Page 1

GenGard* Technology

For Open Recirculating Cooling Systems

• Maintains System Cleanliness

• Only Halogen Stable Technology in the World

• Uncompromised performance under stressed

conditions

Description and Use

GenGard* is the most advanced and effective water

treatment technology for open recirculating cooling

systems. GenGard treatment programs can be applied across the entire pH spectrum from neutral to

alkaline and ensure uncompromising results even

under the most stressful conditions. The programs

incorporate the most advanced deposit and corrosion additives available. The patented GenGard

technology includes a new Stress Tolerant Polymer

(STP), Alkaline Enhanced Chemistry (AEC) and halogen resistant azole (HRA) in combination with phosphate-based steel corrosion inhibitors.

All GenGard treatment components are stable and

retain their effectiveness in the presence of chlorine

and other halogens. Halogen stability allows

Legionella compliance when chlorine or bromine

residuals are continuously applied at effective levels

(0.5-1.0 ppm free Cl

control and during periodic system disinfections

(> 5 ppm free Cl

GenGard provides the freedom to effectively respond to microbial upsets without a loss of deposition or corrosion control.

The stress tolerant polymer (STP) is the culmination

of more than 30 years of polymer research at GE.

) for general microbiological

2

). Unlike conventional treatments,

2

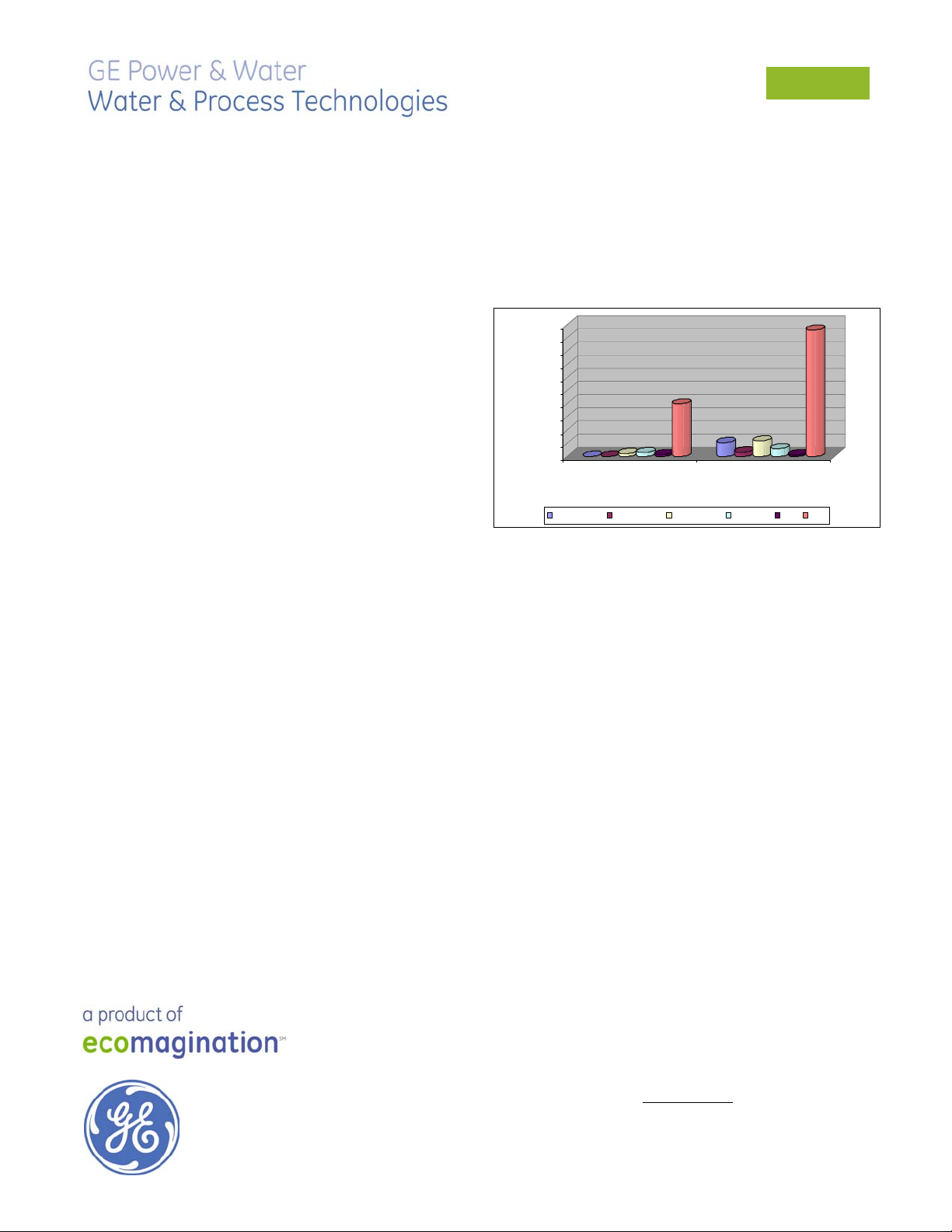

Figure 1: Calcium phosphate inhibition at 400 ppm calcium

hardness, pH 8.2, 10 ppm PO

STP is designed to maintain phosphate-based and

zinc-based corrosion inhibitors soluble. (Figure 1)

The STP performance far exceeds that of conventional polymeric dispersants, providing exceptional

corrosion protection while preventing deposition

even in the most demanding applications. The STP

performance is not adversely affected by aluminum

carryover from influent clarifiers, high temperatures

encountered with low flow heat transfer equipment

or soluble iron generated from corrosion or entering

with the makeup water.

AEC is the only effective non-phosphorus calcium

carbonate scale inhibitor for open recirculating system operation above 2.5 LSI (Langelier Saturation

Index). Breaking the calcium carbonate supersaturation barrier of organic-phosphate scale inhibitors

(phosphonates), AEC provides excellent deposition

control under severe conditions where others fail.

AEC’s superior calcium tolerance and hydrolytic

stability permit high cycle operation even under the

most stressed conditions.

100

90

80

70

60

50

40

30

% PO4 Inhibition

20

10

0

Ter po ly mer C Ter po ly mer B Te rp ol yme r A AA/ AMPS SAA STP

5 ppm 10 ppm

Polymer Dosage (ppm)

, 160ºF (70ºC)

4

Fact Sheet

GenGard products include HRA, a modified azole

that provides unequaled copper alloy corrosion pro-

Find a contact near you by visiting www.ge.com/water

* Trademark of General Electric Company; may be registered in one or more countries.

©2010, General Electric Company. All rights reserved.

and clicking on “Contact Us” .

FS1296EN.doc Jul-10

Page 2

tection. HRA is halogen stable and capable of

maintaining effective corrosion inhibition even in

the presence of chlorine and bromine-based biocides. Conventional azole inhibitors, such as tolyltriazole and benzotriazole, are readily halogenated

in the cooling water, preventing the establishment

and repair of a protective film on the metal surface.

HRA maintains its activity both in the water and on

the metal surface, ensuring continuous protection

for copper alloys. HRA also reduces copper levels in

the cooling water, minimizing copper discharge and

effectively controlling destructive galvanic pitting

on steel surfaces.

The GenGard GN8000 series of products are

designed for waters in the less corrosive alkaline

range above pH 7.8. GN8000 products utilize AEC as

the basic component to allow operation at highly

alkaline conditions without concern for scale formation.

For More Information

For more information on the GenGard Technology,

please contact a GE account representative or visit

us on the web at www.ge.com/water.

Typical Applications

The GenGard GN7000 series of products are

designed for cooling systems operating in the nearneutral pH 6.8 - 7.8 range. They utilize high levels of

inorganic phosphate to promote the formation of a

thin, protective iron oxide film on steel surfaces.

This protective oxide film is extremely tenacious

and does not interfere with heat transfer. STP provides the necessary calcium phosphate control to

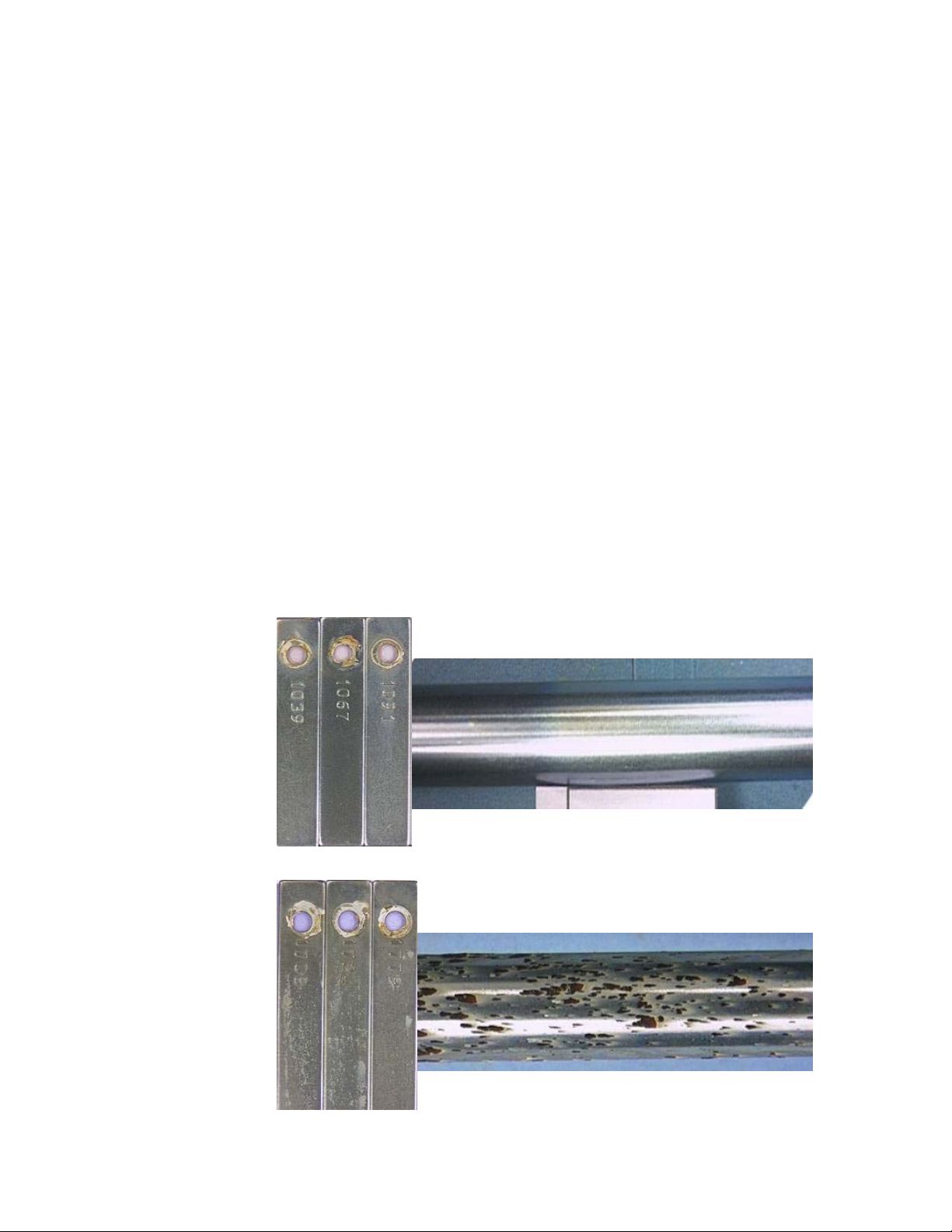

maintain system cleanliness and uninterrupted operation. (See Figure 2.)

2 ppm STP/HRA

LCS <0.5 mpy

ADM <0.2 mpy

8 ppm AA/AMPS /BZT

LCS - 1.4 mpy

ADM - 0.6 mpy

Figure 2: Comparison of Halogen Stable vs. Conventional Treatment, neutral pH,

phosphate program, continuous chlorination (0.5 - 1.0 ppm free Cl2)

Page 2 Fact Sheet

Loading...

Loading...