Page 1

Operating Instructions

Code 790 044 762

RA 21 and RA 21 Special

Pipe Cutting and

Bevelling Machines

GEORG FISCHER +GF+

Page 2

These operating instructions are part

of machine no.: .........................

All rights retained, in particular the rights to reproduction, dissemination and

translation.

Copying or reproduction in any form (print, photocopy, microfilm or data

acquisition) require written permission from Georg Fischer Rohrverbindungstechnik GmbH.

Page 3

Table of Contents

Page

0 About these operating instructions 1

1 Notes on safety 2

2 Description of the pipe cutter 4

3 Features and scope of application

of the pipe cutter 5

4 Technical specifications 7

5 Commissioning 8

5.1 Checking the scope of delivery 8

5.2 Transporting and assembling

the pipe cutter 9

6 Operation 10

6.1 Fitting the saw blade /

additional cutter 10

6.2 Adjusting the pipe diameter 12

6.3 Adjusting the additional cutter 13

6.4 Using stops 14

6.5 Cutting the pipe 16

6.6 Cutting and bevelling the pipe 18

7 Maintenance 20

8 What to do if ...? 22

GEORG FISCHER +GF+

I

Page 4

II

GEORG FISCHER +GF+

Page 5

0 About these operating

instructions

The symbols used in this manual are explained

here to help you quickly understand the

operating instructions and use them effectively.

Symbols

Note on safety

This general hazard symbol accompanies passages of text which you should

read and understand under all circumstances. By failing to do so you could

endanger yourself and others.

Important information

Passages of text which convey important

information are accompanied by this

symbol. Failing to observe them can

cause machine malfunctions or damage.

! Action

This arrow indicates an action you must

perform.

GEORG FISCHER +GF+

1

Page 6

1 Notes on safety

The RA 21/RA 21 Special Pipe Cutting and

Bevelling Machine (referred to as a pipe cutter

in the following) is a state-of-the-art machine.

Using it for purposes other than those described

in this manual may cause injury to the user or to

others. It may also damage the machine or

other equipment.

Therefore:

º Always ensure that the machine is in good

working order and always comply with

these notes on safety.

Proper use

º Only use the materials and types of pipe

specified in this manual (see chapter 3).

Always consult Georg Fischer after-sales

service personnel before using other

materials.

º Only use the pipe cutter for cutting and

bevelling operations as described in

chapter 6.

º Only use original Georg Fischer spare parts

and auxiliaries.

º Inspect the pipe cutter every day for visible

signs of damage or defects. Any damage or

defects must be repaired immediately.

Work on the electrical installations may only

be performed by a qualified electrician.

º Do not use the pipe cutter unless all safety

devises

- restart inhibitor

- overload protection

- saw blade guard

are working properly and the fixtures on the

vise and baseplate are fitted securely.

2

GEORG FISCHER +GF+¹

Page 7

Working with safety in mind

"Make your contribution to safety at the workplace."

Report any unusual behaviour on the part of the

machine to the person in charge immediately.

Always work with safety in mind.

º Wear safety goggles during

cutting and bevelling operations.

º Switch the RA 21 (S) off after

completing each stage of work and

allow the machine to run a stop.

º Disconnect from the mains before

cleaning the pipe cutter.

The cutter and saw blade may cause

injury.

Therefore:

º Keep your hands away from the

tools during cutting and bevelling

operations.

Keep the pipe cutter dry, do not use

in the rain.

Do not use the pipe cutter in areas

subject to explosion hazards.

Disposal

Please make sure that material chips and used

gear oil are disposed of properly.

Further safety rules

Comply with the regulations, standards and

guidelines that apply in your country.

GEORG FISCHER +GF+

3

Page 8

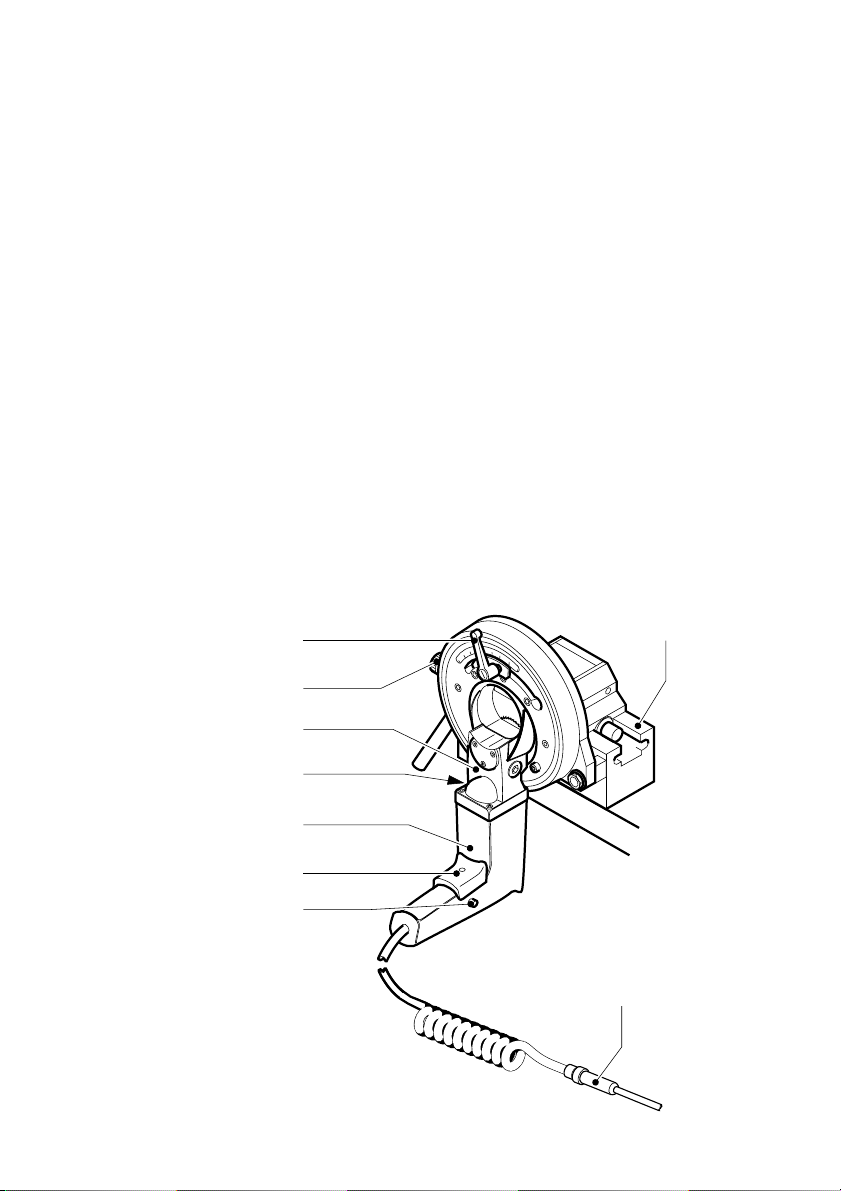

2 Description of the

pipe cutter

The pipe cutter is a robust, user-friendly,

service-friendly and safety-oriented design.

Vise and saw

All mechanically stressed parts are metal.

The rounded, smooth edges help to avoid

accidents.

The saw blade and jaws are close togethers

which reduces vibrations during cutting.

Motor and power cable

The motor can be easily removed. The motor

housing and switches are made from lightweight,

impact-resistant plastic.

Integrated into the power cable is a slipring

contact which prevents the cable from twisting

during cutting.

1 pipe diameter adjusting

facility

2 locking screw

3 worm gear

4 nameplate

5 motor

6 on/off switch

7 locking knob for on/off

switch

8 power cable with slipring

contact

9 vise

4

1

2

3

4

5

6

7

GEORG FISCHER +GF+¹

9

8

Page 9

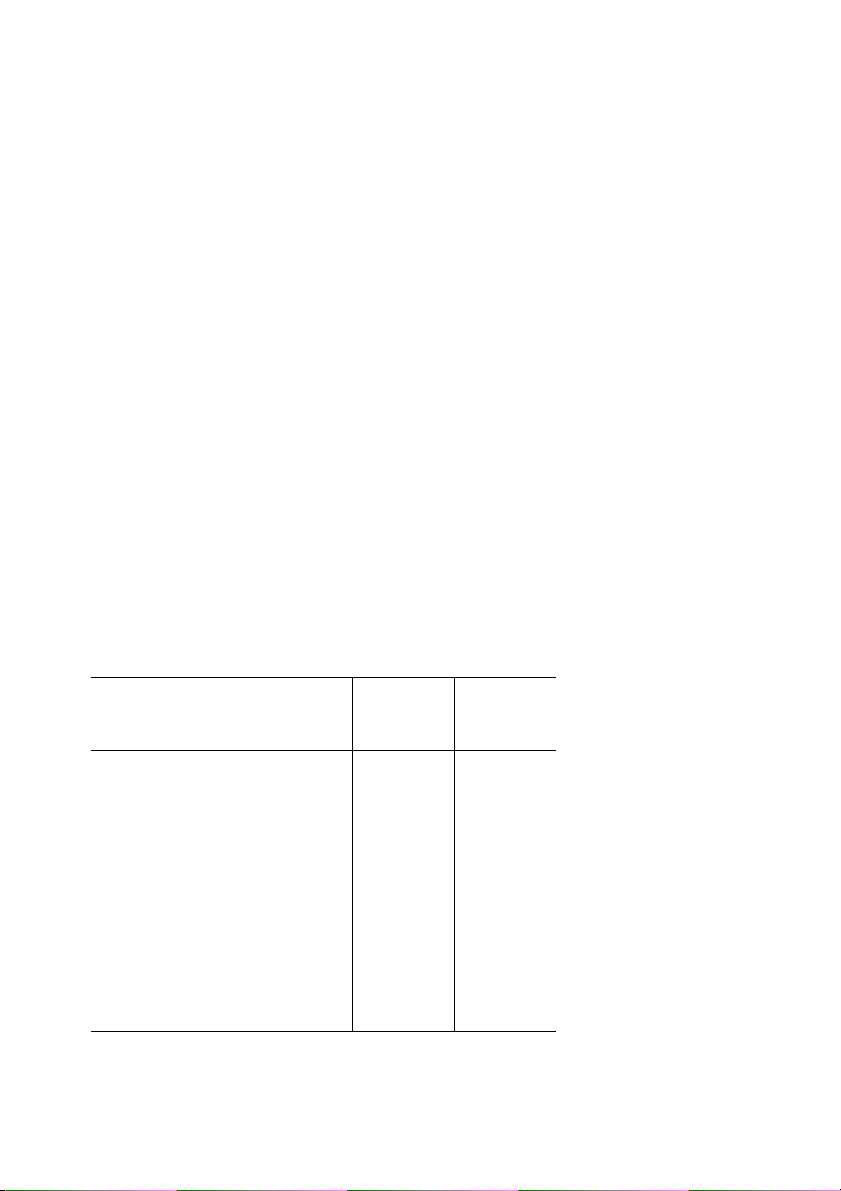

3 Features and scope of

application of the pipe

cutter

The pipe cutter

º is a fully configured working machine suitable

for workshop and building site operation;

º is part of the combined KM 2 and GTM 2

pipe cutting and threading machines;

º works using the safety-enhancing principle:

stationary pipe, rotating tool.

The pipe cutter is suitable for

º cutting and

º bevelling

pipes.

The cut pipes are free from burr, so no

deburring (in- or outside) is required.

This reduces the risk of corrosion.

Scope of application RA 21 RA 21

Special

º pipe Ø 1/4" to 2"

or 10 mm to 63 mm X X

º up to 5.5 mm wall

thickness

Chrome and stainless

steel pipes up to 1.5 mm X

wall thickness

Solid material

Ø 6 mm to 16 mm X

GEORG FISCHER +GF+

5

Page 10

The following materials can be used:

º steel, black or galvanised

º chrome and stainless steel

(up to 2.5 mm wall thickness)

º aluminium

º non-ferrous metals (e.g. copper, brass)

º plastics (PE, PP, PVDE, PVC)

Other materials on request.

Do not use cast pipes with glass-hard

surfaces (GG).

6

GEORG FISCHER +GF+¹

Page 11

4 Technical specifications

Manufacturer Georg Fischer

Rohrverbindungstechnik GmbH

D-78224 Singen

Dimensions 300 x 450 x 300 mm

Weight

(incl. vise) 34 kg

Power 550 W

Protection class Totally insulated in accordance

with Class II DIN VDE 0740

Speed 180 rpm

Versions 1-phase AC

110 ... 120 V, 50/60 Hz

230 ... 240 V, 50/60 Hz

Sound pressure

level at the

workplace at idle: approx. 82 dB (A)

under load: approx. 84 dB (A)

As the noise level may also exceed 84 dB (A)

under unfavourable operating conditions, we

recommend the use of suitable ear protection

when the machine is used for extended periods.

The sound pressure level was measured under

normal operating conditions in accordance with

EN 23741.

Vibration level

in accordance

with EN 28662,

Part 1 < 2.5 m/s

GEORG FISCHER +GF+

2

7

Page 12

5 Commissioning

5.1 Checking the scope of delivery

Check all parts of the delivery for completeness

and transport damage. Please report missing

parts or transport damage to the support

immediately.

Normal accessories

(subject to change without notice)

º 1 saw blade

º 1 ring spanner, 22 mm

º 1 brush

º 2 hexagon Allen keys

º 1 tube of saw blade lubricant

º 1 quick mounting base plate

º 1 tube of special gear oil

8

GEORG FISCHER +GF+¹

Page 13

5.2 Transporting and assembling the pipe cutter

Transport

Disconnect from the power supply

before transporting, mounting or

dismounting and allow the machine to

run a stop.

Mounting the quick mounting base plate

The pipe cutter with the vise is mounted either

º on the quick mounting base plate, or

º on the quick mounting base plate

(special accessory) with clamps.

!Mark and punch

the bolt holes on

the work bench.

Use the quickmounting baseplate

as a template.

!Drill 13 mm Ø holes.

!Bolt down the

quick-mounting

baseplate.

GEORG FISCHER +GF+

!Place the vise with

flanged-on pipe

cutter on the base

plate. Tighten the

hexagon nut (1).

1

9

Page 14

6 Operation

6.1 Fitting the saw blade /

additional cutter

Disconnect the mains plug before fitting

or changing the tool.

The saw blade/additional cutter must be free

from chips and dirt.

Use only original Georg Fischer saw blades

and cutters.

The inscription on the saw blade (1) must

always face the pipe cutter. Observe sign for

saw blade guard.

1

!Loosen the locking

screw (1).

!Turn the pipe cutter

upwards 180°

clockwise.

!Tighten the locking

screw (1).

!Clean the saw blade

shaft (2) and vicinity.

10

Preparatory work

1

2

GEORG FISCHER +GF+¹

Page 15

Fitting the saw blade

1

2

345

Fitting the saw blade and additional cutter

1

2

3456

!Mount the following

on the shaft (1):

º saw blade (3)

º clamping disk (4)

code RA 21:

790 041 188

code RA 21 S:

790 044 192

!Tighten the nut (5)

by turning counterclockwise. Left-hand

thread.

!Loosen the locking

screw (2).

!Turn the pipe cutter

clockwise back

down into its home

position.

!Mount the following

on the shaft (1):

RA 21:

º saw blade (3)

º additional cutter (4)

º clamping disk (5)

RA 21 S:

º saw blade (3)

º additional cutter (4)

!Tighten the nut (6)

by turning counterclockwise. Left-hand

thread.

!Loosen the locking

screw (2).

!Turn the pipe cutter

clockwise back into

its home position.

GEORG FISCHER +GF+

11

Page 16

6.2 Adjusting the pipe diameter

Threaded pipes to DIN 2440

!Release the lever

(1).

!Select pipe diameter

on the scale (3).

!Set the red mark on

the left side of the

stop (2) to the corresponding number.

!Tighten the lever (1).

!Insert the pipe in the

vise.

!Move the pipe

almost up to the

saw blade.

!Tighten the pipe in

the vise.

!Release the lever (1)

and set the stop (2)

to position 2".

Do not tighten.

!Raise the motor of

the pipe cutter as if

to start cutting, until

the points of the

saw blade teeth

project about 1.5

mm into the pipe.

!Tighten the lever (1).

2

3

3

1/4

1

2

/

1

1

2

/8

1/2

1

/4

/4

3

1

All other types of pipe

4

open

1

2

2

/

3

1

1/4

1

1/2

1

1

3/8

2

/

1

1

/

4

12

GEORG FISCHER +GF+¹

Page 17

6.3 Adjusting the additional cutter

Simultaneous cutting and bevelling of steel pipes

up to a wall thickness of 4.5 mm is possible.

3

/8

/2

1

1

/4

1

2

2

/4

3

1

/4

1

1

/2

1

1

!Insert the pipe in the

vise.

!Move the pipe

almost up to the

additional cutter.

!Clamp the pipe in

the vise.

!Release the lever (1)

and set the stop (2)

to position 2".

Do not tighten.

!Raise the motor of

the pipe cutter as if

to start cutting, until

the cutter covers the

wall of the pipe.

!Tighten the lever (1).

!Do a test bevel and

check the result (see

section 6.6).

Bevel OK

GEORG FISCHER +GF+

Move the

stop (2) a

little to the

right

Move the

stop (2) a

little to the

left

13

Page 18

!Mount the length

gauge (1).

!Swing the stop (2) in

to the middle of the

pipe and engage.

!Release the cross

knob (3).

!Set to the desired

length. Use the scale.

!Tighten the cross

knob.

!Push the pipe for-

wards up to the

stop and clamp.

!Swing the stop clear.

!Cut the pipe.

6.4 Using stops

Length gauge up to 250 mm

2

3

1

!Mount the length

gauge (1).

!Swing the stop in to

the middle of the

pipe.

!Use a yardstick to

extend the stop to

the desired length.

!Push the clamp (2)

up against the

housing and turn it

so that it is in

contact with the

work bench.

14

Length gauge over 250 mm

2

1

GEORG FISCHER +GF+¹

Page 19

!Tighten the clamp.

!Push the pipe up

against the stop

and clamp.

!Swing the stop out

and push all the

way back.

!Cut the pipe.

!For the next cut,

extend the stop and

swing into place

clockwise.

GEORG FISCHER +GF+

15

Page 20

!Connect the pipe

cutter to the mains.

!Apply saw blade

lubricant to the saw

blade teeth.

6.5 Cutting the pipe

Cut thin-walled chrome and stainless steel

pipe up to 1.5 mm wall thickness only with

RA 21 Special.

Put on safety goggles before cutting.

Repeat the lubrication every three cuts.

If in contact with drinking water or

foodstuffs, use only Georg Fischer

lubricating gel.

!Mark the cutting

location on the

pipe.

!Insert the pipe in the

vise.

!Push the marked

cutting location over

the saw blade.

!Clamp the pipe in

the vise.

16

³ 1 m

³ 1 m

Use a pipe support for pipes that are over

1 m long.

GEORG FISCHER +GF+¹

Page 21

!Switch on the saw

motor. Press the on/

off switch (1) and

the locking button

1

2

(2).

1

3

3

/

8

2

/

1

1

/4

/4

3

1

/4

1

1

1/2

1

2

For non-stop operation: After cutting, loosen

the hexagon nut on the saw blade to avoid

damage caused by tension.

!Carefully turn the

pipe cutter clockwise until the wall of

the pipe has been

pierced through.

!Continue to turn

rapidly until the pipe

has been cut off and

the marks (3) on the

slide housing and

vise housing are

aligned.

!Turn the pipe cutter

back into its home

position.

!Switch off the saw

motor. Press the on/

off switch (1) again.

GEORG FISCHER +GF+

17

Page 22

!Connect the pipe

cutter to the mains.

!Apply saw blade lu-

bricant to the saw

blade teeth/cutting

surface.

6.6 Cutting and bevelling the pipe

This procedure combines cutting and bevelling

of the pipe. When cutting and bevelling simultaneously, turn the pipe cutter more slowly

around the pipe that you would for cutting

alone, as two tools are used at the same time.

Put on safety goggles before cutting.

Repeat the lubrication every three cuts.

!Mark the cutting

location on the

pipe.

!Insert the pipe in the

vise.

!Push the marked

cutting location over

the saw blade.

!Clamp the pipe in

the vise.

18

If in contact with drinking water or

foodstuffs, use only Georg Fischer

lubricating gel.

³ 1 m

³ 1 m

Use a pipe support for pipes that are more

than 1 m long.

GEORG FISCHER +GF+¹

Page 23

!Switch on the saw

motor. Press the on/

off switch (1) and

the locking button

1

2

(2).

1

3

3/8

2

/

1

1

/

4

4

/

3

1

1/4

1

/2

1

1

2

For non-stop operation: After cutting, loosen

the hexagon nut on the saw blade to avoid

damage caused by tension.

!Carefully turn the

pipe cutter clockwise until the wall of

the pipe has been

pierced through.

!Continue turning

rapidly until the pipe

has been cut off and

the marks (3) on the

slide housing and

vise housing are

aligned.

!Turn the pipe cutter

back into its home

position.

!Switch off the saw

motor. Press the on/

off switch (1) again.

GEORG FISCHER +GF+

19

Page 24

7 Maintenance

Disconnect the mains plug before

doing maintenance work.

Interval

every week

º every time the cutter is

cleaned

º every tool change

Activity

Remove the saw blade and brush off chips.

Oil the four locations marked by the arrows.

Check the oil level of the gear and top up if

necessary.

Do not use compressed air to clean the area at the

end of the shaft marked with an arrow as the rotary

shaft seal may otherwise be damaged by chips.

20

Use a cloth or brush to clean the end of the shaft.

GEORG FISCHER +GF+¹

Page 25

Interval

Activity

after the first 150 hours

of operation

(or after 3 months,

whichever is sooner),

then every 1000 hours of

operation (or every year)

Fill with gear oil up to the threaded hole.

GEORG FISCHER +GF+

21

Page 26

8 What to do if ...?

Problem

Pipe cutter will not turn.

Saw blade is not cutting

and is slipping.

Saw blade is not cutting.

Pipe is not being cut

concentrically.

Pipe is not being cut.

Motor not running.

Cause

Locking screw tightened.

Wrong pipe diameter

set.

Nut on saw blade shaft

not tight enough.

Saw blade wrong way

round.

Pipe cutter not flanged

on. Flange surfaces are

dirty.

Pipe diameter wrongly

set.

Clamping lever not tight.

The restart inhibitor has

tripped.

Remedy

Loosen locking screw.

Set pipe diameter

correctly.

Tighten nut.

Fit saw blade correctly.

Inscription on saw blade

must face the pipe cutting

machine (see chapter 6).

Remove pipe cutter,

clean mounting parts

and flange surfaces, bolt

pipe cutter back on.

Adjust pipe diameter

(see chapter 6).

Tighten clamping lever.

Turn switch to "0", then

switch the pipe cutter on.

22

GEORG FISCHER +GF+¹

Page 27

Service / after-sales service

Spare parts: see separate spare parts list.

Separate service instructions are available for

the elimination of faults.

Alternatively, contact your local Georg Fischer

agent.

A list of addresses is provided on the back

cover of this manual.

Please quote the following data:

º Cutter type: RA 21/RA 21 Special

º Machine number: see nameplate.

The technical data are not binding.

They are not warranted characteristics and

are subject to change.

Please consult our General Conditions of

Supply.

GEORG FISCHER +GF+

23

Page 28

GEORG FISCHER +GF+

A Georg Fischer Rohrleitungssysteme GmbH, Sandgasse 16, 3130 Herzogenburg,

Tel. +43(0)2782/8 56 43-0, Fax +43(0)2782/8 56 64, office@georgfischer.at, www.georgfischer.at

AUS George Fischer Pty Ltd, 186-190 Kingsgrove Road, Kingsgrove NSW 2008,

Tel. +61(0)2/95 54 39 77, Fax +61(0)2/95 02 25 61, sales@georgefischer.com.au,

www.georgefischer.com.au

B/L Georg Fischer NV/SA, Digue du Canal 109-111 – Vaartdijk 109-111, 1070 Bruxelles/Brüssel,

Tél. +32(0)2/556 40 20, Fax +32(0)2/524 34 26, info.be@be.piping.georgfischer.com,

www.georgfischer.be

CHGeorg Fischer Rohrleitungssysteme (Schweiz) AG, Ebnatstrasse 101, Postfach,

8201 Schaffhausen, Tel. +41(0)52/631 30 26, Fax +41(0)52/631 28 97,

info@rohrleitungssysteme.georgfischer.ch, www.piping.georgfischer.ch

D Georg Fischer Rohrverbindungstechnik GmbH, Freibühlstrasse 18/19, 78224 Singen (Htwl.),

Tel. +49(0)7731/79 25 21–23, Fax +49(0)7731/79 25 24, info@rvt.georgfischer.com,

www.rvt.georgfischer.com

DK/IS Georg Fischer A/S, Rugvænget 30, 2630 Taastrup, Tel. +45 70 22 19 75,

Fax +45 70 22 19 76, info@dk.piping.georgfischer.com, www.georgfischer.dk

F George Fischer S.A.S., 105–113, rue Charles Michels, 93208 Saint-Denis Cedex 1,

Tél. +33(0)1/492 21 34 1, Fax +33(0)1/492 21 30 0, info@georgefischer.fr, www.georgefischer.fr

GB George Fischer Sales Limited, Paradise Way, Coventry, CV2 2ST, Tel. +44(0)2476/535 535,

Fax +44(0)2476/530 450, info@georgefischer.co.uk, www.georgefischer.co.uk

I Georg Fischer S.p.A., Via Sondrio 1, 20063 Cernusco S/N (MI), Tel. +3902/921 861,

Fax +3902/921 407 85-6, office@piping.georgfischer.it, www.georgfischer.it

N Georg Fischer AS, Rudsletta 97, 1351 Rud, Tel. +47(0)67/18 29 00, Fax +47(0)67/13 92 92,

info@no.piping.georgfischer.com, www.georgfischer.no

NL Georg Fischer N.V., Postbus 35-8160, 816 PA Epe, Tel. +31(0)578/67 82 22,

Fax +31(0)578/62 17 68, info.vgnl@nl.piping.georgfischer.com, www.georgfischer.nl

Georg Fischer WAGA N.V., Lange Veenteweg 19, Postbus 290, 8160 AG Epe,

Tel. +31(0)578/67 83 78, Fax +31(0)578/62 08 48, info@waga.georgfischer.com,

www.waga.georgfischer.com

S/FIN Georg Fischer AB, Box 113, 12523 Älvsjö-Stockholm, Tel. +46(0)8/506 77 500,

Fax +46(0)8/749 23 70, info@georgfischer.se, www.georgfischer.se

USA George Fischer Inc., 2882 Dow Avenue, Tustin, CA 92780-7258, Tel. +1(714) 731-88 00,

Toll Free 800/854 40 90, Fax +1(714) 731 62 01, info@us.piping.georgefischer.com,

www.us.piping.georgefischer.com

Export Georg Fischer Rohrverbindungstechnik GmbH, Freibühlstrasse 18/19, 78224 Singen (Htwl.),

Tel. +49(0)7731/792-0, Fax +49(0)7731/792 524, info@rvt.georgfischer.com,

www.rvt.georgfischer.com

790 044 762_01/4 (09.03) © Georg Fischer Rohrverbindungstechnik GmbH, D-78224 Singen 2003

Loading...

Loading...