Page 1

Find a contact near you by visiting www.ge.com/water

and clicking on “Contact Us”.

*Trademark of General Electric Company;

may be registered in one or more countries.

©2008, General Electric Company. All rights reserved.

GE Water & Process Technologies

Packaged plants for water

and wastewater treatment

Bulletin 1053EN Sep-08

Page 2

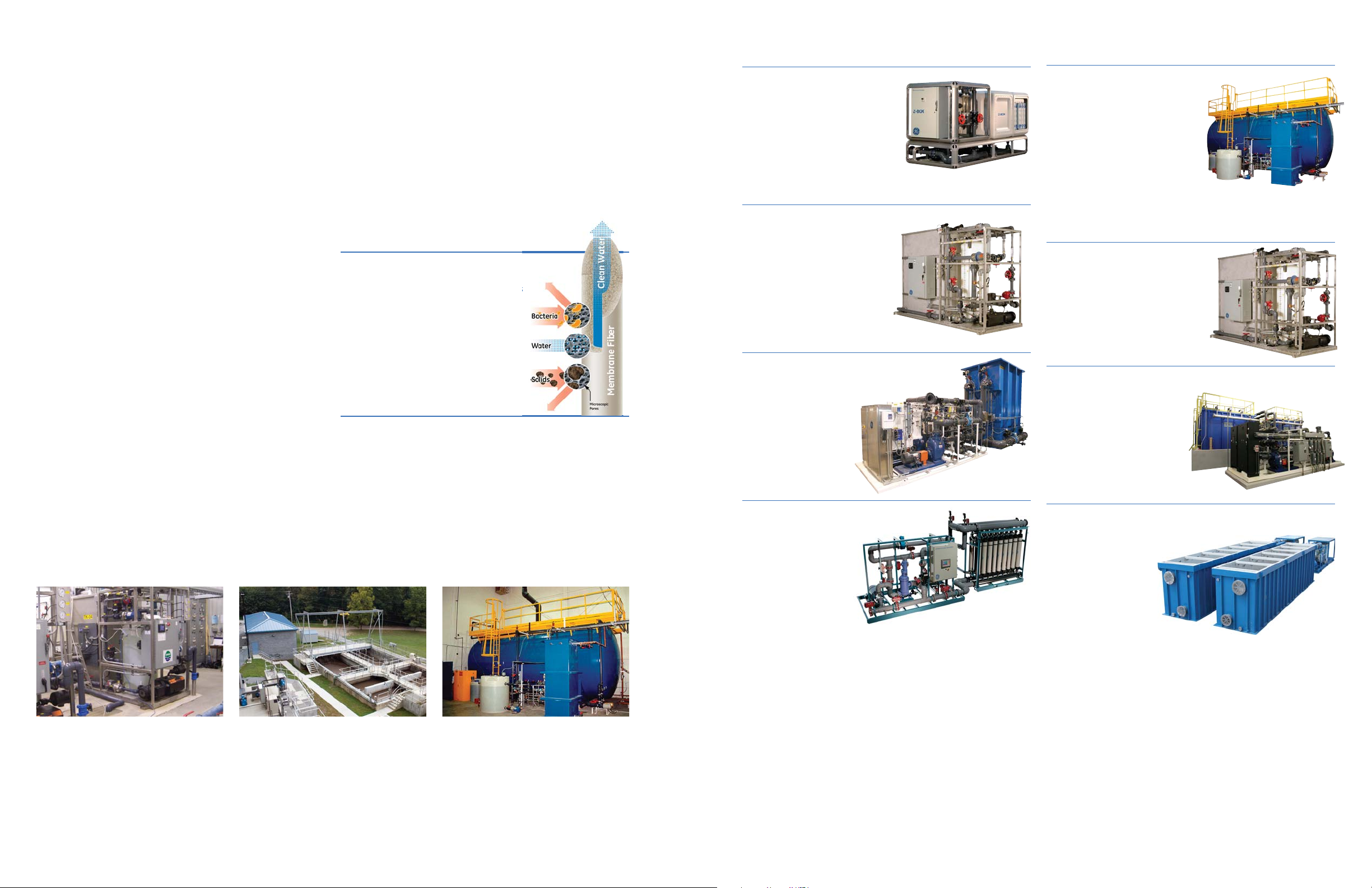

ZeeWeed* packaged plants provide

Water Treatment & Tertiary Systems

Wastewater Treatment Systems

large-scale performance in a compact

pre-assembled system

Incorporating a simple and expandable building-block

design, GE packaged plants can be quickly set up in

virtually any location and feature scalable treatment

capacity that can be increased as demand grows. These

highly automated, plug-and-play UF systems outperform

conventional treatment alternatives in all categories,

offering superior treated water quality that meets or

exceeds regulatory requirements, reduced operating costs,

smaller plant footprints, and highly reliable performance—

at a price that is comparable to conventional systems.

Pre-assembled and factory tested systems offer:

Reduced on-site construction costs with

•

less interconnecting requirements;

Quick delivery with complete engineering

•

package already completed;

Cost-effective solutions for virtually all water

•

and wastewater treatment applications;

Comprehensive cleaning capability for

•

peak system performance;

Municipal Drinking Water

Township of Tay, ON - 70,000 gpd (265 m

Z-BOX M

3

/d) ADF

‡

Municipal Wastewater Treatment

Huntsville, TN - 300,000 gpd (1,136 m

Packaged Equipment Skids Z-MOD L

How membranes work

Membranes are based on filtration methods

found throughout nature. ZeeWeed membranes

are hollow polymer fibers with billions of

microscopic pores on the surface. The pores

are much smaller in size than common

contaminants, bacteria and viruses. This

physical barrier only allows clean water to

pass through while rejecting impurities—

guaranteeing an exceptional water quality

and clarity on a continuous basis. Application

of pressure outside or a slight vacuum inside

is all that is required to draw water into

the membrane and filter out impurities.

Simple and highly automated operation

•

and in-situ membrane cleaning;

Modular building-block design;

•

Simplified start up with minimal installation time;

•

Compact footprint with flexible layout options;

•

Greenfield or retrofit solutions.

•

3

/d) ADF

‡

Decentralized Treatment

Office Park, Oakville, ON - 17,500 gpd (66 m

Z-MOD S

3

/d) ADF

‡

Z-BOX S

up to 400,000 gpd (1,514 m3/d)

Fully integrated process and

•

control components

Less than 6-foot (1.8-meter)

•

tall system readily fits into any

building

Side-loading membrane door for easy access

•

Z-BOX M

up to 350,000 gpd (1,325 m3/d)

Equipped with rugged

•

reinforced membranes to

withstand the harshest

environments and the most

difficult-to-treat water sources

Fully-integrated, skid-

•

mounted system

Z-BOX L

up to 3.25 MGD (12,300 m3/d)

Easily fits beneath a

•

9-foot (2.7-meter)

ceiling

Side loading membrane

•

door for easy access

Z-PAK

up to 720,000 gpd

(2,725 m3/d)

ZeeWeed fiber in a

•

pressurized module

Fully integrated

•

skid-mounted system

with compact footprint

Typical Treated Water Results

Turbidity ………………………………………………………………………………………………………… < 0.1 NTU

Bacteria …………………………………………………………………………………………… > 4-log removal

Giardia ……………………………………………………………………………………………… > 4-log removal

Cryptosporidium …………………………………………………………………………… > 4-log removal

Virus - ZeeWeed 500 ………………………………………………………………… > 2.0-log removal

Virus - ZeeWeed 1000/1500 …………………………………………………… > 3.5-log removal

Iron …………………………………………………………………………………………………………… < 0.05 mg/L

Manganese ……………………………………………………………………………………………… < 0.02 mg/L

TSS …………………………………………………………………………………………………………………… < 1 mg/L

TOC ……………………………………………………………………………………………… 50 - 90% removal

Arsenic ……………………………………………………………………………………………………………… < 5 μg/L

Color ……………………………………………………………………………………………………………… < 5 PCU

§ pre-treatment required

† dependent on raw water quality

* Average Daily Flow‡ Average Daily Flow

Z-MOD S

3

up to 80,000 gpd (303 m

Fully integrated wastewater

•

treatment plant

Can be buried or installed above

•

ground (smaller flows available

for below ground systems)

Complete plug-and-play design

•

with all components in a single tank

Can operate at MLSS concentrations

•

between 3,000 and 15,000 mg/L

/d)

‡

Z-MOD M

up to 110,000 gpd (416 m3/d)

Fully integrated skid-mounted

•

system

Can operate at MLSS

•

concentrations between

3,000 and 15,000 mg/L

‡

Z-MOD L

up to 1 MGD (3,785 m3/d)

Containerized or skid-

•

mounted components

Dual-train systems

•

Can operate at MLSS

•

concentrations between

3,000 and 15,000 mg/L

‡

Z-MOD X

up to 4.0 MGD

(15,142 m3/d)

Equipment skid

•

comes complete with

permeate pump,

process blower, RAS

pump, PLC, MCC,

piping and wiring

Can operate at MLSS concentrations

•

between 3,000 and 15,000 mg/L

Achievable MBR Effluent

Turbidity ………………………………………………………………………………………………………… < 0.1 NTU

BOD

……………………………………………………………………………………………………………… < 2 mg/L

§

§

§†

§†

5

TSS …………………………………………………………………………………………………………………… < 1 mg/L

NH

-N …………………………………………………………………………………………………………… < 0.5 mg/L

3

Total Nitrogen …………………………………………………………………………………………… < 3 mg/L

Total Phosphorous ……………………………………………………………………………… < 0.05 mg/L

Fecal Coliform …………………………………………………………………………… < 2.2 CFU/100 ml

SDI ……………………………………………………………………………………………………………………………… < 2

†† with appropriate biological design and/or chemical addition

§§ after disinfection

‡

††

††

§§

Loading...

Loading...