Page 1

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FS1273EN.doc Nov-13

Membrane

H-Series, Thin-film membrane (TFM*)

Model

Average

permeate flow

gpd (m3/day)

1,2

Average MgSO4

rejection

1,2

Minimum MgSO4

rejection

1,2

HL2540FM

780 (3.0)

98.0%

95.0%

HL4040FM

2,400 (9.1)

98.0%

95.0%

HL8040F 365

10,800 (40.9)

98.0%

95.0%

HL8040F-400

11,500 (43.5)

98.0%

95.0%

Model

Active area

ft2 (m2)

Outer wrap

Part

number

HL2540FM

27 (2.5)

Fiberglass

1207230

HL4040FM

89 (8.2)

Fiberglass

1207236

HL8040F 365

365 (33.9)

Fiberglass

1266702

HL8040F-400

400 (37.2)

Fiberglass

1207240

Model1

Dimensions, inches (cm)

Boxed

A

B2

C3

Weight

lbs (kg)

HL2540FM

40.0

(101.6)

0.75

(1.90) OD

2.4

(6.1) 5 (2.3)

HL4040FM

40.0

(101.6)

0.75

(1.90) OD

3.9

(9.9) 8 (3.5)

HL8040F 365

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

HL8040F-400

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

Typical Operating Pressure

70-300psi (483-2,069kPa)

Typical Operating Flux

10-20GFD (15-35LMH)

Maximum Operating Pressure

Tape elements: 450psi (3,103kPa)

Other outer wrap: 600psi (4,140kPa)

Maximum Temperature

Continuous operation: 122°F (50°C)

Clean In Place (CIP): 104°F (40°C)

pH Range

Optimum rejection: 6.0-7.0,

Continuous operation: 3.0-9.0,

Clean In Place (CIP): 2.0-10.5

Maximum Pressure Drop

Over an element: 12psi (83kPa)

Per housing: 50psi (345kPa)

Chlorine Tolerance

1,000+ ppm-hours,

dechlorination recommended

Feedwater

NTU < 1

SDI < 5

HL Series

Water Softening NF Elements

The H-Series proprietary thin-film nanofiltration

membrane elements are characterized by an approximate molecular weight cut-off of 150-300 daltons for uncharged organic molecules. Divalent and

multivalent ion rejection is dependent upon feed

concentration and composition.

HL Nanofiltration Elements are used for water softening, color removal, and reduction of THM formation potential.

Table 1: Element Specification

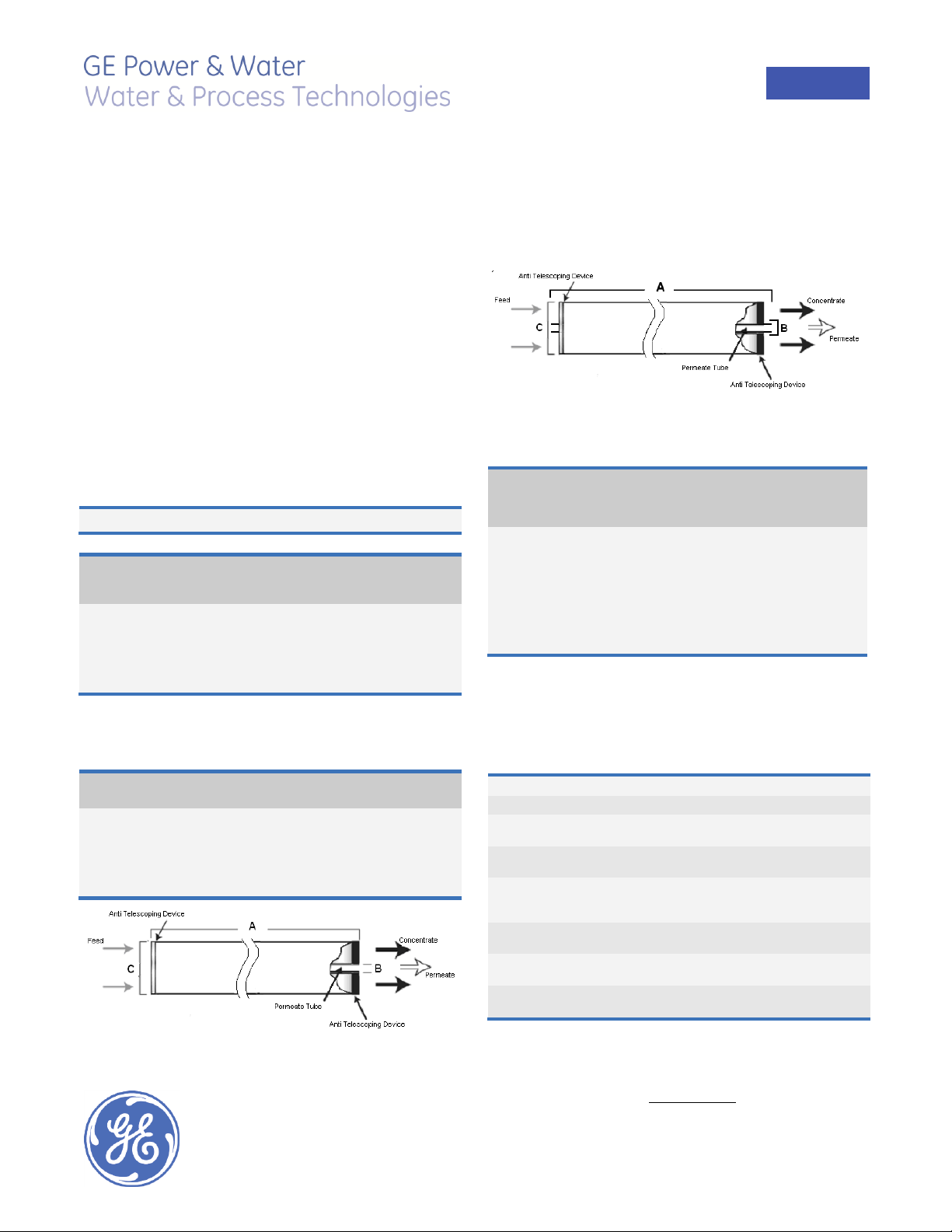

Figure 2: Element Dimensions Diagram (Male)

Table 2: Dimensions and Weight

1

Average salt rejection after 24 hours operation. Individual flow rate may vary

+25%/-15%.

2

Testing conditions: 2,000ppm MgSO4 solution at 110psi (760kPa) operating

pressure, 77°F, pH7.5 and 15% recovery.

Figure 1: Element Dimensions Diagram (Female)

1

These elements are dried then bagged before shipping.

2

Internal diameter unless specified OD (outside diameter).

3

The element diameter (dimension C) is designed for optimum performance in GE

Water & Process Technologies pressure vessels. Other pressure vessel dimension

and tolerance may result in excessive bypass and loss of capacity

Table 3: Operating and CIP parameters

Loading...

Loading...