Page 1

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FSppIPER_EN.doc Jun-13

IPER*

Integrated Pump and Energy Recovery for 1,000 m3/d SeaPRO*

Water Displacement Unit

Three Water Cylinders with dual-acting pistons

Feed Water Valves and Energy Recovery Valves

on all cylinders

Hydraulic Power Unit

Highly Efficient Hydraulic pumps provide the

energy to power the Water Displacement Unit

Hydraulic Cylinders transfer the energy from the

Hydraulic Pumps to the dual-acting pistons

Figure 1: GE’s IPER, inset picture shows hydraulic device

Features

Highly Efficient Positive Displacement (PD)

Pump technology for desalination applications

Solid-state control system for robust, consistent

operation of plant capable of integrating into

existing PLC systems

Smooth, Consistent Flow and Pressure outputs

Basic Specifications

Capacity ............................................. 2,222 to 2,857 m3/day

(587k to 755k gpd)

SWRO Recovery .................................................. 35% to 45%

SWRO Permeate ....................... 1,000 m3/day (264k gpd)

Discharge Pressure (to membranes) ........ 10 to 80 bar

Supply Pressure (to IPER) ................................... 1 to 10 bar

Electric Motor .......................................... 200 h.p. 1800 rpm

Operating Temperature Range ....... 15-29ºC (59-85ºF)

Electronic Control Unit

Sophisticated Solid State control system syn-

chronizes positioning of the dual-acting pistons

and ensures all valves open and close at near

zero flow

Control System is designed to provide long last-

ing, stable control delivering a steady flow and

pressure output from the Water Displacement

Unit

Utilities Required

Motor Voltage (3 phase) .......................... 380 or 460 VAC

Control Voltage (1 phase) ....................... 120 or 220 VAC

Frequency ................................................................ 50 or 60 Hz

Foot Print .............................................................. 2.6 m X 6.0 m

Compressed Air ........................... 10 bar oil-free shop air

Connection Sizes

Feed Water In ....................................... 4.0 inch Cut Groove

High Pressure Out .............................. 4.0 inch Roll Groove

Concentrate In ..................................... 3.0 inch Roll Groove

Concentrate Out .................................. 3.0 inch Cut Groove

Materials of Construction

High-pressure piping ...... 2205 Stainless Steel, Sch. 10

Low-pressure piping ......................................... PVC, Sch. 80

Frame ........................................... Painted blue carbon steel

Control Enclosure ............................................................ IP 548

Page 2

Operational Description

ITEM DESCRIPTION

IPER-1000

Flow Range

Pressure Range

2,222 – 2,857 m3/day

10 - 80 bar

Water Cylinder material of construction

Water Cylinder quantity

Water Cylinder orientation

Sch 40 Duplex 2205 Stainless Steel

3

Horizontal

Feed water valve style

Feed water valve material of

construction

Feed water valve quantity

Energy Recovery valve style

Energy Recovery valve material of

construction

Energy Recovery valve quantity

Single Direction Check

Zeron 100

12

Pilot Operated Check

Zeron 100

12

Hydraulic Cylinder Manufacturer

Hydraulic Cylinder Model

Hydraulic Cylinder quantity

Hydraulic Cylinder Max. Pressure

Milwaukee Hydraulic or

equal

H35D-MPV

3

206 bar

Hydraulic Pump Manufacturer

Hydraulic Pump Model

Hydraulic Pump quantity

Hydraulic Pump Max. Pressure

Hydraulic Pump reservoir size

Parker

Gold Cup P7R

3

206 bar

280 liters

Electronic control unit

manufacturer

Quantity

Controller

Interfaces with PLCs by:

Control Enclosure Material

Control Enclosure Rating

Control Power

GE

1

Solid state

GE, Allen Bradley, Siemens

FRP

IP 54

120 or 200 VAC, 1-phase,

50/60 Hz

Pressure Transmitter Manufacturer

Pressure Transmitter Model

Position Sensor Manfacturer

Position Sensor Model

Dwyer Instruments

626-15-GH-P1-E1-S1

MTS Temposonics

RHT0160UD601V2

Hydraulic Unit Dimensions (WXDXH)

Water Displacement Unit

Dimensions (WXDXH)

260 x 290 x 740 cm

260 x 290 x 740 cm

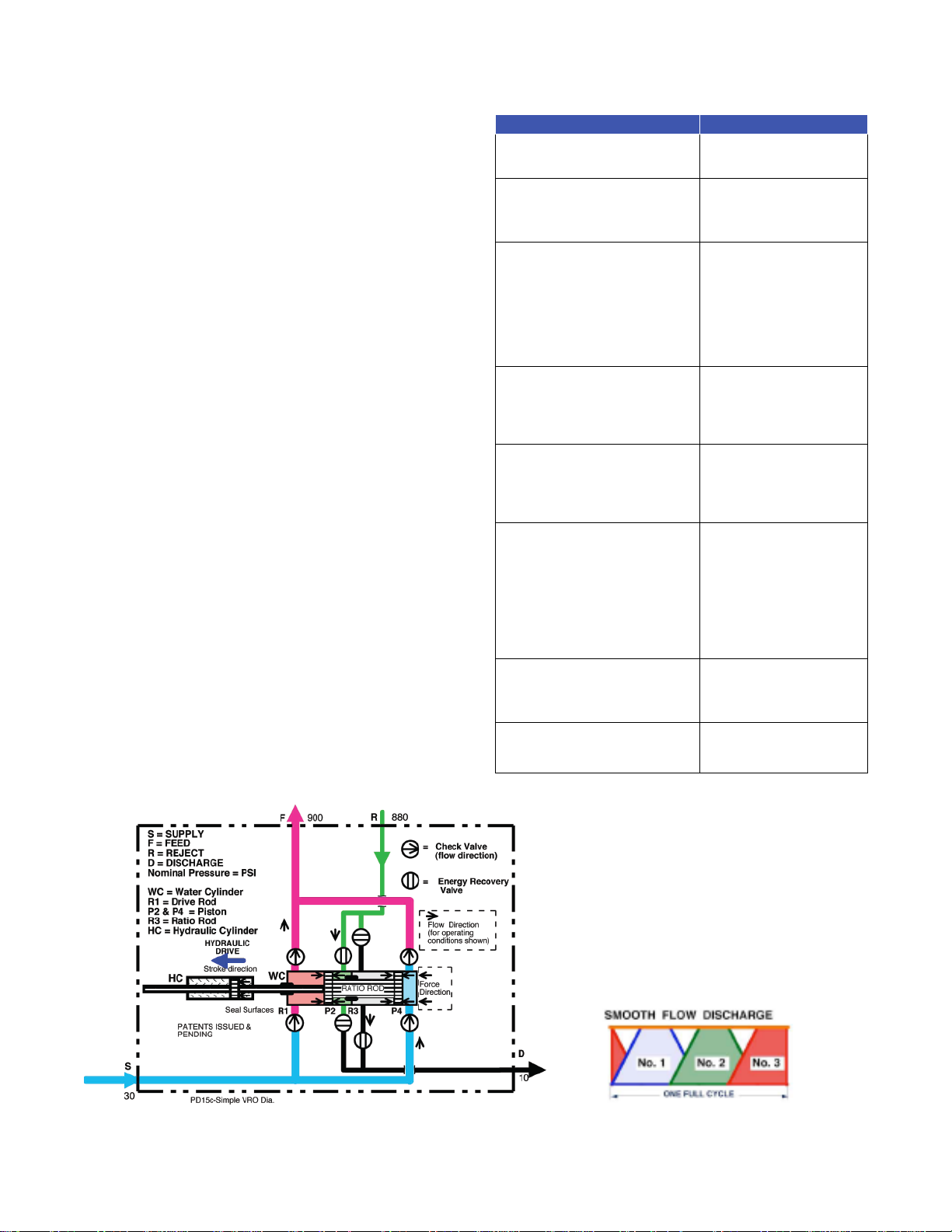

Figure 2 illustrates one of three double acting Water Cylinders (WC), stroking to the left as noted, consisting of Pumping Pistons (P2 & P4), separated by a

Ratio Rod (R3). The Pistons are powered by the

Hydraulic Cylinder (HC) in a trapezoidal wave form

(Figure 3) by means of a Drive Rod (R1).

Feed Pumping Function:

1. Supply pump flow enters at S, to the P4 piston.

2. Feed flow exits from the P2 piston to F to the

SWRO membranes.

Reject Energy Recovery Function:

1. High Pressure Reject returns from the SWRO

membranes to R, then through an Energy Recovery Valve to the back of Piston (P2), into the

smaller Piston area chamber determined by the

Ratio Rod.

2. The Reject pressure assists the Hydraulic Cylin-

der (HC) to create the Feed (F) pressure.

Reject Discharge Function:

1. Low Pressure Reject from a previous stroke ex-

ists from the chamber between R3 and P4.

2. This low pressure reject discharges through an

Energy Recovery Valve to D.

Specifications

Complementary Action:

1. There are three double acting pressure strokes

resulting in six (6) power strokes per cycle. Each

of these pressure strokes have complementary

flow profiles as shown in the Trapezoidal Wave

Form diagram (Figure 3.)

2. For system flushing all of the Energy Recovery

Valves can be put in the open position, allowing

flow from S through F and R, then exiting at D,

without operating the Hydraulic Cylinders (HC)

or Water Cylinders (WC).

Figure 2: IPER Function Figure 3: IPER smooth flow discharge

Page 2 FSppIPER_EN

Loading...

Loading...