Page 1

Customer

Benefits

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

CB1283EN.doc Jun-13

Technology

% Water Recovery

Reverse Osmosis

75% - 80%

Electrodialysis Reversal

80% - 85%

HERO*

85% - 90%

NTBC

93% - 96%

ZLD

99+%

GE’s AquaSel* System

A Non-Thermal Brine Concentrator (NTBC) – design and

performance to meet sustainability targets

Table 1: Technology vs. Water Recovery

AquaSel NTBC systems can effectively treat

wastewater and recover 95% as water suitable for

reuse. In most cases providing water that is equivalent to the raw water that the plant is currently using. Some of the targeted uses:

Water scarcity, higher water costs and stringent

regulations are driving a behavioral change in consumers and industry to optimize the way we use

water. GE’s AquaSel systems offer the ability to minimize the water footprint and achieve near ZeroLiquid Discharge recoveries with a cost effective,

sustainable process.

NF, RO or EDR reject recovery.

High Recovery brackish water desalination

and/or NF/RO pretreatment.

High recovery tertiary wastewater reuse.

Cooling tower blow-down reuse.

The AquaSel product line leverages GE’s know-how

and leadership in thermal evaporation and electrolytic separations. The combination of these technologies removes the barriers to water recovery due to

inorganic scale fouling. Prevalent desalination technologies like reverse osmosis (RO) and electrodialysis reversal (EDR) can be limited by such scaling

when trying to go beyond 70% to 80% water recovery. Table 1 shows the typical water recovery for

technologies in challenging waters with strong

scale potential.

Water is critical

Are you faced with any of the following scenarios?

Lack of available water to expand capacity

Reached limit on wastewater discharge

Unreliable water source

Forced to decrease water consumption

Page 2

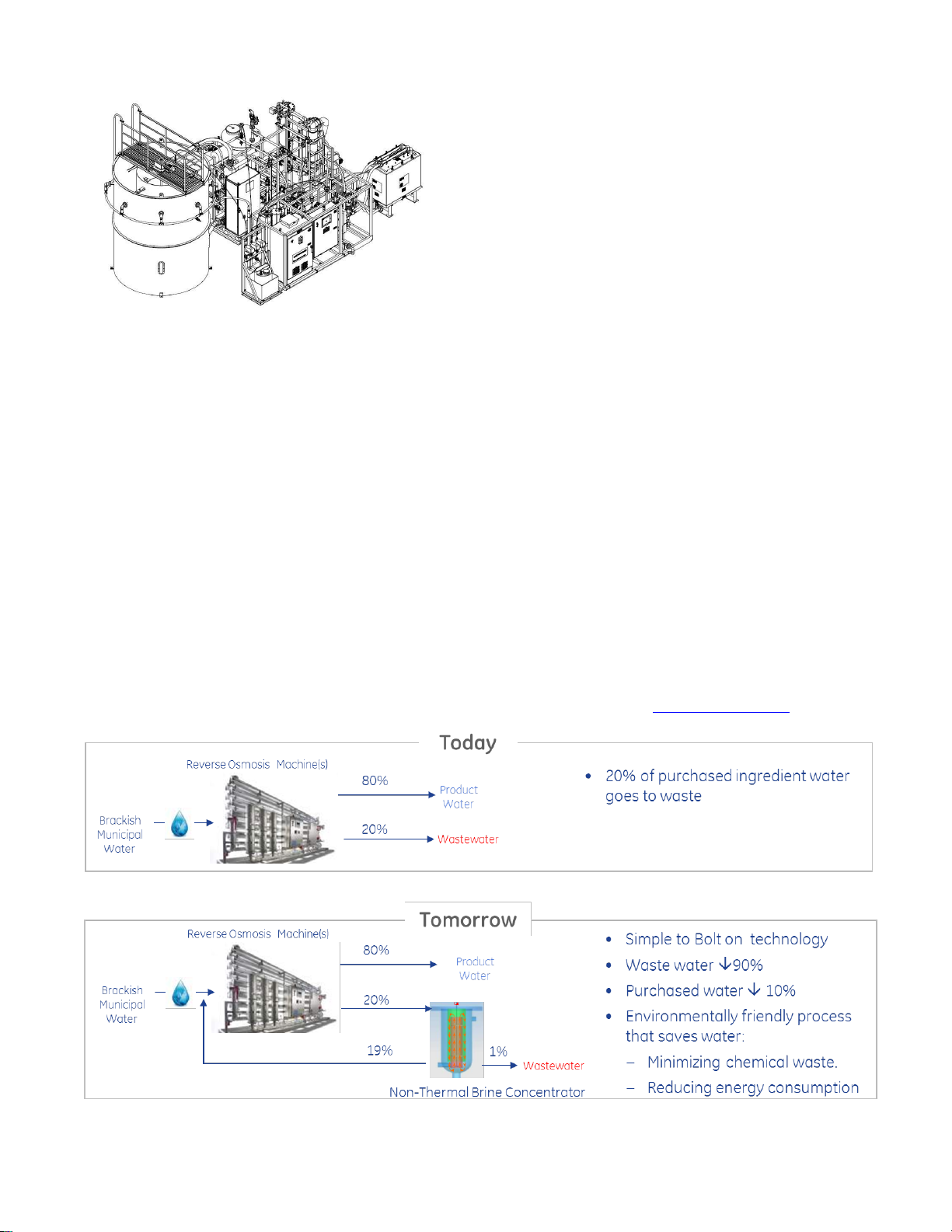

Figure 1: AquaSel general layout (for reference only)

The innovative AquaSel NTBC technology (shown in

Figure1) can augment the water yield of your existing equipment to achieve and overall 99+% recoveries.

Costs are critical

Decrease your wastewater volume 10 to 50 times

and substantially reduce your fresh water intake

without having to boil the water to make it suitable

for reuse. See Figure 2 for a comparison of water

recoveries for traditional vs. AquaSel systems.

If you are faced with high total water costs (feed

and discharge), the thousands of gallons of water

saved per year by using GE’s AquaSel system will

net savings to the plant.

Sustainable performance

Environmentally friendly process that minimizes

waste chemical and energy consumption.

Selection of high quality components and mate-

rial of construction positions GE’s AquaSel systems for reliability over time

AquaSel design can be adapted to site specifici-

ties into unique technical solutions.

Rely on GE experience and expertise

60+ years of thermal and electrolytic process

design experience, with plants installed globally

450+ installations worldwide of the core tech-

nologies

GE’s strong quality control and processes pro-

vides maximum reliability and value

Peace of mind – you receive proven solutions

backed by an industry leader

Quality and reliability from bid to operation

Meeting your unique needs

GE’s NTBC process not only provides you with high

water recovery equipment, but also services, balance of plant, and more.

GE wants to be your water system provider. For

more information on GE’s AquaSel System and other GE offerings, contact your GE account representative or visit us at www.gewater.com.

Figure 2: Water recovery rates comparing current technology with AquaSel

Page 2 Customer Benefits

Loading...

Loading...