Page 1

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FS1242EN.doc Jul-13

GE 2020 EDR Systems

Electrodialysis Reversal Technology

The GE 2020 Electrodialysis Reversal (EDR) product

is a proven and reliable desalination technology

that has been in service in a variety of industrial

and public infrastructure applications.

EDR Features

Use of Carbon Electrodes results in no gas pro-

duced and no separate electrode stream

required.

High Water Recovery, up to 94%

Salt Removal of 50 to 95%

Polarity Reversal self-cleaning with electricity

Free chlorine tolerance

Tolerance to moderate suspended solids

Adjustable product water performance without

blending

Ability to disassemble stacks for inspection

Silica tolerance

EDR Benefits

Efficient use of scarce water resources

Low pretreatment requirements and costs

Low chemical consumption costs

Long membrane life, typically 10+ years

Strong ability to recover from less than ideal

feed water quality

Standard Design and Scope of Supply

MK-IV-2 EDR stacks with GE Carbon Electrodes

Cartridge filter

Concentrate Recirculation pump with VFD

GE Fanuc Micro PLC & 12” (30 cm) color Quick

Panel HMI

Full Owners Operation & Maintenance Manual,

Factory Acceptance Test results and Stack Performance Test results

Instrumentation - Transmitters

Flow ............................ Product Outlet, Concentrate Outlet

Pressure ................................ Cartridge Filter Inlet & Outlet

Conductivity ....................................... Inlet & Product Outlet

Operating Parameters

Water Recovery ....................................................... Up to 94%

Salt Removal .......................................................... 50% to 95%

Silica Removal ...................................................................... none

Temperature ................................... 40 to 100ºF (4 To 38ºC)

Maximum Feed Pressure .............................................. 50 psi

Input Voltage ................................................. 480VAC/3/60Hz

Feed Water Requirements

Typical Feed TDS ........................ 100 to 3,000 ppm (mg/l)

Maximum Feed TDS ............................. 12,000 ppm (mg/l)

Silica (Reactive) .......................................................... unlimited

pH .......................................................................................... 2 to 10

SDI (5 min. test) ........................................................................ 10

Turbidity ....................................................................... < 0.5 NTU

Free Chlorine (continuous) ........................ 0.5 ppm (mg/l)

Concentrate, Recirculation

Pump Outlet, Product Outlet

Page 2

TOC ..................................................................... < 15 ppm (mg/l)

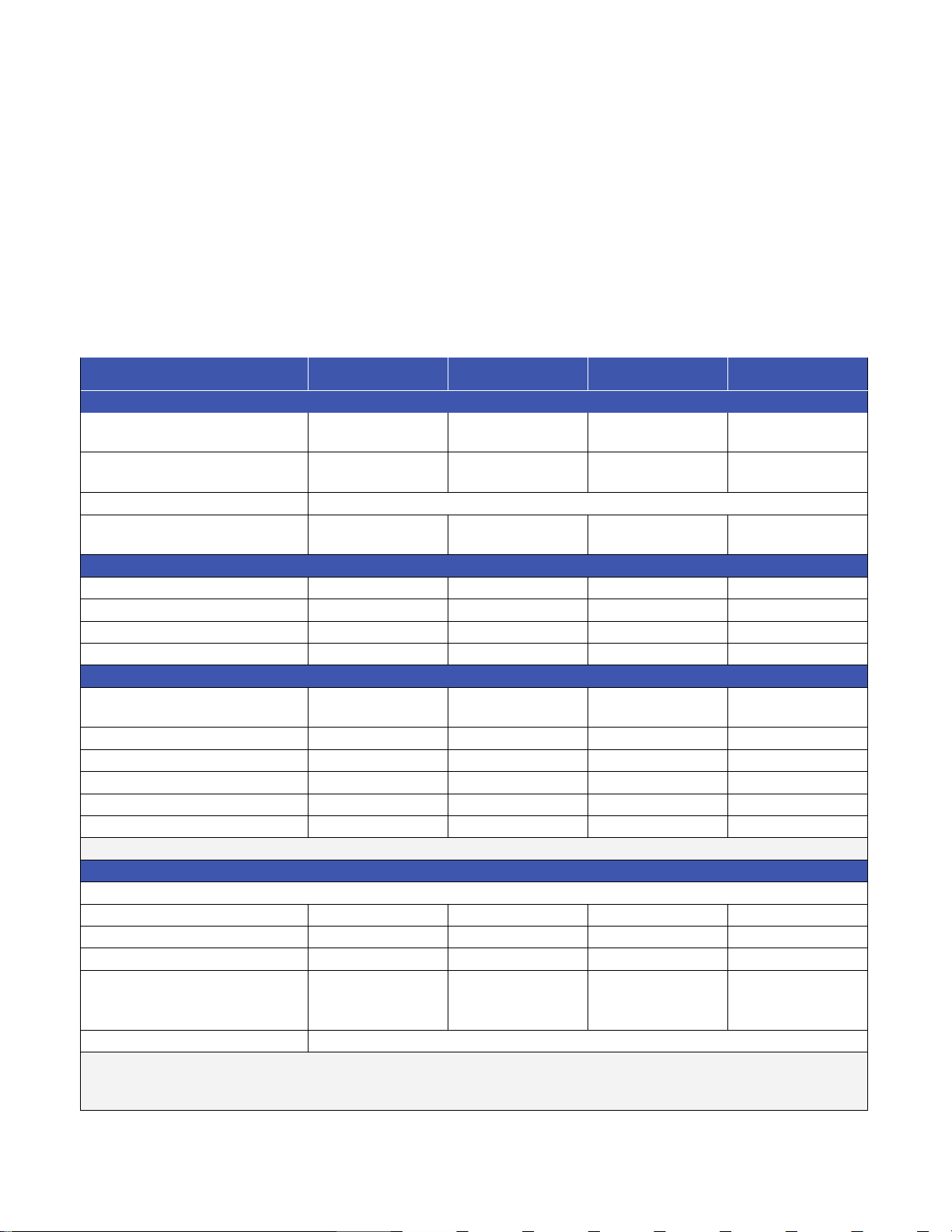

MODEL

2020-2L-2S

2020-2L-3S

2020-4L-2S

2020-4L-3S

Flow Rates

Product Flow Nominal

280 gpm

63.6 m3/h

260 gpm

59.1 m3/h

560 gpm

127.2 m3/h

520 gpm

118.2 m3/h

Product Flow Range

165 to 325 gpm

37.5 to 73.8 m3/h

165 to 270 gpm

37.5 to 61.3 m3/h

325 to 655 gpm

73.8 to 148.8 m3/h

325 to 545 gpm

73.8 to 123.8 m3/h

Concentrate Outlet Flow

Depends on recovery and product

Electrode Outlet Flow

2.2 gpm

8.3 lpm

2.5 gpm

9.5 lpm

4.3 gpm

16.3 lpm

5.0 gpm

19 lpm

General Information

Number of Stacks

4 6 8

12

Number of Lines

2 2 4

4

Number of Stages

2 3 2

3

Type of Stack

MK-IV-2

MK-IV-2

MK-IV-2

MK-IV-2

Dimensions

System Dimensions

Width x Length

90” x 309”

(2.3 x 7.9 m)

90” x 375”

(2.3 x 9.5 m)

169” x 493”

(4.3 x 12.5 m)

169” x 625”

(4.3 x 15.9 m)

Inlet Piping

4” (10 cm)

4” (10 cm)

6” (15 cm)

6” (15 cm)

Product Outlet Piping

4” (10 cm)

4” (10 cm)

6” (15 cm)

6” (15 cm)

Off-Spec Outlet Piping

4” (10 cm)

4” (10 cm)

6” (15 cm)

6” (15 cm)

Electrode Outlet Piping

3” (8 cm)

3” (8 cm)

3” (8 cm)

3” (8 cm)

Concentrate Outlet Piping

1.5” (4 cm)

1.5” (4 cm)

2” (5 cm)

2” (5 CM)

Note: all piping sizes are provided for nominal flow rates at 85% recovery.

Electrical

Maximum Rectifier Output (Per Stack Basis)

Stage 1

590VDC, 46A

590VDC, 26A

590VDC, 46A

590VDC, 26A

Stage 2

518VDC, 18A

518VDC, 14A

518VDC 18A

518VDC, 14A

Stage 3 420VDC, 7.5A

420VDC, 7.5A

Connection Requirement

(Includes Feed pump, which may

be supplied by others)

140 KVA

107 KVA

276 KVA

209 KVA

Typical Power consumption

2 – 4 kWh/1,000 gallons of product water

Performance, number of stages and cell pairs, recovery and power consumption are dependent on inlet feed water

quality and temperature. A Watsys projection must be completed by an authorized GE Water & Process Technologies

design representative for proper system design & for any performance guarantee to be provided.

COD ....................................................... < 50 ppm (mg/l) as O2

Iron .................................................................... < 0.3 ppm (mg/l)

Manganese, Aluminum ........................... < 0.1 ppm (mg/l)

H2S .................................................................... < 0.1 ppm (mg/l)

Allowable Intermittent Levels:

SDI (5 min. test) ......................................................................... 15

Turbidity ............................................................................2.0 NTU

Free Chlorine .................................................................. 30 mg/l

EDR 2020 2 & 4 Line Standard Systems

Material of Construction

Welded Frame................................... Painted Carbon Steel

Dilute and Concentrate Piping ...................... Sch. 80 PVC

Flanges .................................................................................... ANSI

Concentrate Pump ................... Single-stage Centrifugal

Rectifier ......................................................................... NEMA 3R

Control Panel ................................................................. NEMA 4

Quality Assurance

Certification ............................................................................... UL

Facility ................................................................. ISO 9001:2000

Page 2 FS1242EN

Page 3

EDR 2020 6 & 8 Line Standard Systems

MODEL

2020-6L-2S

2020-6L-3S

2020-8L-2S

2020-8L-3S

Flow Rates

Product Flow Nominal

840 gpm

190.8 m3/h

780 gpm

177.2 m3/h

1120 gpm

254.4 m3/h

1040 gpm

236.2 m3/h

Product Flow Range

485 to 985 gpm

110.2 to 223.7 m3/h

485 to 820 gpm

110.2 to 186.2 m3/h

645 to 1315 gpm

146.5 to 298.7 m3/h

645 to 1090 gpm

146.5 to 247.6 m3/h

Concentrate Outlet Flow

Depends on recovery and product flow rate

Electrode Outlet Flow

6.5 gpm

25 lpm

7.5 gpm

28 lpm

8.7 gpm

33 lpm

10 gpm

38 lpm

General Information

Number of Stacks

12

18

16

24

Number of Lines

6 6 8

8

Number of Stages

2 3 2

3

Type of Stack

MK-IV-2

MK-IV-2

MK-IV-2

MK-IV-2

Dimensions

System Dimensions

Width x Length

270” x 493”

(6.0 x 12.5 m)

270” x 625”

(6.0 x 15.9 m)

270” x 493”

(6.0 x 12.5 m)

270” x 625”

(6.0 x 15.9 m)

Inlet Piping1

8” (20 cm)

8” (20 cm)

8” (20 cm)

8” (20 cm)

Product Outlet Piping

8” (20 cm)

8” (20 cm)

8” (20 cm)

8” (20 cm)

Off-Spec Outlet Piping

8” (20 cm)

8” (20 cm)

8” (20 cm)

8” (20 cm)

Electrode Outlet Piping

3” (8 cm)

3” (8 cm)

3” (8 cm)

3” (8 cm)

Concentrate Outlet Piping

3” (8 cm)

3” (8 cm)

3” (8 cm)

3” (8 cm)

Note: all piping sizes are provided for nominal flow rates at 85% recovery.

Electrical

Maximum Rectifier Output (Per Stack Basis)

Stage 1

590VDC, 46A

590VDC, 26A

590VDC, 46A

590VDC, 26A

Stage 2

518VDC, 18A

518VDC, 14A

518VDC 18A

518VDC, 14A

Stage 3 420VDC, 7.5A

420VDC, 7.5A

Connection Requirement

(Includes Feed pump, which may

be supplied by others)

380 KVA

285 KVA

542 KVA

397 KVA

Typical Power consumption

2 – 4 kWh/1,000 gallons of product water

Performance, number of stages and cell pairs, recovery and power consumption are dependent on inlet feed water

quality and temperature. A Watsys projection must be completed by an authorized GE Water & Process Technologies

design representative for proper system design & for any performance guarantee to be provided.

FS1242EN Page 3

Loading...

Loading...