Page 1

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

E-FSpwPRO_EU_Series_Hu_EN.doc Oct-13

PRO EU Series

Reverse Osmosis Machines from 8 to 112 m3/h

Configurations

Controls configuration:

PLC and HMI

I/O box

Membrane Options:

Low Energy Elements

Standard brackish water elements

High rejection Elements

Features

Configurable skid mounted RO system for

industrial brackish water demineralization

Control Cabinet with Siemens S7- 1200 PLC

and TP 277 touchscreen

Ethernet Communication

Motor starter mounted and wired

4-20 mA Instruments displayed locally on

instruments and/or on touchscreen

100% permeate flush on shut down using CIP

tank

High pressure pump & cartridge filter housings

mounted on skid

Instrumentation

Flow Meters transmitters Permeate, Concentrate

Conductivity transmitters Feed, Permeate

Temperature transmitter Permeate

Pressure transmitters After HPPump throttling valve

Prior to concentrate valve

pH/ORP control system (optional) Feed

Pressure indicator/switches: Pre & Post Cartridge Filter

HPPump discharge, post HPPump throttling valve,

Pre/post concentrate orifice, permeate line, Interstage

Banking configuration:

2-Banks (high rejection design)

3 banks (high recovery design)

High pressure pump motor control options:

Motor Starter

Variable Frequency Drive

Optional pH/ORP meter (feed)

PRO EU Accessories

PRO Multi-Media filters

PRO Activated Carbon and Softeners

PRO Clean-in-Place units

PRO Chemical Feed Systems

Transfer Pumps and Storage Tanks

Operating Parameters

Design Recovery1 70%-85%

Design Temperature 15ºC

Operating Temperature Range 5-30 ºC

Nominal rejection 97-99%

System Inlet Pressure 2–4 bar

1

Recovery Rate can vary +/- 5%

Page 2

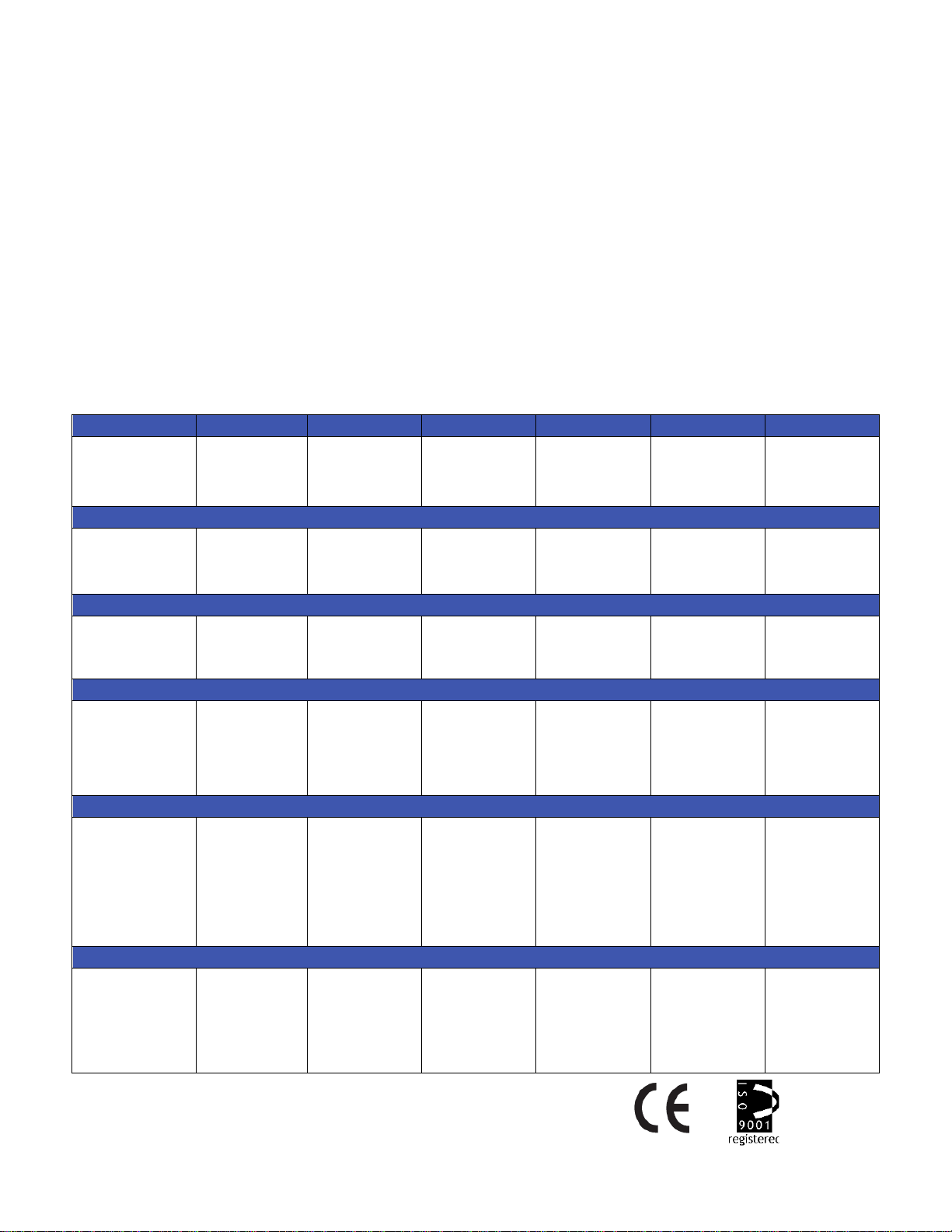

MODEL

PRO-11-EU

PRO-23-EU

PRO-34-EU

PRO-45-EU

PRO-68-EU

PRO-102-EU

Permeate Rate1:

Concentrate Rate:

Concentrate Recycle:

Feed Rate:

8-12 m3/hr

1-5 m3/hr

3 m3/hr

9-17 m3/hr

17-25 m3/hr

3-11 m3/hr

3 m3/hr

20-36 m3/hr

25-37 m3/hr

4-15 m3/hr

NA

29-52 m3/hr

34-49 m3/hr

6-21 m3/hr

4-6 m3/hr

40-70 m3/hr

51-75 m3/hr

9-32 m3/hr

NA

60-107 m3/hr

76-112 m3/hr

7-48 m3/hr

NA

89-160 m3/hr

Pumps and Motors

Manufacturer:

Quantity:

Motor Power and type:

Design boost pressure:

Grundfos

1

11 kW-15KW; IP55

10-16 bar

Grundfos

1

15KW-22 kW; IP55

10-16 bar

Grundfos

1

22KW-30KW; IP55

10-16 bar

Grundfos

1

30KW -45 kW; IP55

10-16 bar

Grundfos

2

22KW-30 kW; IP55

10-16 bar

Grundfos

2

30KW-45 kW; IP55

10-16 bar

Membrane Elements and Housings

Membranes Quantity:

Memb. Housing Style:

Banking Arrangement:

12

4 element long,

4 port

21 or 111

24

4 element long,

4 port

42 or 321

36

6 element long,

4 port

42 or 321

48

4 element long,

4 port

84 or 642

72

6 element long,

4 port

84 or 642

108

6 element long,

4 port

126 or 963

Cartridge Filtration

Housing Model:

Housing Quantity:

Cartridge Filter Model:

Cartridge Filter Length:

Cartridge Filter Qtity:

HX-0740-80-V-316

1

RO.Zs01-40XK

102 cm (40”)

7 per housing,

7/change out

HX-0740-80-V-316

1

RO.Zs01-40XK

102 cm (40”)

7 per housing,

7/change out

HX-0740-80-V-316

2

RO.Zs01-40XK

102 cm (40”)

7 per housing,

14/change out

HX-0740-80-V-316

2

RO.Zs01-40XK

102 cm (40”)

7 per housing,

14/change out

HX-0740-80-V-316

3

RO.Zs01-40XK

102 cm (40”)

7 per housing,

21/change out

HX-0740-3.0-V-316

4

RO.Zs01-40XK

102 cm (40”)

7 per housing,

28/change out

Installation and Utility Requirements

Inlet:

Permeate:

Concentrate:

Inlet Water Pressure:

Air Pressure:

Drain to be Sized for:

Power:

Control Circuit

DN 50 flange

DN 40 flange

DN 25 flange

2 bar, min.

6 bar, oil-free

18 m3/hr

400 VAC, 3-phase, 50Hz

230 VAC, 1-phase, 50Hz

DN 80 flange

DN 80 flange

DN 40 flange

2 bar, min.

6 bar, oil-free

31 m3/hr

400 VAC, 3-phase, 50Hz

230 VAC, 1-phase, 50Hz

DN 80 flange

DN 80 flange

DN 40 flange

2 bar, min.

6 bar, oil-free

31 m3/hr

400 VAC, 3-phase, 50Hz

230 VAC, 1-phase, 50Hz

DN 100 flange

DN 80 flange

DN 50 flange

2 bar, min.

6 bar, oil-free

60 m3/hr

400 VAC, 3-phase, 50Hz

230 VAC, 1-phase, 50Hz

DN 150 flange

DN 100 flange

DN 65 flange

2 bar, min.

6 bar, oil-free

91 m3/hr

400 VAC, 3-phase, 50Hz

230 VAC, 1-phase, 50Hz

DIN 150 flange

DIN 150 flange

DIN 80 flange

2 bar, min.

6 bar, oil-free

136 m3/hr

400 VAC, 3-phase, 50Hz

230 VAC, 1-phase, 50Hz

Skid

Height:

Width:

Depth:

Weight estimates:

Operating:

Shipping:

201 cm

500 cm

95 cm

1870 kg

1550 kg

240 cm

500 cm

95 cm

3355 kg

2350 Kg

242 cm

700 cm

95 cm

4420 kg

3005 Kg

245 cm

500 cm

140 cm

5255 kg

3405 Kg

247 cm

710 cm

140 cm

8110kg

4960 Kg

247 cm

710 cm

170 cm

11430 kg

6740 Kg

Materials of Construction

High-pressure piping 316 Stainless Steel PN 25

Low-pressure piping PVC PN 10/16

Frame Painted blue carbon steel

Enclosure IP 55

Clamps/fittings Zinc-plated

Membrane Elements and Housings

Membrane Model AK8040F-400, AG8040F-400

AK-400 or AG-400

Style Spiral-wound elements

Manufacturer GE

Membrane type TFC (Polyamide)

GE PRO EU Models

Membrane Elements and Housings continued

Average membrane flux 18-28 lmh

Membrane rejection 99.0-99.5 %

Manufacturer GE

Housing material FRP

Housing Pressure Rating 20 or 30 Bar

Cartridge Filtration

Housing model GE HX-0740-80-V316

Housing material 316 Stainless Steel

Cartridge filter 1-micron nominal, ROsave.Z*s

1

At design temperature

Fact Sheet Page 2

Loading...

Loading...