Georgia-Pacific APA Engineered Wood Walls User Manual

Engineered Wood

C O N S T R U C T I O N G U I D E

Engineered Wood Construction Guide

©2011 APA – THE ENGINEERED WOOD ASSOC IATION • ALL RIGHTS RESERVED. • ANY COPYING, MODIFI CATION, DISTRIBUTION OR OTHER USE OF THIS PUBLICATION OTHER THAN AS EXPRESSLY AUTHORIZED BY APA IS PROHIBITED BY THE U.S. COPYRIGHT LAWS.

Engineered wood products are a good choice for the environment. They are

manufactured for years of trouble-free, dependable use. They help reduce waste

by decreasing disposal costs and product damage. Wood is a renewable resource

that is easily manufactured into a variety of viable products.

A few facts about wood.

■

We’re growing more wood every day. Forests fully cover one-third of the

United States’ and one-half of Canada’s land mass. American landowners

plant more than two billion trees every year. In addition, millions of trees seed

naturally. The forest products industry, which comprises about 15 percent of

forestland ownership, is responsible for 41 percent of replanted forest acreage.

That works out to more than one billion trees a year, or about three million trees planted every

day. This high rate of replanting accounts for the fact that each year, 27 percent more timber is

grown than is harvested. Canada’s replanting record shows a fourfold increase in the number of

trees planted between 1975 and 1990.

■

A 200 4 Consort ium for Research on Renewable Industrial Materia ls

(CORRIM) study gave scientific validation to the strength of wood as a

green building product. In examining building products’ life cycles – from

extraction of the raw material to demolition of the building at the end of its

long lifespan – CORRIM found that wood was better for the environment than steel or concrete

in terms of embodied energy, global warming potential, air emissions, water emissions and solid

waste production. For the complete details of the report, visit www.CORRIM.org.

■

Manufactur ing wood is energ y effic ient.

Wood products made up 47 percent of all

industrial raw materials manufactured in the

United States, yet consumed only 4 percent of the

energy needed to manufacture all industrial raw

materials, according to a 1987 study.

■

Good news for a healthy planet. For every ton of wood grown, a young forest

produces 1.07 tons of oxygen and absorbs 1.47 tons of carbon dioxide.

WOOD

The Natural Choice

Life Cycle Assessment shows wood is the greenest building product.

Percent of Percent of

Material Production Energy Use

Wood 47 4

Steel 23 48

Aluminum 2 8

Wood: It’s the natural choice for the environment, for design and for strong,

lasting construction.

NOT ICE :

The recommendations

in this guide apply only

to products that bear

the APA trademark.

Only products bearing

the APA trademark

are subject to the

Association’s quality

auditing program.

ENGINEERED WOOD CONSTRUCTION GUIDE ■ FORM NO. E30V ■ © 2011 APA – THE ENGINEERED WOOD ASSOCIATION ■ WWW.APAWOOD.ORG

2

Engineered Wood Construction Guide

APA engineered wood products are used in a wide range

of construction applications. Time-tested panel products

are used in traditional wood-frame construction and in

combination with other engineered wood products and

systems. For low in-place cost, versatility, and superior

performance, engineered wood systems are simply hard

to beat.

This guide from APA is designed as a reference manual

for both residential and commercial construction. It

contains up-to-date information on APA Performance

Rated panels, glulam, I-joists, structural composite

lumber, specification practices, floor, wall and roof

systems, diaphragms and shear walls, fire-rated systems

and methods of finishing.

If what you want to know about engineered wood

construction systems isn’t fully explained here, chances

are it is in one of our many other publications. Titles cited

throughout this publication can be downloaded or ordered

from the APA website, at www.apawood.org. Or, for

individual assistance with specific application questions or

problems, contact the APA Product Support Help Desk at

(253) 620-7400.

ENGINEERED WOOD CONSTRUCTION GUIDE ■ FORM NO. E30V ■ © 2011 APA – THE ENGINEERED WOOD ASSOCIATION ■ WWW.APAWOOD.ORG

3

WALL CONSTRUCTION

Building codes require that walls resist wind pressures caused by the design wind speeds, resist wall-racking forces

and provide weather protection. This section provides details on how wood structural panels can be used to meet these

fundamental requirements.

APA Sturd-I-Wall

®

The APA Sturd-I-Wall system consists of APA RATED SIDING (panel or lap) applied direct to studs or over nonstructural fiberboard, gypsum or rigid foam insulation sheathing*. Nonstructural sheathing is defined as sheathing not

recognized by building codes for meeting both bending and racking strength requirements.

* Where panel siding is applied over foam sheathing, see APA publication APA Rated Siding Panels over Rigid Foam Insulation Sheathing, Form C465.

TABLE 19

FASTENING APA RATED SIDING (PANEL) APPLIED DIRECT-TO-STUDS OR OVER NONSTRUCTURAL

SHEATHING

APA Rated

Panel Siding

3/8 Performance

Category

APA MDO

GENER AL

APA Rated Siding

APA Rated Siding

(a) Table is based on wind pressures acting toward and away from

building surfaces, at 30-ft height in wall Zone 5 (corners) with

smallest effective area, per Section 6.4.2.2 of ASCE 7-05 and

Section R301.2 of the 2009 IRC. Stud specific gravity = 0.42.

(b) Recommendations of siding manufacturer may vary.

(c) For use as wood structural panel wall bracing, the minimum

fastener spacing of 6" o.c. at panel edges and 12" o.c. at interme-

diate supports shall be sufficient except:

(1) For braced wall section with Performance Categor y 3/8 panel

(a)(b)(c)(d)(e)

Minimum Nail

Shank

Diameter

(in.)

(f)

Penetration

in Framing

(in.)

Wall Stud

Spacing

(in. o.c.)

16 6

1.5

24 6

0.113

16 oc

16 6

2.0

24 oc

siding applied horizontally over studs 24" o.c., space nails

3" o.c. along panel edges.

24 6

Panel Nail Spacing Maximum Wind Speed (mph)

Edges

(in. o.c.)

(g)

Intermediate

Supports

(in. o.c.)

Wind Exposure Category

B C D

12 110 90 90

6 140 120 110

12 90

NP NP

6 130 110 100

12 125 105 90

6 140 120 110

12 100 85

NP

6 140 120 110

(d) Hot-dip galvanized nails are recommended for most siding

applications, see Siding Fasteners section on page 48 for more

information.

(e) Maximum stud spacing shall be in accordance with Table 21A.

(f) See Table 5, page 14, for nail dimensions.

(g) Supported panel joints shall occur approximately along the center-

line of framing with a minimum bearing of 1/2". Fasteners shall

be located 3/8" from panel edges. Siding installed over two or

more spans.

ENGINEERED WOOD CONSTRUCTION GUIDE ■ FORM NO. B360P ■ © 2011 APA – THE ENGINEERED WOOD ASSOCIATION ■ WWW.APAWOOD.ORG

45

Wall Construction

TABLE 20

APA RATED LAP SIDING APPLIED DIRECT-TO-STUDS OR OVER NONSTRUCTURAL SHEATHING

Minimum Nail

Shank Diameter

(in.)

(f)

Penetration in

Framing (in.)

Minimum

Performance

Category (in.)

Wall Stud

Spacing

(in. o.c.)

Lap Siding

Width (in.)

Maximum Wind Speed (mph)

Wind Exposure Category

6 140 120 110

3/8 16

8 140 120 110

12 120 100 90

6 140 120 110

0.113 1.5

7/16 16

8 140 120 110

12 120 100 90

6 140 120 110

7/16 24

8 120 100 90

12 90 NP NP

(a) Table is based on wind pressures acting toward and away from

building surfaces, at 30-ft height in wall Zone 5 (corners) with

smallest effective area, per Section 6.4.2.2 of ASCE 7-05 and

Section R301.2 of the 2009 IRC, Stud specific gravity = 0.42.

(b) Recommendations of siding manufacturer may vary.

(c) APA Rated lap siding rated 16 oc and 24 oc shall be used with

a maximum stud spacing of 16" o.c. and 24" o.c., respectively.

(d) Hot-dip galvanized nails are recommended for most siding applica-

tions, see Siding Fasteners section of page 48 for more information.

(e) Supported panel joints shall occur approximately along the center-

line of framing with a minimum bearing of 1/2". Fasteners shall

be located 3/8" from panel edges. Siding installed over two or

more spans.

(f) See Table 5, page 14, for nail dimensions.

(a)(b)(c)(d)(e)

B C D

TABLE 21A

MAXIMUM STUD SPACING: APA RATED SIDING (PANEL) APPLIED DIRECT-TO-STUDS OR STRUCTURAL SHEATHING

Minimum Performance

Category or

Siding Description

APA MDO GENERAL

APA Rated Siding

(a) Stud spacing may be 24" o.c. for veneer-faced siding panels.

Span Rating

3/8 16 24

15/32 24 24

16 oc 16 16

24 oc 24 24

Maximum Stud Spacing (in.) for Vertical Rows of Nails

Parallel to Supports Perpendicular to Supports

(a)

TABLE 21B

APA RATED SIDING (PANEL) APPLIED TO STRUCTURAL SHEATHING

Minimum Nail

(f)(g)

Panel Nail Spacing Maximum Wind Speed (mph)

Wall Stud

APA Rated

Panel Siding

Shank Diameter

(in.)

3/8 Performance Category

APA MDO GENERAL

APA Rated Siding

0.120 ring shank

16 oc or 24 oc

(a) Table is based on wind pressures acting toward and away from

building surfaces, at 30-ft height in wall Zone 5 (corners) with

smallest effective area, per Section 6.4.2.2 of ASCE 7-05 and

Section R301.2 of the 2009 IRC, Stud specific gravity = 0.42.

(b) Recommendations of siding manufacturer may vary.

(c) For use as wood structural panel wall bracing, the minimum fas-

tener spacing of 6" o.c. at panel edges and 12" o.c. at intermediate

supports shall be sufficient.

Spacing

(in. o.c.)

16 6

24 6

Edges

(in. o.c.)

(d) Hot-dip galvanized nails are recommended for most siding applica-

(e) Maximum stud spacing shall be in accordance with Table 21A.

(f) Ring shank nail shall be used.

(g) See Table 5, page 14, for nail dimensions.

(h) Supported panel joints shall occur approximately along the center-

(a)(b)(c)(d)(e)

Intermediate

(h)

Supports

(in. o.c.)

12 110

Wind Exposure Category

B C D

90 85

6 125 105 90

12

90 NP NP

6 110 90 85

tions, see Siding Fasteners section on page 48 for more information.

line of framing with a minimum bearing of 1/2". Fasteners shall be

located 3/8" from panel edges.

ENGINEERED WOOD CONSTRUCTION GUIDE ■ FORM NO. B360P ■ © 2011 APA – THE ENGINEERED WOOD ASSOCIATION ■ WWW.APAWOOD.ORG

46

Wall Construction

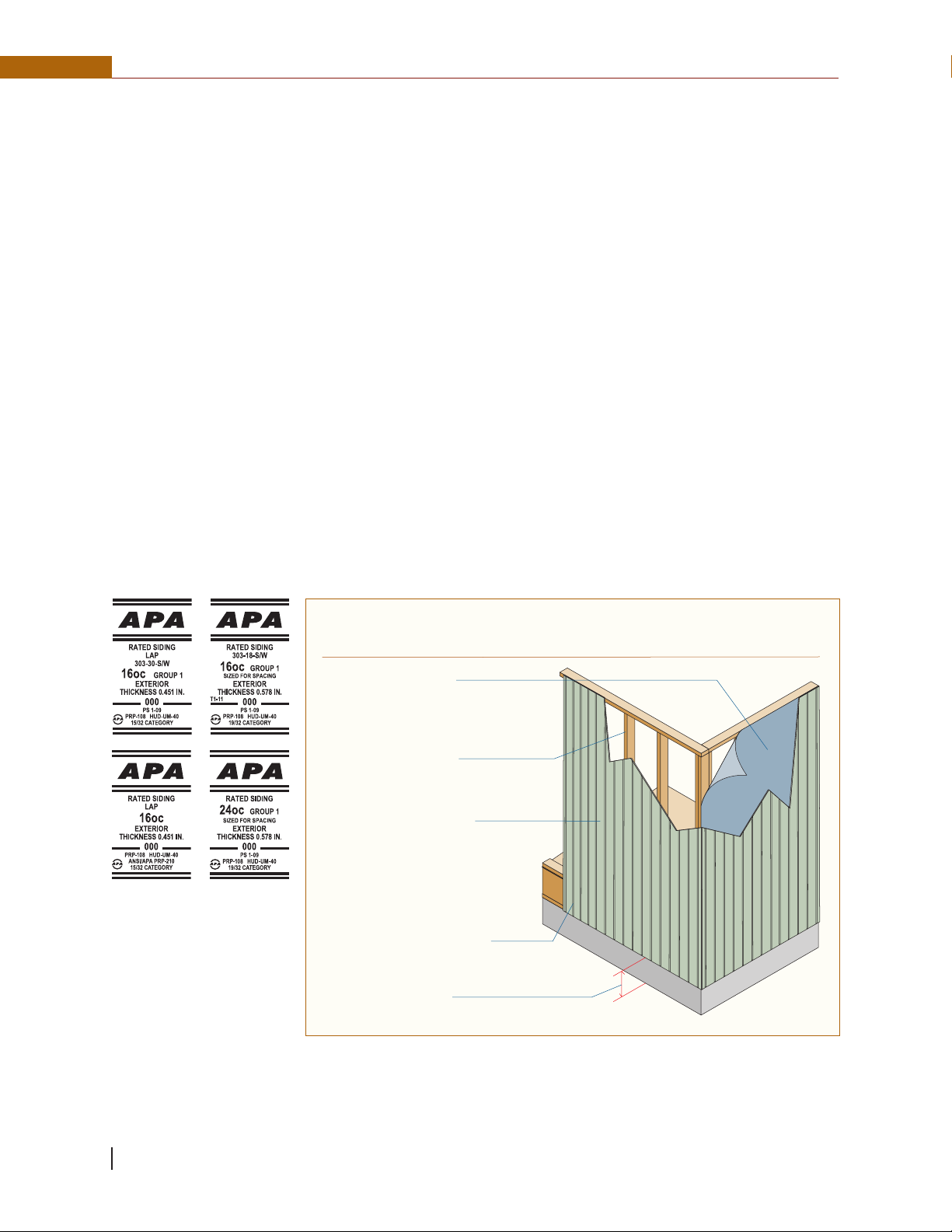

Panel siding meets code

requirements for wall bracing

1/8" spacing is recommended

at all edge and end joints unless

otherwise indicated by panel manufacturer

Building paper or coderecognized weather-resistive

barrier required behind siding

APA RATED SIDING panels.

All edges supported by framing

or blocking.

FIGURE 8

APA STURD-I-WALL (Vertical Panel Installation)

6" minimum clearance,

siding to grade

A single layer of wood structural panel siding, since it is strong and rack resistant, eliminates the cost of installing separate

structural sheathing or diagonal wall bracing. Panel sidings are normally installed vertically, but may also be placed horizontally (long dimension across supports) if horizontal joints are blocked. Maximum stud spacings for both applications are

given in Tables 19, 20 and 21.

When installing panel or lap siding over rigid foam insulation sheathing, drive the nails flush with the siding surface,

but avoid over-driving, which can result in dimpling of the siding due to the compressible nature of foam sheathing.

Sidings are occasionally treated with water repellents or wood preservatives to improve finishing characteristics or moisture resistance for certain applications. If the siding has been treated, allowing the surface treatment to dry will avoid

solvent or chemical reaction with the foam sheathing.

When rigid foam insulation sheathing is used, building codes also generally require installation of 1/2-inch gypsum wallboard,

or other materials of the required thermal barrier rating, on the inside surface of the wall for fire protection.

See Figures 8 through 12 for panel and lap siding installation recommendations for the Sturd-I-Wall system or for siding

installed over nailable sheathing. See APA’s Build A Better Home: Walls, Form A530, for additional recommended details to

avoid moisture penetration in walls.

All panel siding edges in Sturd-I-Wall construction should be backed with framing or blocking. Use nonstaining, noncorrosive nails as described in Tables 19, 20 and 21 to prevent staining the siding.

Where siding is to be applied at an angle, install only over wood structural panel sheathing.

Note: Gluing of siding to framing is not recommended due to the increased potential for panel buckling.

ENGINEERED WOOD CONSTRUCTION GUIDE ■ FORM NO. B360P ■ © 2011 APA – THE ENGINEERED WOOD ASSOCIATION ■ WWW.APAWOOD.ORG

47

Wall Construction

Siding Fasteners

Hot-dip galvanized nails are

recommended for most siding applic ations. For best

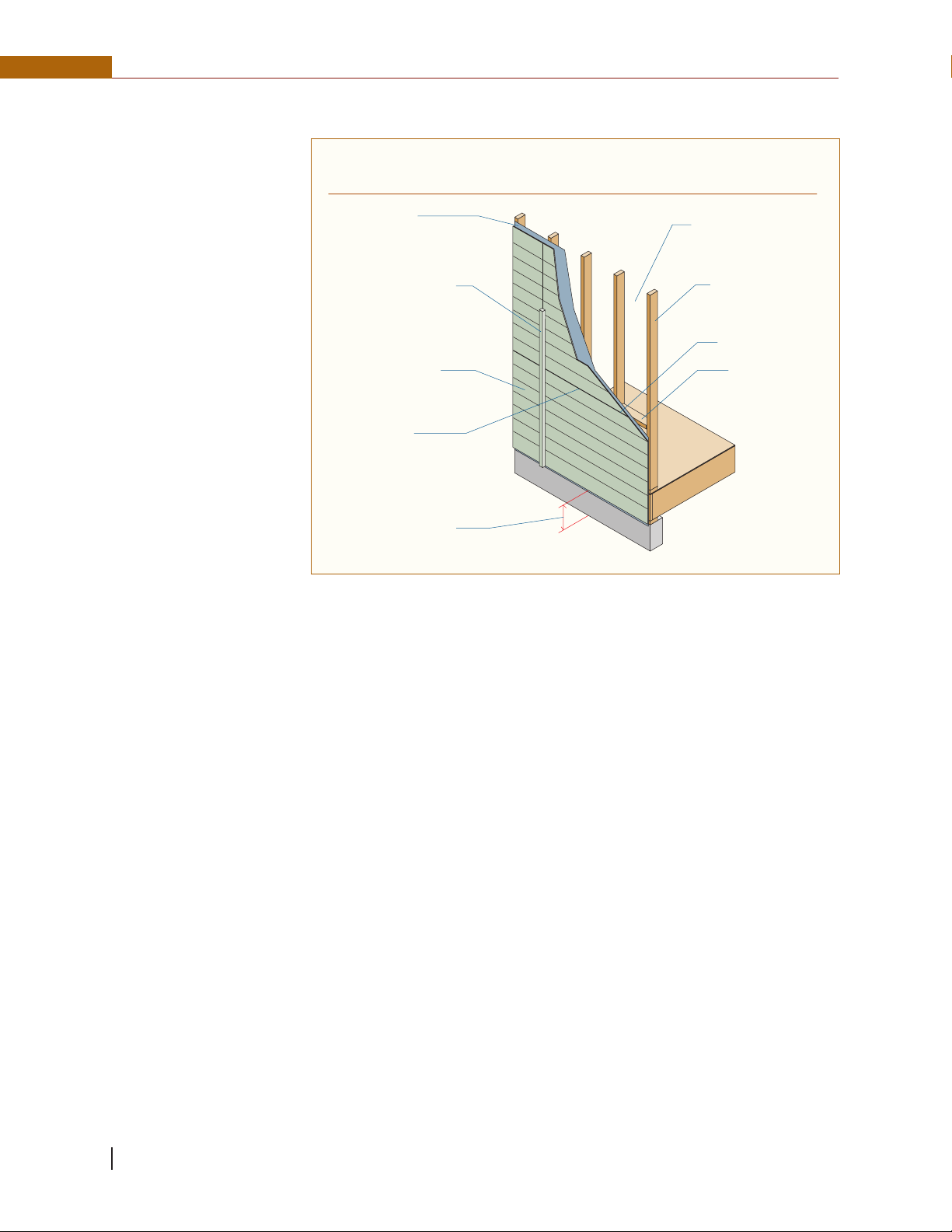

FIGURE 9

APA STURD-I-WALL (Horizontal Panel Siding Installation)

performance, stainless steel

or aluminum nails should

be considered. APA test s

Building paper

or other code-recognized

weather-resistive barrier

also show that electrically

or mechanically galvanized

steel nails appear satisfactory when plating meets or

exceeds thickness requirements of ASTM A641 Class 2

coatings, and is further protected by yellow chromate

coating. Note that galvanized

fasteners may react under wet

conditions with the natural

extractives of some wood species and may cause staining if

left unfinished. Such staining

can be minimized if the sid-

Battens at 4' or 8' o.c.

to conceal butt joints at

panel ends. Nails through

battens must penetrate

studs at least 1".

APA RATED SIDING

panels (nailing as required

for vertical installation)

1/8" spacing is

recommended at all

edge and end joints

unless otherwise

indicated by panel

manufacturer

6" minimum clearance,

siding to grade

ing is finished in accordance

with APA recommendations,

or if the roof overhang protects the siding from direct exposure to moisture and weathering.

See Tables 19, 20 and

21 for maximum

stud spacing

Panel siding meets

code requirements

for wall bracing

Seal panel edges

2x4 blocking at

horizontal joints

Wood Structural Panel Sheathing as a Nail Base for Siding

The recommendations in Tables 22 and 23 for panel and lap siding apply to siding installed over wood structural panel

sheathing. Unless otherwise indicated in the local building code, nailable sheathing includes:

1. Nominal 1-inch boards with studs 16 or 24 inches o.c.

2. APA RATED SHEATHING panels with roof Span Rating of 24 inches or greater installed with strength axis either

parallel or perpendicular to studs 16 or 24 inches o.c. (except 3-ply plywood panels must be applied with strength axis

across studs when studs are spaced 24 inches o.c.).

3. APA RATED SHEATHING panels with roof Span Rating less than 24 inches installed with strength axis either parallel or perpendicular to studs 16 inches o.c. (except plywood panels 3/8 Performance Category or less must be applied

with strength axis across studs).

Lap siding joints, if staggered, and panel siding joints may occur away from studs with wood structural panel sheathing.

Note: In addition to panel edge spacing and the use of straight studs, nailing sequence can also be a factor in maintaining a uniformly flat

appearance of the finished wall. Installation procedure: First, position the panel, maintaining recommended edge spacing, and lightly tack at

each corner. Install the first row of nails at the edge next to the preceding panel from top to bottom. Remove remaining tacking nails. Then nail

the row at the first intermediate stud. Continue by nailing at the second intermediate stud, and finally, at the edge opposite the preceding panel.

Complete the installation by fastening to the top and bottom plates.

ENGINEERED WOOD CONSTRUCTION GUIDE ■ FORM NO. B360P ■ © 2011 APA – THE ENGINEERED WOOD ASSOCIATION ■ WWW.APAWOOD.ORG

48

Loading...

Loading...