Page 1

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FSsmPharmaElements_EN.doc Sep-13

Membrane

Thin film membrane (TFM*)

Model

Average

permeate flow

gpd (m3/day)

Minimum

rejection

PHARMA NF2 3838C30

1,3

1,800 (6.8)

96.0%

PHARMA RO3 3840C30

1,2

1,650 (6.2)

98.5%

PHARMA RO3 8038C35

1,2

6,750 (25.5)

98.5%

Model

Spacer

mil (mm)

Active area

ft2 (m2)

Part

number

PHARMA NF2 3838C30

30 (0.76)

78 (7.2)

1232576

PHARMA RO3 3840C30

30 (0.76)

77 (7.2)

1223957

PHARMA RO3 8038C35

35 (0.89)

315 (29.2)

3021475

PHARMA UF1 3840C30

30 (0.76)

80 (7.4)

1207089

Model2

Dimensions, inches (cm)

Boxed

A

B1

C

Weight

lbs (kg)

PHARMA NF2 3838C30

38.00

(96.5)

0.833

(2.12)

3.79

(9.6)

7

(3.2)

PHARMA RO3 3840C30

38.75

(98.4)

0.833

(2.12)

3.79

(9.6)

7

(3.2)

PHARMA RO3 8038C35

38.0

(96.5)

1.125

(2.86)

7.91

(20.1)

29

(13.2)

PHARMA UF1 3840C30

38.75

(98.4)

0.833

(2.12)

3.79

(9.6)

7

(3.2)

Typical Operating Flux

5-20GFD (8-34 LMH)

Maximum Operating Pressure

600 psi (4,137 kPa)

Maximum Temperature

Continuous operation: 122°F (50°C)

Clean-In-Place (CIP): 122°F (50°C)

pH Range

Continuous operation: 3.0-10.0,

Clean-In-Place (CIP): 2.0-10.5

Maximum Pressure Drop

Over an element: 15psi (103kPa)

Per housing: 60 psi (414 kPa)

Chlorine Tolerance

500+ ppm-hours,

Dechlorination recommended

Pharma Elements

Concentration and Purification of Pharmaceutical Ingredients

The Pharma elements enable the purification and

concentration of high value organic molecules used

in the synthesis of pharmaceutical ingredients.

These elements are used in applications requiring

stringent sanitary procedures.

The Pharma elements feature a patented Durasan*

cage outer wrap, a selection of feed spacers and

polysulfone parts.

The Pharma elements comply with:

• FDA Regulations relevant sections of 21CFR

• EU Framework 1935/2004/EC

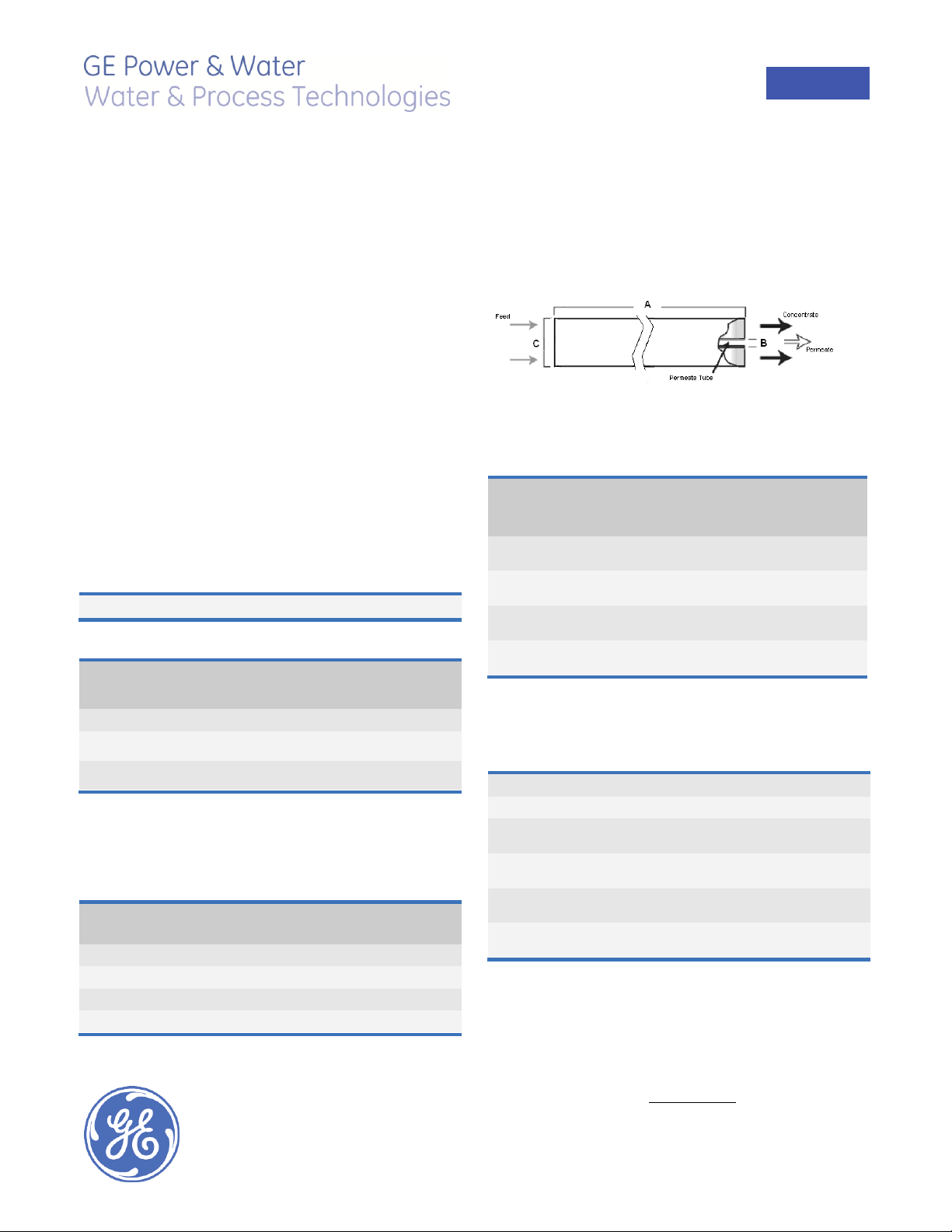

Figure 1: Element Dimensions Diagram (Female)

Table 2: Dimensions and Weight

Table 1: Element Specification

1

Average salt rejection after 24h operation. Individual flow rate may vary ±25%.

2

Testing conditions: 2,000ppm NaCl solution at 425psi (2,930kPa) operating pres-

sure, 77°F (25°C), pH6.5 and 15% recovery.

3

Testing conditions: 2,000ppm MgSO4 solution at 110psi (760kPa) operating

pressure, 77 °F (25°C), 15 % recovery.

1

Internal diameter.

² These elements are bagged dry before shipping.

Table 3: Operating and CIP parameter

Loading...

Loading...