Page 1

Tonkaflo* Pumps

AS 40K Series

• Mixed Flow Stage Design delivers up to 74%

• High Grade Elastomers: all seal materials are

• New Higher Efficiency SS stages in the 40K

• Fabricated Stainless Steel Stages require less

Figure 1: AS 40K Series

The new AS40K pump (Figure 1) combines high flow

with the durability of stainless steel. The AS40K

pump is a multistage centrifugal pump with an all

stainless steel liquid end mounted on a high-thrust

bearing frame. AS40K pumps are available in 60 Hz

and 50 Hz models.

Especially designed for high-flow applications, the

AS40K pumps tolerate punishing applications and

harsh environments. AS40K pumps are ideal for use

in the power generation and municipal industries,

excelling in applications such as large-capacity

membrane systems, general industrial boost applications, sanitizing systems and higher temperature

water recirculation. In many applications one AS40K

pump can take the place of two pumps,

reducing both capital and energy costs.

Features & Benefits

• All Stainless Steel Construction makes AS

Series pumps more durable and less susceptible

to operator error. AS Series pumps are also

chemically compatible with hydrocarbons and

can perform within a greater temperature

range than the standard Tonkaflo SS Series.

• Separate Bearing Frame increases pump reli-

• Modular Liquid End allows service of the

• Flexible Inlet Piping can be modified to fit

• Industry Standard Mechanical Seal on pump

Fact Sheet

efficiency.

EPDM or PTFE in our standard design.

design.

maintenance and eliminate the need to balance

pump impellers as with single-stage pumps. The

end result is smoother operation, less vibration

and longer pump life.

ability and life because there is no thrust load

on the motor. In addition, this feature allows the

AS Series pumps to be powered by standard

motors. The larger AS 40K’s also include our

new high thrust bearing frame design to insure

smooth reliable operation.

mechanical seal without disassembling the liquid end of the pump. The AS Series’ modular

design also facilitates service of both pump and

bearing frame.

almost any application. For pressure boost

applications, 4-inch inlets are available. For

transfer applications, 6-inch inlets are available

to connect with 6-inch piping and improve the

net positive suction head (NPSH) available to

the pump. Victaulic clamps reduce piping stress

and make installation of the AS Series

pumps easier.

inlet delivers higher boost pressure capability

and longer seal life.

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2010, General Electric Company. All rights reserved.

FS1128EN.doc Jan-10

Page 2

General Specifications

Standard Features

• Motor: Standard Air-Cooled NEMA Motors (3550

rpm) 60 Hz; (2950 rpm) 50 Hz

• Mounting: Horizontal (all), Vertical (limited)

• Pump and Motor Combinations: 60 Hz: (8), 50

Hz: (9)

3

• Capacity: 250 to 525 gpm (114 m

• Pressures: up to 410 psid (28.9t bar)

• Total Discharge Head Pressure: up to 1000 psig

(68.9 bar)

• Maximum Operating Temperature: 200°F (93°C)

(limited flow range)

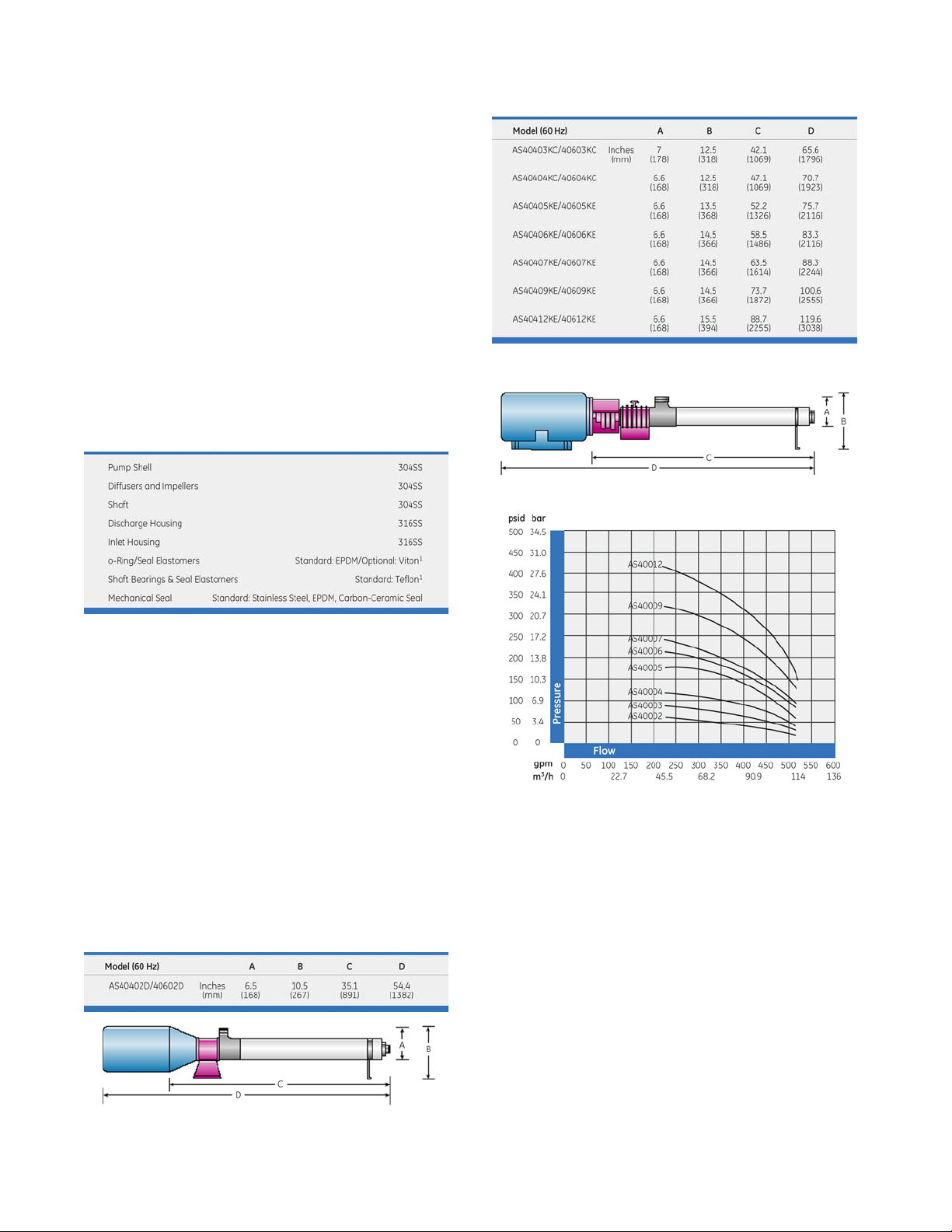

Table 1: Materials of Construction

/h)

Table 2: K-Bearing Frame

For 50 Hz and specific performance data please see individual performance

curves. Dimensions vary by model.

Figure 3: K-Bearing Frame

1

Viton and Teflon are trademarks of DuPont

Connections

• 4- or 6-inch Inlet

• 4-inch Discharge

2

Power

• 60 Hz - 3-phase (230/460 volt); 100Hp: 460

VAC only

• 50 Hz - 3-phase (190/380 volt); 75Hp: 380

VAC only

2

575 volt 60 Hz, 400 volt 50 Hz, 415 volt 50 Hz motors are available on request.

Housing Specifications

Table 2: Close-Coupled Pumps

Figure 4: Performance Curve (60 Hz)

Figure 2: Close-Coupled

Page 2 FS1129EN

Loading...

Loading...