Page 1

OptiSperse* HP54674

Internal Treatment (High Purity Systems)

Fact Sheet

• Outstanding protection against metal oxide

deposition and caustic corrosion

• Designed and field proven for high pressure

boilers

• Cost-effective program cuts downtime and

maintenance

• Provides optimum pH/phosphate control

Description and Use

OptiSperse* HP54674 is an aqueous blend of phosphate and polymeric dispersants. The product contains SCP, a synthetic carboxylated polymer, which

disperses iron and other metal oxides.

OptiSperse HP54674 may be used alone or in combination with other OptiSperse HP products, depending on the feedwater quality, to provide

optimum pH/phosphate control in high pressure

boilers.

Typical Applications

Hardness is a minor constituent in water of high

purity. The major contaminants are typically iron

and copper oxides. Iron deposits are very porous;

this porosity makes the road to caustic corrosion

possible.

As steam escapes through the chimney-shaped

deposits, dissolved solids concentrate under the

deposit. Hydroxide is the predominant anion. As

such, sodium hydroxide can concentrate under the

deposit to produce caustic levels of 10% or more.

This results in caustic gouging of boiler metal.

neutralizes any free caustic in the boiler water. GE

Water & Process Technologies formulates the sodium-to-phosphate ratio required to keep your system within control limits. This combination of

chemical mechanisms provides the most effective

coordinated phosphate/pH control program available. This treatment buffers the boiler water, preventing localized pH excursions that lead to

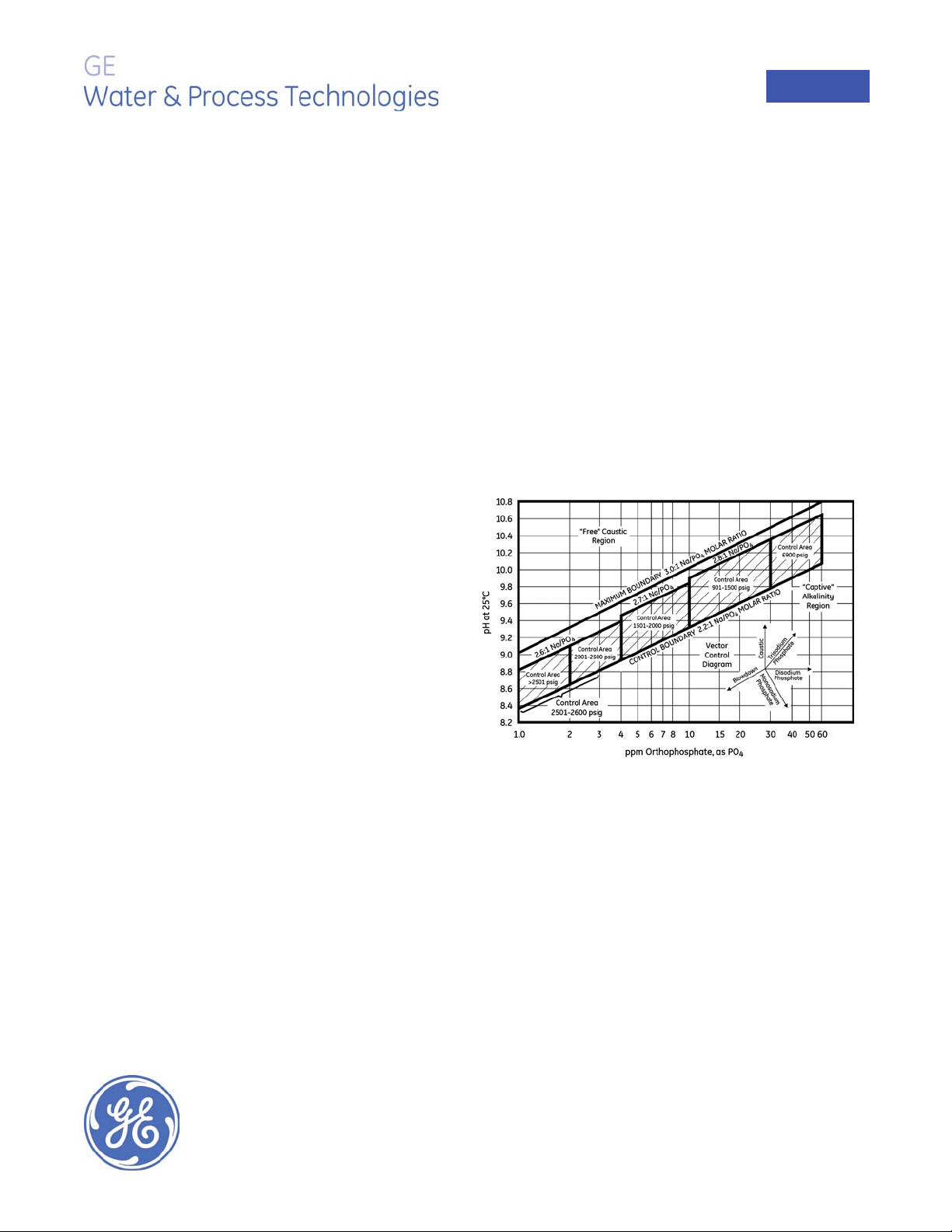

corrosion of boiler metal (Figure 1).

Figure 1: Control diagram for a coordinated phosphate/pH

program.

The other key to GE program effectiveness is our

metal oxide-specific polymeric dispersant technology. Our tailored treatment approach uses SCP,

synthetic carboxylated polymer, to disperse iron

and other metal oxides, maintaining clean heat

transfer surfaces. Caustic corrosion is prevented by

maintaining a phosphate buffer with coordinated

control.

OptiSperse HP54674 fights the problem on two

fronts. First, its exclusive polymer controls metal

oxide deposits. Second, its built-in phosphate buffer

Americas

Watertown, MA

+1-617-926-2500

Find a contact near you by

visiting www.gewater.com or

e-mailing custhelp@ge.com.

©2007, General Electric Company. All rights reserved.

* Trademark of General Electric Company; may be registered in one or more countries.

Global Headquarters

Trevose, PA

+1-215-355-3300

Europe/Middle East/Africa

Heverlee, Belgium

+32-16-40-20-00

AM-FSbOptiSperseHP54674_EN.doc Dec-07

Asia/Pacific

Shanghai, China

+86 (0) 411-8366-6489

Page 2

Treatment and Feeding Requirements

Feed Point - Boiler steam drum via separate chemi-

cal feedline.

Feedrate - Sufficient OptiSperse HP54674 should be

fed to maintain the recommended boiler phosphate

residual. Feedrates depend upon operating pressure, heat transfer rate, feedwater quality, and type

of fuel burned.

Dilution - Use good quality condensate, demineralized water, or deaerated boiler feedwater to make a

convenient feeding strength. The material may be

fed neat (dilution slip stream recommended) or diluted in any proportion. If diluted, mild agitation

should be provided.

Equipment - OptiSperse HP54674 can be fed using

polyolefin tanks with stainless steel piping, pump

internals, fittings, and shut-off valves. Relief valves,

agitator shaft and propeller should be stainless

steel. Consult your GE representative for specific

information.

General Properties

Physical properties of OptiSperse HP54674 are

shown on the Material Safety Data Sheet, a copy of

which is available on request.

Packaging Information

OptiSperse HP54674 is a liquid blend, available in a

variety of containers and delivery methods. Contact

your GE representative for details.

Safety Precautions

A Material Safety Data Sheet containing detailed

information about this product is available upon

request.

Page 2

Loading...

Loading...