Page 1

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FS1654EN.doc Jul-13

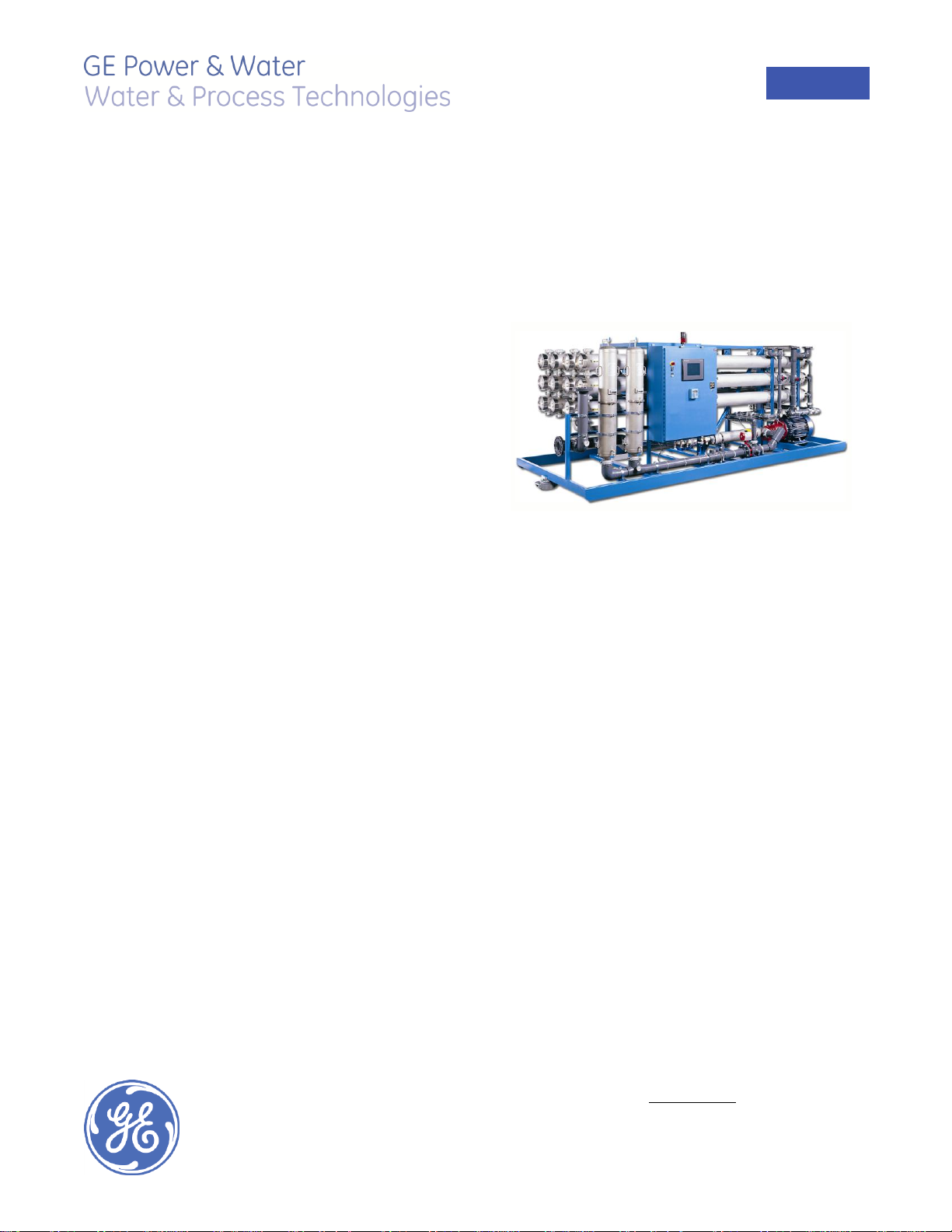

MUNI Series 60 Hz

Reverse Osmosis & Nanofiltration Machines

50 gpm to 1 mgd (11.4 to 157.8 m3/hr)

Features

GE Fanuc Quickpanel, 12.0-inch color display, text

and pictorial operating screens, touchscreen controls

GE Fanuc Versamax, communication: Ethernet

4-20 mA instruments on QuickPanel

Primary and final pressure transmitters

UL 508 listed

Instrumentation

Flow Meters ............................................ Permeate, concentrate

Conductivity ........................................................... Feed, Permeate

pH ........................................................................................................ Feed

Pressure Gauges .......................... Pre-filter, post-filter, pump

discharge, primary, interstage,

final concentrate, permeate

Pressure Transmitters................. Pump discharge, primary,

interstage, final concentrate, permeate

Pressure Switch ....................................................... Low feed,High

permeate, concentrate

ORP ..................................................................................................... Feed

Instrument Center ......................................... Thornton 770 Max

Options Available

Allen-Bradley Control Package

Soft Starters

Variable Frequency Drives

SCADA: 75pt trending package with desktop PC

Electric-actuated operating valves

MUNI Multi-Media filters

MUNI Clean-in-Place units

MUNI chemical feed systems

Transfer pumps and storage tanks

Documentation Included

Operation and maintenance manual

Drawings: piping and instrumentation, electrical

and general dimensional

Operating Parameters

Typical feedwater recovery rate ................................75-85%

Design temp. .............................................................. 60ºF (15.6ºC)

Typical operating range ............. 35 to 85ºF (1.6 to 29.4ºC)

Nominal membrane rejection % ....... Membrane Specific

Minimal inlet pressure .......................................................... 30 psi

Materials of Construction

High-pressure piping .............. 316 Stainless Steel, Sch. 10

Low-pressure piping ............................................... Sch. 80, PVC

Frame ................................................. Painted blue carbon steel

Enclosure .............................................. NEMA 12 (painted blue)

Clamps/fittings............................................................. Zinc-plated

Membrane Elements & Housings

Membrane Model .................................. MUNI–RO-400-HR-LE

Style ......................................................... Spiral-wound elements

Manufacturer ................................................................................... GE

Page 2

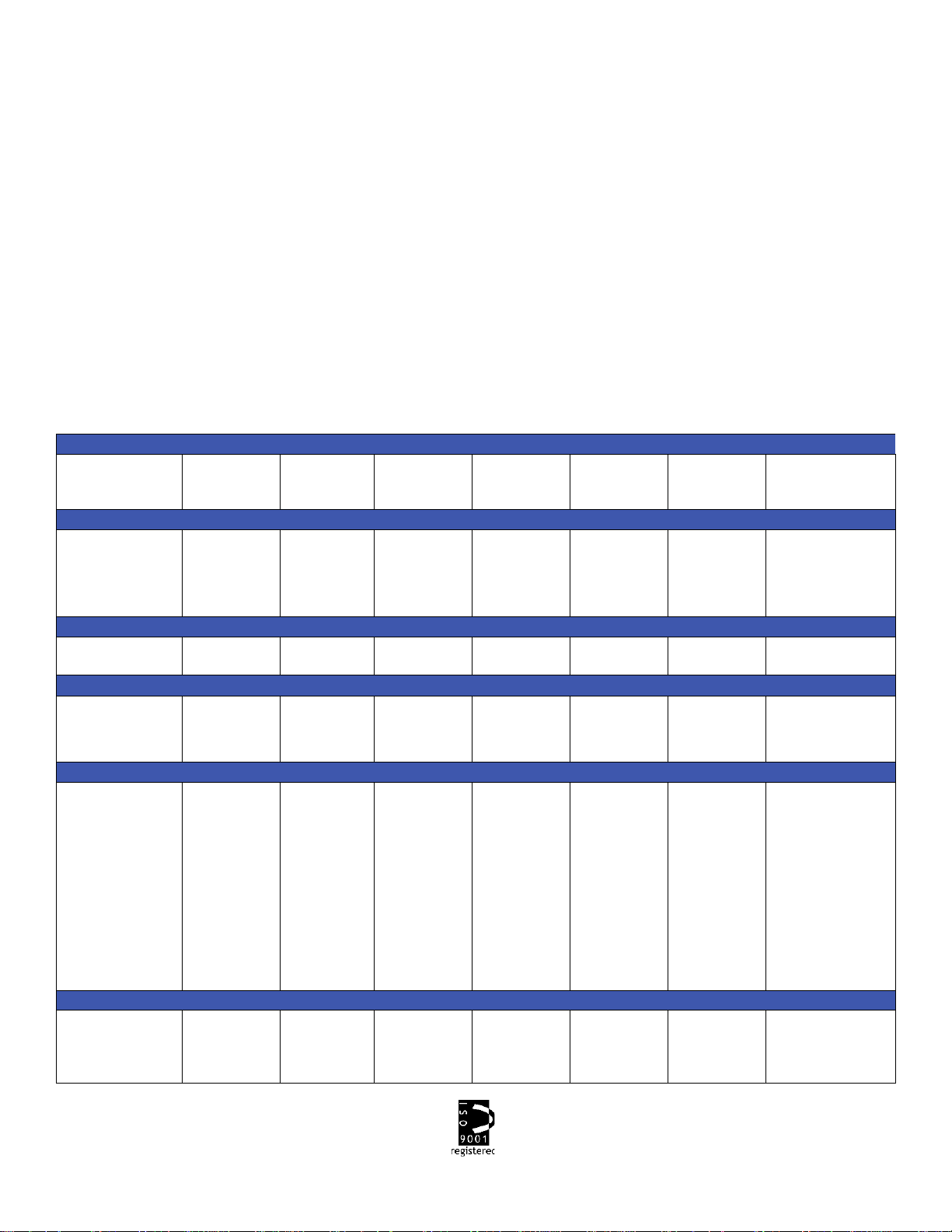

DESIGN

50 GPM

100 GPM

150 GPM

200 GPM

300 GPM

450 GPM

1 MGD

Permeate Rate:

Concentrate Rate:

Feed Rate:

50 gpm

16 gpm

66 gpm

100 gpm

33 gpm

133 gpm

150 gpm

50 gpm

200 gpm

200 gpm

66 gpm

266 gpm

300 gpm

100 gpm

400 gpm

450 gpm

150 gpm

600 gpm

700 gpm

233 gpm

933 gpm

Pumps and Motors

Manufacturrer:

Model:

Quantity:

Motor HP and type:

GE/Tonkaflo

SS8512

1

25HP TEFC

GE/Tonkaflo

SS12512

1

40 HP TEFC

GE/Tonkaflo

SS240003

1

60 HP TEFC

GE/Tonkaflo

AS40407

1

60 HP TEFC

GE/Tonkaflo

AS40409

1

75 HP TEFC

GE/Tonkaflo

AS40407

2

75HP TEFC

FEDCO

Varies, skid mounted,

separate

1

150 HP TEFC

Cartridge Filtration

Elements quantity:

Banking Arrangement:

12

21

24

42

36

42

48

84

72

84

108

126

180

2010

Membrane Elements and Housing

Cartridge Filter:

Filter Quantity:

RO.Zs01-40XK

7

RO.Zs01-40XK

7

RO.Zs01-40XK

14

RO.Zs01-40XK

14

RO.Zs01-40XK

21

RO.Zs01-40XK

28

Varies, skid mounted,

separate

Varies, skid mounted,

separate

Installation and Utility Requirements

Inlet:

Permeate:

Concentrate:

Inlet Water Pressure:

Air Pressure:

Drain to be sized for:

Power:

Control Circuit:

2.0-inch flange

1.5-inch flange

1.5-inch flange

30 psig min.

100 psig. oil-free

80 gpm

460 VAC, 3-phase,

60Hz

120 VAC, 1-phase,

60Hz

3.0-inch flange

3.0-inch flange

2.0-inch flange

30 psig min.

100 psig, oil-free

160 gpm

460 VAC, 3-phase,

60 Hz

120 VAC, 1-phase,

60 Hz

4.0-inch flange

3.0-inch flange

2.0-inch flange

30 psig min.

100 psig, oil-free

200 gpm

460 VAC, 3-phase,

60 Hz

120 VAC, 1-phase,

60 Hz

4.0-inch flange

3.0-inch flange

2.0-inch flange

30 psig min.

100 psig, oil-free

320 gpm

460 VAC, 3-phase,

60 Hz

120 VAC, 1-phase,

60 Hz

6.0-inch flange

4.0-inch flange

3.0-inch flange

30 psig min.

100 psig, oil-free

400 gpm

460 VAC, 3-phase,

60 Hz

120 VAC, 1-phase,

60 Hz

6.0-inch flange

4.0-inch flange

3.0-inch flange

30 psig min.

100 psig, oil-free

600 gpm

460 VAC, 3-phase,

60Hz

120 VAC, 1-phase,

60 Hz

8.0-inch flange

6.0-inch flange

4.0-inch flange

30 psig min.

100 psig, oil-free

933 gpm

460 VAC, 3-phase, 60 Hz

120 VAC, 1-phase, 60 Hz

Skid

Height:

Width:

Length:

Est. Shipping Weight:

74 inches

46 inches

194 inches

3400 lbs.

92 inches

46 inches

194 inches

4500 lbs.

92 inches

48 inches

274 inches

6000 lbs.

77 inches

80 inches

194 inches

7000 lbs.

93 inches

80 inches

274 inches

9500 lbs.

120 inches

80 inches

274 inches

14,500 lbs.

93 inches

90 inches

300 inches

18,000 lbs.

Membrane Elements & Housings Cont.

Membrane type .................................................. TFC (Polyamide)

Average membrane flux rate ................................ 15-18 GFD

Membrane rejection % ........................... Membrane Specific

Housing material ....................... FRP or 316L Stainless Steel

Cartridge Prefiltration

Housing model .............................................. Referenced below

Housing material ........................................ 316 Stainless Steel

Cartridge filter ............ 1 to 5 micron nominal, ROsave.Z*s

GE Water & Process Technologies MUNI RO/NF Models

Machine details noted are typical guidelines of the flow capacities noted for a spiral membrane system operating at a

75% feedwater recovery rate. This information is not intended for final system design as specific project goals, feedwater characteristics, and membrane element selections can vary greatly by application. Please contact GE for further

detailed design information.

Page 2 FS1654EN

Loading...

Loading...