Page 1

CorTrol* OS7785

Oxygen Scavenger

• Controls oxygen corrosion

• Provides superior metal conditioning for feed-

water and condensate systems

• Improves boiler reliability

• Contains no hydrazine or derivatives of hydra-

zine

• Contributes no inorganic solids to feedwater

Fact Sheet

2

(>1000 psig) [70 kg/cm

water solids are a major concern.

CorTrol OS7785 contributes no inorganic dissolved

solids to the system, which may result in a reduction in boiler blowdown with corresponding energy

savings.

] applications where boiler

Description and Use

CorTrol* OS7785 is an aqueous blend of an organic

oxygen scavenging compound and a neutralizing

amine. This product is a rapid and highly effective

oxygen scavenger, and does not contribute to inorganic boiler water solids. In addition, it is safer to

handle than hydrazine.

CorTrol OS7785 is designed for the control of corrosion caused by dissolved oxygen in makeup, condensate, and feedwater systems. It is not suitable

for use where the steam directly contacts food per

FDA 21 CFR 173.310 or USDA Section G6. It is approved for use where steam contacts paper or paperboard used in food packaging per FDA

21CFR176.170 and 176.180.

Typical Applications

Even with good deaerating heater operation, sufficient dissolved oxygen can remain in the feedwater

to damage the boiler system. Even low levels of dissolved oxygen are critical to high-pressure (high

temperature) systems. Oxygen in water produces

pitting which is particularly severe because of its

localized nature. Economizers and feedwater heaters are particularly susceptible to oxygen attack.

While it can effectively be used in low-pressure

boiler systems, CorTrol OS7785 was specially developed as an oxygen scavenger for higher pressure

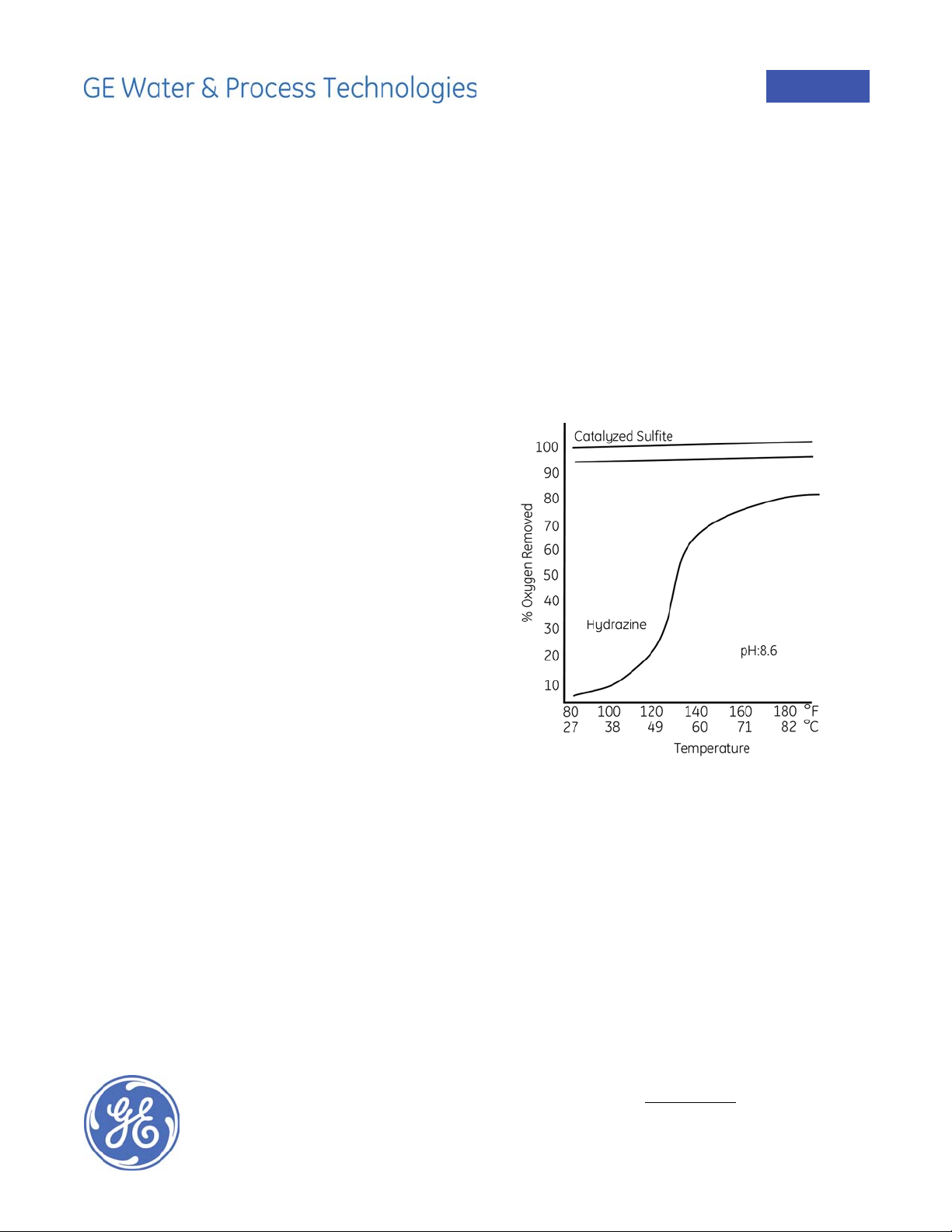

Figure 1: Comparison of CorTrol OS7785 and hydrazine for

The oxygen scavenging efficiency of CorTrol

OS7785 is better than hydrazine (see Figure 1).

Because it is such a strong reducing agent, CorTrol

OS7785 has also demonstrated the ability to reduce

certain forms of metallic oxides, thereby conditioning metal surfaces (see Figure 2).

Because CorTrol OS7785 is an excellent oxygen

scavenger and provides superior metal conditioning

at typical condensate temperatures, the product is

highly desirable for condensate system protection.

CorTrol OS7785

removing dissolved oxygen.

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2009, General Electric Company. All rights reserved.

AM-FSbCorTrolOS7785_EN.doc Sep-09

Page 2

Treatment And Feeding Requirements

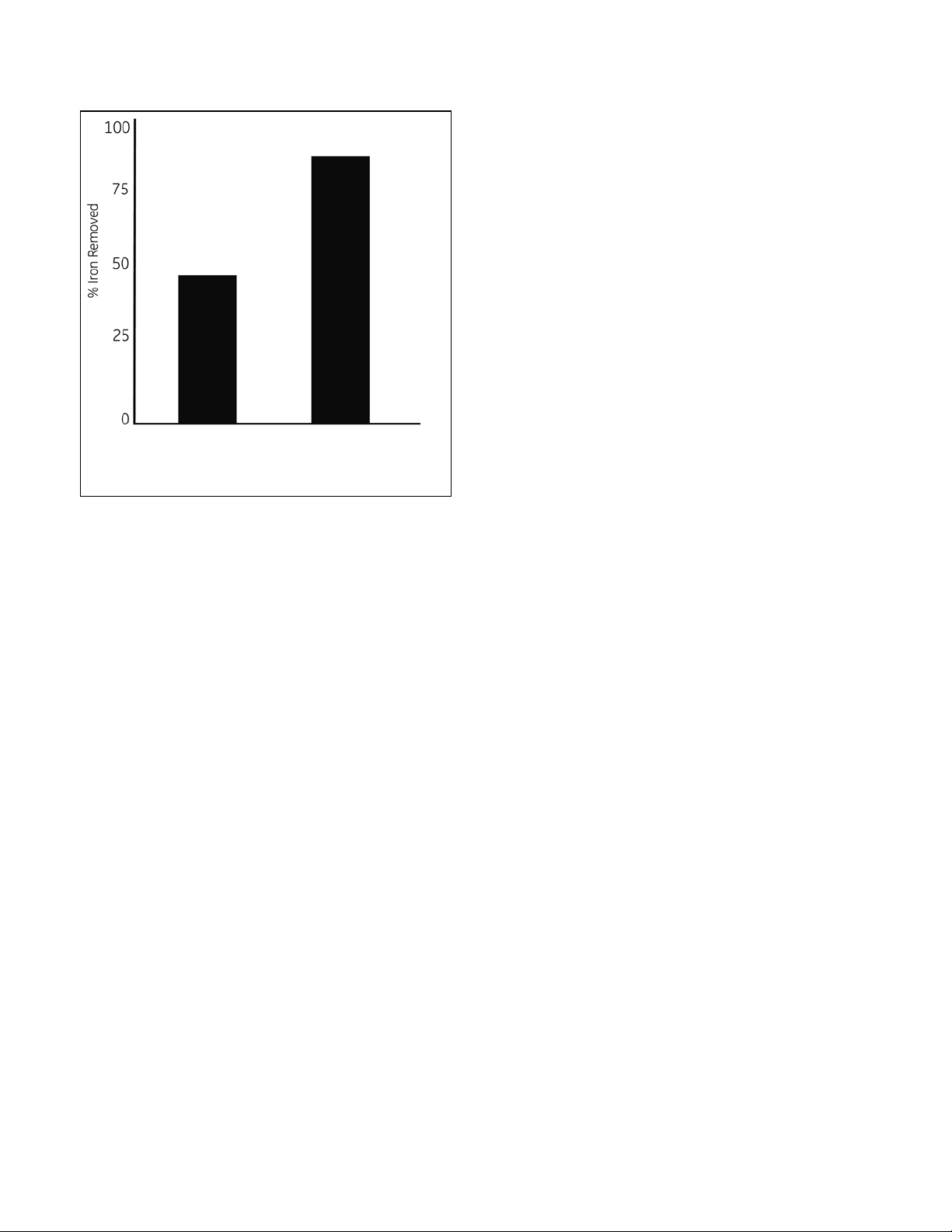

Without With

CorTrol OS7785 CorTrol OS7785

Figure 2: CorTrol OS7785 promotes the reduction of iron

from the red, nonmagnetic state (Fe2O3) to the

black, magnetic state (Fe3O4). As a result, iron

removal with an electromagnetic filter can

increase from approximately 50 percent to over

95 percent.

Feed Point - CorTrol OS7785 should be fed continu-

ously to the deaerator storage section or to the feedwater line. For condensate protection it can be

fed diluted to the steam header or to condensate

lines.

Feedrate - Feed CorTrol OS7785 based on the boiler

feedwater dissolved oxygen level. Feed continu-

ously.

Dilution - Use good quality condensate, demineralized water or deaerated feedwater to make a convenient feeding strength. The material may be

diluted in any proportion. Mild agitation should be

provided for initial mixing only. Product solution

should have minimum exposure to atmospheric

oxygen. If this material is fed from a day tank, it is

recommended that only a 24-hour supply be made

at a time.

Equipment - Feed CorTrol OS7785 using a mild

steel feed system. This product is suitable for use

with PaceSetter* automated chemical feed and

control equipment.

General Properties

The use of CorTrol OS7785 is beneficial where feedwater is used for attemperation. When feedwater

containing an inorganic oxygen scavenger is used

for attemperation, harmful deposits on superheater

tubes and/or turbines may result. CorTrol OS7785 is

also beneficial in petrochemical plants as it does

not affect sulfur-sensitive catalysts.

CorTrol OS7785 can also be used for boiler layup.

Follow the recommended procedures for boiler and

superheater storage and feed at a minimum of

2000 ppm [mg/L] CorTrol OS7785 in the boiler water

3

(16.7 lb/1000 gal [2 kg/m

] of boiler water). If the

boiler is fired during storage, supplemental pH adjustment may be required. Neutralizing amines or

ammonia should be used to keep the boiler water

pH above 10.0.

Physical properties of CorTrol OS7785 are shown on

the Material Safety Data Sheet, a copy of which is

available on request.

Packaging Information

CorTrol OS7785 is a liquid blend, available in a wide

variety of customized containers and delivery

methods. Contact your GE Water & Process Technologies representative for details.

Safety Precautions

A Material Safety Data Sheet containing detailed

information about this product is available upon

request.

Page 2 Fact Sheet

Loading...

Loading...