Georgia-Pacific Engineered Lumber Canada User Manual

GP LAM® LVL

installation Guide

WOOD I BEAM™ JOISTS

WHAT YOU DON’T

™

SEE MATTERS

canadian

Installation Instructions

Storage, Handling & Safety Guidelines

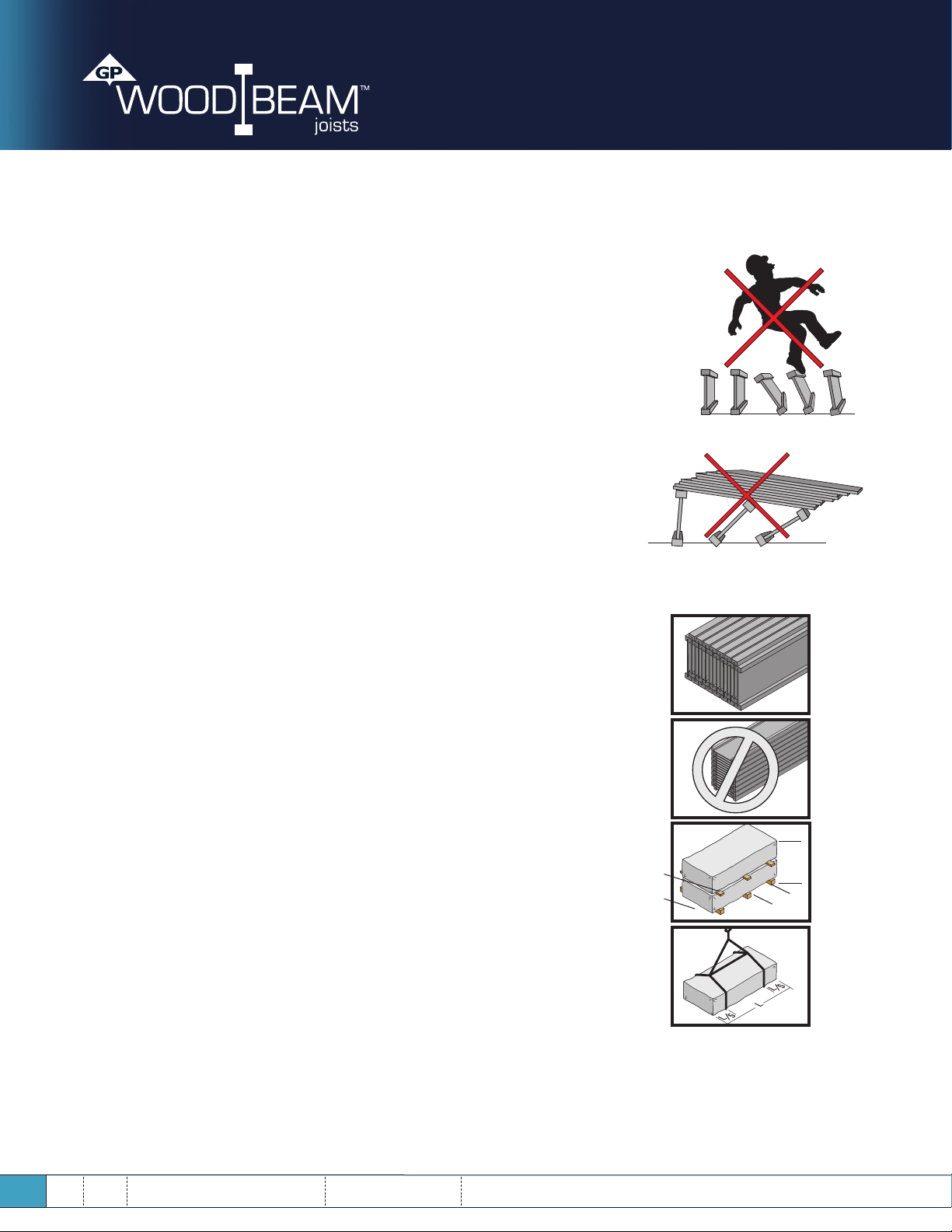

Safety Tips

1. Walking on the joists should not be permitted until they are properly braced.

2. Lateral restraint, such as an existing deck or braced end wall, must be established at the

ends of the bay. Alternatively, temporary or permanent sheathing may be nailed to the

first 4 feet of the joists at the end of the bay.

3. All hangers, rim boards, rim joists and blocking at the supports of the joists must be

installed and nailed properly.

4. During installation, a minimum 1x4 temporary brace at least 8 feet long is required.

Temporary bracing members should be spaced at no further than 10*-0( o.c. and nailed

to each joist with two 8d nails (10d box nails if bracing thickness exceeds 1().

Lap bracing ends and anchor them to temporary or permanent sheathing. Remove the

temporary bracing as the permanent sheathing is attached.

5. The ends of cantilevers must be temporarily braced on both the top and bottom flanges.

6. Never overload sheathed joists with loads that exceed design loads.

7. Do not ship or install any damaged I-joists.

8. When stacking construction material, stack only over beams or walls, NOT on

unsheathed joists.

Storage & Handling

1. CAUTION: Wrap and joists are slippery when icy or wet.

2. Store bundles upright on a smooth, level, well-drained and supportive surface to protect

from the weather (sun and precipitation). Keep covered and strapped until installed.

3. Keep bundles above ground to minimize the absorption of ground moisture and allow air

circulation.

4. Re-cover unused products with bundle wrap. Repair damage to bundle wrap with tape,

more bundle wrap, plastic or weatherproof covering.

5. Place 2x or LVL spacers (at a maximum of 10* apart) under bundles stacked on the

ground, and between bundles stored on top of one another.

6. All handling of joists with a forklift or crane should be done carefully by lifting from below

the bottom of the bundle.

7. Joists should remain upright (web vertical) during handling.

8. Avoid excessive bowing during all phases of handling and installation (i.e., measuring, sawing,

or placement).

9. Damage may result if the I-joist is twisted or a load is applied to it while it’s lying flat.

10. An MSDS is available at www.buildgp.com.

11. When handling I-joists with a crane on the job site (“picking”), take a few simple

precautions to prevent damage to the I-joists and injury to your work crew. Pick I-joists

in bundles as shipped by the supplier. Orient the bundles so that the webs of the I-joists

are vertical. Pick the bundles at the 5th points, using a spreader bar if necessary.

Align stickers

one above

the other

Hard, dry,

level surface

10* max.

10*-0(

max.

GeorGia-Pacific Wood Products

2

PaGe

JaN 2014

caNadiaN iNstallatioN iNstructioNs

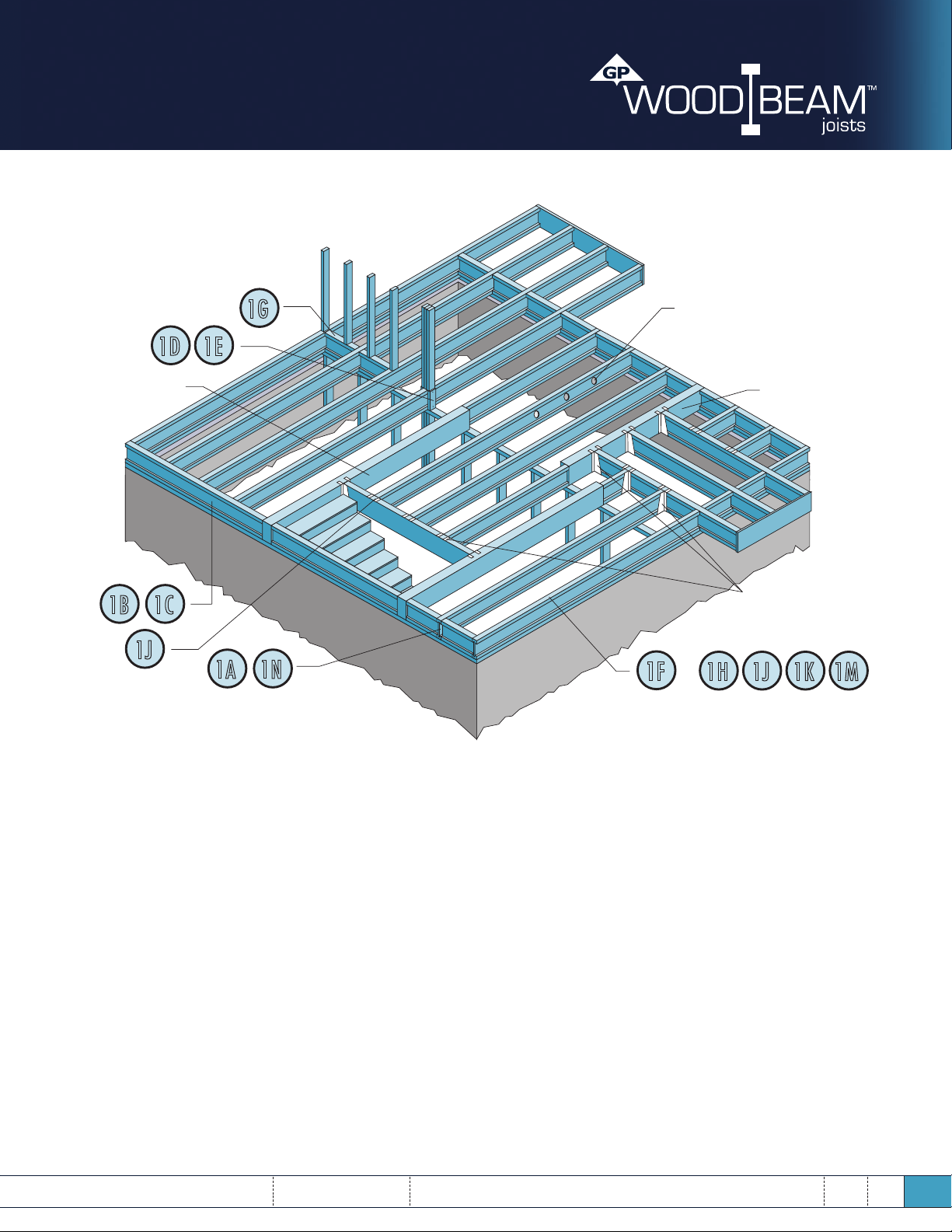

Floor details

Some framing requirements such as

erection bracing and blocking panels

have been omitted

for clarity.

1E

1D

Glulam or multiple

Structural Composite

Lumber (SCL)

headers

1C1B

1G

Holes may be cut in web for

plumbing, wiring and duct work.

NOTE: Never cut or notch flanges.

Glulam or multiple

SCL headers

Use code approved hangers

1J

1N1A

Floor Installation Guidelines

1. Before laying out floor system components, verify that

I-Joist flange widths match hanger widths. If not, contact

your supplier.

2. Except for cutting to length, never cut, drill, or notch

I-Joist flanges.

3. Install I-Joists so that top and bottom flanges are within

1

⁄2" of true vertical alignment.

4. I-Joists must be anchored securely to supports before

floor sheathing is attached, and supports for multiplespan joists must be level.

5. Minimum bearing lengths: 1

1

⁄2” for intermediate bearings.

3

6. When using hangers, seat I-Joists firmly in hanger

bottoms to minimize settlement.

1

7. Leave a

8. Concentrated loads greater than those that can

⁄16” gap between the I-Joist end and a header.

normally be expected in residential construction should

only be applied to the top surface of the top flange.

Normal concentrated loads include track

3

⁄4” for end bearings and

lighting fixtures, audio equipment and security cameras.

Never suspend unusual or heavy loads from the

I-Joist’s bottom flange. Whenever possible, suspend

all concentrated loads from the top of the I-Joist. Or,

attach the load to blocking that has been securely

fastened to the I-Joist webs.

9. Never install I-Joists where they will be permanently

exposed to weather, or where they will remain in direct

contact with concrete or masonry.

10. Restrain ends of floor joists to prevent rollover. Use rim

board or equivalent, rim joists or I-Joist blocking panels.

11. For I-Joists installed over and beneath bearing walls, use

full depth blocking panels, rim board, or squash blocks

(cripple members) to transfer gravity loads through the

floor system to the wall or foundation below.

12. Due to shrinkage, common framing lumber set on edge

may never be used as blocking or rim boards. I-Joist

blocking panels or other engineered wood products

– such as rim board – must be cut to fit between the

I-Joists, and an I-Joist compatible depth selected.

1F

13. Provide permanent lateral support of the bottom flange

of all I-Joists at interior supports of multiple-span joists.

Similarly, support the bottom flange of all cantilevered

I-Joists at the end support next to the cantilever

extension. In the completed structure, the gypsum

wallboard ceiling provides this lateral support. Until the

final finished ceiling is applied, temporary bracing or

struts must be used.

14. If square-edge panels are used, edges must be supported

between I-Joists with 2 x 4 blocking. Glue panels to

blocking to minimize squeaks. Blocking is not required

under structural finish flooring, such as wood strip

flooring, or if a separate underlayment layer is installed.

15. Nail spacing:

• Space nails installed to the flange’s top face in

accordance with the applicable building code

requirements or approved building plans.

• If nails must be installed into the sides of flanges,

spacing shall not be closer than 3 inches o.c. for 8d

common nails, and 4 inches o.c. for 10d common nails.

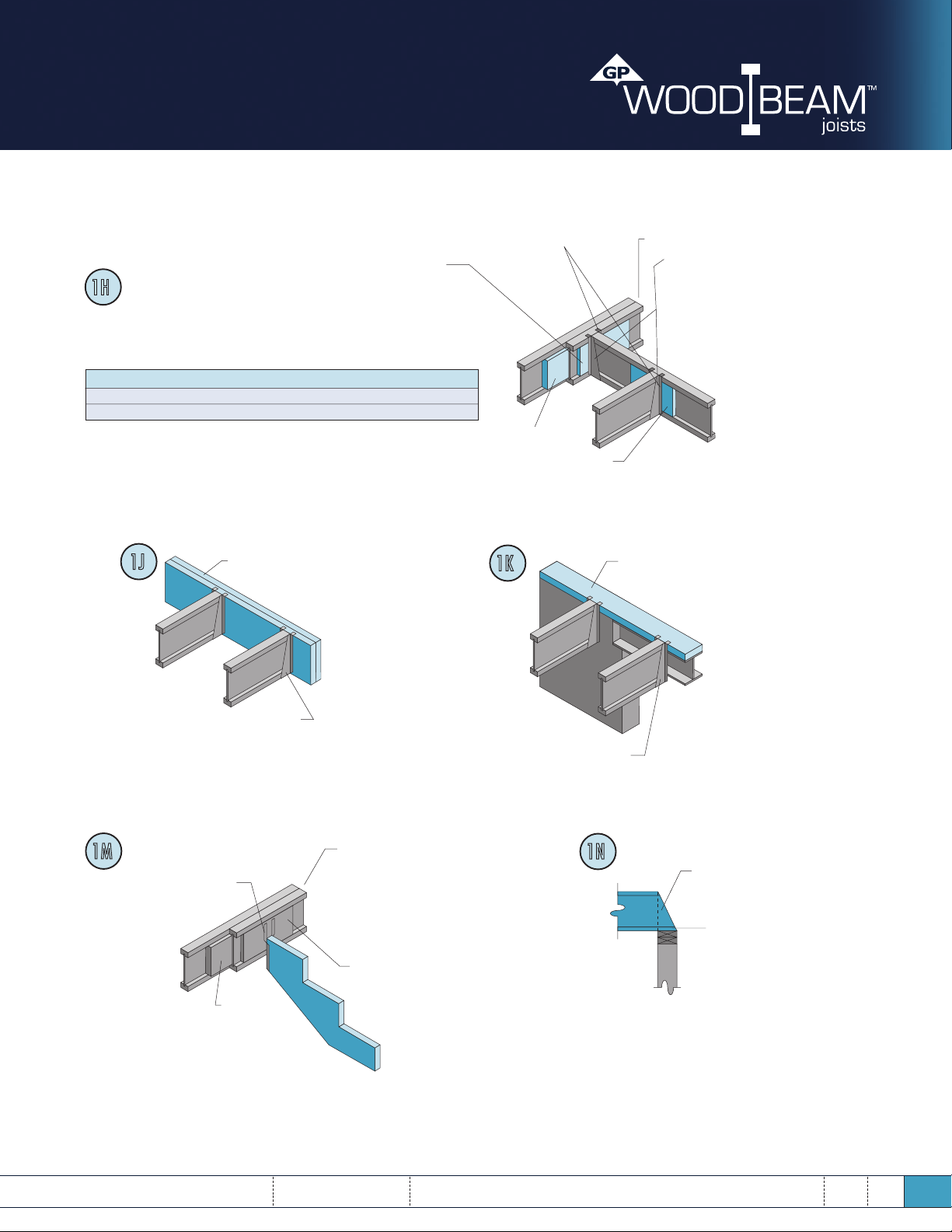

1M1K1J1H

georgiA-pAcific Wood products

JAN 2014

cANAdiAN iNstAllAtioN iNstructioNs

pAge

3

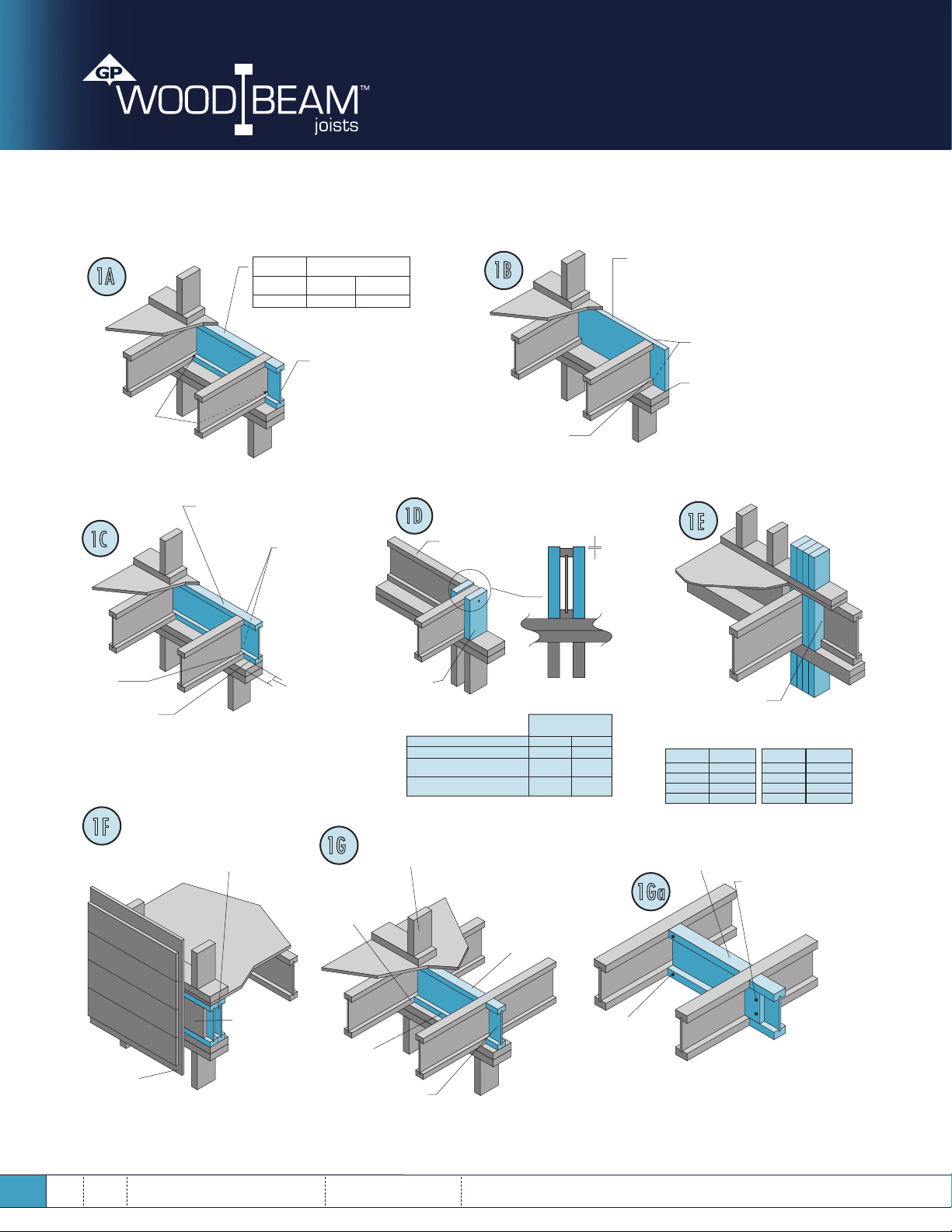

Floor Details (continued)

All nails shown in the details below are assumed to be common nails unless otherwise noted. 10d box nails may be substituted for 8d common shown

in details. Individual components not shown to scale for clarity.

1

/

1

8" APA Rim

Board Plus

8090

1B

Blocking Panel

1A

or Rim Jost

Depth (in.)

up to 16

Maximum Factored

Uniform Vertical Load (plf)

WI 40

WI 60, WI 80

3340

8d nails @ 6" o.c.

(when used for lateral

Attach I-Joist to

top plate per 1B

shear transfer, nail to

bearing plate with same

nailing as required

for decking)

One 8d face

nail at each

side at bearing

To avoid splitting flange, start nails at least 1½"from end of I-Joist.

Nails may be driven at an angle to avoid splitting of bearing plate

For APA Rim Board Plus,

1

1

/8" thick, up to 16" depth

allowable factored vertical

load transfer

= 8090 plf.

One 8d nail at top and

bottom flange

Attach Rim Board to

top plate using 8d box

toe nails @ 6" o.c.

Rim joist vertical load transfer

(see detail 1A for capacities)

1C

Attach I-Joist

per 1B

Attach rim joist to

top plate per 1A

For single I-Joist, see detail 1A

for capacities. For double I-Joist,

1F

the table capacity may be doubled.

Filler block is not required

for this detail.

Provide backer

for siding

Wall

sheathing,

as required

Rim Board may be used in lieu of I-Joists.

Backer is not required when Rim Board is used.

attachment

unless nailable

sheathing is used.

Attach rim

joist to floor

joist with one

nail at top and

bottom. Nail

must provide

1" min.

penetration into

floor joist. Toe nails

may be used.

Min. 1 ¾"

bearing

required

1G

Joist attachment

per detail 1B

Blocking panel

see details 1A and 1B

for vertical load capacities.

1D

Rim Board blocking

panel per 1A

Squash block

Provide lateral bracing

per 1A, 1B or 1C

Pair of Squash Blocks

2x Lumber

1

/

1

8

" APA Rim board, Rim Board

Plus, or Rated Sturd-I-Floor 48 o.c.

1" APA Rim Board or

Rated Sturd-I-Floor 32 o.c.

Load bearing wall above shall align vertically

with the wall below. Other conditions such as

offset walls are not covered by this detail.

Blocking required over all interior supports

under load-bearing walls or when floor

8d nails

at 6" o.c.

to top plate

Vertical load transfer capacity per

pair of squash blocks as shown:

vertical load per pair of

3½" wide 5½" wide

joists are not continuous over support.

In high seismic areas blocking

is required at all intermediate

supports.

1E

1

/

"

16

for lumber

squash

blocks

Transfer load

from above to

bearing below.

Match bearing

area of squash

blocks in floor

cavity to post above.

Maximum factored

squash blocks (lb)

5800

9500

4500

5800

4000 5800

Method 1:

One 8d nail toe nailed at each

side of top and bottom flange

at each end of I-Joist blocking.

Caution: Effective toe nailing

may be difficult to achieve due to limited access of pneumatic nailers.

The builder shall evaluate installation for potential of nail squeak.

Notes:

1- I-Joists do not always need blocking (bridging) between supports. I-Joist blocking must be installed

only where specified by the building designer.

2- Use of construction adhesive is recommended at wood-to-wood contact areas.

3- It shall be permitted to offset (stagger) I-Joist blocking up to the flange width. Nailing

thru the joist flange into the ends of the I-Joist blocking is not permitted.

Blocking panels or Rim Board are also required

for uniform vertical and / or lateral load transfer.

(See details 1A, 1B or 1C as applicable.)

Squash block

I-Joist blocking at mid-span (or at other locations between supports)

may be used to reduce vibration. Two recommended methods

of attachment are shown. Other fastening methods are possible.

1Ga

Factored

load (lbs.)

size

(1) 2 x 42 900

(2) 2 x 45 800

(3) 2 x 48 700

(4) 2 x 4 11 600

Squash block

size

(1) 2 x 64 750

(2) 2 x 69 500

(3) 2 x 6 14 250

(4) 2 x 6 19 000

Method 2:

Minimum two 10d nails face nailed

thru OSB web of I-Joist blocking

into 2 x 6 vertical block and clinched

(preferred) or nailed thru 2 x 6 and

clinched on back face of OSB web

of I-Joist

blocking. In

addition, nail

thru OSB web

of full-length

joist into 2 x 6

with minimum

two 10d nails.

Repeat at opposite

end of I-Joist

blocking.

Factored

load (lbs.)

GeorGia-Pacific Wood Products

4

PaGe

JaN 2014

caNadiaN iNstallatioN iNstructioNs

Floor Details (continued)

All nails shown in the details below are assumed to be common nails unless otherwise noted. 10d box nails may be substituted for 8d common shown

in details. Individual components not shown to scale for clarity.

Backer block (use if factored hanger load exceeds 360 lbs.) Before installing a

backer block to a double I-joist, drive three additional 3 inch nails through the

webs and filler block where the backer block will fit. Clinch. Install backer

1H

tight to top flange. Use twelve 3 inch nails, clinched when possible. Verify

hanger capacity with manufacturer. Maximum factored resistance for

hanger for this detail = 1620 pounds.

Backer blocks (Blocks must be long enough to permit required nailing without splitting)

Flange Width

2 "

½ 5½"

3 ½"

* Minimum grade for backer block material shall be Utility grade SPF (south) or better

for solid sawn lumber and Rated Sheathing grade for wood structural panels.

**For face-mount hangers use net joist depth minus 3¼".

1J

Material Thickness Required*

1"

1½"

7¼"

Glulam or multiple structural composite

lumber (SCL) beams

Minimum Depth**

For nailing schedules

for multiple SCL beams,

see the manufacturer’s

recommendations

Top - or face - mounted hanger Double I-Joist header

Note: Unless hanger sides laterally

support the top flange, bearing

stiffeners shall be used. Backer blocks

are not required for top mount hangers

with factored reactions less than

360 pounds.

Face-mount hangers shallower

than the joist depth shall

have full depth bearing

web stiffenners and

shall have

side flanges

at least 60%

of the joist

Filler block

Backer block required

(both sides for face-mounted hangers)

For hanger capacity see hanger manufacturer’s recommendations.

Verify double I-Joist capacity to support concentrated loads.

1K

depth.

2x plate flush with

inside face of wall

or beam

Top - or face - mounted hanger installed

per manufacturer’s recommendations

Note: Unless hanger sides laterally support the top flange,

bearing stiffeners shall be used.

Install framing anchor

per manufacturer’s

1M

recommendations

(both sides of stringer)

Filler block

Maximum factored support = 1620 pounds

Multiple I-Joist header with

full depth filler block shown.

Glulam and multiple SCL

headers may also be used.

Verify double I-Joist capacity to

support concentrated loads.

Backer block attach per 1H.

Nail with twelve 10d nails,

clinch when possible.

Top-mounted hanger installed

per manufacturer’s recommendations

1N

Note: Blocking required at

bearing for lateral support,

not shown for clarity.

Note: Unless hanger

sides laterally support

the top flange, bearing

stiffeners shall be used.

Do not bevelcut joist beyond

inside face

of wall

Attach

I-Joist

per 1B

georgiA-pAcific Wood products

JAN 2014

cANAdiAN iNstAllAtioN iNstructioNs

pAge

5

Loading...

Loading...