Page 1

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2011, General Electric Company. All rights reserved.

TP1189EN.doc Jun-11

Technical

Paper

Slag Control Treatment Program at a

Southeastern Utility

Authors:

M. Domingo Tubio, Product Applications Engineer

Rick Higginbotham, Account Executive

Abstract

Coal-fired power plants supply over half the electricity to the US grid. Currently, utilities are facing a

range of challenges including decreasing industrial

demand for electricity, competition from low cost

natural gas and rising coal prices. High quality Eastern bituminous Central Appalachian (CAPP) coal

costs are increasing due to rising exports, increasing

transportation and environmental costs and decreasing production, (Buchsbaum 2008; Metzroth

2008). To stay competitive, some utilities are investigating burning lower-cost, lower-quality “opportunity” coals such as Northern Appalachian (NAPP) and

Illinois Basin. The most efficient plants can be dispatched for longer periods for improved financial

performance. The change to lower rank coal and

increased operation can result in increased slag deposits in the furnace and superheater areas, (Gabriel

2011).

A Southeastern utility desired to blend lower-cost

low ash fusion temperature Northern Appalachian

(NAPP) coal with their typical CAPP coal in their 745

MW pulverized-coal boiler. Sootblower cleaning

alone is not effective when slag deposits are a liquid

or pseudo-plastic state which deforms under pressure. A proprietary mixture of chemical additives

was recommended to elevate ash fusion temperature and modify the deposit to make it more easily

removable by sootblowers. The blend is a unique

combination of water-soluble magnesium hydroxide

and copper oxide slurries which has a synergistic

effect when used together to mitigate slag for-

mation and impact. During the fourth quarter of

2010, the utility consumed over 44,000 tons of

NAPP opportunity coal treated with this combination of proprietary fireside chemical additives over

a four week period. GE’s approach allowed the

customer to minimize the detrimental effects of

burning slag prone coal while reducing fuel costs.

This paper summarizes the trial and performance

results.

Slag and Fouling Formation and Cost

There are numerous non-combustible inorganic

impurities in coal besides hydrocarbons. Depending on the ratio of these minerals and compounds,

slagging and convective pass fouling can occur in

boilers. Slag formation accelerates when the furnace exit gas temperature (FEGT) exceeds the fusion temperature of the ash. Indices such as the

basicity ratio can help predict slag viscosity and

ash fusion temperature (Babcock & Wilcox 1978).

As slag density increases with time and temperature, a deposit is formed that is difficult to remove

with sootblowing. Deposits can “grow” as particles

accumulate; it is not uncommon to observe large

deposits on the leading edge of platen superheat

tubes and secondary superheater tubes above the

bull nose of the boiler. When the slag eventually

falls it can damage tube banks lower in the boiler,

resulting in unscheduled outages and lower availability.

CAPP coal typically has a high ash fusion temperature and less tendency to create excessive

slagging. NAPP coal is becoming more economically attractive for several reasons, including

availability at lower delivered costs than CAPP

coal (Pusateri 2009). Figure 1 illustrates the challenge of using NAPP coal with a lower ash fusion

Page 2

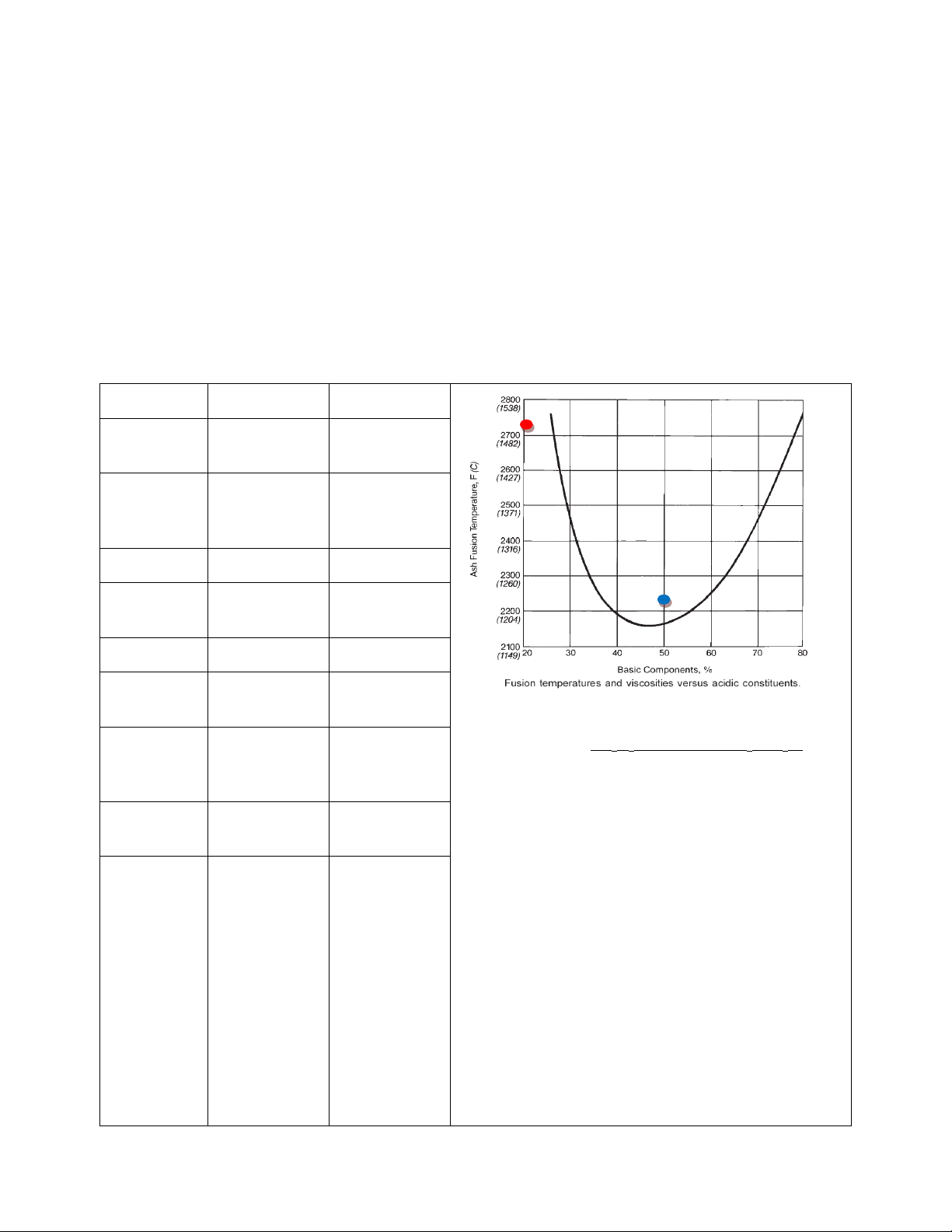

Figure 1: Fuel Comparison and Basicity Ratio (Babcock & Wilcox, 1978)

temperature. Slag deposits are expected to be in

Fuel Type

Typical

Opportunity

** Basicity Ratio = (Fe2O3+CaO+MgO+Na2O+K2O)

(SiO2+Al2O3+TiO2)

Source

Central

Appalachian

Northern

Appalachian

Cost per

ton, $US

(2010)

$70 – $75

$58 – $70

HHV, Btu/lb

~12,000

~13,000

SO2,

lb/MMBtu

1.1 – 1.5

4.5 – 5.0

Ash, wt%

11 – 12

7 – 8

Moisture,

wt%

6.7 – 7.0

6.0 – 7.0

Ash Softening Temp,

deg F

2,700

2,250

Basicity

Ratio **

0.12 – 0.14

0.45 – 0.55

Ash, wt%

SiO2

Al2O3

Fe2O

3

K2O

TiO2

MgO

CaO

Na2O

53 – 56

28 – 30

5 – 6

3.3 – 3.6

1.3 – 1.5

0.9 – 1.0

0.7 – 1.3

0.2 – 0.3

39 – 40

20 – 21

22 – 24

1.3 – 1.4

0.85 – 0.95

1.05 – 1.15

5 – 6

0.95 – 1.05

liquid state at furnace temperatures with noncombustible mineral content present. Sootblower cleaning alone is not effective when the slag is a liquid or

pseudo-plastic state which deforms under pressure.

Fouling, which is closely related to slagging, usually

occurs in the boiler’s cooler convective back-pass

section as gaseous ash components (such as sodium and potassium) condense. It typically occurs in

the vertical and horizontal reheaters and primary

superheater. Fouling deposits can “bridge” across

tubes and restrict gas flow.

That increases induced fan horsepower, which

raises the plant heat rate and, therefore, lowers

plant efficiency. Slagging and fouling can result in

derating (shedding load) and costly unscheduled

outages and repairs from damaging slag falls. But

these problems can be eased by combining chemical additives for fireside applications with mechanical removal (sootblowers).

Boiler and Trial Design

The 745-MW pulverized coal-fired boiler is a Riley

Stoker Corporation front-wall fired boiler with

2,500,000 lbs/hr steam production at 2610 psig

and 1,005 deg F at superheater terminal outlet.

Page 2 Technical Paper

Page 3

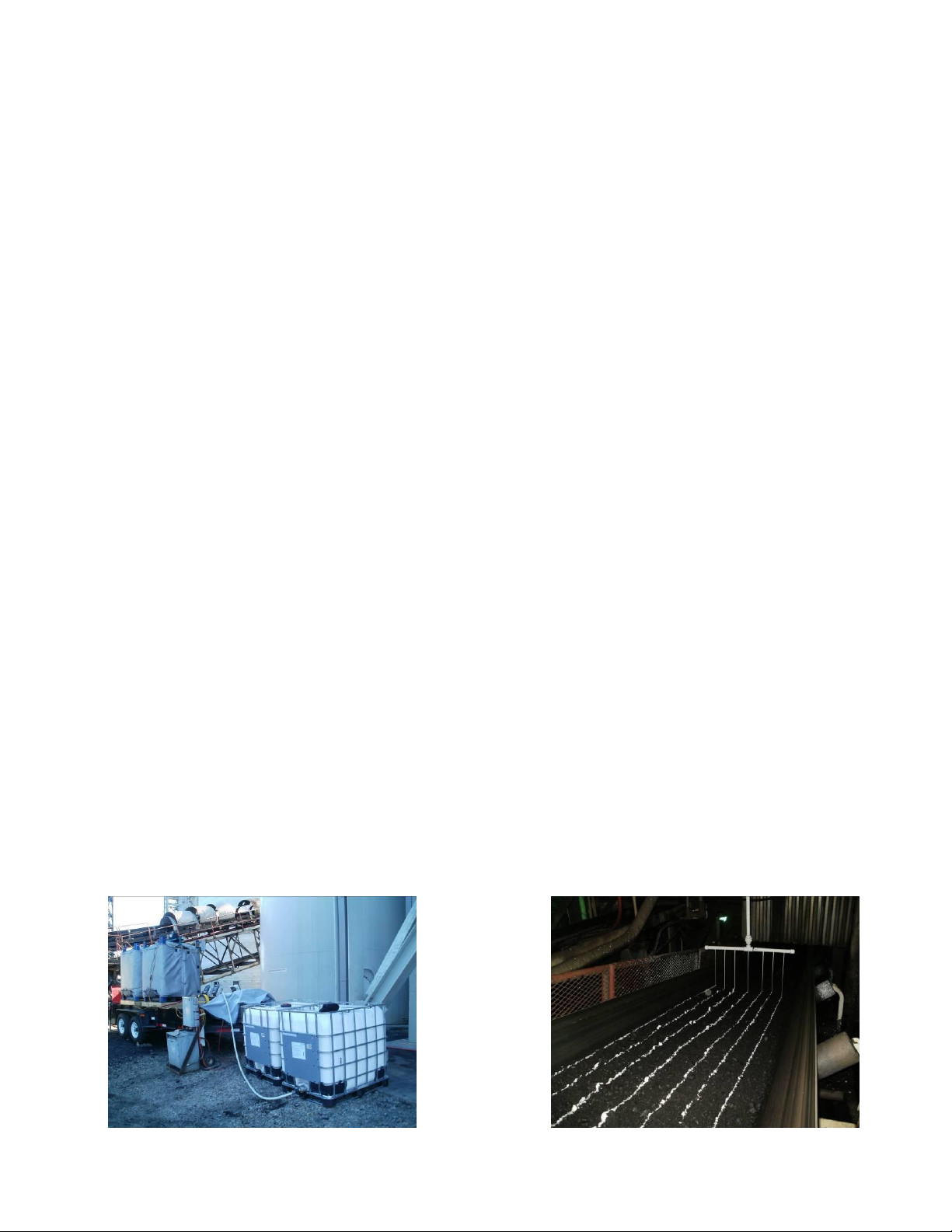

Figure 2: Trial Trailer and totes of additives (left) and applying product to NAPP coal (right)

The boiler fires 250 tons pulverized coal per hour at

maximum load, and the boiler train is equipped with

SCR, cold-side electrostatic precipitators and a wet

flue gas desulfurization (Wet FGD) scrubber system.

Trial results using the same opportunity fuel- NAPP

coal- at a sister station indicated it could not be

burned untreated, as the resulting slag was severe

enough to slag the boiler and block the gas path.

Operating experience indicated boiler conditions

could deteriorate within days of introducing opportunity fuel. To minimize the risks of boiler outage

during trial, the utility blended its typical fuel with a

small proportion of opportunity fuel treated with a

mix of proprietary chemical additives to reduce severity of fireside slagging. Product dosages were

optimized as the percentage of opportunity coal

was increased until it reached the target level of 50

percent.

Chemical Additives for Slag Control

A range of chemical additives were considered before the two products were selected based on ultimate analyses of the fuels. The proprietary mix of

additives selected for this trial included a magnesium based compound and a metal oxide. The magnesium is known in the industry to elevate ash

fusion temperatures due to the high melting point of

magnesium oxide. This treatment keeps the slag in

a solid state instead of liquid-phase deposit. The

metal oxide-based slurry contains copper which has

been used in the industry as a combustion catalyst.

Less well known is that copper can reduce the cohesive strength of the ash via a nucleating effect

with iron species. Gradual thermal decomposition of

the metal oxide product also makes the slag porous

and, therefore, weaker. These mechanisms complement the magnesium effect for certain types of

coals or coal blends, depending on the ratio of minerals and other non-combustible species. Together,

the proprietary additives create fracture planes in

the solidified slag, weakening the deposits so that

they can be more easily removed by sootblowers.

Treatment Application

The chemical additives were transferred from agitated trailer-mounted base totes to the coal belts

via peristaltic pumps, where the chemicals were

the dosed at predetermined amounts via a manifold mounted above the coal conveyor (Figure 2).

Dosing occurred when the coal belts conveyed

NAPP coal. Aqueous magnesium-based slurry

dosages were reduced from 3 lbs of product per

ton of NAPP coal to optimum of 1.0-1.5 lbs. Aqueous metal oxide slurry was introduced to determine its impact on slag mitigation in conjunction

with the magnesium-based product. It was determined that the optimum product feed rate was

0.25 lbs product per ton of NAPP coal. The NAPP

coal quantity was ramped up from 16 percent to

the target of 50 percent, where it was maintained

for a week until the end of the trial. The dynamic

test environment confronted the trial team with

challenges that included outages, inclement

weather, and real time adjustments to the dosage

based on visual observations of furnace slag conditions.

Trial Details

To be considered successful, the trial had to meet

several criteria, including:

1. Demonstrating that the magnesium content

increases the ash fusion temperature and,

therefore, makes the deposit more friable and

easily removable.

2. Demonstrating the metal oxide slurry syner-

gistically assists in slag mitigation.

Technical Paper Page 3

Page 4

3. Determining the optimum product feed rates for

the CAPP/NAPP blends while monitoring (with an

infrared (IR) camera) real-time slagging phenomena along with boiler parameters such as

load, pressure drop, and exit temperature. Customer’s fuel blends included 84 percent CAPP/16

percent NAPP, 77 percent CAPP/33 percent

NAPP, and 50 percent CAPP/50 percent NAPP as

the “highest stress test.” (the untreated “base-

line” NAPP blend slag indices were not available,

as they presented unacceptably high operational risks to the customer.)

Mid-December- following a number of

weather-related outages, inclement

weather compelled the suspension of the

trial.

After a weather-related equipment out-

age, NAPP coal treatment was resumed.

Dosage was increased by 10 percent after

a “gooey slag” was seen in the furnace.

The slag subsequently returned to its

semi-solid state.

December 20- the trial concluded.

4. Demonstrating that the use of magnesium

and/or metal oxide products has no adverse effects on boiler operations- i.e., it does not exacerbate slagging or fouling or emissions.

Obtained Flue Gas Desulfurization (FGD)

wastewater grab samples and ash pond samples, analyzed for copper and other components.

Data was recorded during the “baseline” (100%

CAPP coal) and chemical treatment trial periods, assuming equipment parameters such as tube cleanliness, sootblower availability, and thermocouple

calibrations. Note that during the chemical trial the

unit was not derated overnight for deslagging.

Overnight load shedding allows the slag to contract

in the cooler flue gas, and this uneven contraction in

the matrix causes cracks and gravity-assisted removal of the accumulated slag. This beneficial procedure was not conducted during most of the

chemical trial (Figure 3).

Here is the key chronology of the trial

November 15- the chemical trial began as

16 percent NAPP coal was dosed at 3.0

lbs/ton magnesium-based product on the

coal belt en route to bunkering silos #5 and

#6.

DCS Data

The trial team collected data every 5 minutes from

the customer’s “Pi” distributed control system

(DCS), including load (MW), heat rate (MMBtu/hr),

furnace exit gas temperature (FEGT, deg F), sootblower, and coal mill operation including feeder

flow (kpph). For the analysis, the team removed all

data points below 700 MW so that only “full load”

data was considered and outliers could not impact calculations.

The most obvious change over time was sootblower activity. If at least one of the 60 IR (radiant)

or IK (convective) sootblowers was active when

the data was recorded, the event was logged in Pi.

In the DCS, sootblowers were either “on” or “off”; it

was not possible to record which sootblowers

were active. The trial team decided to record the

average number of sootblowers per day to understand how this rate was changing over time. The

frequency seemed to have doubled as the NAPP

was increased from 0 (baseline) to 33 percent and

apparently tripled by the time the trial achieved 50

percent NAPP. It is important for a utility to keep

this parameter in mind given operations concerns

such as steam consumption and tube wear over

time.

November 24-29- the trial was suspended

over Thanksgiving

December 1 and 2- duct testing occurred.

The flue gas sampling successfully obtained

a baseline for the CAPP/NAPP blend while

the treatment consisted only of magnesiumbased product. The magnesium-based

product dosage was decreased as the metal

oxide product was introduced.

Page 4 Technical Paper

Furnace Exit Gas Temperature (FEGT) data is valuable for a slagging study since it can be a proxy

indictor of slag conditions. FEGT values should rise

as slag increases, since slag is an excellent insulator and because increasing slag conditions will

push the fireball farther back into the convective

pass of the furnace, this analysis indicated that

furnace operation vis-à-vis FEGT was approximately equivalent during the baseline and chemical treatment periods. The team observed

decreasing temperature variances between east

and west side thermocouples across the boiler.

Page 5

Figure 3: Key Dates of Trial and Results Summary (for Gross Load >700 MW)

The data below (Figure 3) presents average parame-

PARAMETERS

(start – end dates)

10/18 –

11/14

11/15 –

11/23

11/30 –

12/3

12/4 –

12/8

12/10 –

12/12

12/17

12/18 –

12/20

NAPP Coal, %

0

16

33

33

50

50

50

Magnesium product, lbs/ton

0

3.0

2.0

1.5

1.5

1.0

1.1

Metal oxide product, lbs/ton

0 0 0

0.25

0.25

0.25

0.275

# of Pi data points

4,118

342

634

391

699

123

771

Avg # of sootblows/day

36

57

63

82

104

94

157

Avg Heat Input, MMBtu/hr

7,003

7,060

6,278

6,216

6,892

6,953

6,986

Avg Coal to Boiler, ton/hr

336

321

325

327

327

332

331

U3A Avg Max FEGT, oF

2,318

2,683

2,602

2,496

2,468

2,561

2,627

U3B Avg Max FEGT, oF

2,497

2,536

2,464

2,486

2,521

2,479

2,511

ter values from the trial, implies that chemical

treatment does not adversely impact the boiler. A

longer trial could indicate if boiler operation significantly improvers with chemical treatment while

burning the opportunity coal.

Infrared Photography

The camera’s integral flame filter and high temperature range covered the boiler’s operating

range throughout the trial and its multi-spot temperature measurement capability enabled final

images to include reference temperature profiles,

(Mikron 2011). Thermal photos of the boiler slag

conditions were recorded at the boiler ports

throughout the trial.

The trial team used port inspection and photography to monitor boiler slagging conditions in the

furnace. The team developed a standardized naming convention for referencing boiler ports at vari-

ous elevations. For example, port “3A4E” refers to

Unit 3, Alpha side, Level 4, Port E. This ensured that

slagging conditions were properly recorded, since

more than a dozen trial team members viewed,

photographed, and commented on the visual conditions during the trial.

Visual and infrared (IR) photos of conditions at the

various boiler elevation ports (Figure 4) were made

with an Olympus brand “point-and-click” digital

camera and a Mikron Lumasense brand infrared

camera.

Slag conditions inside the boiler were recorded with

a portable, battery-operated Lumasense Mikronbrand model 7604F infrared camera.

Not only were visual observations of these conditions important, they were, arguably, the best way

to measure the impact of chemical treatment on

boiler slag, since instantaneous changes in many

variables (such as sootblower activity, number of

pulverizers in operation, load changes, etc.) make

it difficult to compare with other parameters in

isolation (such as FEGT).

Several photos of the slagging conditions in the

boiler on November 23 and 30 (Figures 5 and 6)

clearly show the bottom of the superheater (SH)

pendant and no or minimal slag accumulation.

There was some initial concern about the underside of the tubes at Level 3; however, the slag was

removed with a firm push of a spade. Overall

slagging was considered minor at this point, and

noticeably worsened as the inspection continued

down the boiler. (The worst slag was near the

burners.)

Technical Paper Page 5

Page 6

Figure 4: Unit 3 Ports (Elevation Drawing #69085B5, revised 2-19-99)

Plant monitoring and the attached pictures from the

Port Name

Port Qty

Elevation

Notes

Level 1

Ports A,B

2

~580’

Pendant Superheater

Level 2

Ports A,B,C,D

4

~566’

Cold Reheat Piping

Level 2.5

Port A

1

~563’

Above bullnose

Level 3

Ports A,B

2

~550’

Below bullnose

Level 4 Ports

A,B,C,D,E,F

6

~538’

Bullnose

Level 5

Ports A,B,C,D

4

~520’

Wall tubes

Level 6

Ports A,B,C,D

4

~506’

Wall tubes

Level 7

Ports A,B,C,D

4

~496’

Wall tubes

Level 8

Ports A,B

2

~488’

Overfire Air

Level 9

Ports A,B,C,D

4

~483’

Burners

Level 10

Ports A,B

2

~473’

Below burners

early phase of the trial revealed that the slag formation was minimal, with little day-to-day change,

and was being removed by the sootblowers where

possible. Several locations were identified for possible future installations of IK sootblowers to minimize

slag formation. Initial indications showed the slag to

be self-limiting and still friable. Operations and GE

continued to monitor and report on slag formation,

and GE continued to photograph the Unit at these

ports and report the finding after each inspection.

By December 17, the trial team began burning 50

percent NAPP, dosed with 1.0 lbs. magnesiumbased product per ton and 0.25 lbs. metal oxidebased product per ton. Since the slag appeared

gooey and there was concern over the subminimum amount of feed required for operation,

both feeds were increased 10 percent (Figure 6).

By December 20, the boiler recovered and slagging conditions had improved.

Page 6 Technical Paper

Page 7

3A Level 1 Port A, 11-30-10

3A Level 1 Port A, 11-30-10

3A Level 3 Port B, 11-30-10

3A Level 3 Port C, 11-23-10

3B Level 4 Port E, 11-30-10

3A Level 4 Port A, 11-23-10

Figure 5: Visual and IR Photography, 11-23 and 11-30

Technical Paper Page 7

Page 8

Figure 6: Visual and IR Photography, contrasting 11-30-10 with 12-17-10

Wastewater and Ash Pond Analyses

3A Level 5 Port D, 11-30-10

(note the minor slag)

3A Level 5 Port D, 12-17-10

(note the large formation on the wall)

3A Level 3 Port B, 11-30-10

(note the minor blinding)

3A Level 3 Port A, 12-17-10

(note the blinding and hot runny formation)

SO3 Testing

Two FGD water discharge samples were collected in

order to establish a baseline. No measureable copper was detected and no significant change in operation was noted. In future trials, additional

samples should be taken to provide a greater understanding of the normal state of the FGD composite analysis.

Ash pond water samples were collected on November 19 and 20 (prior to the metal oxide addition) and

on December 12 (after the metal oxide feed) to determine the effects of copper in the ash pond. The

trial team wanted to rule out any negative impacts

from copper carryover from the bottom ash sluice

into the ash pond and subsequent NPDES outfall. No

measurable copper was detected in the ash pond

on all three sample dates.

The trial team also conducted two duct tests,

sampling flue gas to determine the sulfur trioxide

(SO3) concentration during varying operating conditions and when chemicals were added to the

coal feed. Samples were collected from a single

point approximately seven feet from the duct wall

at a test port downstream of the SCR- the only

test port available at the furnace. Measurements

were conducted to observe the treatment regi-

men’s effect on “blue plume”. (There have been

studies on magnesium oxide’s effect on SO3 in

fossil fuel-fired furnaces (Schmidtchen 2002)).

Ammonia injection was off during the testing to

avoid free ammonia interference with the analysis. A third-party stack testing firm was contracted

to collect samples using the Controlled Condensate Method (US EPA Method 8A) and analyze

them by High Performance Liquid Chromatography (HPLC).

Page 8 Technical Paper

Page 9

The untreated opportunity fuel SO3 baseline was

Run No.

Sample Time (EST)

SO3 Concentration (ppm, dry basis)

Start

End

11/30 and 12/1 – 33% NAPP Coal, 2.0 lb/ton magnesium-based product

1

10:40

11:40

11.3

2

13:05

13:50

12.3

3

14:45

15:30

13.0

4 *

16:25

17:10

6.0 *

5

08:37

09:22

12.4

6

12:10

12:55

9.5

7

14:05

14:50

11.6

8

16:05

16:50

15.3

Average

12.2

12/11 – 50% NAPP Coal, 1.5 lb/ton magnesium-based product

and 0.25 lb/ton metal oxide-based product

9

08:30

09:15

13.6

10

10:05

10:50

12.1

11

11:30

12:15

9.5

12

12:45

13:30

10.4

Average

11.4

Run 4 is suspected as an outlier when compared to other runs under the same operating condition and is not included in the

calculated average.

Figure 7: SO3 Testing Summary

unavailable, and the SCR is expected to convert

some SO2 to SO3. The testing indicated that the apparent SO3 removal was within sampling error and

that there was no observable difference in the SO3

mitigation when MgO addition rates were varied.

Thus, the results did not indicate that the MgO

chemical treatment significantly mitigated SO3 in

the furnace. However, it is also important to note

that there was no apparent increase in SO3 formation overall on December 11, when the copperbased metal oxide slurry was added to the system

(Figure 7).

Trial Results and Conclusions

The magnesium-based product alone showed an

improvement in slag removal until the NAPP blend

increased above 33%. Magnesium alone could not

elevate ash fusion temperature to avoid sticky

deposits in the upper regions of the furnace, Tenacious, viscous deposits throughout the boiler

became firmer and were easily removed by IR and

IK sootblowers during the trial once the magnesium and metal oxide products were combined.

Technical Paper Page 9

Page 10

The visual observations and operator feedback indicated that the synergistic combination of the 1.0-lb

to 1.5-lb magnesium-based product range per ton

of NAPP coal in conjunction with 0.25-lb metal oxide-based product per ton of NAPP coal was very

effective in mitigating slag of the blended fuel. Different coals or coal blends may require customized

product ratios to appropriately address potential

slagging issues.

In addition, several locations were identified as possible sites for future IK sootblowers and observation

ports to control and monitor slag formation. Lessons

learned include the importance of freeze protection

on the lines and providing options for continuous

mixing with water-based slurries to reduce material

handling difficulties. Future trial goals include quantifying loss on ignition (LOI) with the metal oxide slurry and evaluation of different additives for SO3

control in the furnace.

Estimates for fuel cost savings are projected to

range from $5,000,000 to $13,000,000 per year by

switching to a 50 percent blend of NAPP opportunity

coal. Even greater savings could be achieved by increasing the blend to include Southern Illinois Basin

(ILB) coal, (Figure 8).

References

Babcock & Wilcox. “Steam”. 39

1978.

Buchsbaum, Lee. “New Coal Economics”. En-

ergybiz, November / December 2008.

Retrieved from

http://energycentral.fileburst.com/EnergyBizO

nline/2008-6-novdec/Financial_Front_New_Coal.pdf

Gabriel, Mark, Manager of Business Develop-

ment, GE Water & Process Technologies. “Slag

Control Treatment Program at EKPC Spurlock

Station.” Presented at Electric Power Conference, Chicago, IL. May 2011.

Hatt, Rod. “Correlating the Slagging of a Utility

Boiler with Coal Characteristics”.

Retrieved from

http://www.coalcombustion.com/PDF%20Files

/CorreSlagefc03.pdf April 2011

Metzroth, Lawrence, VP Analysis & Strategy,

Arch Coal Inc. “Regulatory and Other Con-

straints on CAPP Coal Supply.” Presented at

7th Annual Coal Trading Conference, New York

City, NY. December 2008. Retrieved from

http://www.coaltrade.org/wpcontent/uploads/2011/02/Metzroth.pdf

th

Edition,

Mikron camera information retrieved April

2011 from

http://www.mikroninfrared.com/EN/products/t

hermal-imagers-detectors-andcores/portable-thermal-imagers/portablespecial/m7604f.html

Pusateri, Robert, President Consol Energy

Sales. “NAPP and the Marketplace.” Presented at McCloskey Coal USA 2009 Conference,

New York City, NY. June 2009. Retrieved from

http://www.consolenergy.com/Newsroom/Spe

Figure 8: Customer’s Coal Price Ranges

eches/McCloskeyNewYork2009.pdf

Schmidtchen, Paul. “High Activity Magnesia

Use for SCR Related SO3 Problems.” Presented

at NETL 2002 Conference. Retrieved from

http://www.netl.doe.gov/publications/proceed

ings/02/scr-sncr/schmidtchensummary.pdf

Page 10 Technical Paper

Loading...

Loading...