Page 1

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FS1600EN Mar-13

Fact Sheet

Osmo* TITAN Series

Reverse Osmosis Machines

120–700 gpm (27–158 m3/hr)

Key Benefits

Compact treatment system for variable water

quality

Configurable process flow to meet changing water

demands; two pass or two train operability in a

single system on two models

Skid mounted VFD for high pressure pump to opti-

mize energy usage and accommodate varying water temperatures

Designed to ANSI B31.1 specifications

Premium instrumentation with HART protocol

Skid-mounted; reduces onsite installation time and

costs

Easy to install

Simple to operate

Operating Parameters

Recovery.........................................................................................66-75%

Design temp. ......................................................................... 60ºF (16C)

Operating range .................................................. 60-77 F (16-25C)

Nominal System rejection .....................................................97-99%

Minimum inlet pressure .......................................... 30 PSIG (2 bar)

Average membrane flux ....................................................12-14 gfd

Design TDS Basis ..................................................... 1500-2500 ppm

Standard Features

Allen Bradley ControlLogix 1756 PLC with Ethernet

Allen Bradley PanelView Plus 1000 10-inch color

touchscreen interface

ASME code housings

Full system or Bank-by-bank cleaning

Automatic permeate flush on shutdown

Materials of Construction

High-pressure piping ..................... 316 Stainless Steel, Sch. 10

Low-pressure piping ...................... 316 Stainless Steel, Sch. 10

Frame ........................................................ Painted blue carbon steel

Enclosure ....................................................................................... NEMA 4

Membrane Elements

Membrane Model ......................................................... AG8040F-400

Style ................................................................ Spiral-wound elements

Membrane type ........................................................ TFC (Polyamide)

Average Membrane rejection ................................................ 99.5%

Cartridge Filtration

Housing material ............................................... 316 Stainless Steel

Cartridge filter .............................. 1-micron nominal, ROsave.Z*

Page 2

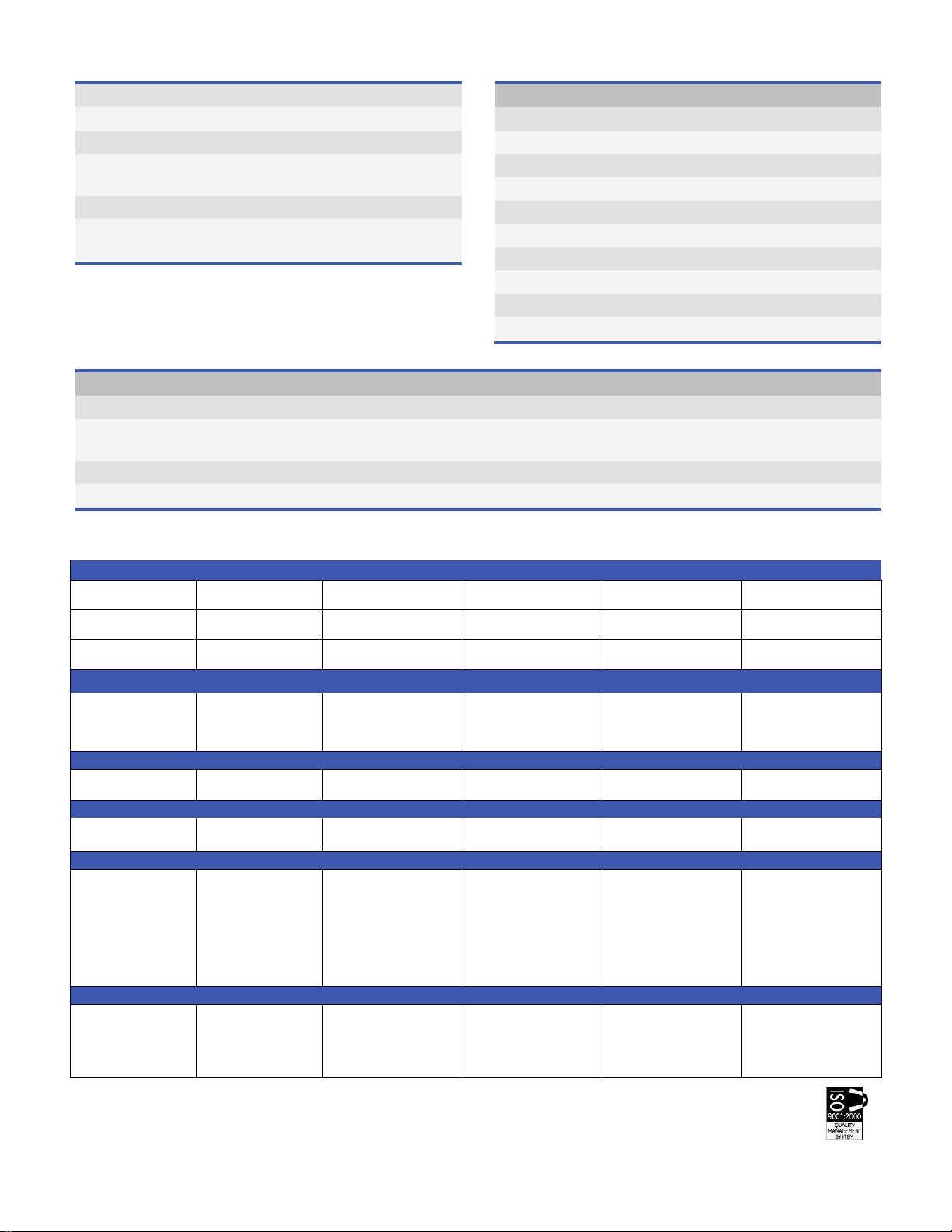

Table 1: Standard Instrumentation

Flow

Permeate, concentrate

Conductivity

Feed, permeate

pH

Feed

Pressure Indicators

Primary, permeate, concentrate pump discharge

Pressure Switch

Permeate, concentrate

Pressure Transmitter

Pre-filter, post-filter, primary,

final, permeate final

Equipment

Manufacturer

Cartridge Filter

GE

Membrane Element

GE

High Pressure Pump

GE Tonkaflo

Cartridge filter housing

Filtrek

Membrane Housing

Codeline

Flow Measurement

Rosemount

Conductivity, pH

Rosemount

Pressure Transmitters

Rosemount

PLC Components

Allen Bradley

Valves

Bray

Option

Description

TITAN Media Filters

Media filtration pretreatment with stainless steel internals and face piping

TITAN Clean-in-Place

Cone-bottom HDPE tank with painted carbon steel stand and CIP pump for bank-bybank cleaning

Chemical Feed Systems

Electronic metering pump for chemical pretreatment

Motor Starters

Motor starters for CIP pumps, shipped loose for field installation

MODEL

TITAN-36

TITAN-72

TITAN-90

TITAN-144

TITAN-180

Permeate rate:

130 gpm

260 gpm,

130 gpm per train

325 gpm two train,

166 gpm two pass

520 gpm,

260 gpm per train

650 gpm two train,

332 gpm two pass

Concentrate Rate:

43 gpm

86 gpm,

43 gpm per train

109 gpm two train,

65 gpm two pass

174 gpm,

87 gpm per train

217 gpm two train,

130 gpm two pass

Feed Rate:

173 gpm

346 gpm,

173 gpm per train

433 gpm two train,

217 gpm two pass

694 gpm,

347 gpm per train

867 gpm two train,

461 gpm two pass

Pumps and Motors

Manufacturer:

Model:

Quantity:

Motor HP and type:

Tonkaflo

AS22512

1

50 HP TEFC

Tonkaflo

AS22512

2

50 HP TEFC

Tonkaflo

AS40407/AS22512

1/1

60 HP/50 HP TEFC

Tonkaflo

AS40409

2

75 HP TEFC

Tonkaflo

AS40407/AS40409

2/1

2x60 HP/75 HP TEFC

Membrane Elements and Housings

Membranes quantity:

Banking Arrangement:

36

42

72

42, 42

90

63, 42

144

84, 84

180

126, 84

Cartridge Filtration

Cartridge Filter:

Filter Quantity:

RO.Zs01-40XK

12

RO.Zs01-40XK

24

RO.Zs01-40XK

31

RO.Zs01-40XK

50

RO.Zs01-40XK

57

Installation and Utility Requirements

Inlet:

Permeate:

Concentrate:

Inlet Water Pressure:

Air Pressure:

Drain to be Sized for:

Power:

Control Circuit:

3.0-inch flange

3.0-inch flange

1.5-inch flange

30 psig min.

100 psig, oil-free

173 gpm

460 VAC, 3-phase, 60Hz

120 VAC, 1-phase, 60Hz

2x3.0-inch flange

2x3.0-inch flange

2x1.5-inch flange

30 psig min.

100 psig, oil-free

346 gpm

460 VAC, 3-phase,60Hz

120 VAC, 1-phase, 60Hz

4.0-inch/3.0-inch flange

2x3.0-inch flange

2.0-inch/1.5-inch flange

30 psig min.

100 psig, oil-free

433 gpm

460 VAC, 3-phase, 60Hz

120 VAC, 1-phase, 60Hz

2x4.0-inch flange

2x4.0-inch flange

2x2.0-inch flange

30 psig min.

100 psig, oil-free

694 gpm

460 VAC, 3-phase, 60Hz

120 VAC, 1-phase, 60Hz

6.0-inch/4.0-inch flange

2x4.0-inch flange

3.0-inch/2.0-inch flange

30 psig min.

100 psig, oil-free

867 gpm

460 VAC, 3-phase,60Hz

120 VAC, 1-phase, 60Hz

Skid

Height:

Width:

Length:

Shipping Weight:

Operating Weight:

101.7”

48”

309”

6,500LB (2,950Kg)

8,900LB (4,037Kg)

101.7”

72”

309”

11,300LB (5,126Kg)

16,300LB (7,394Kg)

102.7”

84”

309”

12,800LB (5,806Kg)

18,900LB (8,573Kg)

102.5”

92”

309”

16,200LB (7,350Kg)

25,200LB (11,430Kg)

105.6”

92”

460”

21,200LB (9,616Kg)

32,700LB (14,832Kg)

Table 3: Optional Features

Table 2: Major Component Manufacturers

OSMO TITAN Models

Page 2 FS1600EN

Loading...

Loading...