Page 1

Fact Sheet

ZeeWeed* Mobile Water Treatment System

Applications:

• Reverse Osmosis pre-treatment

• Industrial process water

• Production of potable water

• Treatment of secondary effluent

Unit Capacity:

Up to 0.78 MGD (123 m3/hr) at up to 10 psi (69 kPa)

Key Benefits:

• Easily transportable

• Proven, reliable barrier technology

• Fully tested and ready for installation

• Fully automated for ease of operation

• Minimal installation time required

• Membranes shipped installed

• Insulated, heated, and air-conditioned container

• Handles large variations in raw water quality

• Strongest purewater ultrafiltration membrane

on the market

• Includes chemical cleaning and neutralization

system

• Integrated PLC/MCC control room

Mobilization/Demobilization Services:

Mobilization includes:

• Preparation of equipment at GE Water & Process Technologies

• Full drawing package to detail system layout

• System startup and operator training

• System performance checks

Demobilization includes:

• Complete mechanical checkout of equipment

• Coordination of Customer supplied mechanical

and electrical contractors

• Supervision of membrane preparation for return

shipment (cleaning, removal, preservation, bagging and crating)

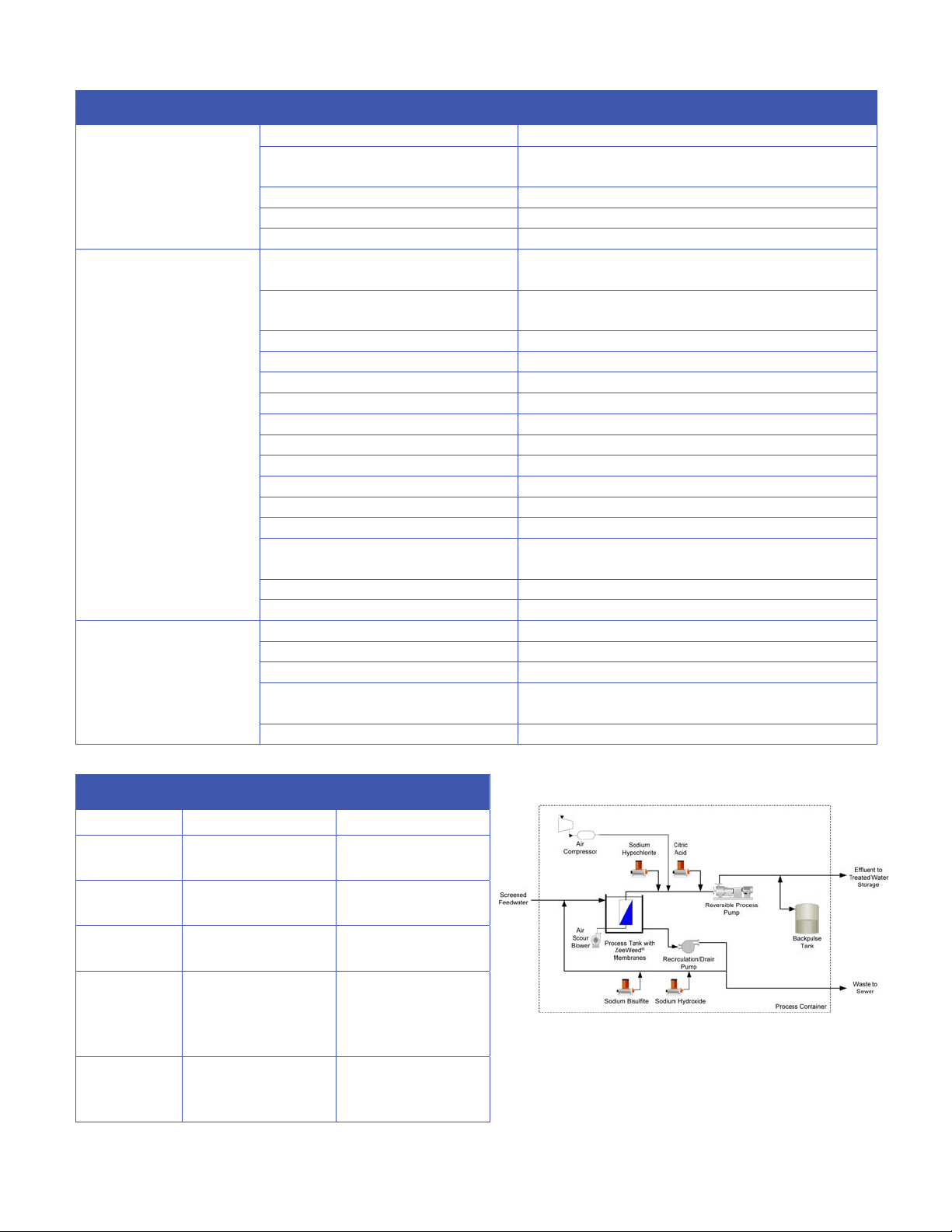

Termination Points

Tag Size Connection Function

A 10” 150# FLG RF UF Feed

B 8” 150# FLG RF Permeate

C 8” 150# FLG RF Reject

D 1.5” 150# FLG FF Waste

E 10” 150# FLG RF Overflow

F 0.5” 150# FLG RF Potable water

G 1” ODT Tube Instrumentation drain

H 2” 150# FLG FF Cleaning Supplemental

potable water

I 2” 150# FLG FF Potable water to BP tank

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us” .

* Trademark of General Electric Company; may be registered in one or more countries.

©2008, General Electric Company. All rights reserved.

TS-MWTS-Mobile-EN-0107-NA GE Logo Mar-08

Page 2

Standard Features:

Membrane

Membrane Module ZeeWeed 500 (NSF Certified)

Membrane Type Reinforced, low pressure, immersed hollow fi-

ber

Permeate Flow Path Outside-in

Nominal Pore size 0.04 microns

Membrane material PVDF

System

Configuration 1 train with 4 cassettes, 26 modules per cas-

sette

Dimensions 40’L x 8.0'W x 9.5’H (40’(12m) HC ISO Container)

12.2m L x 2.5m W x 2.9m H

Membrane tank 316 Stainless Steel

Process piping 316 Stainless Steel

MIT (membrane integrity test) Yes

Automatic backpulse cleaning Yes

LT2 compliance Yes

Process tank volume 4,800 gal; 18,168 L

Clean in Place (CIP) tank volume 1,184 gal; 4,481 L

Weight, shipping/operating 55,000 / 130,000 lbs (24,950 / 58,970 kg)

Aeration scour Blower self-contained

Control - Interface Allen Bradley PLC with Transduction PC (HMI)

Instrumentation Feed and permeate turbidimeters and perme-

ate particle counter

Data Collection System ZenoTrac™

Technical support 24/7 Yes

Requirements

Overhead clearance 12 ft (3.66 m) minimum

Surrounding access 5 ft (1.5 m) minimum

Electrical 460V/3ph/60Hz/236 amps

Raw water pressure 5 psig (34.5 kPa) minimum

20 psig (138 kPa) maximum

Raw water screening < 1 mm

Process Flow Diagram

Average Feed Water Characteristics

Source Parameters Permeate

Direct

Filtration

Enhanced

Coagulation

Settled

<100 NTU turbidity

<0.3 NTU turbidity

<5 mg/L TOC

<100 NTU turbidity

<0.3 NTU turbidity

>5 mg/L TOC*

<5 NTU turbidity <0.3 NTU turbidity

Water

Oxidation

(Fe & Mn)

<10 NTU turbidity

<5 mg/L TOC

<0.3 NTU turbidity

>1 mg/L Fe,*

>0.3 mg/L Mn*

Secondary /

<100 mg/L TSS <0.3 NTU turbidity

Tertiary

Effluent

* Operating parameters to be confirmed with GE membrane solutions under these conditions

Page 2 TS-MWTS-Mobile-EN-0107-NA GE Logo Mar-08

Loading...

Loading...