Page 1

Case Study

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

E-CHbFuelSolvFS3954_EN.doc 05

FuelSolv* FS3954: Controls Ash-Clogging

in an Incinerator Boiler

Setting up a FuelSolv FS3954 treatment program on a 7

ton/hour household waste incinerator that produces electricity

for EDF and heats horticultural greenhouses

Challenge

During its winter season, a household waste incinerator faces many shutdowns due to the accumula-

tion of deposits on the boiler’s exchange surfaces.

As a result of that reduction in heat exchange, the

limit temperature acceptable for the first superheater is reached quickly.

Several shutdowns are necessary during the season

(5 months) for a quick cleaning of the smoke pathways, i.e. one shutdown about every six weeks.

Those shutdowns cause operating losses:

Treatment of household waste at an outside

site (transfer cost)

EDF penalty for not supplying electricity

Outside servicing costs

Solution

GE Water & Process Technologies offers an expansive FuelSolv FS3954 treatment that limits boiler

clogging to reduce the number of shutdowns for

cleaning over the course of the season.

A laboratory study of vitrification tests was done on

ashes from stages 2 and 3 of the boiler. Those tests

show the effect of FuelSolv FS3954 for a dosing

greater than 2% with respect to ash at a temperature of 750°C/1380°F).

White 1% 2% 4%

Due to the rate of ash generated by household

waste, we recommend a dosing of 500 g of FuelSolv

FS3954/ton of waste incinerated.

FuelSolv FS3954 comes in the form of nonhygroscopic particles that can be injected into the

boiler using a compressed-air doser.

View of Injection System

Page 2

In the test, two injection points were placed at the

outlet of the furnace in the first riser stage of the

boiler (smoke temperature 850°C/1560°F, the minimum temperature for injection being 760°C/

1400°F).

The test was conducted from December 2002 to

May 2003.

Results

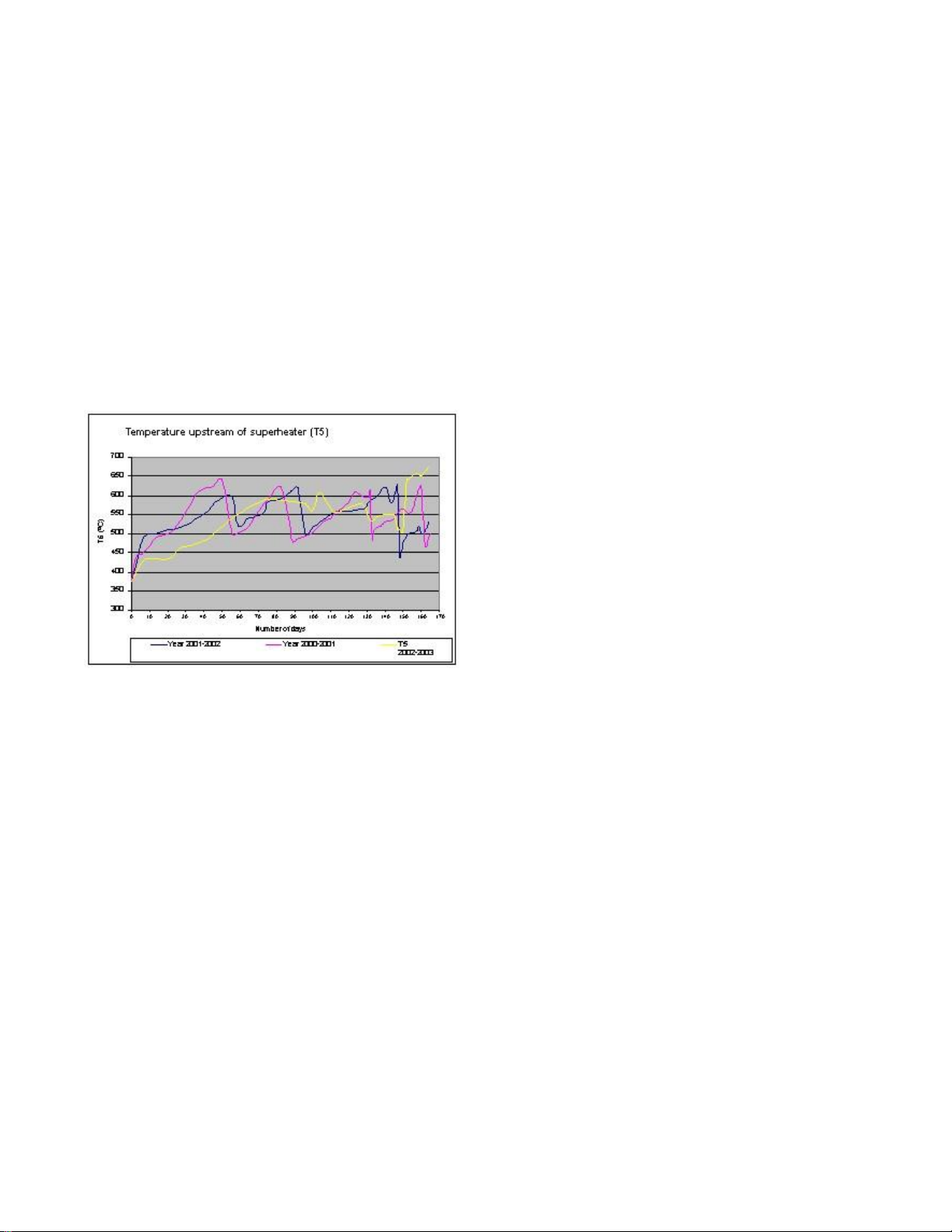

The critical parameter for validating the test is the

temperature of the smoke (T5) upstream of the

superheaters. That temperature enables the operator to determine the shutdown for cleaning of the

installation. (650°C/1200°F).

Thanks to our technology, the client achieved its

primary goal: no shutdown between the two scheduled annual technical maintenances.

Achieving that goal enabled the operator to make

significant gains:

Fulfill electricity-supply commitments with EDF

No additional cost from outside treatments of

household waste

Reduction in operating cost

Page 2 Case Study

Loading...

Loading...