Georg Fischer Signet 274X, 275X, 277X Operating Instructions

Signet 274X Series Diff erential DryLoc® pH and ORP Electrodes

Signet 275X Series Wet-Tap DryLoc® pH and ORP Electrodes

Signet 277X Series Threaded DryLoc

®

pH and ORP Electrodes

*3-2744.090*

3-2744.090 Rev 1 02/20

Operating Instructions

Description

The Signet General Purpose 275X Wet-Tap and High Performance 274X and 277X series

of pH and ORP electrodes are designed to minimize maintenance time and maximize

performance longevity and value. All three family of pH and ORP electrodes are memory

chip enabled to store Manufacturing, Calibration and Operational Data. For more fl exibility

274X

275X

and unique features, pair any pH or ORP electrode with a 2751 Smart Sensor Electronics

and the 9900 Transmitter, 9950 Dual Channel Transmitter or the 0486

Profi bus Concentrator.

The 275X Wet-Tap electrodes are all-purpose sensors ideal for applications where the probe

can be removed for cleaning and maintenance without the system shutdown. They feature a

unique foul-proof DryLoc

with the Signet 2751 Smart Sensor Electronics, and 2760 Preamplifi er. These dependable

and highly responsive electrodes feature a large reference chamber and intelligent

positioning of internal elements that combine to extend the service life. The electrodes

are o ered with a bulb sensing element that can be used for general purpose applications

where a fast response is required even at low temperatures. The choice of a Pt1000 or

3 K temperature sensor allows compatibility into all Signet pH/ORP instruments. The 3719

Wet-Tap assembly allows installation and removal of electrode even under process pressure

without the need for process shutdown.

®

connector with gold-plated contacts, designed specifi cally for use

English

277X

• English

• Deutsch

• Français

• Español

• 中文

California Prop. 65

WARNING:

Cancer and Reproductive Harm

www.p65warnings.ca.gov

The Signet 274X Series Di erential pH and ORP electrodes feature a Ryton® body and

PTFE reference junction to resist fouling, clogging and chemical attack under harsh

chemical applications. The glass in the pH di erential electrodes is special formulation for

high performance in media with high pH, elevated temperatures or high concentration of

suspended solids. The Di erential electrodes use a 3-electrode technique, measuring the

pH and reference electrodes against a ground electrode for a more stable output signal. The

solution ground eliminates noisy measurements by draining electrical current away from the

reference electrode. The reference electrode is housed in a glass half-cell embedded in the

reference chamber to protect it from poisioning or contamination. The electrolyte chamber is

refi llable and the salt bridge is fi eld replaceable.

The Signet 277X Series pH and ORP electrodes are highly responsive electrodes featuring

a PTFE double reference junction, potassium nitrate, KNO3, in the front chamber (to block

various poisoning ions such as copper (Cu2+), lead (Pb2+), mercury (Hg2+)) and a large

reference chamber. The two chambers combine to extend the service-life of the electrode.

Both the 274X Series and the 277X Series feature a unique foul-proof DryLoc® connector

with gold-plated contacts designed specifi cally for use with the Signet 2751 Smart Sensor

Electronics and 2760 Preamplifi er. They are available with either fl at or bulb style sensing

elements. The bulb protected style electrodes can be used for low temperature or low

conductivity applications or where a fast response time is required. The fl at versions

allow sediment and particles to sweep past the measurement surface, minimizing risks of

abrasion, breakage and coating. The temperature device in the pH electrodes is positioned

at the tip of the measurement surface, resulting in a temperature response of less than 1

minute. Temperature devices available include 3 K, or Pt1000 RTD.

Warranty Information

218 mm

(8.57 in.)

35 mm

(1.4 in.)

11.9 mm

(0.47 in.)

Chemical Compatibility

Refer to your local Georg Fischer Sales o ce for the most

current warranty statement.

All warranty and non-warranty repairs being returned must

include a fully completed Service Form and goods must be

returned to your local GF Sales o ce or distributor. Product

returned without a Service Form may not be warranty replaced

or repaired.

Signet products with limited shelf-life (e.g. pH, ORP, chlorine

electrodes, calibration solutions; e.g. pH bu ers, turbidity

standards or other solutions) are warranted out of box but not

warranted against any damage, due to process or application

failures (e.g. high temperature,

mishandling (e.g. broken glass,

chemical poisoning, dry-out) or

damaged membrane, freezing

and/or extreme temperatures).

Product Registration

Thank you for purchasing the Signet line of Georg Fischer

measurement products.

If you would like to register your product(s), you can now register

online in one of the following ways:

• Visit our website www.gfsignet.com.

Under Service and Support click on

Product Registration Form

• If this is a pdf manual (digital copy),

click here

Safety Information

The retaining nuts of pH and ORP sensors are not designed

for prolonged contact with aggressive substances.

Strong acids, caustic substances and solvents or their

vapor may lead to failure of the retaining nut, ejection of the

sensor and loss of the process fl uid with possibly serious

consequences, such as damage to equipment and serious

personal injury. Retaining nuts that may have been in

contact with such substances, e.g. due to leakage or spilling,

must be replaced.

• The use of this product assumes

operators are trained and familiar

with this type of device.

• Operators should be knowledgeable

of the potential risks associated with

pressurized piping systems.

• Operators MUST follow all

necessary safety procedures.

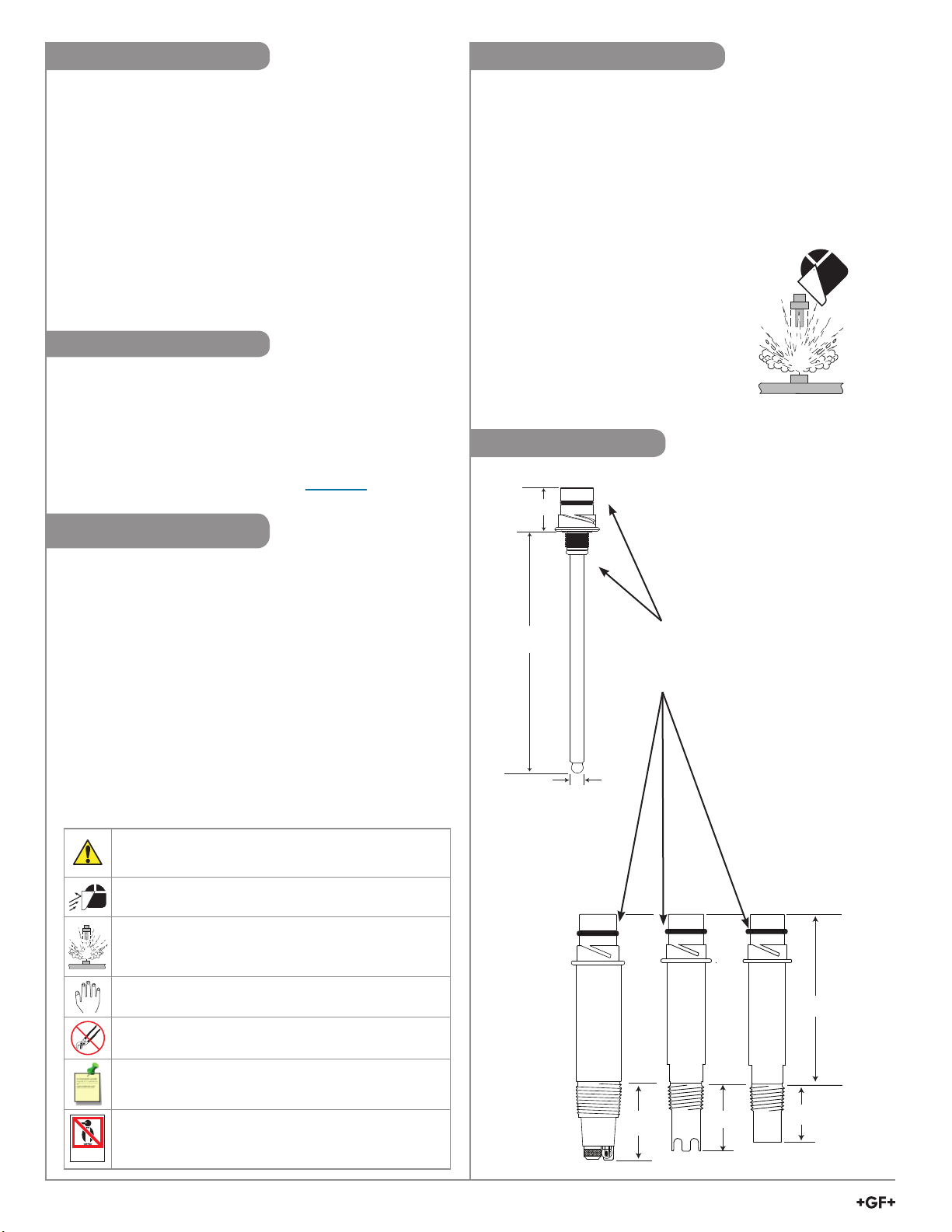

Dimensions

2756 Wet-Tap pH

2757 Wet-Tap ORP

Electrode

1. Use appropriate eye, face, hand, body and/or

respiratory protection when using chemicals or solvents.

2. Prior to installation or removal:

• Depressurize and vent system

• Drain below sensor level.

3. Confi rm chemical compatibility before use.

4. Do not exceed the max. temperature/pressure

specifi cations.

5. Do not alter product construction.

If installing into a threaded connection:

6. Inspect threads to ensure integrity. Do not install a sensor

that has damaged threads.

7. Apply PTFE tape to the 3/4" M-NPT or ISO 7/1-R 3/4 process

connection threads in accordance with industry practices.

8. HAND TIGHTEN the sensor into the process connection.

DO NOT USE TOOLS.

Caution / Warning / Danger

Indicates a potential hazard.

Failure to follow all warnings may lead to equipment damage, injury, or

death

Personal Protective Equipment (PPE)

Always utilize the most appropriate PPE during installation and service of

Signet products.

Pressurized System Warning

Sensor may be under pressure, take caution to vent system prior to

installation or removal.

Failure to do so may result in equipment damage and/or serious injury.

Hand Tighten Only

Overtightening may permanently damage product threads and lead to

failure of the retaining nut.

Do Not Use Tools

Use of tool(s) may damage product beyond repair and potentially void

product warranty.

Note / Technical Notes

Highlights additional information or detailed procedure.

Do Not Freeze

Products are temperature sensitive and may contain freezable liquids.

Freezing damage to pH, ORP, and Chlorine electrodes voids product

DO NOT

warranty.

FREEZE

Lubricate O-rings with a

non-petroleum based,

viscous lubricant (grease)

compatible with the

system.

274X Series

Differential

Electrode

1 in.

NPT

45 mm

(1.8 in.)

277X Series

Bulb Electrode

¾ in.

NPT

43 mm

(1.7 in.)

277X Series

Flat Electrode

¾ in.

NPT

32 mm

(1.3 in.)

121 mm

(5.27 in.)

2

Signet 275X, 274X, 2777X Series pH and ORP Electrodes

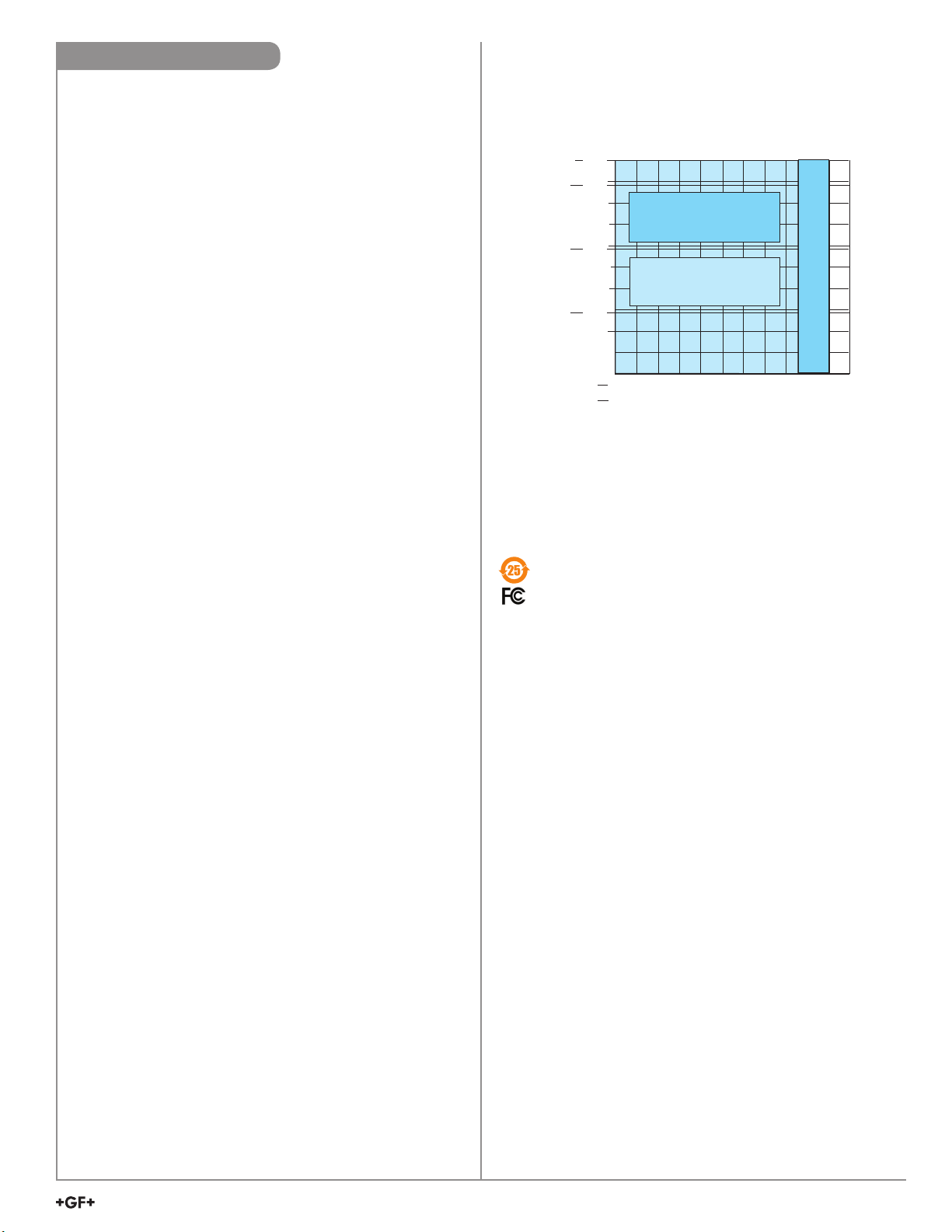

Specifi cations

274X Series Diff erential Electrodes

277X Series Threaded Electrodes

General

Compatibility ......................... Signet 2751 and 2760

Shipping Weight ................... 0.25 kg (0.55 lbs.)

Operating Range

274X Series ......................... 0 to 14 pH, ± 1500 mV ORP

277X Series .......................... 0 to 14 pH, ± 2000 mV ORP

Reference Electrolyte

274X Series ......................... Bu ered KNO

277X Series ......................... KCI/AgCl gel with KNO

bridge

Reference Element

274X Series .......................... pH glass electrode

277X Series .......................... Ag/AgCl

Temperature Sensor

274X Series pH .................... 3 K or Pt1000 RTD

277X Series pH .................... 3 K or Pt1000 RTD

274X Series ORP ................. 10 K ID for Signet instruments;

277X Series ORP ................. 10 K ID for Signet instruments

3 solution

3 salt

bar

6.89

pH/ORP Electrodes

274X Series and 277X Series

psi

100

6

4

2

°F

Pressure vs. Temperature

80

60

40

20

0 40506070°C90 10080

32 122

274X Series

10 °C to 100 °C @ 6.89 bar

(50 °F to 212 °F @ 100 psi)

277X Series

0 °C to 85 °C @ 6.89 bar

(32 °F to 185 °F @ 100 psi)

10 20 30

274X Series ONLY

21217650 86

Wetted Materials

Body ..................................... Ryton

®

Reference junctions .............. PTFE

Sensing surface .................... Glass (pH), Platinum (ORP)

O-rings .................................. FKM and EPDM

Solution ground .................... Carbon graphite

(274X series only)

Operating Temperature

274X Series .......................... 10 °C to 100 °C (50 °F to 212 °F)

277X Series .......................... 0 °C to 85 °C (32 °F to 185 °F)

Storage Temperature ............ > 0 °C (32 °F)

Max Operating Pressure ..... 6.89 bar (100 psi)

275X Series Wet-Tap Electrodes

General

Compatibility ......................... Signet 2751 and 2760

Shipping Weight ................... 0.25 kg (0.55 lbs.)

Operating Range .................. 0 to 14 pH, ± 1500 mV ORP

Reference Electrolyte ........... Polymerized Acrylamide Gel

Wet-Tap electrolyte ............... 3.5 M KCl

Reference Element ............... Ag/AgCl

pH Temp Sensor ................... Pt1000 RTD or 3 K Balco

ORP Identifi cation ................. 10 K ID for Signet instruments

Wetted Materials

Wet-Tap body ....................... PAS (Poly Aryl Sulphone)

Wet-Tap Junctions ................ Porous PTFE

Sensing surface .................... Glass (pH), Platinum (ORP)

O-rings .................................. FKM

Standards and Approvals

• CE, WEEE, RoHS Compliant

• Manufactured under ISO 9001 for Quality,

ISO 14001 for Environmental Management and

OHSAS 18001 for Occupational Health and Safety.

China RoHS (Go to www.gfsignet.com for details)

Declaration of Conformity according to FCC Part 15

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received,

including interference that may cause undesired operation.

REACH Information Obligation: in accordance with Article 33

of the European REACH Regulation (EC) No. 1907/2006, the

substances Lead and Acrylamide are present in the glass

matrix and as a polymerized gel respectively; in a concentration

>0.1% (w/w). During normal use, the articles do not pose any

risks and no additional information is required for safe use.

Temperatures

Operating Temperature ......... 0 °C to 85 °C (32 °F to 185 °F)

Storage Temperature ............ 0 °C to 85 °C (32 °F to 185 °F)

Maximum Temperature and Pressure rating

6.89 bar @ 0 °C to 65 °C (100 psi @ 32 °F to 149 °F)

4.00 bar @ 65 °C to 85 °C (58 psi @ 150 °F to 185 °F)

Ryton® is a registered trademark of Chevron Phillips Chemical

Signet 275X, 274X, 2777X Series pH and ORP Electrodes

3

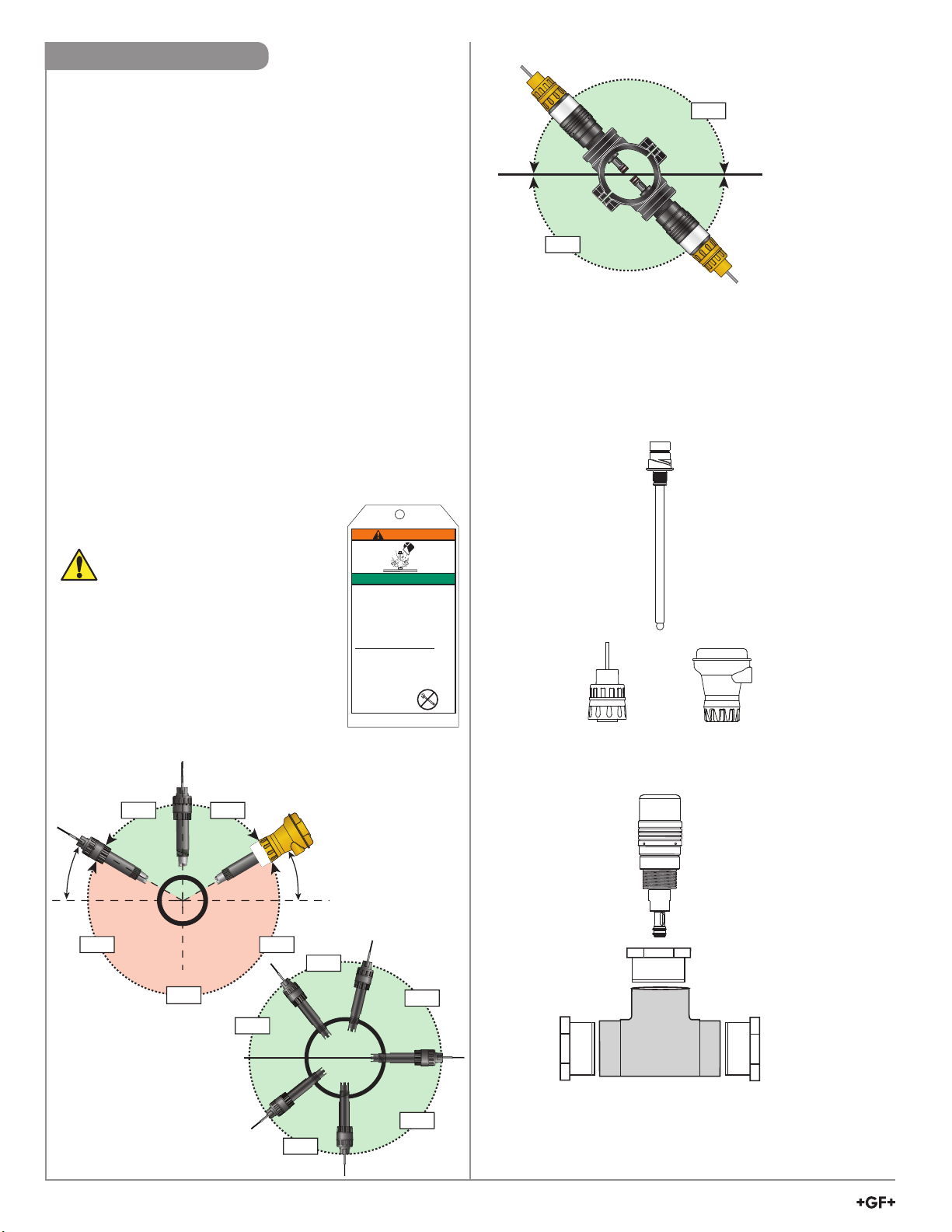

In-Line Installation

1. 2774 and 2775 electrodes can be mounted at any angle

2. Di erential (274X series) electrodes must be mounted at a

downward angle (> 15° from horizontal)

3. 275X Wet-Tap electrodes must be mounted in a 3719

Assembly at any angle

4. Avoid air pockets and sediments

5. Select a Signet installation fi tting (0.5” to 4” size range) for

convenience. Lightly lubricate o-ring with a non-petroleum

based lubricate (grease) compatible with the system.

6. Use the ¾ in. M-NPT or ISO 7/1-R ¾ threads on the electrode

body to install the electrode into reducing tee fi ttings.

7. Inspect threads to ensure integrity. Do not install an electrode

with damaged threads.

8. Apply PTFE tape to the M-NPT or ISO 7/1-R ¾ process

connection threads, in accordance with industry standards.

9. Use piping installation hardware with smooth,

well-fi nished threads to facilitate the installation.

10. If necessary, the pipe should be plumbed with a depression

(trap) so liquid is maintained around the electrode tip.

11. Hand-tighten the electrode into the process connection.

Do not use any tools to install the electrode.

The use of wrenches, pliers or similar may over-stress the

sensor body and lead to breakage and

subsequent spillage of the process liquid.

CAUTION:

A broken sensor may be ejected

forcefully from the fi tting and can cause

severe injury.

12. The safety instructions have an

adhesive label and should be placed

near the sensor.

NOTE:

When mounting in a standard threaded

fi tting, the electrode must be mounted

horizontal to 60 degrees below horizontal

position only:

0°

SAFETY INSTRUCTIONS

1. Use appropriate eye, face, hand, body

and/or respiratory protection when using

chemicals or solvents

2. Prior to installation or removal:

a. Depressurize and vent system

b. Drain below sensor level

3. Confirm chemical compatibility before use

4. Do not exceed the maximum

temperature/pressure specifications

5. Do not alter product construction

If installing into a threaded connection:

6. Inspect threads to ensure integrity. Do not

install a sensor that has damaged threads

7. Apply PTFE tape to the process connection

threads in accordance with industry

practices

8. Hand tighten the sensor into the process

connection. DO NOT USE TOOLS

Failure to follow

these instructions may

result in personal injury

See peel & stick warning label on back!

WARNING

Attach near sensor

3-2700.615 (B-04/08)

YES

275X Wet-Tap

YES

275X Wet-Tap with 2751 or 2760 and

3719 pH/ORP Wet-Tap Assembly

1) Choose sensor; 2) Choose preamplifi er or sensor electronics;

3) Choose Wet-Tap assembly; 4) Choose customer supplied

mounting option

1

Wet-Tap pH or

ORP Sensor:

3-2756-WTP

3-2756-WTP-1

3-2757-WTP

2

2760

Preamplifier:

3-2760-11

3-2760-21

OR

2751 Smart Sensor

Electronics:

3-2751-1

3-2751-2

4

-15°

YES

YES

+15°

274X

NO

NO

277X

Signet 275X, 274X, 2777X Series pH and ORP Electrodes

NO

YES

YES

0°

Horizontal

YES

YES

YES

3

3719 Wet-Tap Assembly:

3-3719-11

3-3719-12

3-3719-21

3-3719-22

4

Customer supplied Tees and Fittings

Loading...

Loading...