Page 1

Fact Sheet

Standard Brackish RO

BEV ULE

Ultra-low energy RO

BEV RO CA

Chlorine tolerant RO

er recovery.

GE BEV Series

Membrane Systems for Ingredient Water

100-600 gpm (23–136 m3/hr)

Features

• GE BEV Pre-engineered RO units are configu-

rable and integrate with pre and post treatment options into a full GE Ingredient Water

System.

• Two-pass and two-train designs ensure capa-

bility to meet product water requirements

• Stainless Steel construction for durability and

suitability in a wet environment

• BEV Full-fit/Cage Wrap membrane elements

for a more sanitary construction and permeate output

• Skid-mounted systems reduce onsite installa-

tion time and costs

Configurable Options

• Stainless steel housings

• VFD for high pressure pump to optimize ener-

gy usage

• Concentrate recovery: Additional In/off skid

membrane area to improve water yield.

• Bank-by-bank cleaning

• Pretreatment: Carbon, Multimedia Filters.

• In-line UV sterilizer

• Inlet chlorine monitor

• Interbank pressure transmitters

• Remote monitoring with data trending

• Stainless Steel Air Tubing

• Leveling Feet

Documentation Included

• Operation and maintenance manual

• Drawings: process flow, piping and instrumenta-

tion, electrical and general arrangement

Operating Parameters

Recovery .............................................................. 75% to 95%

Design temp. ....................................................... 60ºF (16°C)

Operating range ................................. 40-100 °F (4-38°C)

Minimum inlet pressure .......................... 30 PSIG (2 bar)

Average membrane flux .......................................... 16 gfd

Materials of Construction

High-pressure piping ............... Stainless Steel, Sch. 10

Low-pressure piping ................ Stainless Steel, Sch. 10

Frame ................................................................ Stainless steel

Enclosure .................................... NEMA 4X Stainless Steel

Membrane Elements

NSF Certified Spiral-wound Membrane Options

BEV RO

BEV NF CA Chlorine tolerant NF for high-

Cartridge Filtration

Housing material ............................... 316 Stainless Steel

Cartridge filter .................. 1-micron nominal, ROSave*

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2014, General Electric Company. All rights reserved.

FS1601EN Jan-14

Page 2

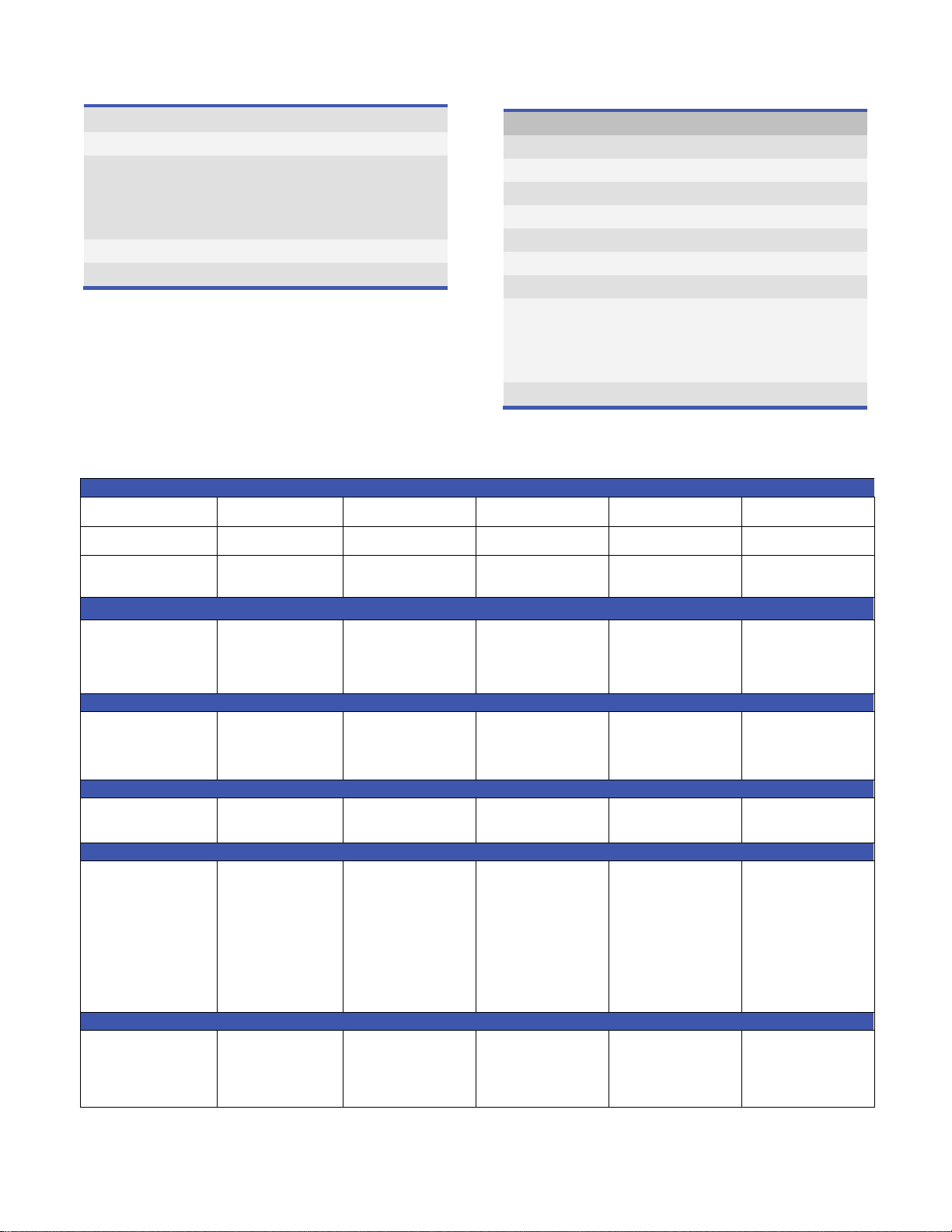

Table 1: Standard Instrumentation

Feed and concentrate

Conductivity

Feed, permeate

pH

Feed

Pump discharge, Inter-bank

Pressure Switch

Permeate, concentrate

Pressure Transmitter

Primary, final

Equipment

Manufacturer

Cartridge Filter

GE

Membrane Element

GE

High Pressure Pump

GE Tonkaflo*

Cartridge filter housing

GE

Membrane Housing

Wave Cyber

Flow Measurement

Signet

Conductivity, pH

Signet

View+1000

Logix

Valves

Bray

MODEL

BEV 6

BEV 9

BEV 15

BEV 18

BEV 18x2

Permeate rate:

600 gpm

300 gpm per train

Concentrate Rate:

38 gpm,

44 gpm two-pass

63 gpm,

74 gpm two-pass

150 gpm

75 gpm per train

Feed Rate:

Manufacturer:

Tonkaflo

Tonkaflo

Tonkaflo

Tonkaflo

Tonkaflo

Membrane Elements and Housings

Membranes quantity:

24

36, 84

60, 120

72

144 (72 per train)

Cartridge Filtration

Cartridge Filter:

RO.Zs01-40XK

RO.Zs01-40XK

RO.Zs01-40XK

RO.Zs01-40XK

RO.Zs01-40XK

Installation and Utility Requirements

Inlet:

3.0-inch flange

phase, 60Hz

60Hz

3.0-inch flange

4.0-inch flange

4.0-inch flange

2x4.0-inch flange

Skid

Height:

112

112, 114 (two-pass)

102, 113 (two-pass)

113

112

Flow*

Pressure Pre-Filter, Post-Filter, Primary,

Final, Permeate, Concentrate,

Table 2: Major Component Manufacturers

*Display of calculated permeate flow.

GE BEV Models

100 gpm 150 gpm 250 gpm 300 gpm

25 gpm

125 gpm

Model:

Quantity:

Motor HP

Banking Arrangement:

AS22512

1

50 HP

3→2→1

188 gpm,

194 gpm two-pass

Pumps and Motors

AS22512

1 / 2 (two-pass)

50 HP

3→2→1

4→2→2, 4→2

(two-pass)

HMI Components Allen Bradley Panel

PLC Components Allen Bradley Compact

75 gpm

313 gpm,

324 gpm two-pass

AS40409

1 / 2 (two-pass)

75 HP

5→3→2

6→4→2, 4→2→2

(two-pass)

375 gpm

AS40409

1

75 HP

6→4→2

750 gpm

375 gpm per train

AS40409

75 HP

6→4→2 (per train)

2

Filter Quantity:

Permeate:

Concentrate:

Inlet Water Pressure:

Air Pressure:

Drain to be Sized for:

Power:

Control Circuit:

Width:

Length:

Shipping Weight:

Page 2 FS1601EN

7

3.0-inch flange

1.5-inch flange

30 psig min.

100 psig, oil-free

125 gpm

460 VAC, 3-

120 VAC, 1-phase,

48

218

4500

14

3.0-inch flange

1.5-inch flange

30 psig min.

100 psig, oil-free

188 gpm, 194 gpm

(2 pass)

460 VAC, 3-phase,60Hz

120 VAC, 1-phase, 60Hz

48, 72 (two-pass)

274 (274 (two-pass)

5900, 12000 (two-pass)

21

4.0-inch flange

2.0-inch flange

30 psig min.

100 psig, oil-free

313 gpm, 324

(2 pass)

460 VAC, 3-phase, 60Hz

120 VAC, 1-phase, 60Hz

51, 90 (two-pass)

274, 274 (two-pass)

9000, 15000

(two-pass)

21

4.0-inch flange

2.0-inch flange

30 psig min.

100 psig, oil-free

375 gpm

460 VAC, 3-phase, 60Hz

120 VAC, 1-phase, 60Hz

51

274

9400

42 (21 per train)

2x4.0-inch flange

2x2.0-inch flange

30 psig min.

100 psig, oil-free

750 gpm

460 VAC, 3-phase,60Hz

120 VAC, 1-phase, 60Hz

115

274

17600

Loading...

Loading...