GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 1

AC-23 Accelerometer

User Manual

Company:

GeoSIG Ltd

Wiesenstrasse 39, 8952 Schlieren, Switzerland

Tel: +41 44 810 21 50, Fax: +41 44 810 23 50, E-mail: info@geosig.com

Author:

Serge Rudaz

Checked:

Markus Epp

Approved:

Johannes Grob

Distribution:

GeoSIG Ltd (1), Customer on request

GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 2

DOCUMENT REVISION

Date

Version

Author

Checked

Description

15.04.95

0

SR

JP

Created

11.04.00

1

JG

GCO

Format/Font changes

05.07.01

2

SR

JG

Update pictures and connector description for new 12 poles

version.

Added principle of operation.

30.05.2003

3

LG

JG

Changes for new housing

06.06.2003

4

LG

JG

Corrected axis polarity for new housing. Movement in axisdirection gives positive response.

05.12.2003

5

SR

JG

Updated

21.04.2004

5

JG

JG

Reformatted

05.05.2006

6

SR

JG

Adapted to new DH housing

12.12.2007

7

TB

TB

Adapted to new sensor housing

File name and title change

13.12.2007

8

TB

TB

Detailed sensor full scale & offset adjustment

18.03.2011

9

THL

TAB

Board connector pinning added

05.08.2013

10

JLT

MAE

Update PCB to V3 and orientation of axis

15.10.2014

11

SER

MAE

Adjusted formatting of figures.

29.07.2015

12

PAT

JON

Picture update

07.05.2019

13

VAG

ALB

Mounting section updated

27.05.2019

14

JOG

TAB

P/N correction on item 1.2

GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 3

TABLE OF CONTENT

1 ELECTRICAL CONNECTION................................................................................................................... 4

1.1 MAIN CONNECTOR PIN ASSIGNMENT ........................................................................................................ 4

1.2 MATING CONNECTOR ............................................................................................................................... 4

2 MOUNTING ............................................................................................................................................... 5

3 THEORY OF OPERATION ....................................................................................................................... 6

3.1 INTRODUCTION ........................................................................................................................................ 6

3.2 PRINCIPLE ............................................................................................................................................... 6

3.3 BASIC SPECIFICATIONS ............................................................................................................................ 7

4 ELECTRICAL CONFIGURATION ............................................................................................................ 8

5 OFFSET ADJUSTMENT:.......................................................................................................................... 9

6 MOUNTING (DOWNHOLE SENSOR) .................................................................................................... 10

6.1 BOREHOLE PREPARATION ...................................................................................................................... 10

6.2 INCLINOMETER TUBE INSTALLATION ........................................................................................................ 11

6.3 SENSOR INSTALLATION .......................................................................................................................... 12

6.4 INCLINOMETER CASING ASSEMBLY .......................................................................................................... 13

6.5 AXIS ORIENTATION ................................................................................................................................. 15

7 INSTALLATION VERIFICATION ............................................................................................................ 15

The sensor housing provides no protection against explosive atmosphere. It must not be directly operated in

area where explosive gases are present.

GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 4

1 Electrical Connection

1.1 Main Connector Pin Assignment

All the AC-2X accelerometers use the same 12 pins male metallic style connector as the AC-43 and AC-63.

The connector pins standard assignments are as follows:

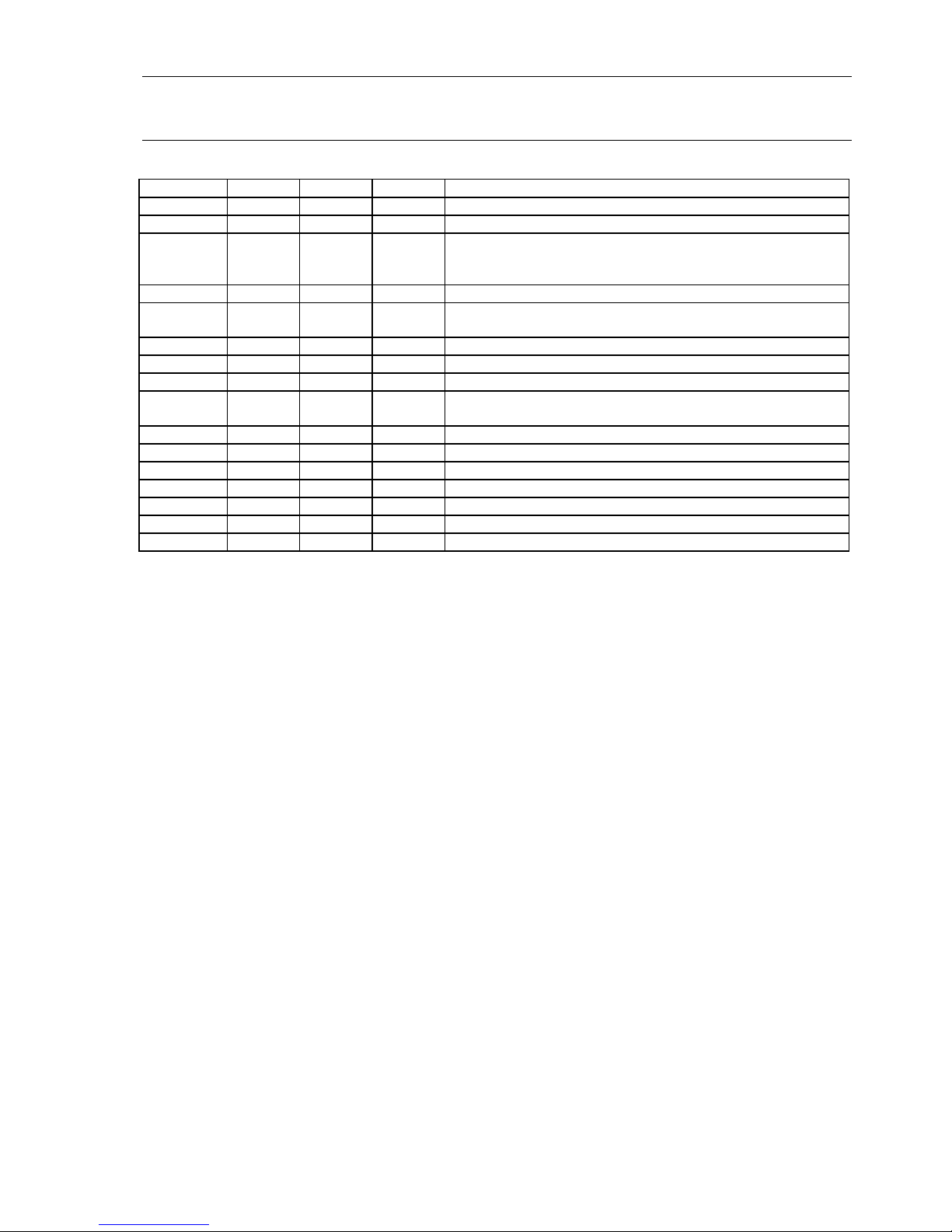

Pin

SIGNAL

Comment

Colour

1

OUTPUT X (+)

0 V ± 5 V voltage output, 47 output impedance

White

2 OUTPUT X (-)

0 V ± 5 V voltage output inverted, 47 output impedance

Brown

3 OUTPUT Y (+)

0 V ± 5 V voltage output, 47 output impedance

Green

4 OUTPUT Y (-)

0 V ± 5 V voltage output inverted, 47 output impedance

Yellow

5

OUTPUT Z (+)

0 V ± 5 V voltage output, 47 output impedance

Grey

6

OUTPUT Z (-)

0 V ± 5 V voltage output inverted, 47 output impedance

Pink

7

TEST INPUT

Test input, output will result in a sensor step response

Blue

8 GROUND

Ground, not connected to mechanical ground

Red 9

+12 VDC power

Power input, +10 to +15 VDC range, 50 mA @ +12 VDC

Black

10

GROUND

Ground, not connected to mechanical ground

Violet

11

AUX

Auxiliary input (reserved)

- 12

GROUND

Ground, not connected to mechanical ground

-

Table 1 AC-2X Connector Pin Assignment

In case no connector is mounted at the cable end (like usually for down-hole version), the colour code is

given in the above table.

1.2 Mating connector

GeoSIG

P/N #J_CIR.012.007.F

CONINVERS

P/N RC 12 S 1 N 12L 300

Binder Serie 623

P/N 99-4622-00-12

Figure 1, Mating connector

Cable gland nut has to be determined as per cable external diameter and must be separately ordered. It has

also to provide the cable shield connection to connector case.

GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 5

2 Mounting

Figure 2, AC-2X housing

Small size and single bolt attachment allow the AC-2X to be easily installed saving installation time. Levelling

is accomplished via three-point levelling screws.

a

Do not overtighten the three-point levelling mechanism. This may damage the sensor.

165.0

68.0

40.0

23.0

20.0

R 1.5

195.0

14.0

28.0

181.5

15.0

4.0

10.0

41.0

112.0

80.0

96.0

99.0

16.0

6.0

15.0

165.0

6.0

3 x M6

ø 15

152.0

15.0

ø9

R 3.0

R 3.0

R 1.5

R 6.5

76.0

41.0

56.0

19.0

+0.1

-0.0

20.3

+0.2

-0.2

Minimum Space Allowance for the Connector and Cable:

Sensor with Connector: 300 mm from sensor housing

Sensor with Cable Inlet: 200 mm from sensor housin

*

*

Figure 3, Sensor housing dimensions

The accelerometers must be firmly mounted to a surface and levelled, as the application requires. Check to

be sure that the accelerometer is aligned to produce the desired output signals. Acceleration in the direction

indicated on the case will produce a positive output signal. The orientation definitions as shipped are:

X = East, Y = North and Z = Vertical (Up).

The accelerometer has single-bolt, 3-feet-levelling mechanism.

GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 6

The surface should have a scribed north/south orientation line accurately surveyed from reliable markers.

The X-axis of the sensor has to be pointed to East or to any other main direction of the structure to monitor.

One M8 expanding nut rock anchor must be used for the sensor fixation.

3 Theory of operation

3.1 Introduction

The AC-23 sensor package is a triaxial accelerometer designed for free field and industrial applications

regarding STRONG-MOTION earthquake survey, monitoring and research. This sensor is well suited for

applications where a high sensitivity is required.

The AC-23 sensor can be optionally installed into a rugged protective housing. This optional protective

housing is in stainless steel for optimal environmental resistance. As option, the protective housing could be

executed with an IP68 grade for Free field location where the possibility exists of housing submersion.

The sensor could be installed on floor or wall with a modification of the axis organization. With the help of the

TEST LINE, the complete sensor can be very easily completely tested. Full scale can be field selected by the

user with jumpers.

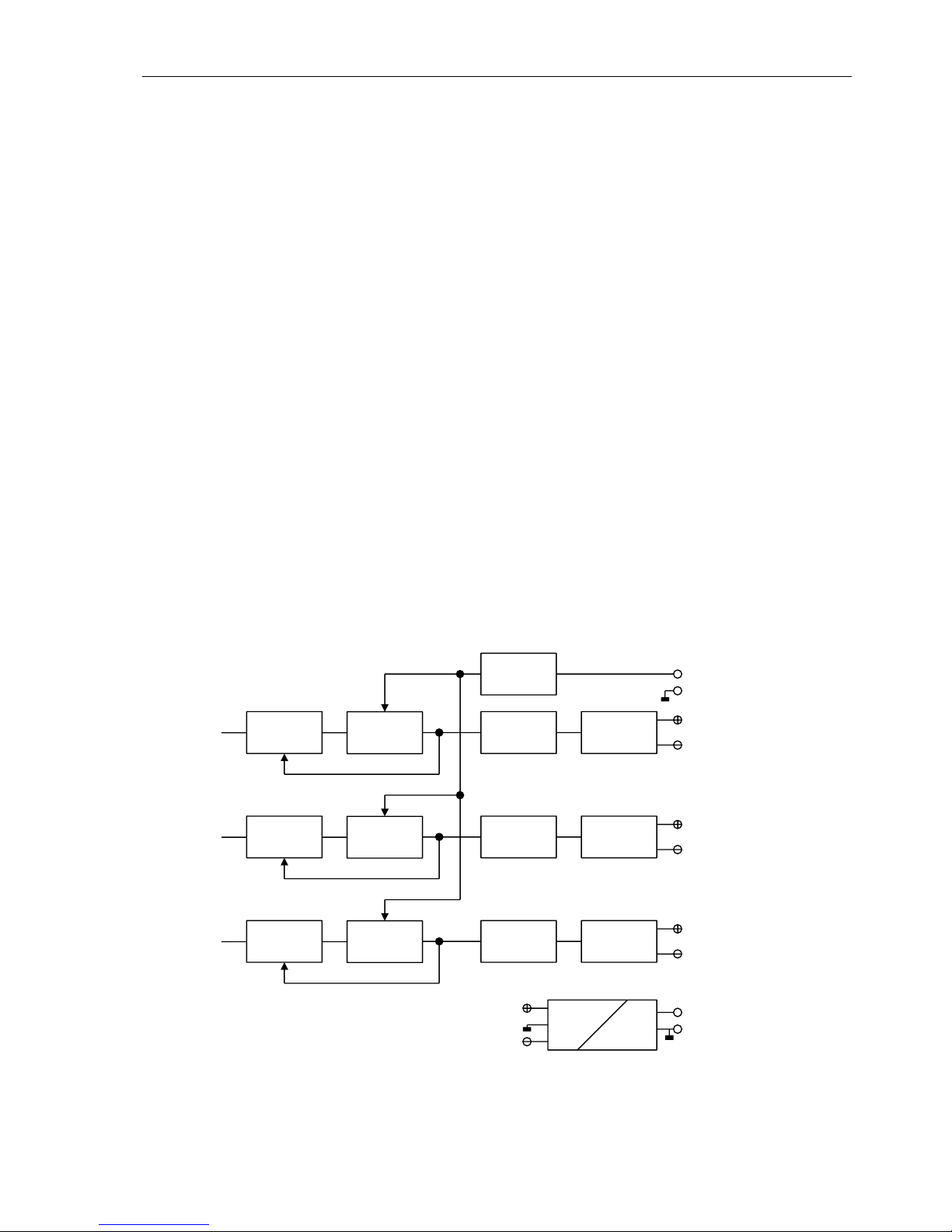

3.2 Principle

The accelerometer is based on a geophone mass-spring system with electronic correction. This type of

sensors gives a very good stability in temperature and aging because of the very simple principle. It uses a

damped mass spring oscillator called "Geophone" to convert seismic movement into electrical value

proportional to the velocity. In a graphic with constant acceleration, the geophone response will present a

maximum at the frequency called "Natural Frequency" which is the resonant frequency of the mass-spring

oscillator. Above and below this point, the response will decay with one pole slope (±20 dB / decade). The

corrector will over-damp the geophone by applying a voltage with opposite polarity over the geophone and

the output response will be flat and proportional to the acceleration in this frequency band.

Motion on

the X axis

geophone

4.5 Hz

Note : all inputs, outputs & power supply entry are surge protected.

Feedback

amplifier

Low pass

filter

Output

amplifier

Differential

Output to

recorder

Test input

Pulse

scaling

Motion on

the Y axis

geophone

4.5 Hz

Feedback

amplifier

Low pass

filter

Output

amplifier

Differential

Output to

recorder

Motion on

the Z axis

geophone

4.5 Hz

Feedback

amplifier

Low pass

filter

Output

amplifier

Differential

Output to

recorder

Power

supply

9/15 Vdc

+8 V

- 8 V

Figure 4 AC-23 Sensor block diagram

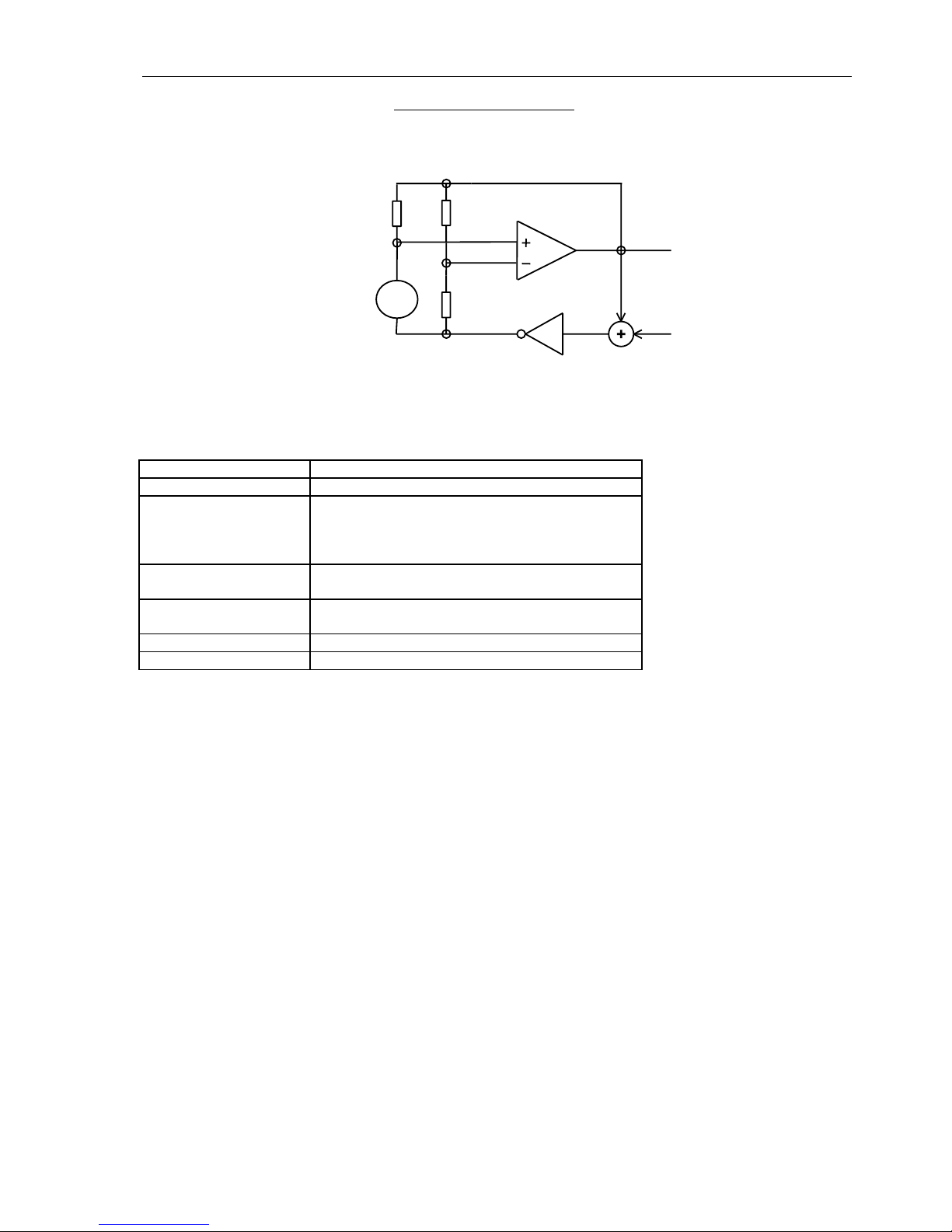

The geophone is connected in a resistor bridge, driven by a feedback amplifier, which applies the amplified

bridge differential signal in opposite polarity. The bridge is balanced during calibration. The test-line shifts the

voltage at one side of the bridge, which produces a current flow in the geophone.

GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 7

This current flowing in the Geophone will move the seismic mass. The movement of the mass generates a

voltage across the Geophone, which is detected by the differential amplifier and induces an output signal.

TEST LINE

GEOPHONE

OUTPUT

Feedback loop

Amplifier

Inverter

Figure 5 TEST INPUT configuration

3.3 Basic specifications

Detailed specifications

AC-23

Input range

Acceleration, ±0.2, ±0.5, ±1.0 g, ±2.0 g or ±4.0 g

Output range

0 ± 10 Volt differential output OR

0 ± 5 Volt differential output OR

2.5 ± 2.5 Volt single-ended output OR

0 – 20 mA Current-loop (OPTION)

Frequency range

from 0.1 Hz to 100 Hz

(optional 200 Hz)

Protections

All connectors pins protected by Transzorb

diodes and VDR

Power supply

10 – 15 VDC

Current drain

Typical 30 mA @ 12 VDC

GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 8

4 Electrical configuration

The full scale can be adjusted without gain re-calibration by means of jumpers with fixed 0.1% precise

amplifiers.

Figure 6, Full scale setting

The full scale adjustment can be:

Full scale Jumper position

0.1 g 1-2

0.2 g 3-4

0.5 g 5-6

1.0 g 7-8

2.0 g 9-10

4.0 g 11-12

Full scale Y:

1-2: +/- 0.1 g

3-4: +/- 0.2 g

5-6: +/- 0.5 g

7-8: +/- 1.0 g

9-10: +/- 2.0g

11-12: +/- 4.0g

Full scale Z:

1-2: +/- 0.1 g

3-4: +/- 0.2 g

5-6: +/- 0.5 g

7-8: +/- 1.0 g

9-10: +/- 2.0g

11-12: +/- 4.0g

Full scale X:

1-2: +/- 0.1 g

3-4: +/- 0.2 g

5-6: +/- 0.5 g

7-8: +/- 1.0 g

9-10: +/- 2.0g

11-12: +/- 4.0g

Z

Y

X

GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 9

5 Offset adjustment:

Figure 7, Offset potentiometer location

After the new full scale has been selected, the offset must be checked and eventually the potentiometer °

must to be re-adjusted to remove any small offset change at output.

In such case, be sure be sure to identify correctly the offset potentiometers and don't touch any other

potentiometers as it would void its calibration.

Connect a Digital Voltmeter (DVM) as shown on the above figure and adjust the offset potentiometers so that

the DVM readings stay within the ranges indicated in the following table, according to the sensor output

range given in Section 3.3:

Sensor Label*

Sensor Output Range

DVM Reading

±10 Volts

0 ± 10 Volt differential output

0.00 ±0.05 V

±5 Volts

0 ± 5 Volt differential output

0.00 ±0.05 V

2.5 ±2.5 Volts

2.5 ± 2.5 Volt single-ended output

2.50 ±0.02 V

10 ±10 mA

0 - 20 mA Current-loop (OPTION)

2.50 ±0.02 V

1

*:The output range is written on the sensor label.

1

The DVM must be connected on the load (at recorder) for current loop.

DVM

+

Offset

Adjust

Pin 12

Pin 1

Z Y X

GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 10

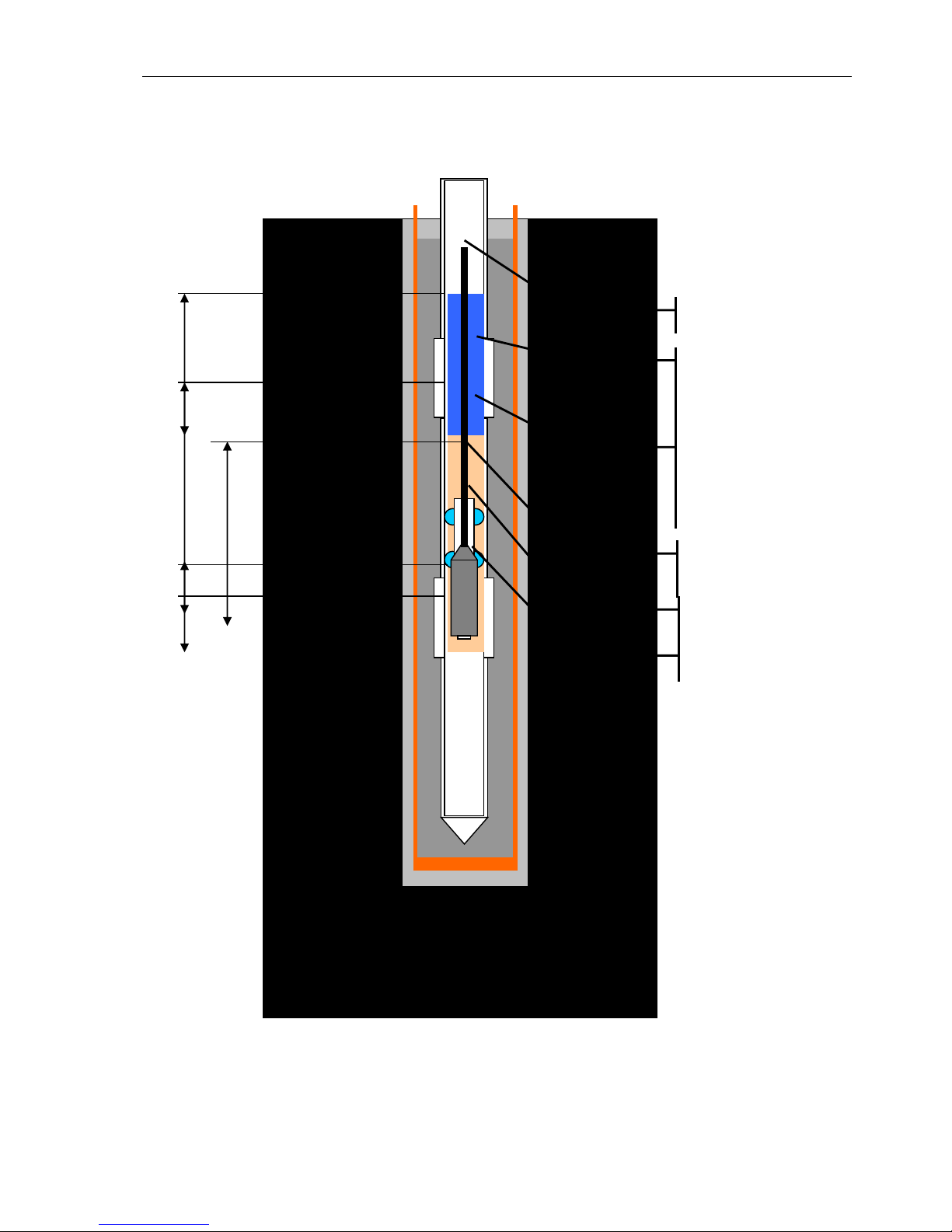

6 Mounting (downhole sensor)

The sensor must be installed in a 3-inch inclinometer tube. At least a 100 mm

borehole must be drilled. Depending on the soil condition, it could be required

to drill a higher dimension hole and to implement a 120 mm PVC casing to

insure a free path when the inclinometer tube is inserted in the borehole.

6.1 Borehole preparation

Note: Do not scale the drawing.

Do not allow concrete mix from casing sealing to enter the casing.

Cap

Casing

sealing

PVC tubing

Minimum free

diameter inside

casing: 120 mm.

Depth of drilled borehole

12 cm

Surface level

GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 11

6.2 Inclinometer tube installation

Note: Do not scale the drawing. The number of sections is only an example.

30 cm

Inclinometer tube

in 3 meters

section.

Coupling elements,

fixed with “pop”

rivets. Must be fully

sealed to avoid any

concrete inside the

tube.

Bottom cap.

Must be fully

sealed to avoid any

concrete inside the

tube.

Sealing

(concrete

mix) of tube

3 meters

GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 12

6.3 Sensor installation

Note: Do not scale the drawing. The number of sections is only an example.

About 70 cm

Sand (50 cm)

Guiding system

Sensor AC-23-DH,

diameter 54 mm.

Cable

Concrete sealing of

sensor. At least 1

meter above the

sensor.

The maximum water

level above the

sensor must be

maximum 50

meters.

50 m maximum

About 50 cm About 170 cm

GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 13

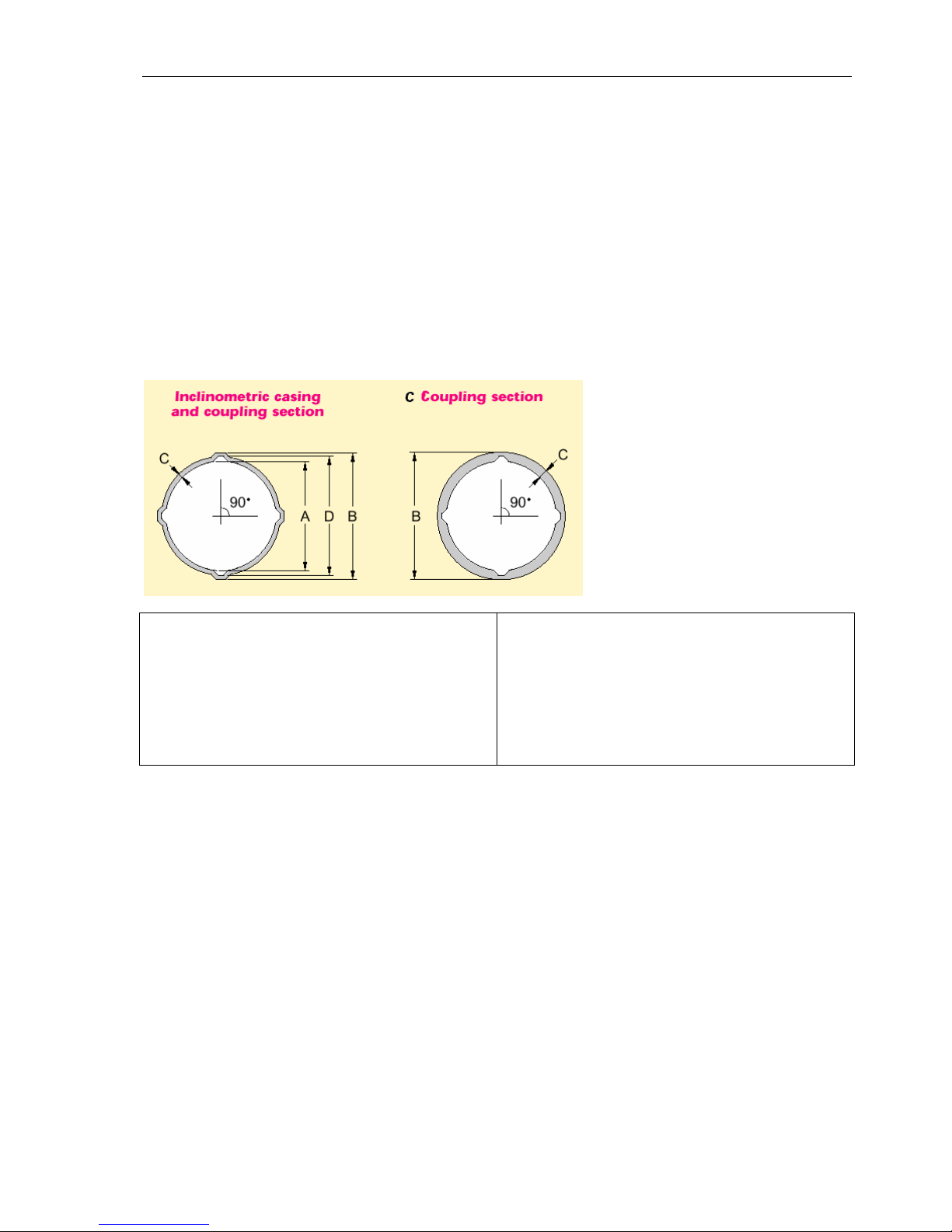

6.4 Inclinometer casing assembly

The borehole must have a casing or the soil must insure that a free path for the inclinometer tube is

warranted. It is recommended to insert the inclinometer tube as soon the borehole is ready.

The free path for the inclinometer tube should be 10 to 15 cm, 12 cm typically.

It could be required to insert some water in the casing to sustain the water pressure at the bottom of the

borehole.

The inclinometer tube should be mounted with a maximum deviation of ±1° / 3 meters and with a maximum

deviation from vertical at sensor location of ±3°. The functional limit for the sensor is ±9°.

The water level in the inclinometer tube should be maximum 50 meters, including fast elevation due to heavy

rain.

It is recommended to use the optional assembly kit that GeoSIG can provide (optional) with the inclinometer

tube. It will insure a perfect sealing of the tube elements and would avoid concrete mix to enter the tube.

The dimensions of the inclinometer tube are:

INCLINOMETRIC CASING (3 m section)

A Inner diameter 76.1 mm

B Groove outer diameter 86.4 mm

C Thickness 2.2 ±0.1 mm

D Groove inner diameter 82.0 mm

Length 3 meters

Weight 1.4 Kg/m

Borehole diameter > 120 mm

COUPLING ELEMENT

A Inner diameter 81.0 mm

B Outer diameter 92.0 mm

C Thickness 2.2 mm

D Groove inner diameter 87.6 mm

Length 300 mm

Weight 0.5 kg

GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 14

The following elements will be inserted in the borehole.

Figure 8

Torpedo (the sensor and its cable)

Figure 9

Guiding system

Figure

10

Inclinometer tube

GeoSIG Ltd GS_AC-23_UserManual_V14.docx/27.05.2019

AC-23 Accelerometer Manual Page 15

6.5 Axis orientation

Figure 11, Down hole axis orientation

Before the sensor is inserted in the inclinometer tube, the guiding system must be mounted bellow it. The

guiding system must be orientated before the insertion.

The engraved mark on bottom cover is showing the positive direction of X axis:

View for top:

7 INSTALLATION VERIFICATION

Please note that temperature compensation device is mounted for each axis inside the sensor and that the

temperature in the sensor has to stabilize before accurate measurement can be done. Allow at least half an

hour for temperature stabilization.

Mark

Y axis

X axis

Z axis:

Vertical,

positive up

X axis

Engraved

mark

Y axis

Z axis

Loading...

Loading...