Page 1

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FS1262EN.doc Nov-13

Membrane

A-Series, Thin-Film Membrane (TFM*)

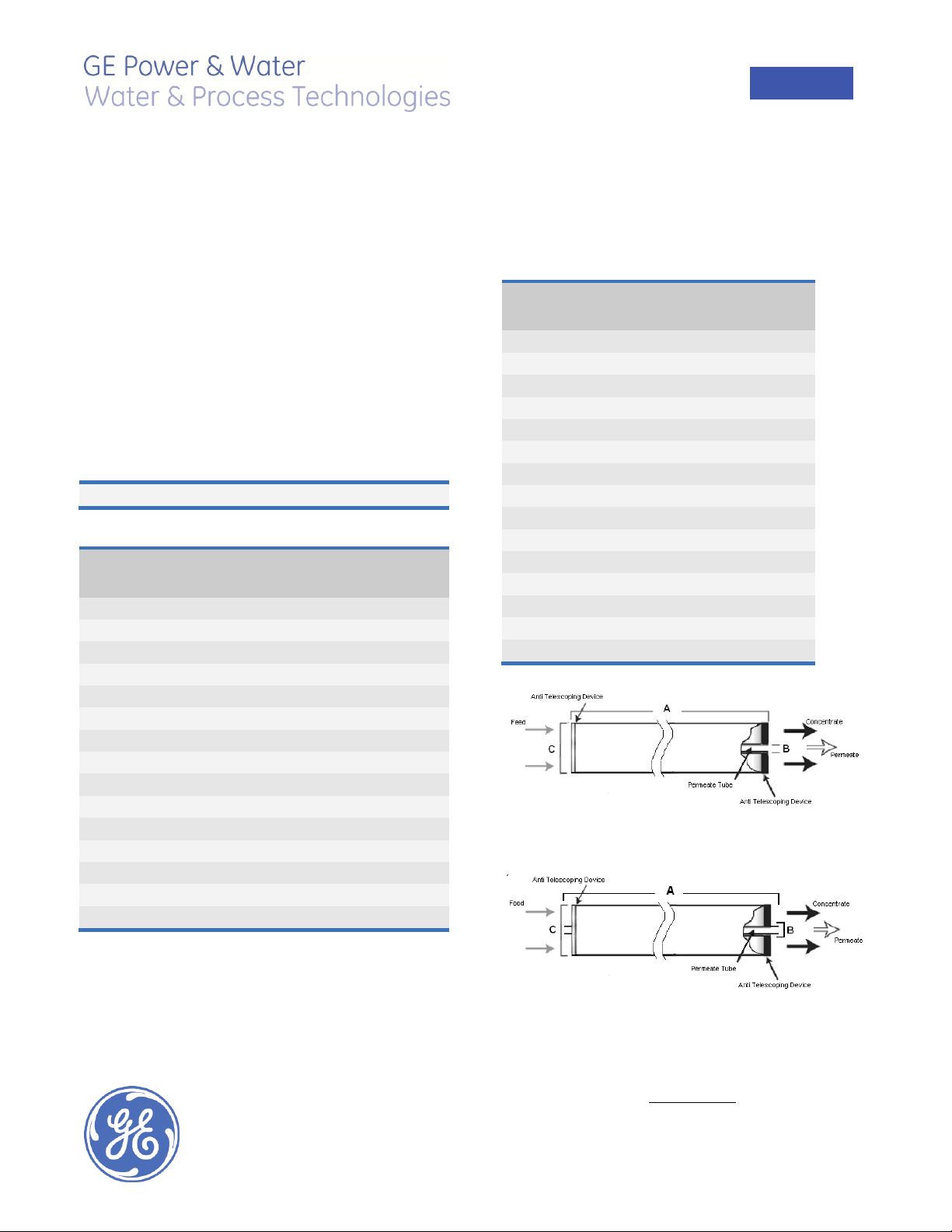

Model

Average

permeate flow

gpd (m3/day)

1,2

Average NaCl

rejection

1,2

Minimum NaCl

rejection

1,2

AG2540TM

710 (2.7)

99.5%

99.0%

AG4025T

1,600 (6.0)

99.5%

99.0%

AG4026F

1,600 (6.0)

99.5%

99.0%

AG4040C

2,400 (9.1)

99.5%

99.0%

AG4040FM

2,200 (8.3)

99.5%

99.0%

AG4040FM WET

2,200 (8.3)

99.5%

99.0%

AG4040TM

2,200 (8.3)

99.5%

99.0%

AG8040C

9,900 (37.3)

99.5%

99.0%

AG8040F

9,600 (36.3)

99.5%

99.0%

AG8040F WET

9,600 (36.3)

99.5%

99.0%

AG8040F 400

10,500 (39.8)

99.5%

99.0%

AG8040F 400 WET

10,500 (39.8)

99.5%

99.0%

AG8040N

9,600 (36.3)

99.2%

98.5%

AG8040N 400

10,500 (39.8)

99.2%

98.5%

AG8340F 400

10,500 (39.8)

99.5%

99.0%

Model

Membrane

area

ft2 (m2)

Outer wrap

Part

Number

AG2540TM

29 (2.6)

Tape

1206729

AG4025T

60 (5.6)

Tape

1206754

AG4026F

60 (5.6)

Fiberglass

1206756

AG4040C

90 (8.4)

Cage

1206757

AG4040FM

85 (7.9)

Fiberglass

3032513

AG4040FM WET

85 (7.9)

Fiberglass

3035659

AG4040TM

85 (7.9)

Tape

3032514

AG8040C

380 (35.3)

Cage

1222546

AG8040F

365 (33.9)

Fiberglass

3032515

AG8040F WET

365 (33.9)

Fiberglass

3032516

AG8040F 400

400 (37.2)

Fiberglass

3032518

AG8040F 400 WET

400 (37.2)

Fiberglass

3032519

AG8040N

365 (33.9)

Net

1231784

AG8040N 400

400 (37.2)

Net

1231786

AG8340F 400

400 (37.2)

Fiberglass

3048370

AG Series

Standard Brackish Water RO Elements

The A-Series, family of proprietary thin-film reverse

osmosis membrane elements are characterized by

high flux and high sodium chloride rejection. AG

Standard Brackish Water Elements are selected when

high rejection and operating pressures as low as 200

psi (1,379 kPa) are desired. These elements allow moderate energy savings, and are considered a standard in

the industry.

Table 1: Element Specification

1

Average salt rejection after 24 hours operation. Individual flow rate may vary

+25%/-15%.

2

Testing conditions: 2,000 ppm NaCl solution at 225 psi (1,551 kPa) operating

pressure, 77°F (25°C), pH 7.5 and 15% recovery.

Figure 1: Element Dimensions Diagram – Female

Figure 2: Element Dimensions Diagram – Male

Page 2

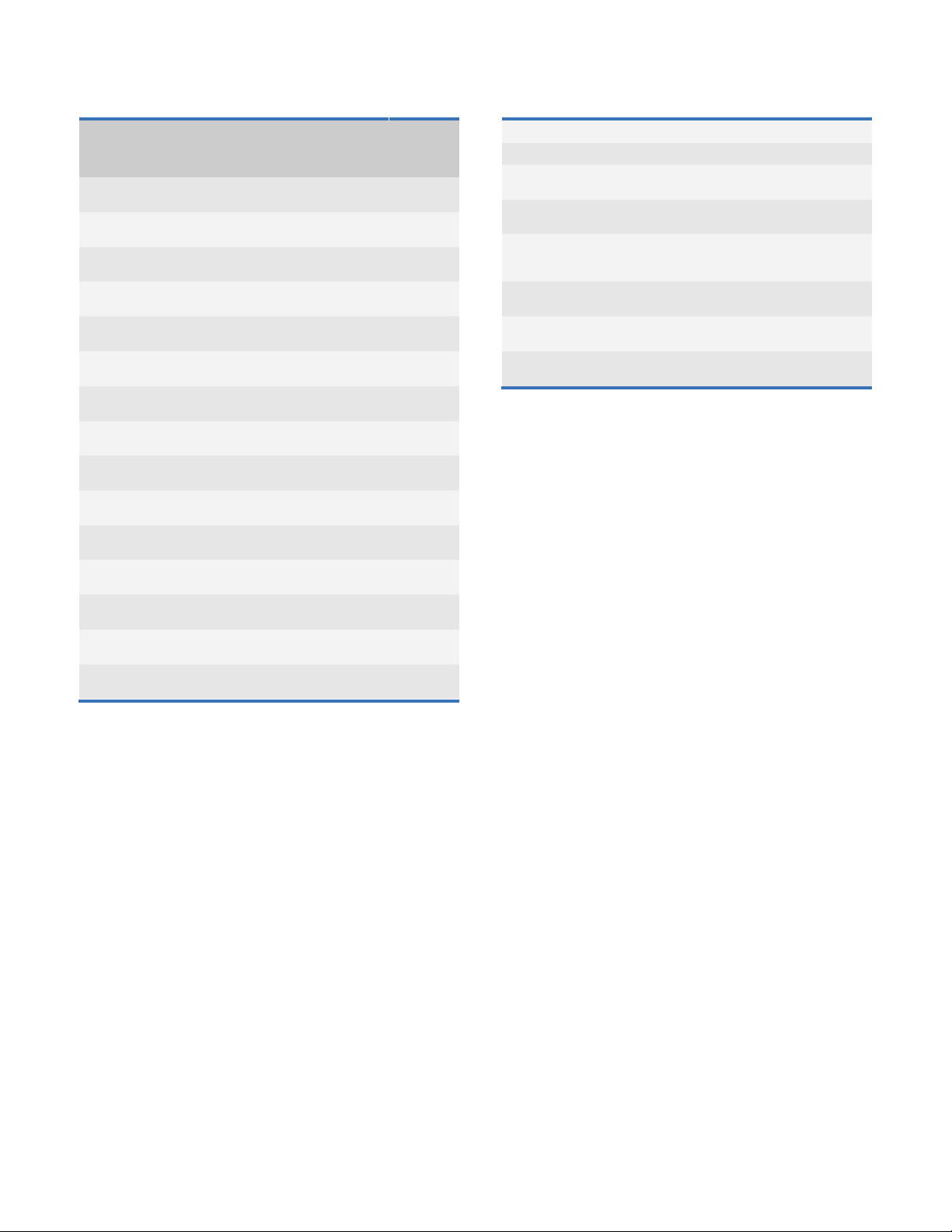

Model1

Dimensions, inches (cm)

Boxed

A

B2

C3

Weight

lbs (kg)

AG2540TM

40.0

(101.6)

0.75

(1.90) OD

2.4

(6.1) 5 (2.3)

AG4025T

25.0

(63.5)

0.625

(1.59)

3.9

(9.9) 5 (2.3)

AG4026F

26.0

(66.7)

0.625

(1.59)

3.9

(9.9) 6 (2.7)

AG4040C

40.0

(101.6)

0.625

(1.59)

3.9

(9.9) 8 (3.5)

AG4040FM

40.0

(101.6)

0.75

(1.90) OD

3.9

(9.9) 8 (3.5)

AG4040FM WET

40.0

(101.6)

0.75

(1.90) OD

3.9

(9.9) 8 (3.5)

AG4040TM

40.0

(101.6)

0.75

(1.90) OD

3.9

(9.9) 8 (3.5)

AG8040C

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

AG8040F

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

AG8040F WET

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

35

(16)

AG8040F 400

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

AG8040F 400 WET

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

35

(16)

AG8040N

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

AG8040N 400

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

AG8340F 400

40.0

(101.6)

1.125

(2.86)

8.3

(21.1)

42

(19.1)

Typical Operating Pressure

200 psi (1,379 kPa)

Typical Operating Flux

10-20GFD (15-35LMH)

Maximum Operating Pressure

Tape 450 psi (3,103 kPa)

Other outerwrap: 600 psi (4,137 kPa)

Maximum Temperature

Continuous operation: 122°F (50°C)

Clean-In-Place (CIP): 122°F (50°C)

pH Range

Optimum rejection: 7.0-7.5,

Continuous operation: 4.0-11.0,

Clean-In-Place (CIP): 2.0-11.5

Maximum Pressure Drop

Over an element: 12 psi (83 kPa)

Per housing: 50 psi (345 kPa)

Chlorine Tolerance

1,000+ ppm-hours,

Dechlorination recommended

Feedwater

NTU < 1

SDI < 5

Table 2: Dimensions and Weight

Table 3: Operating and CIP parameters

1

These elements are bagged dried, unless specified WET, before shipping.

2

Internal diameter unless specified OD (outside diameter).

3

The element diameter (dimension C) is designed for optimum performance in

GE pressure vessels. Other pressure vessel dimension and tolerance may

result in excessive bypass and loss of capacity.

Page 2 FS1262EN

Loading...

Loading...