Page 1

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FSpsDairyHWS_EN.doc Sep-13

Fact Sheet

Dairy HWS

Dairy Industry

Dairy HWS elements utilize polysulfone parts and

unique element construction to meet the requirements for hot water sanitization. Comprised of high

quality materials that meet 3A standards and conform to guidelines set by the Code of Federal Regulations, Dairy HWS elements feature a patented

Durasan* Cage protective sleeve that enhances

element integrity by securing the spiral. In addition,

the sleeve improves sanitizing effectiveness by

maintaining a controlled by-pass between the element and pressure vessel wall without the use of

traditional brine seals.

Hot Water Sanitization

Meeting Stringent Requirements

Without question, the dairy industry is faced with

increasingly stringent sanitary regulations. To help

meet these requirements, GE Water & Process

Technologies introduces the Dairy HWS family. Ideal

for applications with biologically active feeds, Dairy

HWS elements are designed for hot water sanitization (pasteurization) by periodic exposure to temperatures up to 90°C (194°F). An innovative breakthrough, you can now sanitize the permeate side of

a membrane element without risking membrane

damage. Additional benefits of Dairy HWS elements

include sanitization without the use of ineffective or

harmful chemicals, as well as protection against

detrimental bacterial growth on the membrane surface – thus limiting replacement costs.

Membrane Technology

A Valuable Solution

The use of spiral membrane technology in dairy applications allows plants to recover valuables, create

saleable products, recycle water and reduce plant

effluent. By utilizing Dairy HWS elements, spiral

membrane systems can strategically concentrate:

Sweet Whey

Lactose

Whole Milk

Skim Milk

A Market Leader

GE’s Commitment to You

After over 30-years of innovation in membrane

technology, GE has become a market leader in developing new ways to solve even the most difficult

industrial and commercial challenges. For sanitization specifications and protocols based on your

unique dairy process, please consult a GE representative.

Page 2

Membrane

Thin-film membrane (TFM*)

Model

Spacer

mil (mm)

Active area

ft2 (m2)

Part

number

Dairy HWS RO3840C30

30 (0.76)

85 (7.9)

1228223

Dairy HWS RO8038C30

30 (0.76)

390 (36.2)

1206651

Dairy HWS NF3840C30

30 (0.76)

85 (7.9)

1232322

Dairy HWS NF8038C50

50 (1.27)

360 (33.4)

3002372

Model1

Dimensions, inches (cm)

Boxed

A

B2

C

Weight

lbs (kg)

3840C

38.75

(98.4)

0.833

(2.12)

3.8

(9.6)

7

(3.2)

8038C

38.00

(96.52)

1.125

(2.86)

7.91

(20.1)

29

(13.2)

Typical Operating Pressure

200-500 psi (1,379-3,447 kPa)

Typical Operating Flux

5-20 GFD (8–34 LMH)

Clean Water Flux1

RO : 14 GFD (24 LMH)@ 225 psi

NF : 14 GFD (24 LMH) @ 110 psi

Maximum Operating Pressure

600 psi (4,137 kPa): 41 – 122°F (26 – 50°C)

Maximum Temperature

Continuous operation: 122°F (50°C)

Hot Water Sanitization: 194°F (90°C)

pH Range

RO elements: 3.0 – 10.0

NF elements: 3.0 – 9.0

Chlorine Tolerance

500+ ppm hours,

dechlorination recommended

Maximum Pressure Drop

Over an element: 15 psi (103 kPa)

Per housing: 60 psi (414 kPa)

Temperature

‘pH minimum

‘pH maximum

50°C (122°F)

2.0

11.5

45°C (113°F)

1.5

11.5

35°C (95°F)

1.5

11.5

25°C (77°F)

1.0

12.0

Temperature

‘pH minimum

‘pH maximum

50°C (122°F)

3.0

10.0

45°C (113°F)

2.0

10.5

35°C (95°F)

1.5

11.5

25°C (77°F)

1.0

11.5

Table 1: Element Specification

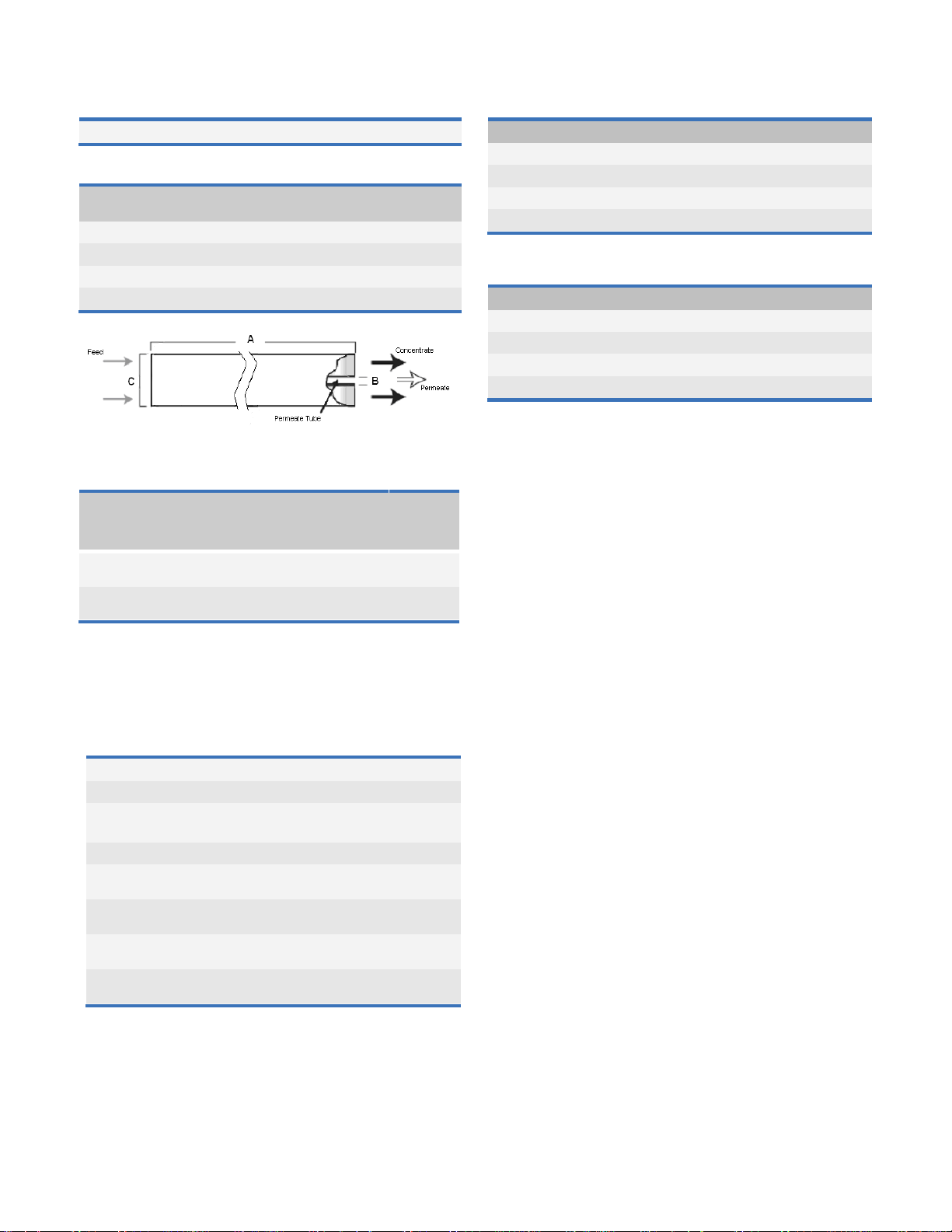

Figure 1: Element Dimensions Diagram - Female

Table 2: Dimensions and Weight

1

These elements are dried and bagged before shipping.

2

Internal diameter.

Table 3: Operating parameters

Do not exceed 20 GFD (33 LMH) or 2,000 Wagner

units under any circumstance.

Table 4: CIP limits for RO elements

Table 5: CIP limits for NF elements

Hot Water Sanitization

Recommendations

For optimal performance, Dairy HWS elements

should always be cleaned using approved CIP

procedures and flushed with fouling free water

before the sanitization process. Feed pressure

during sanitization should not exceed 40psi

(275kPa) and the crossflow should not incur a

pressure drop greater than 2psi (14kPa) per

element. Heating rate to sanitizing temperature and

cool down should not be faster than 5°C (41°F) per

minute. Maximum sanitization temperature is 90°C

(194°F).

Loss of Permeate Flow after Repeated

90°C Sanitization Cycles

1

Clean water flux (CWF) is the rate of water permeability through the membrane

after cleaning (CIP) at reproducible temperature and pressure. It is important to

monitor CWF after each cleaning cycle to determine if the system is being

cleaned effectively. CWF can vary ±25%.

Page 2 Fact Sheet

It is almost impossible to exactly predict the percentage of permeate flow rate lost from the high

temperature sanitations, which among other factors depends on:

1) Rate of temperature increase and decrease.

2) Presence of other species like organics, ionic

and metallic compounds that could locally decrease or increase the temperature at the surface of the membrane.

3) Feed flow rate and specifically the heat transfer

rate to the membrane surface.

4) The thickness and geometry of the feed spacer

used.

Page 3

At optimum conditions measured in controlled environment with deionized water, between 30% and

50% of the original permeate flow rate was lost before the element performance had stabilized after

repeated heat treatments (over 90% of this flow

reduction occurred during the first heat treatment).

With the loss of permeate flow rate, the salt rejection increases. The rate of cooling and heating was

not more than 5C (41°F) per minute, and the differential pressure drop per element did not exceed 2

psi.

Pilot testing based on the criteria noted above will

give the best operating parameters for any specific

application.

Fact Sheet Page 3

Loading...

Loading...