Page 1

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FSsmDuracid_EN.docx Sep-13

Metal Ion

Feed

Concentration

Rejection in 5%

H2SO

4

1

Rejection in 5%

H3PO

4

1

Fe2+

2000ppm

>90%

>85%

Al3+

2000ppm

>90%

>85%

Cu2+

2000ppm

>90%

>85%

Cd2+

100ppm

>90%

>85%

Ni+

2000ppm

>90%

>85%

Acid

Concentration

HCl

5-37%

H2SO4

5-20%

H3PO4

5-20%

Duracid Series

Industrial Acid Stable Nanofiltration Elements

Description and Use

The Duracid NF membrane element is engineered

to operate continuously under extreme acid conditions where pH is at or below zero.

The family of Duracid proprietary thin-film nanofiltration membrane elements is characterized by an

approximate molecular weight cut-off of 150-200

Dalton for unchanged organic molecules. Divalent

and multivalent ions are preferentially rejected by

the membrane while monovalent ions and mineral

acids commonly have full transmission through the

membrane (transmission can vary depending upon

feed concentration and composition). Since mineral

acids and monovalent ions have high passage

through the membrane, these substances have a

minor contribution to the osmotic pressure.

Among other applications, Duracid NF Elements are

used for acid purification and metals concentration

in low pH streams.

They feature patented feed spacers, polysulfone

parts and a fiberglass outer wrap. All materials of

construction are low pH tolerant.

Markets

Metal Surface Treatment / Coating / Galvanic

Heap Leaching Process in Mining

Phosphate-based Chemical Production

Spent Acid Recovery

Application Data

Table 1: Membrane Metal Rejection

1

Based on flat sheet test conducted at 25°C (77°F) under 400 psig operating

pressure in a dead-end filtration mode. A single acid feed solution was dosed with

a mixture of all metals listed in Table 1 for each type.

Table 2: Typical Process Streams

Features and Benefits

Extreme low pH stability

100% wet testing Quality Assurance

Durable construction

High temperature compatibility

Page 2

Membrane

Duracid, Thin-film membrane (TFM*)

Model

Average

permeate

flow, gpd

(m3/day)

1,2

Average

permeate

flow, gpd

(m3/day)

1,3

Maximum

crossflow gpm

(m3/hr)

Average

MgSO4

rejection

1,2

Duracid NF2540F30

120

(0.5)

560

(2.1)

7

(1.6)

98 %

Duracid NF4040F35

405

(1.5)

1900

(7.2)

18

(4.1)

98 %

Duracid NF8040F35

2210

(8.4)

10400

(39.4)

70

(15.9)

98 %

Model

Spacer

mil (mm)

Active

area

ft2 (m2)

Outer wrap

Part

number

Duracid NF2540F30

30 (0.76)

15 (1.4)

Fiberglass

1231058

Duracid NF4040FM

35 (0.89)

52 (4.8)

Fiberglass

3050564

Duracid NF8040F35

35 (0.89)

285 (26.5)

Fiberglass

1231068

Model1

Dimensions, inches (cm)

Boxed

A

B2

C

Weight

lbs (kg)

Duracid NF2540F30

40.0

(101.6)

0.75

(1.9) OD

2.4

(6.1) 4 (1.8)

Duracid NF4040F35

40.0

(101.6)

0.75

(1.9) OD

3.9

(9.9)

9

(4.1)

Duracid NF8040F35

40.0

(101.6)

1.125

(2.86)

7.9

(20.0)

29

(13.2)

Typical Operating Pressure

400 – 800psi (2758 – 5516kPa)

Typical Operating Flux

5 – 14 GFD (9 – 24 LMH)

Clean Water Flux (CWF)1

10-19 GFD (17-32 LMH) @ 225psi (1551kPa)

Maximum Operating

Pressure

1200psi (8,273kPa)

800psi (5,515kPa)

600 psi (4,136kPa)

32 – 77°F (0 – 25°C)

78 – 122°F (26 – 50°C)

123 – 158°F (51 – 70°C)

Maximum Temperature

Continuous operation: 158°F (70°C)

Clean-In-Place (CIP): 158°F (70°C)

pH Range

Continuous operation: < 9

Clean-In-Place (CIP): < 9

Chlorine Tolerance

500 ppm-hrs,

dechlorination recommended

Range

0°C-50°C

psig (kPa)

51°C-70°C

psig (kPa)

Over an element

15 (103)

7 (48)

Per housing

60 (414)

30 (207)

Table 3: Element Specification

1

Average permeate flow and salt rejection measured on pre-conditioned ele-

ments after 24 hours operation. Individual flow rate may vary ±25%

2

Testing conditions: 2,000ppm MgSO4 solution at 110psi (760kPa) operating

pressure, 77 °F (25°C), 15 % recovery.

3

Testing conditions: 3% glucose solution at 440psi (3034kPa) operating pressure,

77⁰F (25⁰C), 15% recovery.

Table 4: Dimensions and Weight

1

These elements are dried then bagged before shipping.

2

Internal diameter unless specified OD (outside diameter).

Table 5: Operating and CIP parameters

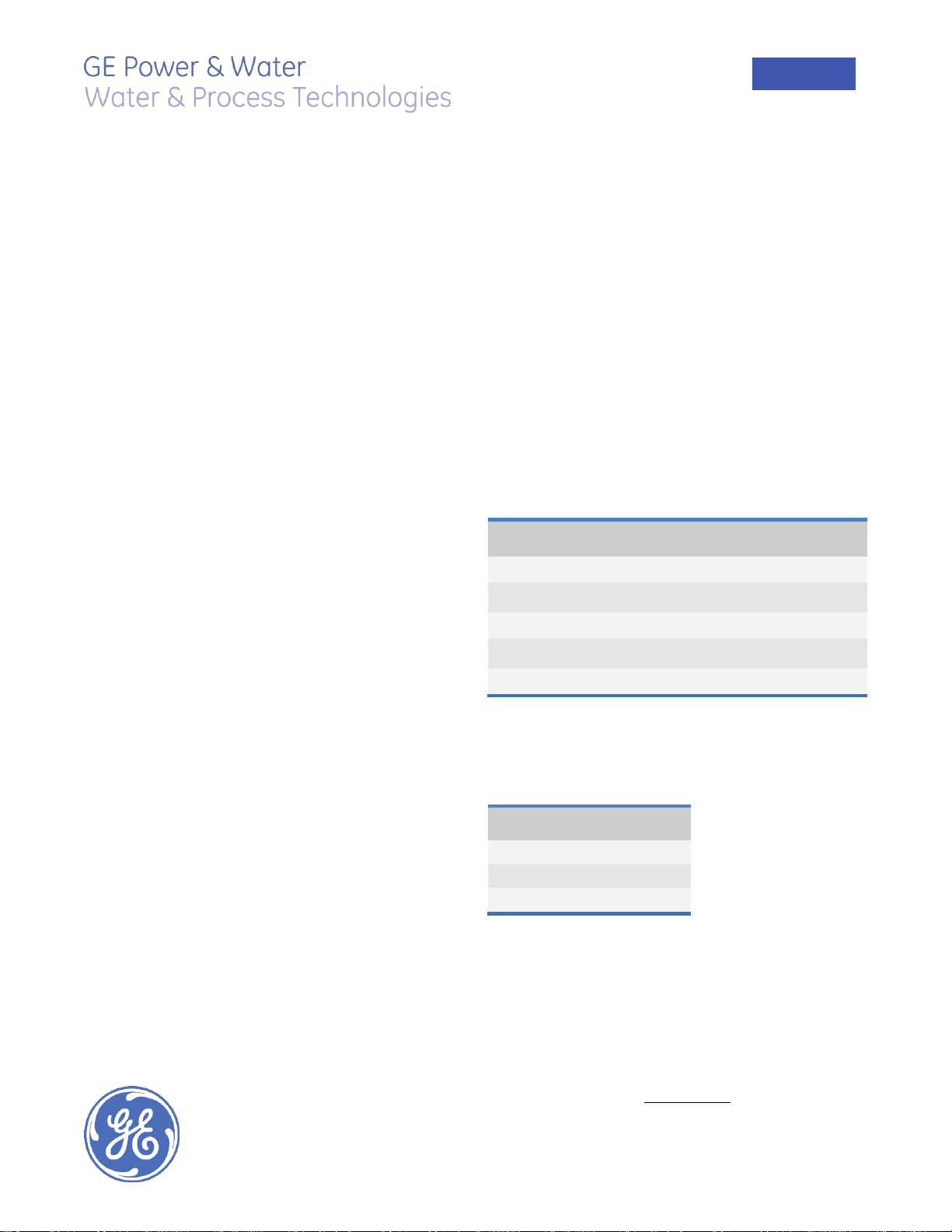

Figure 1: Element Dimensions Diagram (Male) – 2540 &

4040

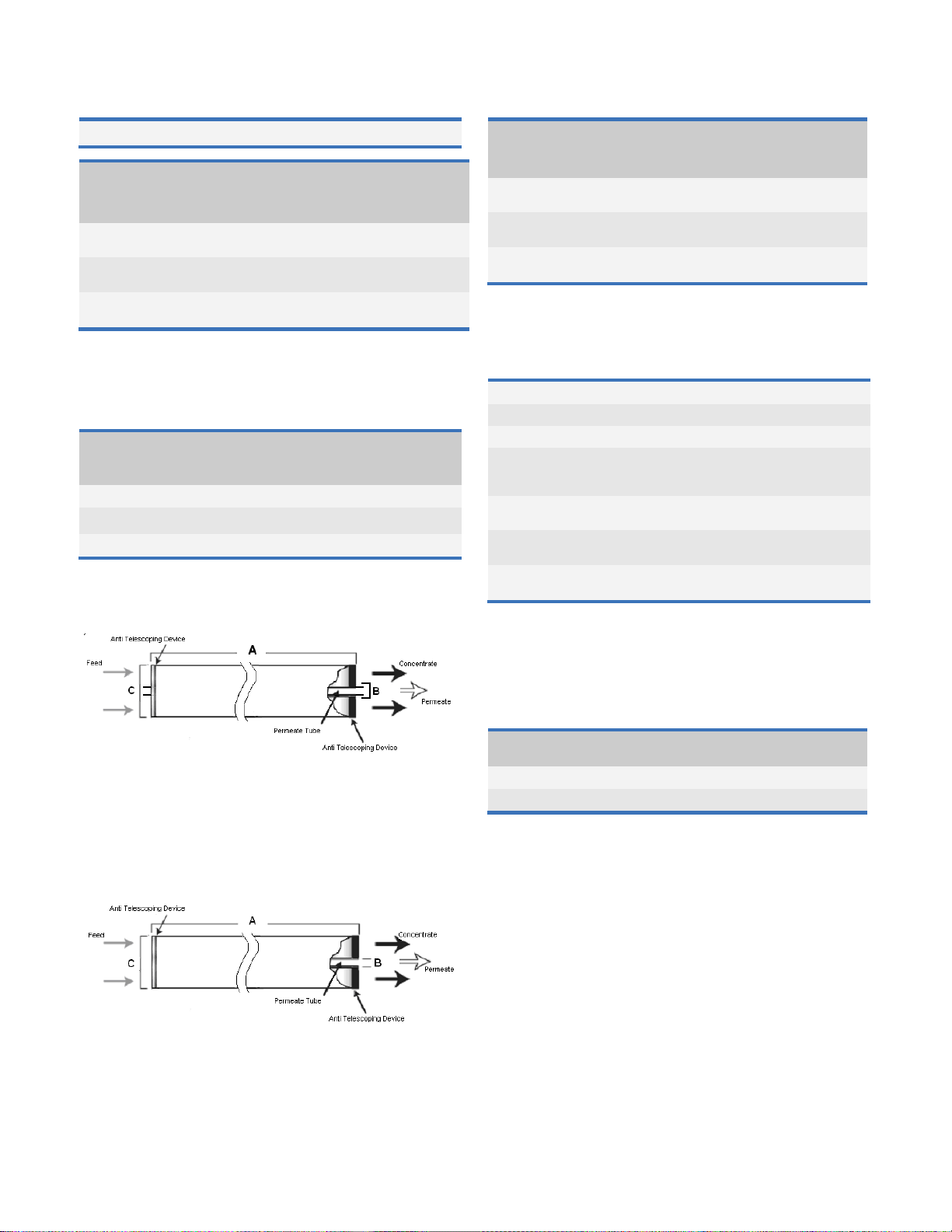

Figure 2: Element Dimensions Diagram (Female) – 8040

1

Clean water flux (CWF) is the rate of water permeability through the membrane

after cleaning (CIP) at reproducible temperature and pressure. It is important to

monitor CWF after each cleaning cycle to determine if the system is being

cleaned effectively. CWF can vary ±25%.

Table 6: Maximum Pressure Drops

Pre-conditioned Elements

To optimize flow and rejection performance of

Duracid membranes, a pre-conditioning step is required. Element pre-conditioning consists of a 5min

pure water flush at a minimum pressure of 500 psig

(3447kPa) at ambient temperature.

Page 2 Fact Sheet

Loading...

Loading...