Page 1

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

AM-FSpwPRO_NA_Series_60Hz_EN.doc May-13

Fact Sheet

Osmo* PRO NA Series

60 Hz Reverse Osmosis Machines from 50 to 450 gpm

Options Available

Allen Bradley CompactLogix PLC Control Package

Membrane Options:

- 400 Square Foot Elements

- High Rejection Elements

Motor Starter

Variable Frequency Drive

ORP Meter

Specific Basic Features (BAS)

GE Fanuc QuickPanel 6.0-inch monochrome

display Touch screen controls

GE Fanuc Versamax Micro Communication:

RS232

4-20 mA instruments displayed on instrument

center

UL/cUL Electrical Panel

pH Meter (Option for basic)

PRO NA Accessories

PRO Multi-Media filters

PRO Activated Carbon and Softeners

PRO Clean-in-Place units

PRO Chemical Feed Systems

Transfer Pumps and Storage Tanks

Specific Premium Features (PRE)

GE Fanuc Quickpanel, 12.0-inch color display

Text and pictorial operating screens, Touch

screen controls

GE Fanuc Versamax, Communication: Ethernet

4-20 mA instruments on QuickPanel

Primary and final pressure transmitters

RO permeate flush on shutdown

UL / cUL Electrical Panel

pH Meter on RO Feed

Instrumentation

Flow Meters ........................................ Permeate & Concentrate

Conductivity ........................................................................ Permeate

Pressure ...............................................Pre & Post Cartridge Filter

RO Feed , Pump Outlet, Interstage (x2)

Concentrate & Permeate

Pressure Switch ....................... Feed, Permeate, Concentrate

pH (Optional) .................................................................................. Feed

ORP (Optional) ............................................................................... Feed

Instrument Center (BAS) ............GF Signet 8900 Multimeter

Operating Parameters

Design Recovery1 ......................................................................... 80%

Design Temperature .................................................... 60ºF (16ºC)

Operating Temperature Range .................. 35-85ºF (2-29ºC)

Nominal rejection ................................................................. 97-99%

System Inlet Pressure ..................................................... 30-60 PSI

1

Recovery Rate can vary +/- 5%

Materials of Construction

High-pressure piping ................ 316 Stainless Steel, Sch. 10

Low-pressure piping ................................................. PVC, Sch. 80

Frame ....................................................Painted blue carbon steel

Enclosure ................................................................................... Nema 4

Clamps/fittings............................................................... Zinc-plated

Membrane Elements and Housings

Membrane Model .............................................................. AG8040F

Style ........................................................... Spiral-wound elements

Manufacturer ..................................................................................... GE

Membrane type .................................................... TFC (Polyamide)

Page 2

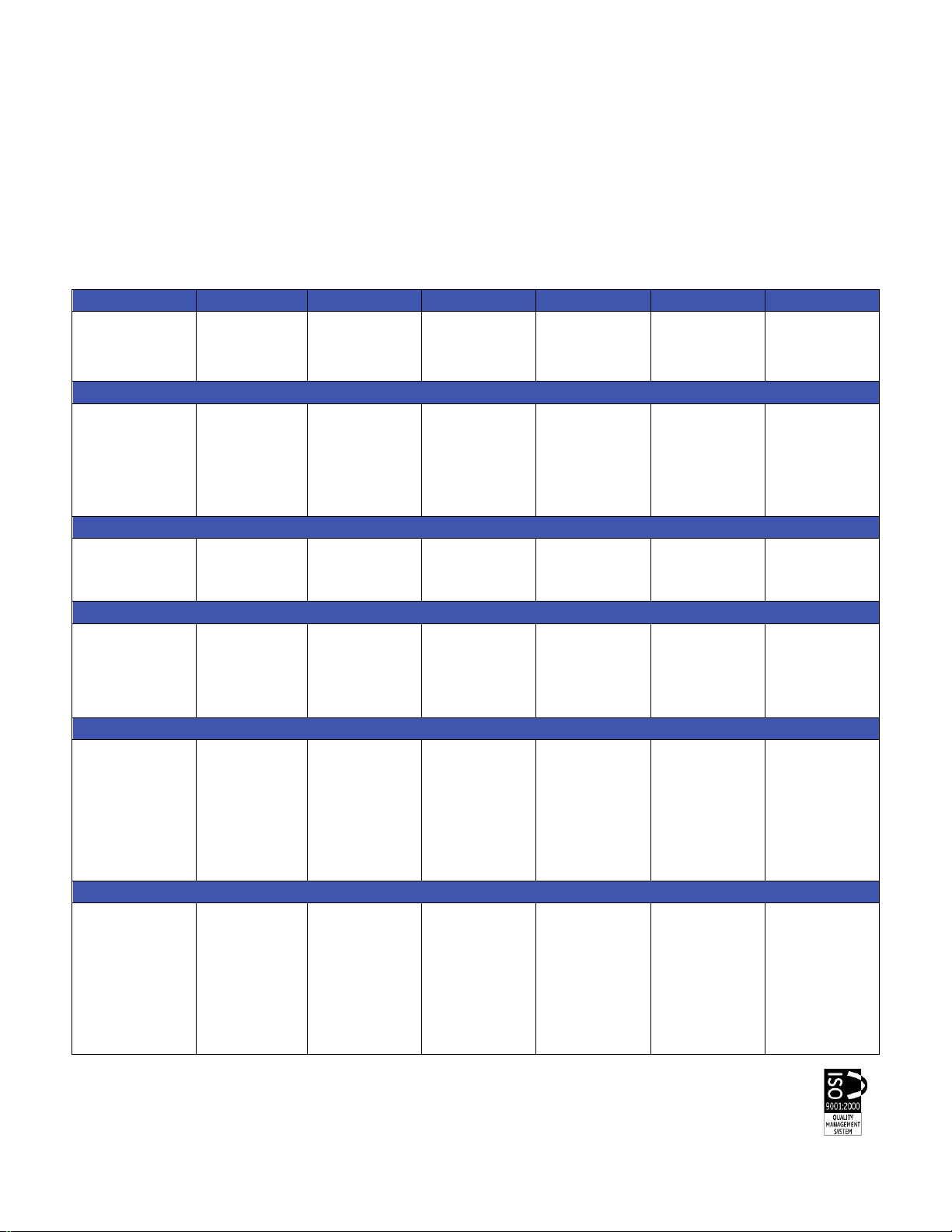

MODEL

PRO-50-NA

PRO-100-NA

PRO-150-NA

PRO-200-NA

PRO-300-NA

PRO-450-NA

Permeate Rate

2

:

Concentrate Rate:

Concentrate Recycle:

Feed Rate:

50 gpm (11 m3/hr)

13 gpm (3 m3/hr)

10 gpm (2.3 m3/hr)

63 gpm (14 m3/hr)

100 gpm (23 m3/hr)

25 gpm (6 m3/hr)

10 gpm (2.3 m3/hr)

125 gpm (28.5 m3/hr)

150 gpm(34 m3/hr)

38 gpm (8.5 m3/hr)

NA

188 gpm (43 m3/hr)

200 gpm (45 m3/hr)

50 gpm (11 m3/hr)

15 gpm (3.4 m3/hr)

250 gpm (57 m3/hr)

300 gpm (68 m3/hr)

75 gpm (17 m3/hr)

NA

375 gpm (85 m3/hr)

450 gpm (100 m3/hr)

113 gpm (26 m3/hr)

NA

563 gpm (128 m3/hr)

Pumps and Motors

Model:

Manufacturer:

Quantity:

Motor Power and type:

Installed Power:

Design Flow Rate:

Design boost pressure:

SS8516

GE/Tonkaflo

1

25HP (18.6 KW) TEFC

18.6 KW

73 gpm (17 m3/hr)

330 psig (23 Bar)

SS12512

GE/Tonkaflo

1

40 Hp (30 KW) TEFC

30 KW

135 gpm (31 m3/hr

275 psig (19 Bar)

SS24009

GE/Tonkaflo

1

60 Hp (45 KW) TEFC

45 KW

188 gpm (43 m3/hr)

280 psig (19.3 Bar)

AS40407

GE/Tonkaflo

1

60 Hp (45 KW) TEFC

45 KW

265 gpm (60 m3/hr)

240 psig (16.5 Bar)

AS40409

GE/Tonkaflo

1

75 Hp (56 KW) TEFC

56 KW

375 gpm (85 m3/hr)

260 psig (18 Bar)

AS40409

GE/Tonkaflo

2

75 Hp (56 KW) TEFC

112 KW

563 gpm (128 m3/hr)

300 psig (20.7 Bar)

Membrane Elements and Housings

Membranes Quantity:

Memb. Housing Style:

Banking Arrangement:

12

4 element long,

4 port

111

24

4 element long,

4 port

321

36

6 element long,

4 port

321

48

4 element long,

4 port

642

72

6 element long,

4 port

642

108

6 element long,

4 port

963

Cartridge Filtration

Housing Model:

Housing Quantity:

Cartridge Filter Model:

Cartridge Filter Length:

Cartridge Filter Qty:

HX-0740-3.0-V-316

1

RO.Zs01-40XK

40-inch (120 cm)

7 per housing,

7/change out

HX-0740-3.0-V-316

1

RO.Zs01-40XK

40-inch (102 cm)

7 per housing,

7/change out

HX-0740-3.0-V-316

2

RO.Zs01-40XK

40-inch (102 cm)

7 per housing,

14/change out

HX-0740-3.0-V-316

2

RO.Zs01-40XK

40-inch (102 cm)

7 per housing,

14/change out

HX-0740-3.0-V-316

3

RO.Zs01-40XK

40-inch (102 cm)

7 per housing,

21/change out

HX-0740-3.0-V-316

4

RO.Zs01-40XK

40-inch (102 cm)

7 per housing,

28/change out

Installation and Utility Requirements

Inlet:

Permeate:

Concentrate:

Inlet Water Pressure:

Air Pressure:

Drain to be Sized for:

Power:

Control Circuit

2.0” flange

1.5” flange

1.0” flange

30-60 psig

80 psi, oil-free

67 gpm (15 m3/hr)

460-480 VAC, 3-phase,

60Hz

120 VAC, 1-phase, 60Hz

3.0” flange

3.0” flange

1.5” flange

30-60 psig

80 psi, oil-free

133 gpm (30 m3/hr)

460-480 VAC, 3-phase,

60Hz

120 VAC, 1-phase, 60Hz

3.0” flange

3.0” flange

1.5” flange

30-60 psig

80 psi, oil-free

200 gpm (45 m3/hr)

460-480 VAC, 3-phase,

60Hz

120 VAC, 1-phase, 60Hz

4.0” flange

3.0” flange

2.0” flange

30-60 psig

80 psi, oil-free

267 gpm (61 m3/hr)

460-480 VAC, 3-phase,

60Hz

120 VAC, 1-phase, 60Hz

4.0” flange

4.0” flange

2.0” flange

30-60 psig

80 psi, oil-free

400 gpm (91 m3/hr)

460-480 VAC, 3-phase,

60Hz

120 VAC, 1-phase, 60Hz

6.0” flange

6.0” flange

3.0” flange

30-60 psig

7 bar, oil-free

600 gpm (136 m3/hr)

460-480 VAC, 3-phase,

60Hz

120 VAC, 1-phase, 60Hz

Skid

Height:

Width:

Depth:

Skid Shipping Weight

Estimate Without

Membranes:

Membranes Shipping

Weight Estimate:

Operating Weight

Estimate:

79” (200 cm)

46” (117 cm)

194” (493 cm)

3454 lb (1567kg)

420 lb (191 kg)

4300 lb (1951 kg)

79” (200 cm)

47” (119cm)

194” (493 cm)

4408 lb (2000 kg)

840 lb (381 kg)

5650 lb (2563 kg)

79” (200 cm)

47” (119cm)

274” (696 cm)

5712 lb (2591 kg)

1260 lb (572 kg)

7550 lb (3425 kg)

79” (200 cm)

80” (203 cm)

194” (493 cm)

6966 lb (3160 kg)

1680 lb (762 kg

9400 lb (4264 kg)

79” (200 cm)

80” (203 cm)

274” (696 cm)

8624 lb (3912 kg)

2520 lb (1143 kg)

12000 lb (5443 kg)

102” (259 cm)

80” (203 cm)

276” (701cm)

13736 lb (6231 kg)

3780 lb (1715 kg)

19600 lb (8890 kg)

Membrane Elements and Housings continued

Average membrane flux ............................................. 16-17 gfd

Membrane rejection ............................................... 99.0 to 99.5%

Manufacturer......................................................................................GE

Housing material ............................ 316 Stainless Steel or FRP

Housing Pressure Rating .................................................. 450 psi

1

Flux can be reduced by using 400-sqft membranes.

PRO NA Models

Cartridge Filtration

Housing model ......................................... GE HX-0740-80-V316

1

Housing material .......................................... 316 Stainless Steel

Cartridge filter ....................... 1-micron nominal, ROsave.Z*s

2

Maximum permeate rate listed at design temperature. Permeate rate can be reduced by up to 15%.

AM-FSpwPRO_NA_Series_60Hz_EN.doc Page 2

Loading...

Loading...