Page 1

Fact Sheet

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2010, General Electric Company. All rights reserved.

FSfilMemtrexHFE-T_EN.doc Feb-10

Core and cage

Polyester

Support layer

Halar (ECTFE)

Membrane

ePTFE

End caps

Polyester

Memtrex* HFE-T

Pleated Filters with PTFE Membrane

Features and Benefits

Memtrex* HFE-T features a ePTFE membrane

edge-laminated on Halar (ECTFE) (Halar is a

trademark of Ausimont.), with polyester plastic

parts. Halar is an industrial-grade fluoropolymer

with excellent solvent resistance. MHFE-T benefits

of the edge lamination technology assuring a lower pressure drop and increasing flow rate. MHFE-T

filters can withstand very harsh process conditions due to its construction using these highly

resistant materials. Providing broad chemical

compatibility, you can count on our filters to produce consistent, uniform process streams in your

most demanding filtration applications. MHFE deliver high flow rates and high purity results with

absolute rated efficiencies (99.9% filtration efficiency at rated pore size based on ASTM F795 and

F661 test methods) and retention characteristics

that outperform other filters.

The MHFE-T filter is just one example of our strong

commitment to fluid treatment. Our complete

portfolio includes filters for every stage of processing, and we offer custom solutions for your

unique applications. GE Water & Process Technologies is your complete source for filters, crossflow

membranes, housings, and other filtration equipment.

Figure 1 : Memtrex HFE-T filter

General Properties

Memtrex HFE-T filters are available the following

absolute pore size micron ratings: 0.05, 0.1, 0.2,

0.45 and 1 µm. Tables 1, 2, 3 and 4 show further

details on materials of construction, dimensions,

operational limits and flow performance in water.

Typical Applications

MHFE-T filters offer outstanding performance in

very harsh chemical environments. These filters

are manufactured and packaged in a cleanroom

environment for assured cleanliness. Typical applications include:

Chemicals

Microelectronics

Pharmaceuticals

Table 1: Materials of Construction

Page 2

Table 2: Dimensions

Filter model

Nominal O.D.

Nominal I.D.

MHFE85-T

MHFE91-T

MHFE92-T

MHFE94-T

MHFE01-T

2.75” (70mm)

2.75” (70mm)

2.75” (70mm)

2.75” (70mm)

2.75” (70mm)

1.25” (31mm)

1.25” (31mm)

1.25” (31mm)

1.25” (31mm)

1.25” (31mm)

Maximum forward differential pressure

Maximum reverse differential pressure

Maximum operating temperature

60 psi (4.14 bar)

at 70°F (21.1°C)

30 psi (2.07 bar)

at 70°F (21.1°C)

205ºF (96.1ºC)

at 25 psid (1.7 bar)

Type

Absolute Micron

Rating

Nominal cartridge

Length

End #1 Adapter

End #2 Adapter

Elastomer material

Product Grade

MHFE-T

85 = 0.05 µm

91 = 0.1 µm

92 = 0.2 µm

94 = 0.45 µm

1 = 10 in (25 cm)

2 = 20 in (51 cm)

3 = 30 in (76 cm)

4 = 40 in (102 cm)

A = Open End

Gasket

E = 222 O-Ring

F = 226 O-Ring

A = Open End

Gasket

E = Closed End Cap

H = Fin Adapter

T = Teflon² Encapsulated Viton²

E = Electronic grade

rinse

Pre Wet = Rinsed

and packed wet

Table 3: Operational Limits

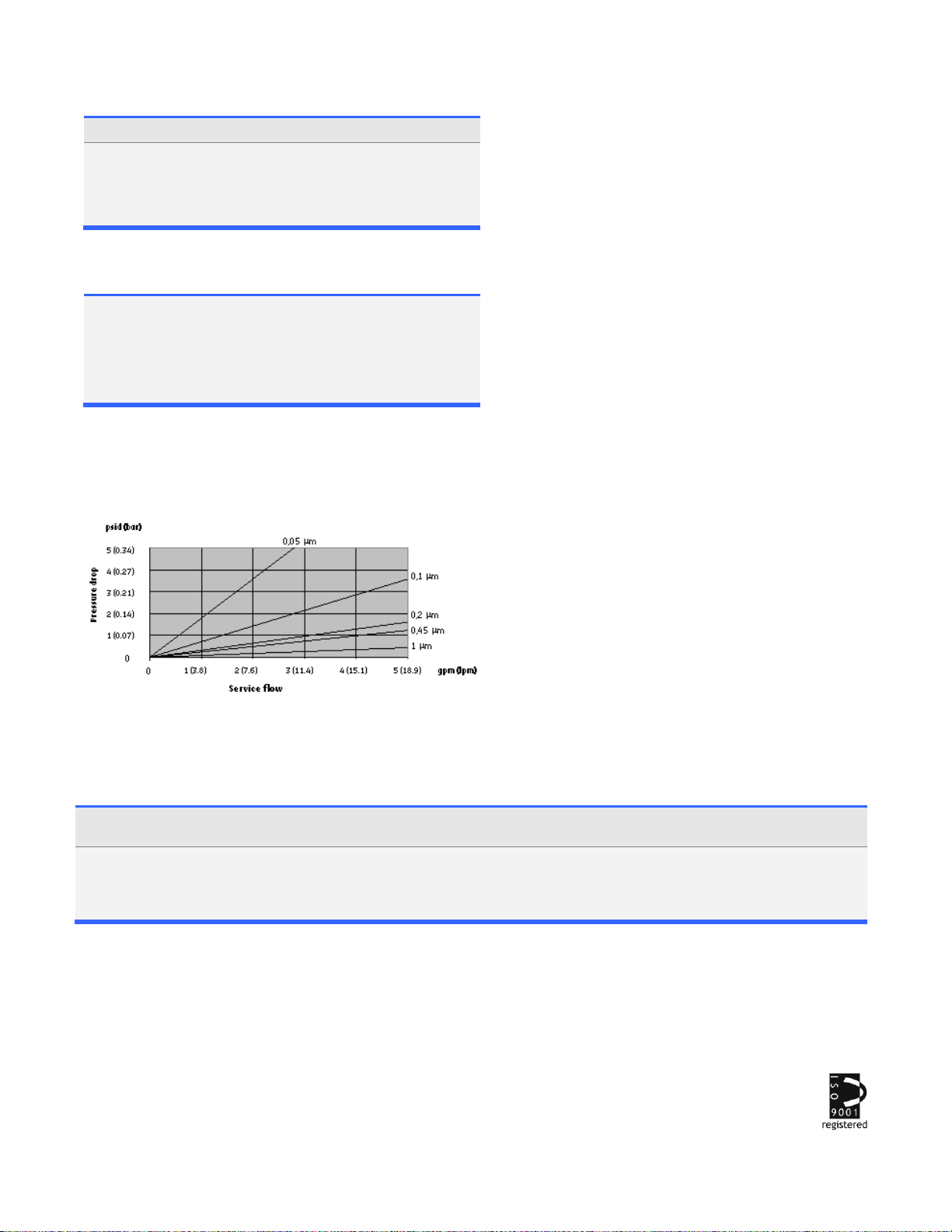

Table 4: Flow Performance in CleanWater

1

Data based on 10” length filter

Integrity Testing

0.05 μm 5 cc / min at 40 psig (2.76 bar)

0.1 μm 5 cc / min at 40 psig (2.76 bar)

0.2 μm 5 cc / min at 30 psig (2.07 bar)

0.45 μm 5 cc / min at 20 psig (1.38 bar)

1 μm 5 cc / min at 15 psig (1.38 bar)

Additional Information

Memtrex HFE-T filters may be sanitized with

compatible chemical agents. The filters must

not be autoclaved or steam sterilized.

GE certifies that the material contained in its

Memtrex HFE-T pleated filters meet U.S. FDA

1

requirements for food contact under the applicable regulations in 21 CFR. For further information, contact GE technical services.

Memtrex HFE-T filters meet the test criteria for

USP class VI-121°C Plastics.

Aqueous extracts from Memtrex HFE-T filters

contain less that 0.25 EU/ml. The filters typically exhibit low levels of non-volatile residues.

GE filter cartridges are designed and manu-

factured for resistance to a wide range of

chemical solutions. Conditions will vary with

each application and users should carefully

verify chemical compatibility. Please contact

your GE distributor for more information.

Table 5 provides additional ordering information. Table 5: Ordering Information

²Teflon and Viton are a registered trademark of DuPont.

Page 2 Fact Sheet

Loading...

Loading...