Page 1

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

AM-FSroPRO_E-Cell_EN.doc Sep-13

Fact Sheet

PRO E-Cell* Series

Integrated RO/EDI Machines 50 to 200 gpm 60 Hz

Accessories

PRO Multi-Media filters

PRO Activated Carbon and Softeners

PRO Clean-in-Place units

PRO Chemical Feed Systems

Transfer Pumps and Storage Tanks

Operating Parameters

Features

RO and EDI mounted on common skid

PRO E-Cell* 50 and 100 are 2 pass RO designs

PRO E-Cell 150 and 200 are 1 pass RO designs

RO Pump VFD(s) and EDI DC Drive mounted on

skid

RO permeate flush sequence on shutdown and

divert to drain on startup

Allen Bradley control system with Compact

Logix PLC and PanelView Plus 1000 interface

UL/cUL Electrical Panel

Instrumentation

Design Recovery RO1 ............ 75% Pass 1; 85% Pass 2

Design Recovery EDI ................................................. 90-95%

Design Temperature .......................................... 60ºF (16ºC)

Operating Temperature Range ........ 40-85ºF (5-29ºC)

System Inlet Pressure ........................ 30-60 PSI (2-4 Bar)

1

Recovery Rate can vary +/- 5%

Materials of Construction

High-pressure piping ....... 316 Stainless Steel, Sch. 10

Low-pressure RO & EDI piping .................... PVC, Sch. 80

Frame ...................................... Epoxy-coated carbon steel

Enclosure ............................................ Nema 4 carbon steel

Clamps/fittings .................................................... Zinc-plated

Flow Meters ....................RO Permeate, RO Concentrate

EDI Product, EDI Concentrate, EDI Electrode

Pressure Gauge ..................... Pre & Post Cartridge Filter

Primary, Final, Interstage, RO Permeate,

RO Concentrate, RO Pump Discharge,

Pressure Switch............................ RO Feed, RO Permeate

RO Concentrate

Pressure Transmitter ..................... RO Primary, RO Final

RO Permeate, EDI Product, EDI Concentrate,

EDI Electrode, EDI Dilute Feed

pH Meter ......................................................... RO Feed pass 1

(also pass 2 for 50-100 model)

ORP (Optional) ............................................... RO Feed pass1

Membrane Elements and Housings

Model (50-100) GE ....................................................... AK-400

Model (150-200) ........................ GE PRO-RO-400-HR-WT

Average membrane flux (50-100)......... 12 GFD pass 1

21 GFD pass 2

Average membrane flux (150-200) ..................... 14 GFD

Membrane rejection ..................................... 99.0 to 99.5%

Housing material ................................................... Fiberglass

Housing Pressure Rating ....................................... 450 psi

Page 2

EDI Stacks

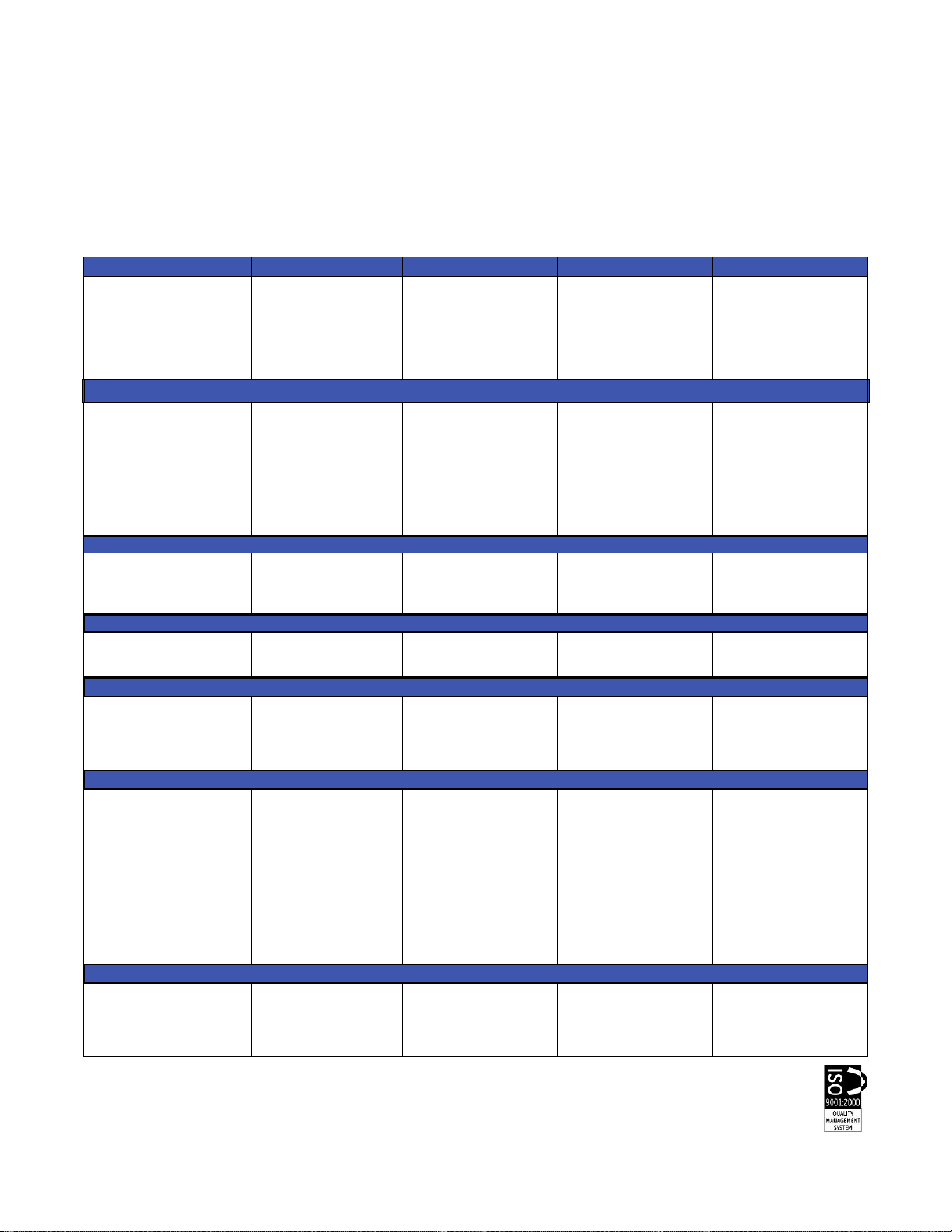

MODEL

PRO E-Cell 50DP

PRO E-Cell 100DP

PRO E-Cell 150

PRO E-Cell 200

RO Permeate Rate2:

RO Concentrate Rate:

Concentrate Recycle:

RO Feed Rate:

EDI Product Rate:

EDI Concentrate Rate (max):

EDI Electrode Rate:

52.5 gpm (11.9 m3/hr)

21 gpm (4.8 m3/hr)

10 gpm (2.3 m3/hr)

74 gpm (16.8 m3/hr)

50 gpm (11.4 m3/hr)

1.6 gpm (0.36 m3/hr)

1 gpm (0.23 m3/hr)

105 gpm (23.9 m3/hr)

42 gpm (9.5 m3/hr)

10 gpm (2.3 m3/hr)

147 gpm (33.4 m3/hr)

100 gpm (22.7 m3/hr)

3.2 gpm (0.73 m3/hr)

2.1 gpm (0.48 m3/hr)

158 gpm (36 m3/hr)

52.7 gpm (12 m3/hr)

NA

211 gpm (48 m3/hr)

150 gpm (34 m3/hr)

4.7 gpm (1.1 m3/hr)

3.2 gpm (0.73 m3/hr)

210 gpm (48 m3/hr)

70 gpm (16 m3/hr)

NA

280 gpm (63.6 m3/hr)

200 gpm (45 m3/hr)

6.3 gpm (1.4 m3/hr)

4.2 gpm (0.95 m3/hr)

Pumps and Motors

Model:

Manufacturer:

Quantity:

Motor Power and type:

Installed Power:

SS8512 Pass 1

SS8512 Pass 2

GE/Tonkaflo*

2

20HP (15 KW) TEFC Pass

1

20HP (15 KW) TEFC Pass

2

30 KW

SS24007 Pass 1

SS12509 Pass 2

GE/Tonkaflo

2

50 Hp (37 KW) TEFC Pass 1

30 Hp (22.5 KW) TEFC Pass

2

60 KW

SS24009

GE/Tonkaflo

1

60 Hp (45 KW) TEFC

45 KW

AS40409

GE/Tonkaflo

1

75 Hp (56.3 KW) TEFC

56.3 KW

Membrane Elements and Housings

Membrane Quantity:

Memb. Housing Style:

Banking Arrangement:

20 Pass 1 ; 12 Pass 2

4 element long,

4 port

32 Pass 1 ; 21 Pass 2

36 Pass 1 ; 18 Pass 2

6 element long,

4 port

42 Pass 1 ; 21 Pass 2

42

6 element long,

4 port

52

54

6 element long,

4 port

63

EDI Stacks

Stack Model :

Stack Quantity:

Power (DC drive, 300 VDC):

GE E-Cell MK-3

3

16 A max

GE E-Cell MK-3

6

31.2 A max

GE E-Cell MK-3

9

46.8 A max

GE E-Cell MK-3

12

62.4 A max

Cartridge Filtration

Housing Model:

Housing Quantity:

Cartridge Filter Model:

Cartridge Filter Length:

Cartridge Filter Qty:

HX-0740-3.0-V-316

1

ROSave.Zs, RO.Zs01-40XK

40-inch (120 cm)

7

HX-0740-3.0-V-316

2

ROSave.Zs, RO.Zs01-40XK

40-inch (102 cm)

14

HX-0740-3.0-V-316

2

ROSave.Zs, RO.Zs01-40XK

40-inch (102 cm)

14

HX-0740-3.0-V-316

2

ROSave.Zs, RO.Zs01-40XK

40-inch (102 cm)

14

Installation and Utility Requirements

RO Inlet:

RO Reject to Drain:

RO Product Dump:

EDI Product Outlet:

EDI Product Dump:

EDI Concentrate Outlet:

EDI Electrode Outlet:

Inlet Water Pressure:

Air Pressure:

Drain to be Sized for:

Power:

Control Circuit

3” ANSI flange

1.5” ANSI flange

1.5” ANSI flange

1.5” ANSI flange

1.5” ANSI flange

0.5” ANSI flange

0.5” ANSI flange

30-60 psig

80 psi, oil-free

95 gpm (22 m3/hr)

460 VAC, 3-phase, 60Hz

120 VAC, 1-phase, 60Hz

3” ANSI flange

2” ANSI flange

3” ANSI flange

3” ANSI flange

3” ANSI flange

0.5” ANSI flange

0.5” ANSI flange

30-60 psig

80 psi, oil-free

150 gpm (35 m3/hr)

460 VAC, 3-phase, 60Hz

120 VAC, 1-phase, 60Hz

4” ANSI flange

1.5” ANSI flange

3” ANSI flange

3” ANSI flange

3” ANSI flange

0.5” ANSI flange

0.5” ANSI flange

30-60 psig

80 psi, oil-free

220 gpm (50 m3/hr)

460 VAC, 3-phase, 60Hz

120 VAC, 1-phase, 60Hz

4” ANSI flange

2” ANSI flange

4” ANSI flange

4” ANSI flange

4” ANSI flange

0.5” ANSI flange

0.5” ANSI flange

30-60 psig

80 psi, oil-free

280 gpm (64 m3/hr)

460 VAC, 3-phase, 60Hz

120 VAC, 1-phase, 60Hz

Skid Dimensions and Weights

Height:

Width:

Length:

Shipping Weight :

Operating Weight:

96” (244 cm)

72” (183 cm)

197” (500 cm)

9050 lb. (4150 kg)

11150 lb. (5100 kg)

96” (244 cm)

58” (147 cm)

277” (704 cm)

13650 lb. (6250 kg)

17050 lb. (7750 kg)

90” (229 cm)

80” (203 cm)

282” (716 cm)

12350 lb. (5650 kg)

15200 lb. (6950 kg)

90” (229 cm)

80” (203 cm)

282” (716 cm)

14600 lb. (6650 kg)

18250 lb. (8300 kg)

Cartridge Filtration

Model ................................................................ GE E-Cell MK-3

Stack product flow rate, nom ..... 16.7 gpm (3.8 m3/hr)

Performance ..................................................... 16 MOhm-cm

Silica Removal ............................................................. <10 ppb

PRO E-Cell Models

Housing model................................ GE HX-0740-80-V316

Housing material ................................. 316 Stainless Steel

Cartridge filter ................................. 1-µ nom, ROSave.Zs*,

RO.Zs01-40XK

2

Maximum permeate rate listed at design temperature. Permeate rate can be reduced by up to 15%.

Page 2 Fact Sheet

Loading...

Loading...