Page 1

Fact Sheet

Modular Ultrapure Water Plant

Flexible, Pre-Engineered, Proven Designs

Pre-Engineered HERO Packages

Model Flow Rate m3/hr (gpm)

Mini-Mod

50 to 100 m3/hr (220-440 gpm)

Figure 1: HERO Modular Ultrapure Water Plant

For many years, GE has partnered with our

customers requiring ultrapure water and

treatment of other difficult to treat streams and

provided solutions based on the patented High

Efficiency Reverse Osmosis (HERO

HERO operates at a very high water conversion

factor (typically an overall recovery of 90% to

98%) while producing a much higher quality

effluent water when compared to traditional

water treatment technologies. The HERO process

can operate reliably at a flux rate of 30 GFD or

more, handle higher levels of silica in the feed,

reject silica and boron more efficiently, and eliminate biofouling – parameters that are difficult to

achieve using a traditional RO.

Now, GE has taken the benefits of the HERO process and added more value with our preengineered design packages. Depending on the

application, one, some, or all of these design modules (See Figure 2) can be utilized to treat a variety

of feed sources.

TM

) process. The

S-Mod

M-Mod

L-Mod

100 to 150 m3/hr (440-661 gpm)

150 to 250 m3/hr (661-1101 gpm)

250 to 400 m3/hr (1101-1761 gpm)

Design Standards

• CSA/UL

• ASME

• ASTM

• NEMA

Design Details

Power Requirements................380 V, 50 Hz, 3-phase

Piping (Modules 1 &2)............................................ 304L SS

Piping (Module 3) ..................................... 304L & 316L SS

Piping (Modules 4 &5).......................................PP & PVDF

Piping (Module 6) ..............................................................PVC

Max. Skid Size.......................1190L x 228W x 260H cm

(469L x 90W x 102H in)

Optional Packages

A. Single-Pass RO for HERO Module

B. Upgrade to EDI from Primary Mixed Beds

C. 460 V, 60 Hz, 3-phase power

D. Operating and maintenance service contracts

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2010, General Electric Company. All rights reserved.

FSroHERO_EN.doc Nov-10

Page 2

r

p

t

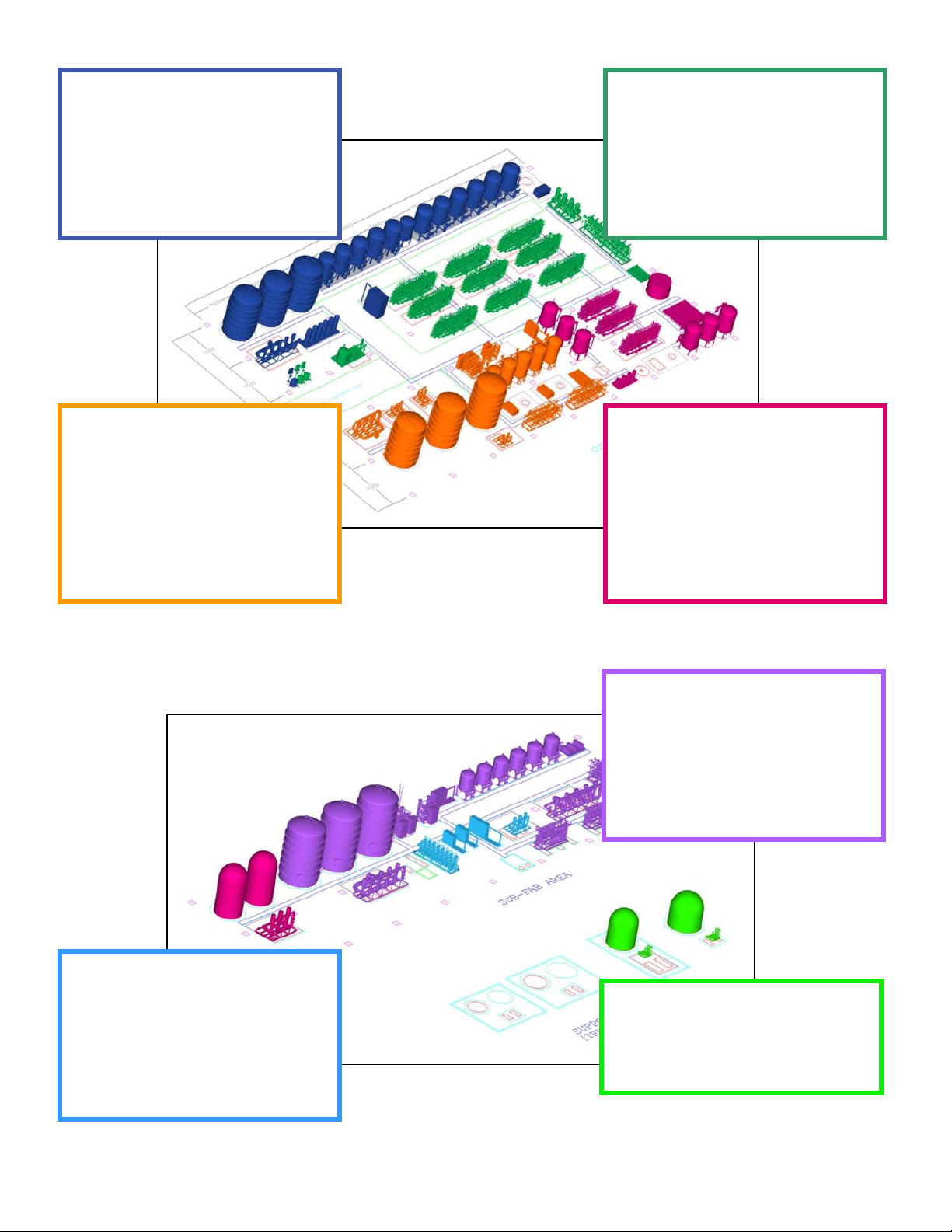

Figure 2: UPW Design Modules

MOD-1 – Pretreatment

.

Unit operations selected based on

feed water characteristics such as

hardness and alkalinity. In general,

this module can consist of blend water

tank and pumps, prefiltration, heat

exchanger, softener, and weak or

strong acid cation columns.

MOD-3 – Primary UPW

A storage tank with a nitrogen blanket

is provided for RO permeate collection.

From the storage tank, product is

transferred through TOC UV units to

either electrodeionization (EDI) stacks

or primary mixed beds. Finally, gastransfer membranes are used to

remove CO2 and further enhance

roduct water quality.

MOD-2 – HERO System

Either a single-pass or a tw

o-pass RO

system operating at 90%+ overall

recovery. The RO system is preceded

by cartridge filtration and a

degasification step. Optional CIP

System for RO cleaning.

MOD-6 – Rinse Reclaim / Recycle

Last rinse water from the cold and hot

UPW manufacturing operations are

diverted to this module for treatmen

and reuse. The heart of this process is

a patented reverse osmosis step, with

overall recovery greater than 90%.

MOD-5 – Hot UPW

A side stream of polished (pre-UF) water from Module 4 is diverted as feed

to this module. Product Water is

brought to temperature before going

through a hot UF step. The UF permeate then goes to the plant for consumption

MOD-4 – Polishing Loop / Cold UPW

Product water from Module 3 (above)

is collected in a blanketed storage

tank. A TOC reducing UV and cooling

heat exchanger serve as a precurso

to polishing mixed beds and a final

cold ultrafiltration (UF) step.

MOD-7 – Support Equipment

Miscellaneous system support operations include necessary regeneration

storage tanks and transfer pumps.

Page 2 FSroHERO_EN.doc

Loading...

Loading...