Page 1

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FSpsDairyUltraUF_EN.doc Nov-13

Membrane

Polyethersulfone

Model

Spacer

mil (mm)

Active area

ft2 (m2)

Part

number

DAIRY ULTRA UF3838C30

30 (0.76)

78 (7.3)

1268732

DAIRY ULTRA UF3838C50

50 (1.27)

51 (4.7)

1268736

DAIRY ULTRA UF6338C30

30 (0.76)

219 (20.3)

1268738

DAIRY ULTRA UF6338C50

50 (1.27)

174 (16.2)

1268739

DAIRY ULTRA UF6338C30 TAIL1

30 (0.76)

219 (20.3)

3050567

DAIRY ULTRA UF6338C50 TAIL1

50 (1.27)

174 (16.2)

3050576

DAIRY ULTRA UF8038C30

30 (0.76)

330 (30.6)

1268740

DAIRY ULTRA UF8038C50

50(1.27)

254 (23.6)

3048906

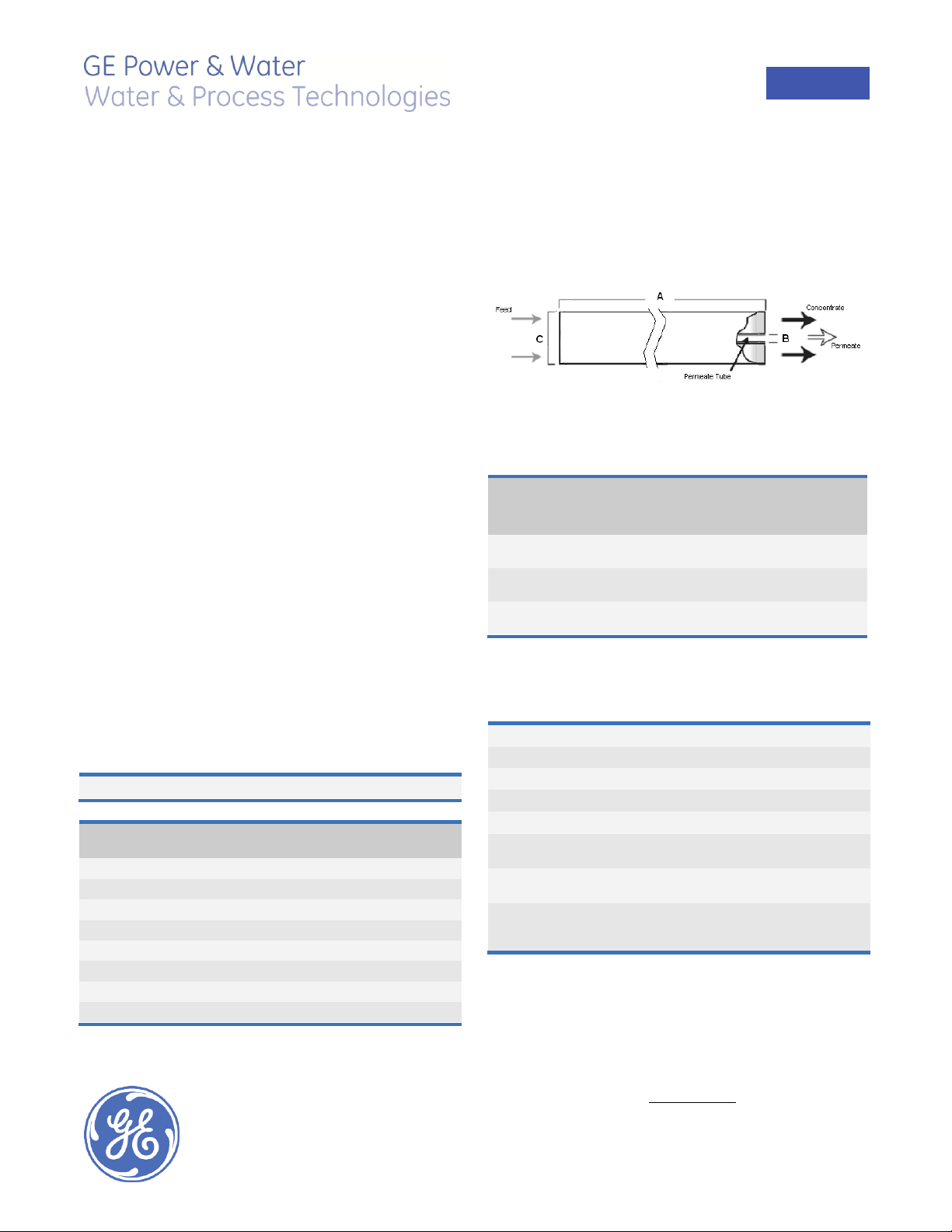

Model1

Dimensions, inches (cm)

Boxed

A

B2

C

Weight

lbs (kg)

DAIRY ULTRA UF3838C

38.00

(96.5)

0.833

(2.12)

3.79

(9.6)

10

(4.5)

DAIRY ULTRA UF6338C

38.00

(96.5)

1.138

(2.89)

6.34

(16.1)

18

(8.2)

DAIRY ULTRA UF8038C

38.00

(96.5)

1.125

(2.86)

7.91

(20.1)

29

(13.2)

Typical Operating Pressure

80 - 135psi (555 – 931kPa)

Typical Operating Flux

5-20 GFD (8–34 LMH)

Clean Water Flux (CWF)1

45-55 GFD (76 - 93 LMH) @ 20 psi and 50°C

Maximum Operating Pressure

150 psi (1,034 kPa)

Maximum Temperature

122°F (50°C)

‘pH range

Continuous Operation: 3.0-10.0,

Clean-In-Place (CIP): 2.0-11.5

Maximum Pressure Drop

Over an element: 15psi (103kPa)

Per housing: 60psi (414kPa)

Chlorine Tolerance

5,000+ ppm-days

180 ppm for 20 min MAXIMUM chlorine caustic

cycle

Dairy Ultra UF Series

Ultrafiltration – Superior Flux

Exclusively used for food related processes requiring stringent sanitary procedures, the typical applications include whey and milk fractionation where

the Dairy Ultra UF membrane displays exceptional

process flux and protein retention due to a specific

membrane structure while being easily cleanable.

The Dairy Ultra UF membrane features a 10,000 Da

molecular weight cut-off and has great performance in acid and sweet whey applications.

Element features include:

High protein rejection

High process flux

Durable membrane

Patented Durasan* Cage outer wrap

Polysulfone parts and standard feed spacers

The Dairy Ultra UF elements comply with:

Figure 1: Element Dimensions Diagram

Table 2: Dimensions and Weight

1

These elements are bagged dry before shipping.

2

Internal diameter.

FDA Regulations relevant sections of 21CFR

EU Framework 1935/2004/EC

Table 1: Element Specification

1

Extra caging material included that can be cut to length to retrofit a 3.9” diame-

ter element.

Table 3: Operating and CIP parameters

1

Clean water flux (CWF) is the rate of water permeability through the membrane

after cleaning (CIP) at reproducible temperature and pressure. It is important to

monitor CWF after each cleaning cycle to determine if the system is being

cleaned effectively. CWF can vary ±25%.

Loading...

Loading...