Page 1

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

AM-FSroReNEWNA_EN.doc Jun-13

ReNEW NA Series

Wastewater Reuse Reverse Osmosis Machines 50 to 330 gpm

Pressure: ................................. Pre & Post Cartridge Filter

.......... RO Feed , Pump Outlet, Interstage (x2)

...................................... Concentrate & Permeate

Pressure Switch:………. Feed, Permeate, Concentrate

The ReNEW NA has been designed at a special

low-flux for wastewater reuse applications (i.e. after MBR or tertiary UF treatment).

This new platform is a perfect fit to polish GE

Z-MOD*, Z-BOX and Z-PAK Series MBR and UF

packaged plants effluents.

Features

Separated Control & High Voltage

Enclosures with single power disconnect

Allen Bradley CompactLogix PLC

Communication RS485

HMI Allen Bradley PanelView+700 Touch

Screen

4-20 mA Instruments on Touch Screens

Primary and Final Pressure Transmitters

Motor Starter: VFD (mounted on frame)

Bank-by-bank cleaning manifolds and valves

RO permeate Flush on Shutdown

Instrumentation

Flow Meters: ............................ Permeate & Concentrate

Conductivity: .............................................. Permeate, Feed

pH: ......................................................................................... Feed

ORP:…………………………………………………………………………Feed

Options Available

GE Fanuc PLC

Ethernet Communication

CIP PRE with heater for advanced

membranes cleaning

DuraSlick* membrane elements for higher

fouling applications (with flow & recovery decrease and pump change)

Feed water Guidelines

BOD < 20 ppm; TOC < 5 ppm

COD - must define what is creating COD

Phosphate – Use Argo Analyzer to simulate

scaling and calculate antiscalant dose

NTU < 1; SDI < 5

TDS design 2,000 ppm. Higher levels

require pump size review

Operating Parameters

Design Recovery1 ............................................................ 75%

Design Temperature ...................................... 60 ºF (15 ºC)

Operating Temperature Range .... 36-87 ºF (2-30 ºC)

System Inlet Pressure ...................... 30-60 psi (2–4 bar)

System Back Pressure .............................. < 15 psi (1 bar)

1

Recovery Rate can vary +/- 5%

Page 2

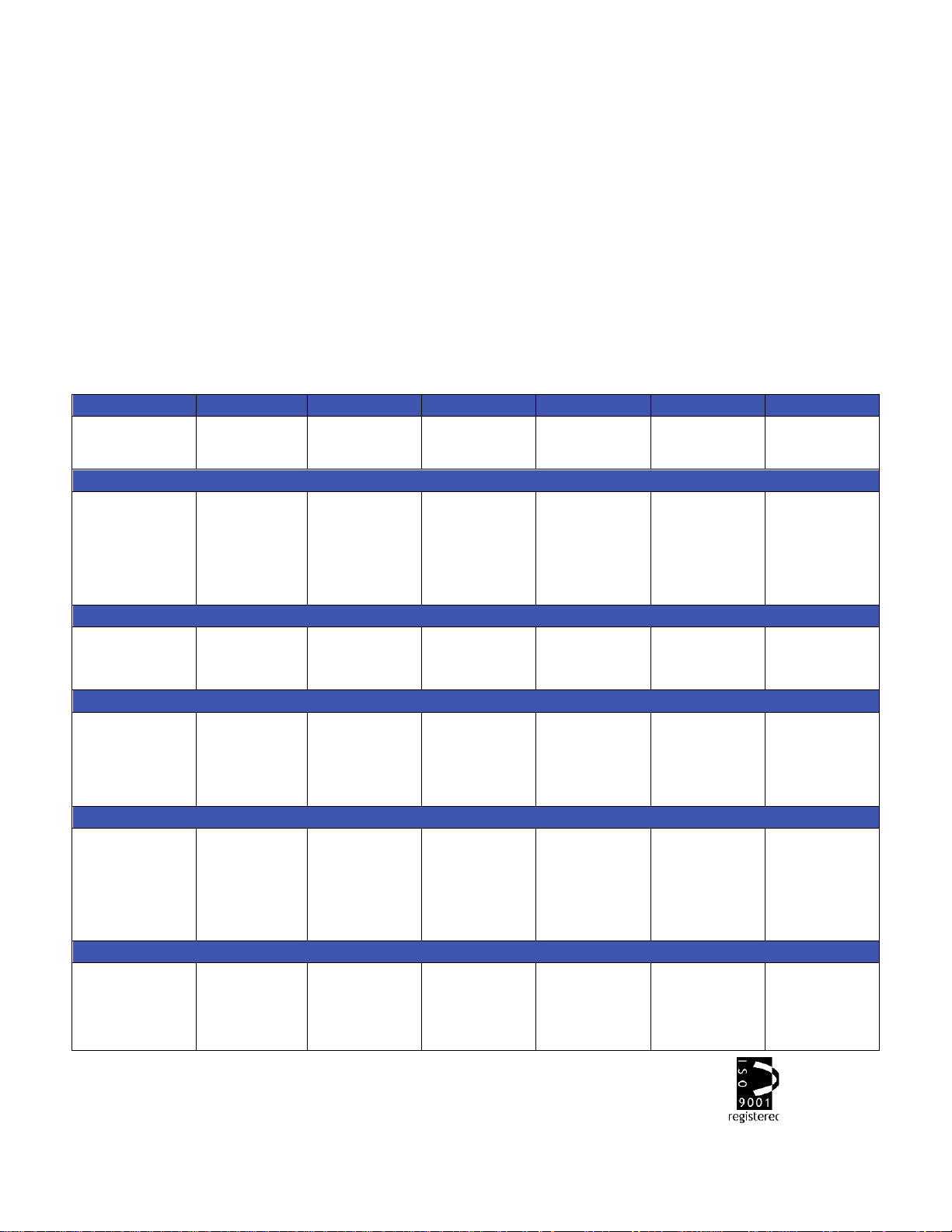

MODEL

ReNEW-18-NA

ReNEW-36-NA

ReNEW-54-NA

ReNEW-72-NA

ReNEW-90-NA

ReNEW-108-NA

Permeate Rate1:

Concentrate Rate:

Feed Rate:

55 gpm

18 gpm

73 gpm

110 gpm

37 gpm

147 gpm

165 gpm

55 gpm

220 gpm

220 gpm

73 gpm

293 gpm

275 gpm

92 gpm

367 gpm

330 gpm

110 gpm

440 gpm

Pumps and Motors

Model:

Manufacturer:

Quantity:

Motor Power and type:

Installed Power:

Design Flow Rate:

Design boost pressure:

SS8516

GE Tonkaflo

1

25 HP

39 Amps

73 gpm

250 psi

SS12512

GE Tonkaflo

1

40 HP

52 Amps

147 gpm

250 psi

SS24009

GE Tonkaflo

1

60 HP

77 Amps

220 gpm

250 psi

AS40407

GE Tonkaflo

1

60 HP

77 Amps

293 gpm

230 psi

AS40409

GE Tonkaflo

1

75 HP

96 Amps

367 gpm

250 psi

AS40409

GE Tonkaflo

1

75 HP

96 Amps

440 gpm

230 psi

Membrane Elements and Housings

Membranes Quantity:

Memb. Housing Style:

Banking Arrangement:

18

6 element long,

4 port

21

36

6 element long,

4 port

42

54

6 element long,

4 port

63

72

6 element long,

4 port

84

90

6 element long,

4 port

105

108

6 element long,

4 port

126

Cartridge Filtration

Housing Model:

Housing Quantity:

Cartridge Filter Model:

Cartridge Filter Length:

Cartridge Filter Qtity:

HX-0740-3.0-V-316

1

RO.Zs01-40XK

102 cm (40”)

7 per housing,

7/change out

HX-0740-3.0-V-316

2

RO.Zs01-40XK

102 cm (40”)

7 per housing,

14/change out

HX-0740-3.0-V-316

2

RO.Zs01-40XK

102 cm (40”)

7 per housing,

14/change out

HX-0740-3.0-V-316

3

RO.Zs01-40XK

102 cm (40”)

7 per housing,

21/change out

HX-0740-3.0-V-316

4

RO.Zs01-40XK

102 cm (40”)

7 per housing,

28/change out

HX-0740-3.0-V-316

4

RO.Zs01-40XK

102 cm (40”)

7 per housing,

28/change out

Installation and Utility Requirements

Inlet:

Permeate:

Concentrate:

Inlet Water Pressure:

Air Pressure:

Drain to be Sized for:

Power:

2.0-inch flange

1.5-inch flange

1.5-inch flange

30 psi, min.

80 psi, oil-free

73 gpm

480 VAC, 3-phase, 60Hz

3.0-inch flange

3.0-inch flange

1.5-inch flange

30 psi, min.

80 psi, oil-free

147 gpm

480 VAC, 3-phase, 60Hz

3.0-inch flange

3.0-inch flange

1.5-inch flange

30 psi, min.

80 psi, oil-free

220 gpm

480 VAC, 3-phase, 60Hz

4.0-inch flange

3.0-inch flange

2.0-inch flange

30 psi, min.

80 psi, oil-free

293 gpm

480 VAC, 3-phase, 60Hz

4.0-inch flange

4.0-inch flange

2.0-inch flange

30 psi, min.

80 psi, oil-free

367 gpm

480 VAC, 3-phase, 60Hz

6.0-inch flange

4.0-inch flange

3.0-inch flange

30 psi, min.

80 psi, oil-free

440 gpm

480 VAC, 3-phase, 60Hz

Skid

Height:

Width:

Depth:

Shipping Weight

Estimate:

90 inch

274 inch

48 inch

4500 lb

90 inch

274 inch

48 inch

5900 lb

92 inch

274 inch

48 inch

7500 lb

98 inch

274 inch

80 inch

9400 lb

104 inch

274 inch

98 inch

14000 lb

104 inch

274 inch

98 inch

16000 lb

Materials of Construction

High-pressure piping ....... 316 Stainless Steel Sch 10

Low-pressure piping ........................................ PVC Sch 80

Frame ....................................... Painted blue carbon steel

Enclosure ...................................................................... Nema 4

Clamps/fittings ...................................................Zinc-plated

Cartridge Filtration

Housing model………………………..GE HX-0740-3.0-V316

Housing material………………………… 316 Stainless Steel

Cartridge filter……..….1-micron nominal, ROsave.Z*s

GE ReNEW Models

Membrane Elements and Housings

Housing material ............................................................... FRP

Housing Pressure Rating ..................................... 450 PSI

Average membrane flux ................................. 10-11 GFD

Membrane rejection ...................................... 98.0-99.0 %

Membrane Model ................................................. AG-400LF

Style ............................................... Spiral-wound elements

Manufacturer ........................................................................ GE

Membrane type ............. TFC (Polyamide) Low Fouling

1

At design temperature

Fact Sheet Page 2

Loading...

Loading...