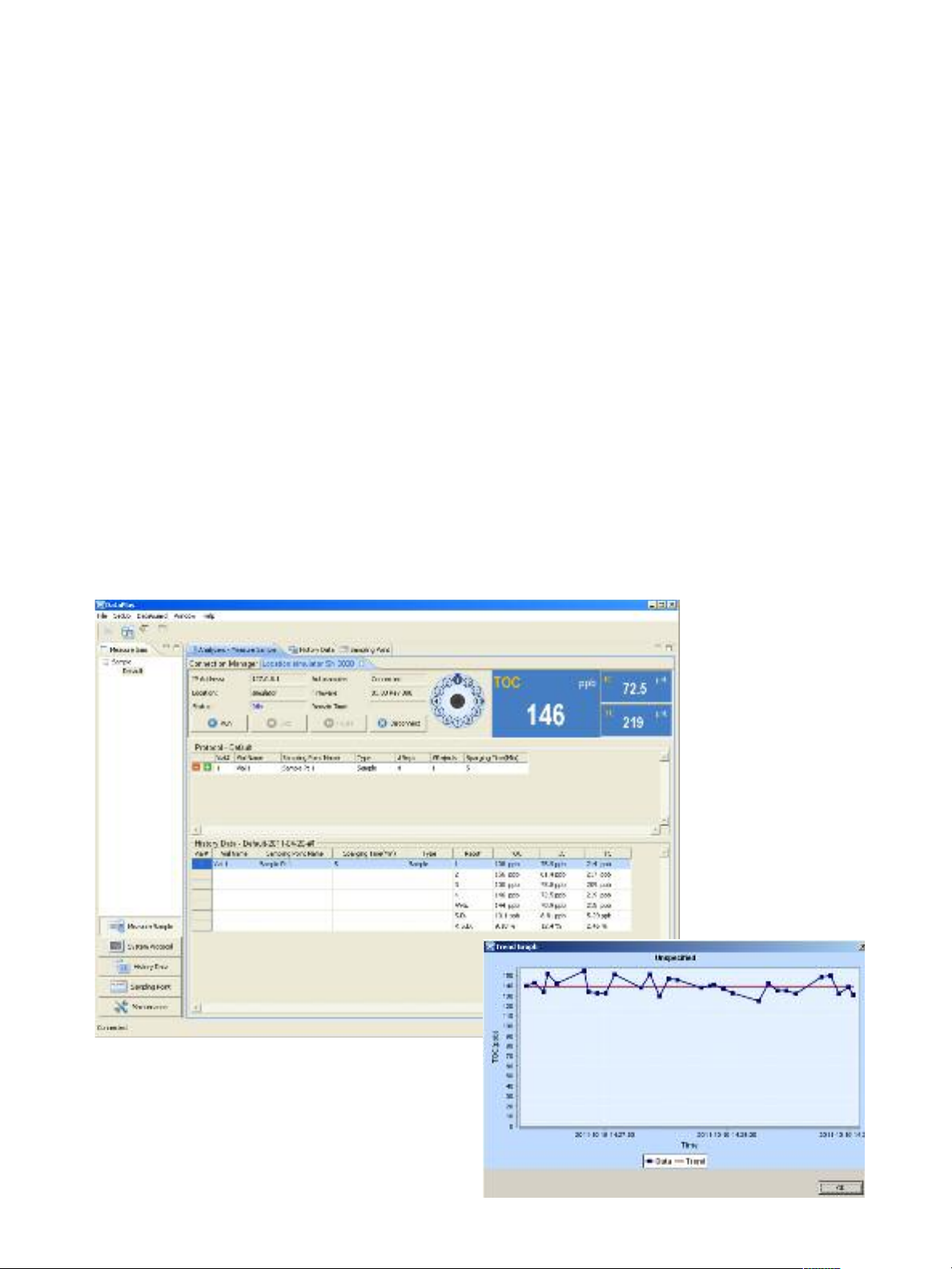

Best-in-Class Software — The Sievers 860 has an intuitive

PC-based interface for easy analyzer operation, data

management, document creation, and pharmaceutical

regulatory compliance. The DataPlus software gives

operators new insight into water system performance.

DataPlus lets you monitor each sampling point, chart

trends, and quickly identify changes in water quality.

Low Maintenance — The Sievers 860 provides one-year

calibration stability and needs only a few hours of annual

preventive maintenance.

Reliable Company and Brand — Established in 1878, GE

is known for continuous innovation and high quality. GE’s

Sievers brand brings industry-leading TOC analysis technology to the global pharmaceutical market . GE’s skilled

service engineers and distributor network in India are

ready to address customer questions and service needs.

Page 3

Sievers Membrane Conductometric

TOC Technology

The Sievers 860 uses the Sievers Membrane

Conductometric Detection method, which has proven to

be an extremely reliable technique for measuring TOC. It

uses a gas-permeable membrane that selectively passes only the CO2produced from the oxidation of organics.

By preventing compounds such as acids, bases, and

halogenated compounds from interfering with the measurement of CO2from oxidation, the Membrane

Conductometric Method delivers unmatched sensitivity,

selectivity, stability, accuracy, and precision. This technique also can tolerate higher conductivity and remove

inorganic carbon more effectively than TOC analyzers

that use the direct conductometric technology.

• Set up sampling protocols in just minutes.

• Create trending charts for a single sample point for

internal quality control and troubleshooting.

• Export data as .csv or .xls files, and print reports and

trending charts in pdf format.

• Track consumables usage and conduct routine

maintenance easily.

• Run up to four Sievers TOC analyzers from one PC via

an Ethernet connection.

Firmware Upgrades

Firmware can be updated easily using a USB key. You

can take advantage of the latest features and optimize

performance without changing hardware.

Options and Accessories

DataPlus Software

The Sievers 860 can operate standalone or with a PC.

When using a PC, the innovative, easy-to-use

DataPlus* software allows users to operate the Sievers

860, manage and analyze water sample data, and

comply with pharmaceutical water testing regulations.

The most robust laboratory TOC data management

tool available, DataPlus lets you:

DataGuard Software

Sievers DataGuard software for the Sievers 860 offers

comprehensive support for compliance with the FDA’s

requirements for control of electronic records and electronic signature. DataGuard provides an administratively controlled user access system, complete audit

trail functionality, and electronic signature management for compliance with 21 CFR Part 11.

DataPlus Measurement Screen

DataPlus Sample Point

Trending Graph

Page 4

GE Autosampler RT12

The GE Autosampler is a highly-automated, compact

accessory for optimizing laboratory TOC measurement

and is designed for use with the Sievers 860. The GE

Autosampler RT12 is designed to increase productivity

and enhance ease of use. Offering the highest degree

of reliability, the RT12 requires little maintenance or

adjustment. Key features and benefits include:

Single-line connection and operation via DataPlus

With only one cable, the GE Autosampler RT12 can

connect to both the Sievers 860 TOC analyzer and the

power supply. Using a computer and the DataPlus software you can operate the Autosampler easily.

High sampling capacity and simultaneous

in-vial sparging

The GE Autosampler RT12 can handle up to 12 40-mL

vials. Because of its rotary design, it is easy to set up

the sampling sequence according to the vial position in

the rack. The RT12 enables overnight calibration and

verification to ensure the Sievers 860 is ready to go the

next day.

The GE Autosampler RT12 has the same sipper needle

design as the Sievers 860,so it can conduct in-vial

sparging before sampling. When IC is high—especially

when it is involatile IC—acidification is needed.

Sparging effectively reduces the inorganic carbon and

enhances measurement accuracy.

Compact, space-saving size

The RT12’s slim 23.1-cm wide profile requires minimal

bench space. When operated side-by-side with the

21.5-cm wide Sievers 860 Laboratory Analyzer, the two

units occupy just 46.6 cm of horizontal space. The RT12

only requires three connections—a sample inlet tube, a

gas liquid waste outlet tube, and a power cable to the

Sievers 860—keeping the lab bench neat and clean.

Sievers Certified Standards and TOC Vials

GE Analytical Instruments offers Sievers Certified

Reference Materials, including calibration and verification standards, for the Sievers 860, as well as reliable

and economical 40-mL TOC vials.

GE Autosampler RT12 Specifications

Capacity Twelve (12) 40-mL vials

Power Supply Power supplied by the Sievers 860 Laboratory TOC Analyzer

Ambient Temperature 10 °C to 40 °C

Normal Operating Environment Intended for indoor use only

Maximum Relative Humidity Up to 95%, non-condensing

Maximum Altitude 3,000 m (9,843 ft)

Dimensions H: 36.8 cm (14.5 in); W: 23.1 cm (9.1 in); D: 25.4 cm (10.0 in)

Weight 3.9 kg (8.6 lb)

Safety Certifications CE

1

Page 5

Sievers 860 Laboratory System Specifications

ISO

9001:2008

QUALITY

MANAGEMENT

SYSTEM

1

Total Organic Carbon

Linear Range 0.3 ppb–1.5 ppm TOC

Precision 0.1 ppb or 1%, whichever is greater

Accuracy ± 5% at 500 ppb C of sucrose

Analysis Time 6 minutes

Sample Flow Rate (nominal) Analysis mode: 0.25 mL/min

Fast Flush (between samples): 0.5 mL/min

Sample pH <3

Sampling Method Grab sampling

Operation PC or standalone operation; one PC can control up to four analyzers

Analyzer Specifications

Power Requirements 100–240 ±10% VAC, 60 W, 50/60 Hz

Fuses T1.6 A, 250 VAC (SloBlo), size 5 x 20 mm (appliance inlet)

Ambient Temperature 10 °C to 40 °C

Normal Operating Environment Intended for indoor use only

Maximum Relative Humidity Up to 95%, non-condensing

Maximum Altitude 3,000 m (9,843 ft)

Sparge Gas (if used) Inlet pressure: 30 psig to 50 psig

Sparge Gas Flow Rate 120 mL/min to 150 mL/min

Calibration Stability Typically stable for 12 months

Outputs One USB port to support printer or Flash drive, and one Ethernet port

Installation/Overvoltage Category II

Safety Certifications CE, ETL listed. Conforms to UL Std. 61010-1. Certified to CSA C22.2

No. 61010-1.

Pollution Degree 2

Display Color LCD

Dimensions H: 43.0 cm (16.9 in); W: 21.5 cm (8.5 in); D: 40.5 cm (15.9 in)

Weight 10.5 kg (23.0 lb)

* Trademark of General Electric Company; may be registered in one or more countries.

1

Stated analytical performance is achievable under controlled laboratory conditions that minimize operator and standards errors.

The Americas

GE Analytical Instruments

6060 Spine Road

Boulder, CO 80301-3687 USA

T +1 800 255 6964

T +1 303 444 2009

F +1 303 527 1797

geai@ge.com

www.geinstruments.com

© 2011, General Electric Company. All rights reserved.

Europe/Middle East/Africa

GE Analytical Instruments

Unit 3, Mercury Way

Urmston, Manchester

UK M41 7LY

T +44 (0) 161 864 6800

F +44 (0) 161 864 6829

geai.europe@ge.com

India

GE Analytical Instruments

C 402, Delphi

Hiranandani Business Park

Powai, Mumbai

India - 400076

T +(91) 900 4343626

F +(91) 4005 9840

geai.india@ge.com

www.geinstruments.com/india

300 00228 Rev B

MC11-168

Loading...

Loading...