Page 1

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FS1280EN.doc Nov-13

Membrane

Thin-Film Membrane (TFM*)

Model

Average

permeate flow

gpd (m3/day)

1,2

Average NaCl

rejection

1,2

Minimum NaCl

rejection

1,2

OSMO-PHARMA-RO-4040-FF

2,200 (8.3)

99.0%

98.0%

OSMO-PHARMA-RO-365-FF

9,600 (36.3)

99.0%

98.0%

Model

Active area

ft2 (m2)

Outer wrap

Part

number

OSMO-PHARMA-RO-4040-FF

83 (7.7)

Full-Fit*

1233036

OSMO-PHARMA-RO-365-FF

365 (33.9)

Full-Fit*

1233035

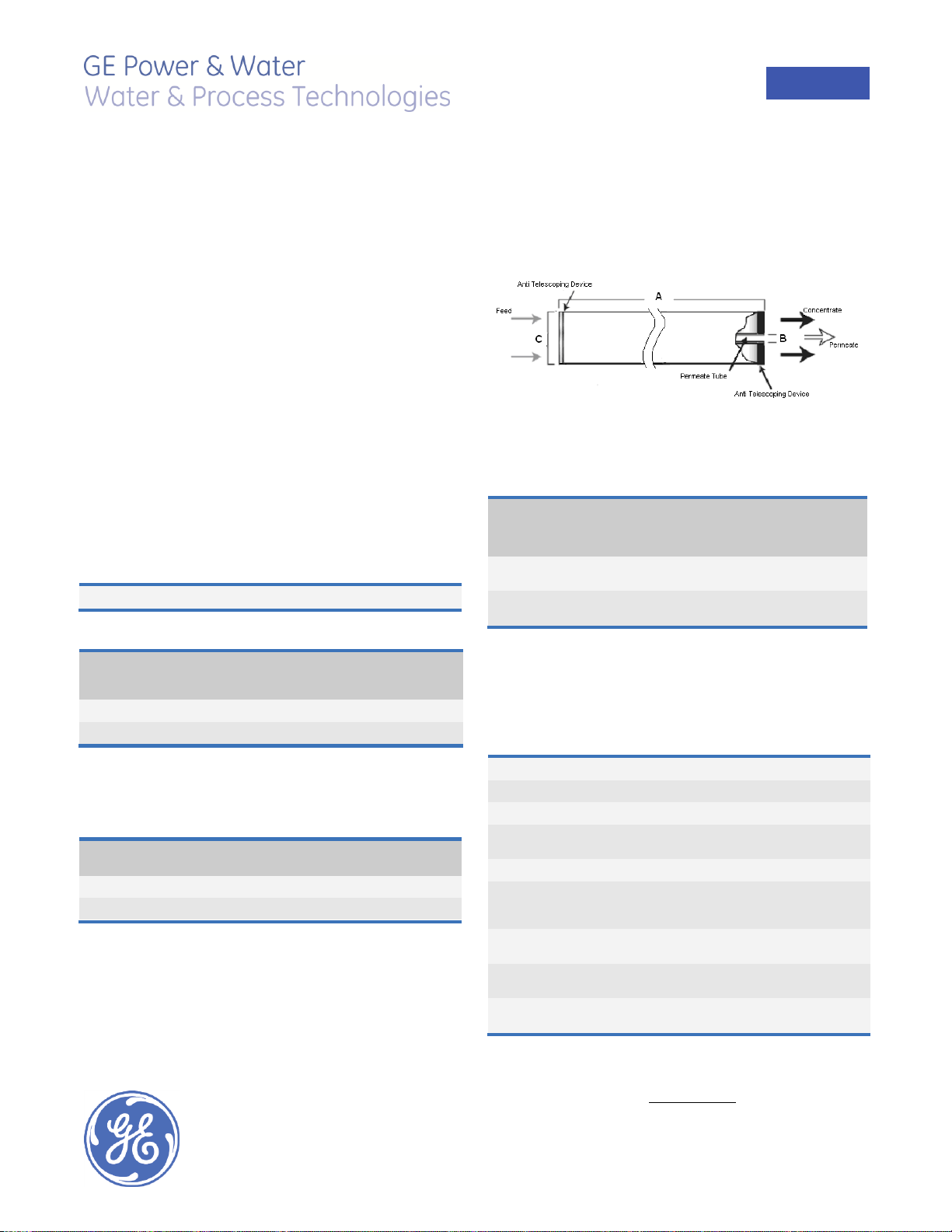

Model1

Dimensions, inches (cm)

Boxed

A

B2

C3

Weight

lbs (kg)

OSMO-PHARMA-RO-4040-FF

40.0

(101.6)

0.775

(1.97)

4.0

(10.2) 8 (3.5)

OSMO-PHARMA-RO-365-FF

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

Typical Operating Pressure

200 psi (1,379 kPa)

Typical Operating Flux

10-20 GFD (15-35LMH)

Maximum Operating Pressure

600 psi (4,137 kPa),

Maximum Temperature

Continuous operation: 122°F (50°C)

Clean-In-Place (CIP) 122°F (50°C)

Minimum Crossflow

30gpm (6.8 m3/hr) for 365 ft² element only

pH Range

Optimum rejection: 7.0-7.5

Continuous operation: 4.0-11.0

Clean-In-Place (CIP): 2.0-11.5

Maximum Pressure Drop

Over an element: 12 psi (83 kPa)

Per housing: 50 psi (345 kPa)

Chlorine Tolerance

1,000+ ppm-hours,

dechlorination recommended

Feedwater

NTU < 1

SDI < 5

OSMO PHARMA Elements

Pharmaceutical Grade Net Wrapped RO Elements

All the OSMO PHARMA elements:

Are manufactured from FDA-acceptable

materials.

Have passed Class VI testing for all materials.

Feature a net wrapped design.

Have an electropolished 316L stainless steel

permeate tube.

Are wet-tested for performance integrity.

Are shipped with a certificate of compliance.

Figure 1: Element Dimensions Diagram – Female

Table 2: Dimensions and Weight

Table 1: Element Specification

1

Average salt rejection after 24 hours operation. Individual flow rate may vary

+25%/-15%.

2

Testing conditions: 2,000 ppm NaCl solution at 225 psi (1,551 kPa) operating

pressure, 77 °F, pH 7.5 and 15% recovery.

1

These elements are dried and bagged before shipping.

2

Internal diameter.

3

The element diameter (dimension C) is designed for optimum performance in GE

Water & Process Technologies pressure vessels. Others pressure vessel dimension

and tolerance may result in excessive bypass and loss of capacity.

Table 3: Operating and CIP parameters

Loading...

Loading...