Page 1

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

AP-FSpwPRO_ANZ_Series_50Hz_EN.doc Jul-13

Fact Sheet

PRO ANZ Series 50 Hz

Reverse Osmosis Machines from 11 to 102 m3/hr

Instrumentation

Flow Meters ............................................ Permeate, concentrate

Conductivity......................................................................... Permeate

Pressure ....................................... Pre-filter, post-filter, primary,

final, permeate, concentrate,

pump discharge

Pressure Switch ....................... Feed, permeate, concentrate

pH (Optional with Basic Electrical) ..................................... Feed

Basic Features

1000 mg/L feed TDS and 20C water temperature

design

AS3000 compliant electrical panel

GE Fanuc Micro VersaMax PLC with 6-inch Quick

Panel touchscreen

4-20 mA instrument display on instrument center

Non return valve on inlet and 3-way valves or pres-

sure relief valves on outlets

Optional 2500 mg/L feed TDS and 16C water tem-

perature design.

Optional pH and ORP sensors

Optional skid mounted Wye-Delta motor starter

ORP (Optional with Basic Electrical) .................................. Feed

Instrument Center ....................................................... Signet 8900

Premium Features

1000 mg/L feed TDS and 20C water temperature de-

sign

AS3000 compliant electrical panel with Allen Bradley

CompactLogix PLC and PanelView 700 color

touchscreen

pH and ORP Sensors included

Skid mounted and wired variable speed drive

Non return valve on inlet and 3-way valves or pres-

sure relief valves on outlets

Automatic concentrate flow control valve

Optional 2500 mg/L feed TDS and 16C water tem-

perature design.

Materials of Construction

High-pressure piping........................................... 316 SS, Sch. 10

Low-pressure piping .................................................. PVC, Sch. 80

Frame ................................................... Painted blue carbon steel

Enclosure ..........................................IP54 (painted carbon steel)

Documentation Included

Operation and maintenance manual

Drawings: piping and instrumentation, electrical and

general dimension

Operating Parameters

Design Recovery1 ......................................................................... 75%

Design temp.2 ................................................................................ 20ºC

Operating range ................................................................. 2 to 30ºC

Nominal rejection ................................................................. 97-99%

Design inlet pressure ........................................................... 2-4 bar

1

Recovery Rate can vary +/- 5%

2

Option available for 16ºC water temperature

Page 2

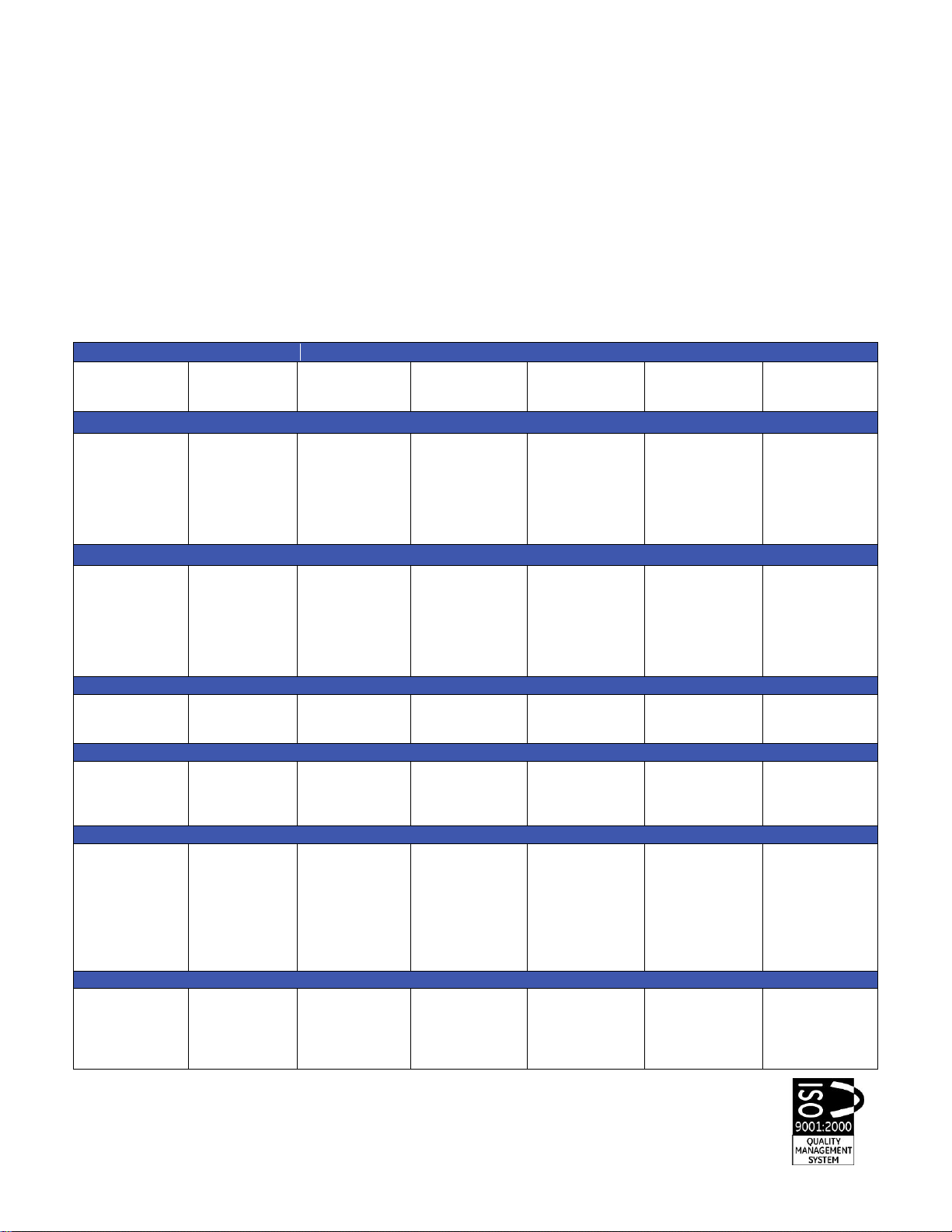

MODEL

PRO-11-ANZ-50

PRO-23-ANZ-50

PRO-34-ANZ-50

PRO-45-ANZ-50

PRO-68-ANZ-50

PRO-102-ANZ-50

Permeate rate:

2

Concentrate Rate:

Feed Rate:

11.4 m3/hr

3.8 m3/hr

15.1 m3/hr

22.7 m3/hr

7.5 m3/hr

30.2 m3/hr

34.1 m3/hr

11.4 m3/hr

45.4 m3/hr

45.4 m3/hr

14.9 m3/hr

60.4 m3/hr

68.1 m3/hr

22.7 m3/hr

90.8 m3/hr

102.2 m3/hr

34.1 m3/hr

136.3 m3/hr

Pumps and Motors – Up to 1000 mg/L Feed TDS and 20C water temperature design

Manufacturer:

Model

Quantity:

Motor HP:

Design Flow Rate:

Design boost pressure:

Grundfos

CRN 15-14 A-FGJ-G-

E-HQQE

1

11 kW

18.2 m3/hr

15.0 bar

Grundfos

CRN 32-9-2 A-G-G-E-

HQQE

1

18.5 kW

32.4 m3/hr

12.3 bar

Grundfos

CRN 45-7-2 A-G-G-E-

HQQE

1

30 kW

45.4 m3/hr

13.5 bar

Grundfos

CRN 64-6-2 A-G-G-E-

HQQE

1

30 kW

64.9 m3/hr

12.3 bar

Grundfos

CRN 45-7-2 A-G-G-E-

HQQE

2

2 x 30 kW

90.8 m3/hr

13.5 bar

Grundfos

CRN 64-6 A-G-G-E-

HQQE

2

2 x 37 kW

136.3 m3/hr

13.4 bar

Pumps and Motors – Up to 2500 mg/L Feed TDS and 16C water temperature design

Manufacturer:

Model

Quantity:

Motor HP:

Design Flow Rate:

Design boost pressure:

Grundfos

CRN 15-17 A-FGJ-G-

E-HQQE

1

15 kW TEFC

18.6 m3/hr

18.0 bar

Grundfos

CRN 32-13-2 A-G-G-E-

HQQE

1

30 kW TEFC

33.2 m3/hr

18.0 bar

Grundfos

CRN 45-9 A-G-G-E-

HQQE

1

37 kW TEFC

46.5 m3/hr

18.0 bar

Grundfos

CRN 64-8-1 A-G-G-E-

HQQE

1

45 kW TEFC

64.6 m3/hr

18.0 bar

Grundfos

CRN 45-9 A-G-G-E-

HQQE

2

2 x 37 kW TEFC

91.0 m3/hr

18.0 bar

Grundfos

CRN 64-8-1 A-G-G-E-

HQQE

2

45 kW TEFC

136.0 m3/hr

18.0 bar

Membrane Elements and Housings

Membranes quantity:

Memb. housing style:

Banking Arrangement:

12

4 element long, 4 port

111

24

4 element long, 4 port

321

36

6 element long, 4 port

321

48

4 element long, 4 port

642

72

6 element long, 4 port

642

108

6 element long, 4 port

963

Cartridge Filtration

Cartridge Filter:

Filter Length:

Filter Quantity:

RO.Zs01-40

102 cm (40”)

7 per housing

7/change out

RO.Zs01-40

102 cm (40”)

7 per housing

7/change out

RO.Zs01-40

102 cm (40”)

7 per housing

14/change out

RO.Zs01-40

102 cm (40”)

7 per housing

14/change out

RO.Zs01-40

102 cm (40”)

7 per housing

21/change out

RO.Zs01-40

102 cm (40”)

7 per housing

28/change out

Installation and Utility Requirements

Inlet:

Permeate:

Concentrate:

Inlet Water Pressure:

Air Pressure:

Drain to be Sized for:

Power:

Control Circuit:

ANSI 2" flange

ANSI 2" flange

ANSI 1.5" flange

2 bar min.

6.9 bar, oil-free

15.1 m3/hr

380 VAC, 3-phase, 50Hz

220 VAC, 1-phase, 50Hz

ANSI 3" flange

ANSI 3" flange

ANSI 1.5" flange

2 bar min.

6.9 bar, oil-free

30.2 m3/hr

380 VAC, 3-phase, 50Hz

220 VAC, 1-phase, 50Hz

ANSI 3" flange

ANSI 3" flange

ANSI 1.5" flange

2 bar min.

6.2 bar, oil-free

45.4 m3/hr

380 VAC, 3-phase, 50Hz

220 VAC, 1-phase, 50Hz

ANSI 4" flange

ANSI 3" flange

ANSI 2" flange

2 bar min.

6.2 bar, oil-free

60.4 m3/hr

380 VAC, 3-phase, 50Hz

220 VAC, 1-phase, 50Hz

ANSI 4" flange

ANSI 4" flange

ANSI 2" flange

2 bar min.

6.9 bar, oil-free

90.8 m3/hr

380 VAC, 3-phase, 50Hz

220 VAC, 1-phase, 50Hz

ANSI 6" flange

ANSI 4" flange

ANSI 3" flange

2 bar min.

6.9 bar, oil-free

136.3 m3/hr

380 VAC, 3-phase, 50Hz

220 VAC, 1-phase, 50Hz

Skid

Approx.Height:

Approx. Width:

Approx.Depth:

Approx. Shipping

Weight :

2000 mm

800 mm

4900 mm

1543 kg

2200 mm

900 mm

5050 mm

2132 kg

2240 mm

950 mm

6850 mm

2722 kg

2240 mm

1250 mm

5200 mm

3085 kg

2420 mm

1400 mm

6950 mm

4490 kg

2475 mm

1850 mm

7080 mm

6124 kg

Membrane Elements and Housings

Membrane model............................................................... AG8040F

Style ............................................................ Spiral-wound elements

Membrane manufacturer ............................................................GE

Membrane type .................................................... TFC (Polyamide)

Average membrane flux1 .............................. 28 lmh (16.4 gfd)

Membrane rejection .................................................... 99.0-99.6%

Housing manufacturer .......................... Wave Cyber or Equal

Housing material and rating ....................FRP, 300psi ASME

GE PRO-ANZ Models

Cartridge Filtration

Housing model ........................................ 7 Rounds, 102cm (40“)

Housing material .................................................................... 316 SS

Cartridge filter ....................... 1-micron nominal, ROsave.Z*s

1

Flux can be reduced to 25.5 lmh (15 gfd) by using 400sqft

elements. Rated flow can be further reduced by up to 20%.

2

300psi housings used for 1000 TDS, 20C design. 450psi

housings used for 2500 TDS 16C

2

2

Maximum permeate rate listed at design temperature. Permeate rate can be reduced by up to 20%

AP-FSpwPRO_ANZ_Series_50Hz_EN Page 2

Loading...

Loading...