Page 1

Fact Sheet

Patented DEOX* Process

Description and Use

The removal of dissolved oxygen from aqueous

streams to <1ppb O

application uses a patented deoxygenation process.

at ambient temperatures. This

2

Typical Applications

Dissolved oxygen is a significant factor influencing

corrosion damage in boilers and steam generator systems. The GE DEOX process is a simple, effective and

proven process. The versatility of the process allows

use on virtually any source, including filtered surface

water, well water, reverse osmosis permeate, condensate and demineralised water. The chemical deoxygenation method consists of the addition of hydrazine

to an oxygenated effluent, then passing the mixture

through activated carbon to catalyse the reaction between oxygen and hydrazine, followed by a suitable

ion exchange bed downstream to remove any carbon

leachables or excess hydrazine.

Table 1: Reaction

General Properties

Equipment

The GE DEOX process is available for extended term or

emergency and supplemental service. Custom systems are recommended for extended term use, and a

variety of mobile systems are available for emergency

and supplemental requirements. The process is also

available under license agreement for users who wish

to use and operate the equipment employed.

The carbon catalysed reaction is stoichiometric and

rapid even at cold (1°C or 34°F) influent water temperatures. Dissolved oxygen effluent concentrations of

<1ppb are common from influent containing 12 to

14ppm dissolved oxygen. Activated carbon is a true

catalyst and is not consumed during the process. No

metallic catalysts are involved. The reaction products

are inert nitrogen gas and water.

Hydrazine has a unique advantage over other chemical oxygen scavengers such as carbohydrazine, diethyl hydroxylamine (DEHA), hydroquinone and sodium

sulfite; which add TOC, dissolved solids, carbon dioxide

and other impurities downstream. A “flywheel” effect

allows the system to operate temporarily after shut

down or loss of hydrazine feed without significant

quality degradation.

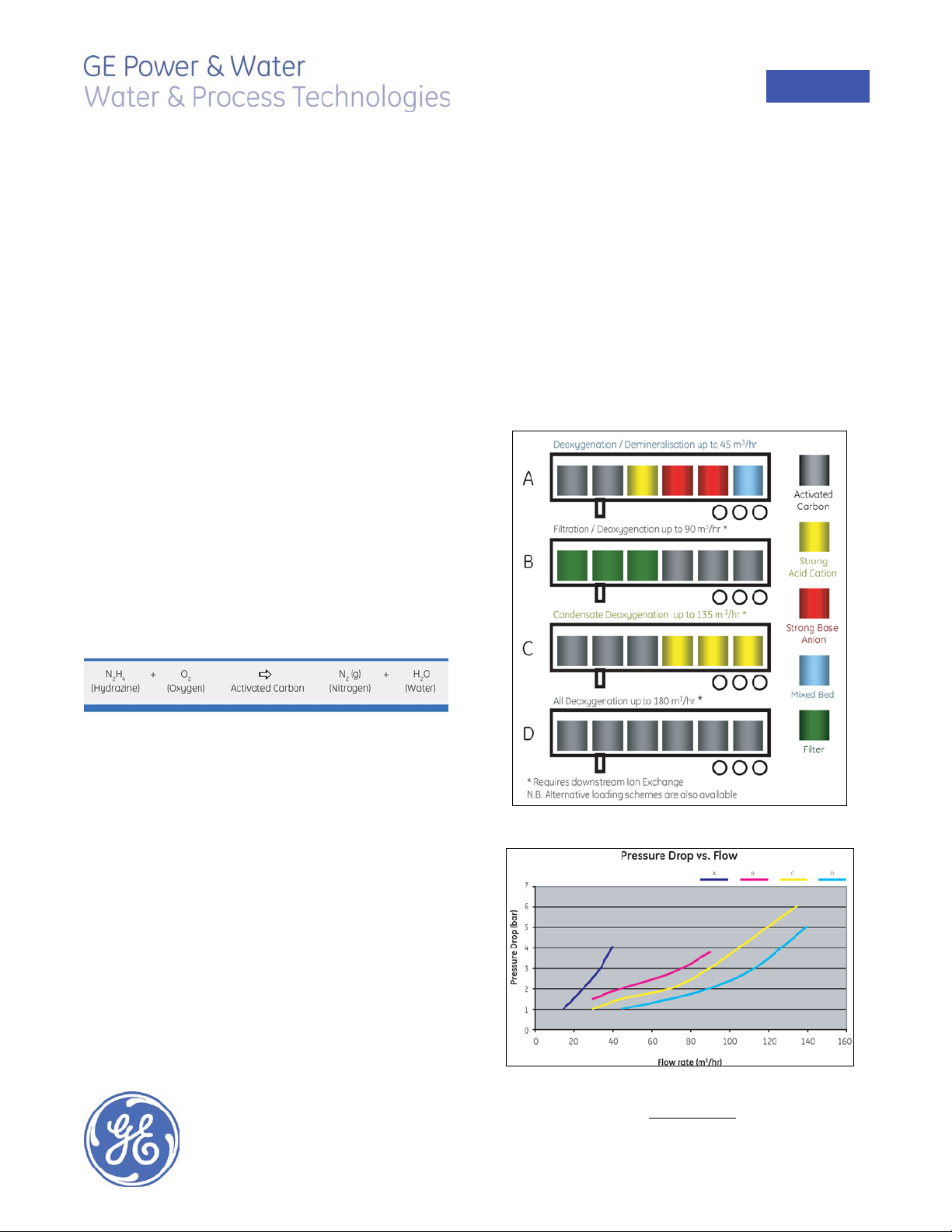

Figure 1: MobileFlow* Typical Loading Schemes

Figure 2: Typical loading performance

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2014, General Electric Company. All rights reserved.

FS1056EN.doc 06

Loading...

Loading...