Georg Fischer Central Plastics Piping System User Manual

Georg Fischer

Central Plastics

Connector and

Equipment Catalog

(800) 654-3872 (405) 273-6302 www.centralplastics.com

Piping System Solutions

The Right

Georg Fischer Central Plastics: Not Just a Different

Connection but a Connection that makes a

Difference.

How do you select a business partner with the right

connections? If quality, service and value are important to you—not to mention sophisticated design,

engineering and manufacturing capabilities—Central

is tough to beat. In short, we make the connections

you need for your company and your applications.

Founded in 1955, we have long been a stable, professionally managed and forward-thinking organization. Partnering with Georg Fischer Central

Plastics means you can trust us. Trust us to not just

manufacture and supply reliable products for piping

systems you service, but also trust us in finding the

right way to meet the unique needs of your company.

The Central Advantage: Technology Meeting Your

Most Demanding and Changing Challenges

The speed of the professionals in our design department is unsurpassed. Combine that with the highvolume capacity of our manufacturing facility, and

you begin to understand how Central can ship even

your largest order so quickly. And that’s a connection

you can use to your advantage in today’s hurry-up

marketplace.

Another way Central makes the right connection is

by constantly staying abreast of new technology. If

there’s a better way to do something we’ll either find

it or invent it. Many Central processes are proprietary, a result of our employees and clients recognizing and acting on an opportunity for improvement.

Which means you’ll get a solution customized to your

specific application.

Everyone talks “quality,” but what does it really

mean? To Central, quality starts with a relentless

analysis of customer need and a near obsession with

precision—precision to your standards as well as our

own.

Computer-aided design and computer-controlled

machinery assure that the products you order are

perfectly made. And that if you order more of the

same, even years from now, they will be precisely the

same as today’s.

Our Uncompromising Quality Contributes to Your

Company’s Value to Your Customers

Our commitment is documented. Central earned ISO

9001 certification in 1998, testimony to years of excellence not only in product design, development and

production, but also in marketing, purchasing and

customer service

from Main to Meter.

Responsive GF Central Service Before, During and

After Your Order: It’s Just Good Business!

At Georg Fischer Central Plastics, customer service

actually starts before you’re technically a customer.

It starts with our listening. Top management is accessible to every client, large or small, taking the

time to understand your requirements up front. Our

customer service reps are more than order-takers.

They’re knowledgeable industry consultants and

they’re specially trained to answer the hard questions,

talk through complex plans, and give smart answers

for your unique application. And, you never have to

wait for answers or action. It’s the connection you

need to make your problem go away.

GF Central: The Comprehensive Source for all your

Piping System Connector needs.

We think about quality, service and value so you don’t

have to. That’s why we take such pains to make sure

things are done right the first time, consistently and

predictably.

That’s not all. Because we also help you explore new

ways of doing things, you know where to turn when it’s

time to get something innovative done. So, if you have

an interesting product idea, we would like to discuss it

with you.

We create the technology to build our fittings, sell

our fittings and service our fittings. Nobody else puts

it together the way we do. Georg Fischer Central

Plastics is the one connection you really need to

make.

The Right Connection

Table of Contents

Conventional Fusion Products and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

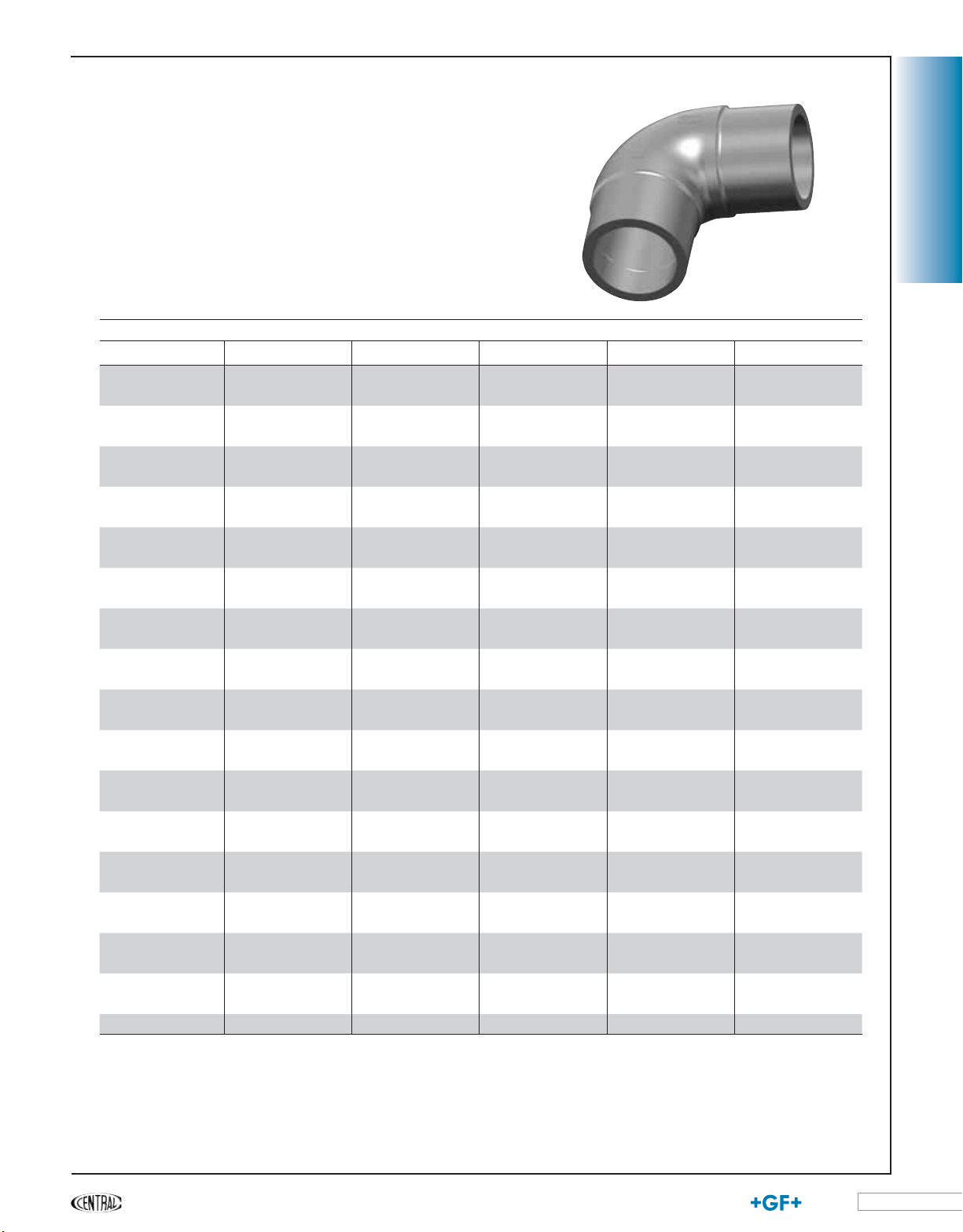

Butt Fittings: 45° Butt Elbow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

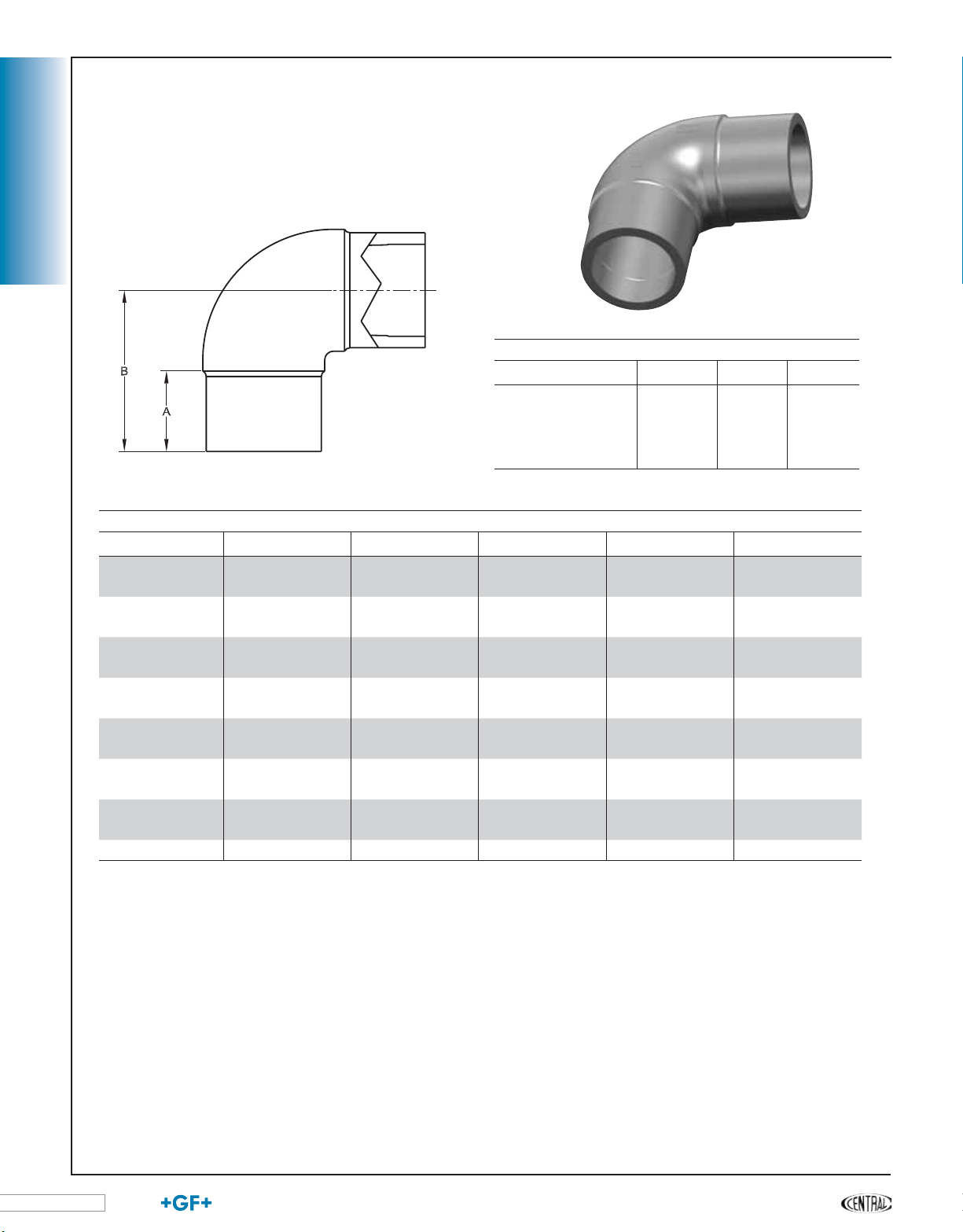

Butt Fittings: 90° Butt Elbow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

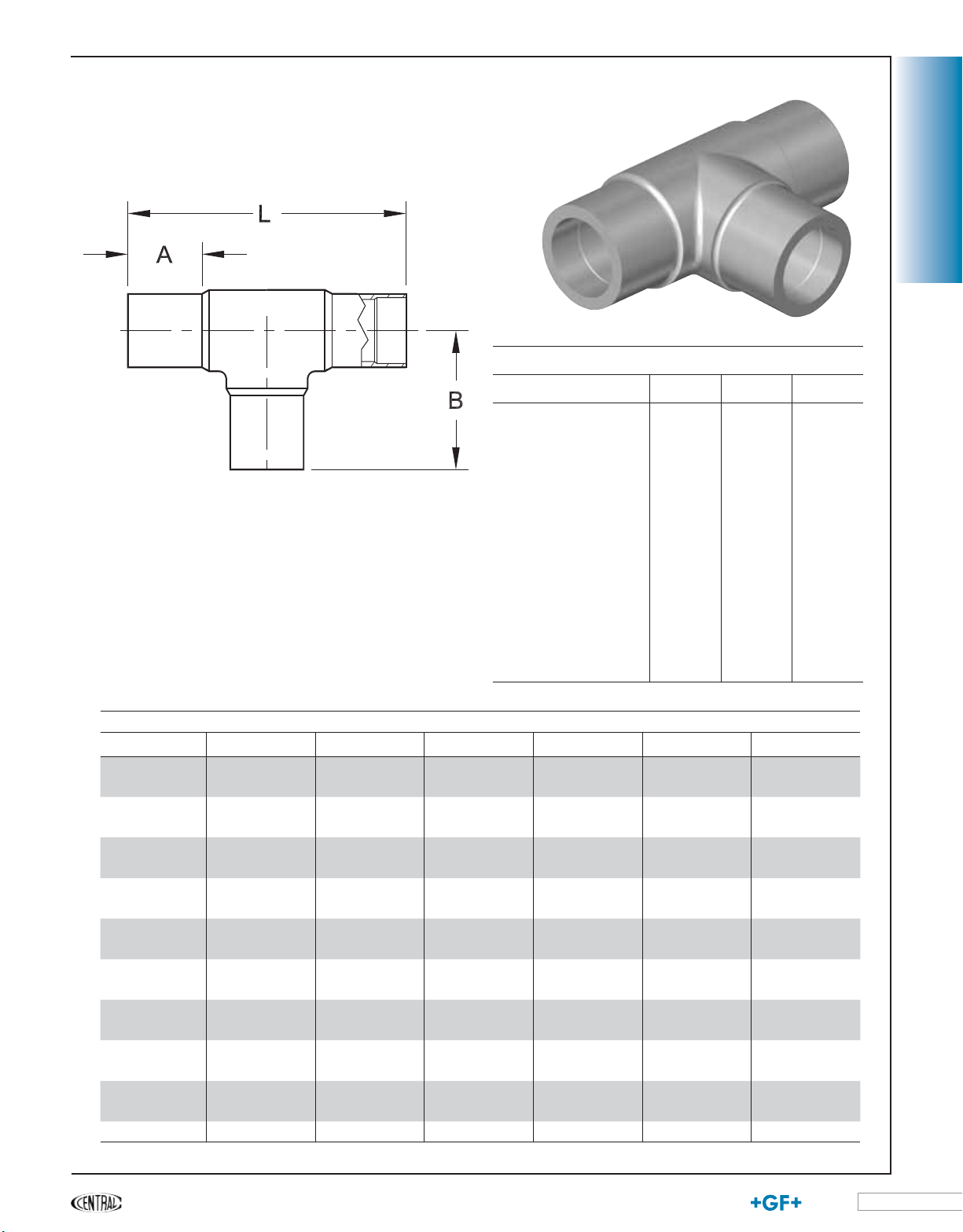

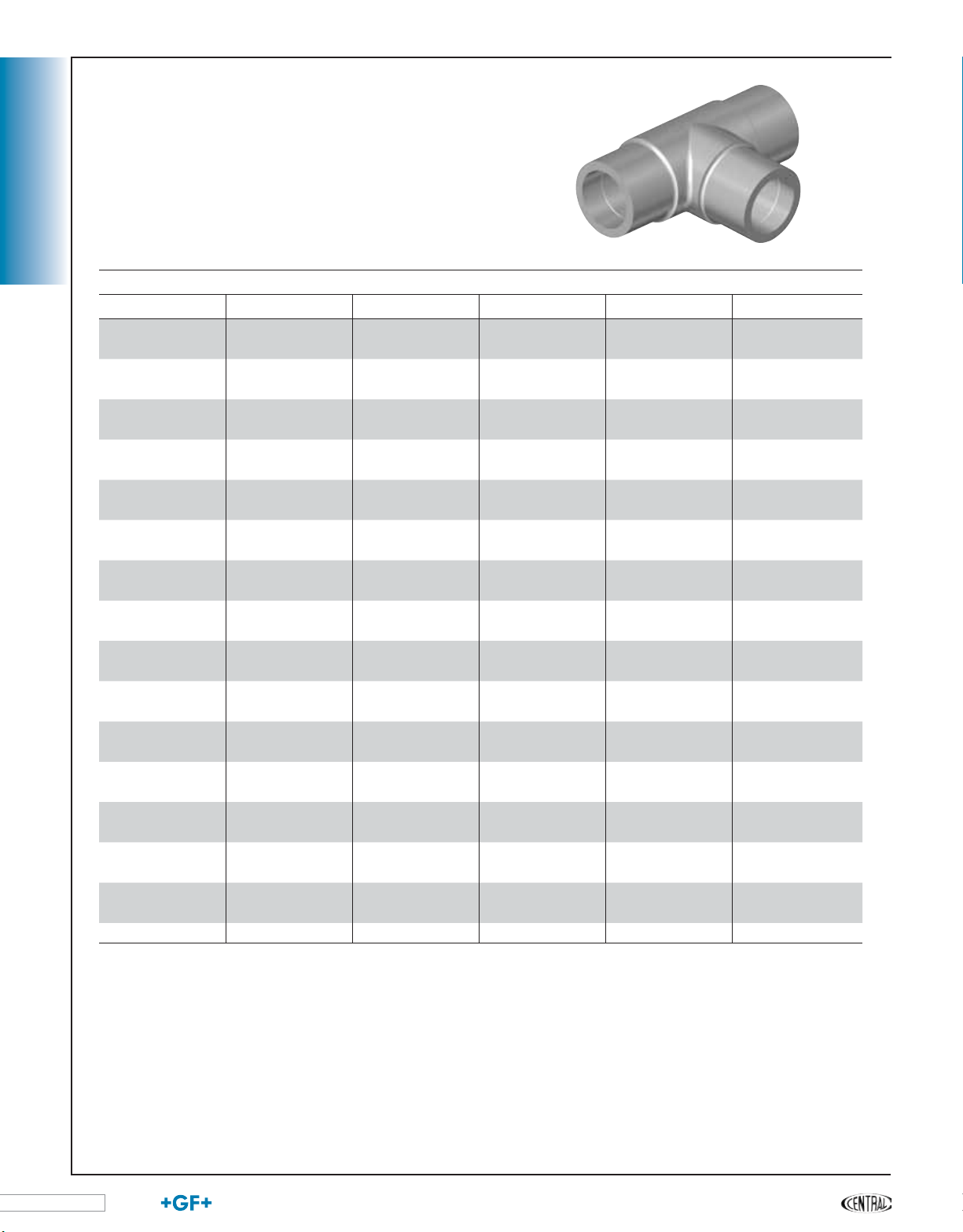

Butt Fittings: Butt Tee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Butt Fittings: Butt Reducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Butt Fittings: Butt Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Butt Fittings: Purge Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Butt Fittings: Purge Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Butt Fittings: Geo-Loops (U-Bends) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Saddle Fittings: Ser vice Saddles w/Butt Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Saddle Fittings: Ser vice Saddles w/Socket Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Saddle Fittings: Ser vice Saddles w/Combo Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Saddle Fittings: Tapping Tee w/Rectangular Base and Butt Outlet . . . . . . . . . . . . . . . 35

Saddle Fittings: Tapping Tee w/Round Base and Butt Outlet . . . . . . . . . . . . . . . . . . . . 39

Saddle Fittings: Tapping Tee w/Rectangular Base and Socket Outlet . . . . . . . . . . . . . 40

Saddle Fittings: Tapping Tee w/Rectangular Base and Combo Outlet . . . . . . . . . . . . . 42

Saddle Fittings: Tapping Tee Trainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Saddle Fittings: Tapping Tee w/Stab Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Saddle Fittings: Tapping Tee w/Excess Flow Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Saddle Fittings: High Volume Tapping Tee w/Square Base . . . . . . . . . . . . . . . . . . . . . . 46

Saddle Fittings: Cast Iron Tapping Tee w/Brass Threads . . . . . . . . . . . . . . . . . . . . . . . 49

Saddle Fittings: Round Base Branch Saddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Socket Fittings: Couplings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Socket Fittings: Elbows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Socket Fittings: Tees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Socket Fittings: Reducing Tees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Socket Fittings: Reducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Socket Fittings: End Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Flange Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Flange Adapters: Back-up Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

MJ Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Gasketed Adapters: Gasketed PE Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Polyethylene Ball Valves: Full Port PE3408/PE4710 . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Fusion Equipment: BS-4 Fusion Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Fusion Equipment: Geo-Loop Fusion Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Fusion Equipment: Socket Fusion Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Fusion Equipment: Model SF3 Base Fusion Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Fusion Equipment: Aldyl-A Tap Tee Repair Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Fusion Equipment: Sidewall Fusion Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Fusion Equipment: Depth Gages and Chamfer Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Fusion Equipment: Cold Rings and Fitting Holders . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Fusion Equipment: Heating Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Fusion Equipment: Butt and Socket Heater Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Fusion Equipment: Sidewall Heating Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Fusion Equipment: Squeeze-Off Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Fusion Equipment: 14M Butt Fusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Fusion Equipment: 28CQ Butt Fusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Fusion Equipment: 28HP Butt Fusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Fusion Equipment: 28HP Butt Fusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Fusion Equipment: 28EP Butt Fusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Fusion Equipment: 414EP Butt Fusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Fusion Equipment: 414SC Butt Fusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Fusion Equipment: 620SC Butt Fusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Fusion Equipment: 824EP Butt Fusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Fusion Equipment: 1442EP Butt Fusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Fusion Equipment: DataConnect Data Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

2

Table of Contents

Electrofusion Products and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Electrofusion Fittings: Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Electrofusion Fittings: Large Diameter Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Electrofusion Fittings: Elbows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Electrofusion Fittings: Tees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Electrofusion Fittings: Reducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Electrofusion Fittings: End Cap Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Electrofusion Fittings: Tapping Tees w/Socket Outlet . . . . . . . . . . . . . . . . . . . . . . . . . 109

Electrofusion Fittings: Tapping Tee Trainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Electrofusion Fittings: Tapping Tees w/Excess Flow Valve . . . . . . . . . . . . . . . . . . . . . 111

Electrofusion Fittings: Tapping Tees w/Stab Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Electrofusion Fittings: Tapping Tees (EFTT) w/Butt Outlet . . . . . . . . . . . . . . . . . . . . . 113

Electrofusion Fittings: Branch Saddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Electrofusion Fittings: Transition Saddles (Corp Saddles) . . . . . . . . . . . . . . . . . . . . . 127

Electrofusion Fittings: Branch Unions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Electrofusion Fittings: Gasketed Sewer Saddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Electrofusion Fittings: WYE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Electrofusion Fittings: Flex Restraint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Electrofusion Processors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Scrapers: Pencil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Electrofusion Equipment: Calibration Mandrel/Scraper Gauge . . . . . . . . . . . . . . . . . 143

Electrofusion Equipment: Molded Scrapers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Electrofusion Equipment: Large Diameter Scrapers . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Electrofusion Equipment: Cast Rotary Scraper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Electrofusion Equipment: Machined Rotary Scrapers . . . . . . . . . . . . . . . . . . . . . . . . . 146

Electrofusion Equipment: Coupling Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Electrofusion Equipment: Reducing Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Electrofusion Equipment: Clamps Kits and Liners . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Electrofusion Equipment: Side Wall Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Electrofusion Equipment: Tools and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Electrofusion Equipment: Re-Rounding Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Plastic Mechanical Fitting Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Plastic Compression Fittings: IPS Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Plastic Compression Fittings: IPS Reducing Coupling . . . . . . . . . . . . . . . . . . . . . . . . 154

Plastic Compression Fittings: IPS Male Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Plastic Compression Fittings: IPS Equal Tee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Plastic Compression Fittings: IPS Reducing Tee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Plastic Compression Fittings: IPS Tee w/Threaded Offtake . . . . . . . . . . . . . . . . . . . . 158

Plastic Compression Fittings: IPS 90° Elbow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Plastic Compression Fittings: IPS End Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Plastic Bolt-On Saddles: Premier IPS Clamp Saddle . . . . . . . . . . . . . . . . . . . . . . . . . 161

Plastic Bolt-On Saddles: Standard IPS Clamp Saddle . . . . . . . . . . . . . . . . . . . . . . . . . 164

Conversion Kits: PVC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Factory Mutual (FM) Approved Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

Factory Mutual: Butt Tee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Factory Mutual: 45° Butt Elbow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Factory Mutual: 90° Butt Elbow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Factory Mutual: Butt Reducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Factory Mutual: Butt Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Factory Mutual: Class 150 Flange Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Factory Mutual: Class 200 Flange Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Factory Mutual: IPS Back Up Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Factory Mutual: IPS MJ Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Factory Mutual: Electrofusion Branch Saddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Factory Mutual: Electrofusion Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Factory Mutual: Thread End Transition Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

3

Table of Contents

Factory Mutual: Weld End Transition Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Factory Mutual: Flanged Transition Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Meter Connection Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Meter Swivels: Straight Insulated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Meter Swivels: Female Insulated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Meter Swivels: Offset Insulated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Meter Swivels: Insulated Elbows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Meters Swivels: Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Meters Swivels: Nut Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Meters Swivels: Connection Blind . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Meter Swivels: Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Meter Connection Products: Insulating Unions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Meter Connection Products: Meter Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Meter Connection Products: Loops, Bends and Manifolds . . . . . . . . . . . . . . . . . . . . . 196

Meter Connection Products: Meter Set Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Risers and Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Anodeless Risers: with PE2406/PE2708 Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Risers and Transitions: Transition Risers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Transition Risers: with PE2406/PE2708 Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Transition Risers with Anodes: with PE2406/PE2708 Pipe . . . . . . . . . . . . . . . . . . . . . 209

Risers and Transitions: Compression Risers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Compression Riser with Anodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Risers and Transitions: Transition Fittings Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Weld-End Transition Fittings: with PE2406/PE2708 Gas Pipe . . . . . . . . . . . . . . . . . . 216

Threaded External Coated Transitions:

with PE2406/PE2708 Gas Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Flange Transition Fittings: with PE2406/PE2708 Pipe . . . . . . . . . . . . . . . . . . . . . . . . . 221

Victaulic Transition Fittings: with PE3408 Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Risers and Transitions: Brass and Stainless Transition Fittings . . . . . . . . . . . . . . . . 222

Brass Transition Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Stainless Steel Transition Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Category 3 Transitions: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Geothermal Transitions: Socket Fusion Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Specialty Transition Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Steel Mechanical Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Steel Mechanical Fittings: Over view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Steel Mechanical Fittings: Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Steel Mechanical Fittings: Tees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Steel Mechanical Fittings: Male Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Steel Mechanical Fittings: Risers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Flange Insulation Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Flange Connection Insulation: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Petrolatum Coating Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

STAC Coating System: STACprime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

STAC Coating System: STACfill and STACfill Lite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

STAC Coating System: STACwrap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

STAC Coating Systems: STACguard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Rod Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Waga Fittings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Butterfly Valves: PVC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

4

Butt Fittings

Saddle Fittings

Socket Fitttings

Flange Adapters

MJ Adapters

PE Ball Valves

Fusion Equipment

Conventional Fusion Products & Equipment

The Right Connection

1-800-654-3872

1-405-273-6302

www.centralplastics.com

Conventional Fusion: General Product Information

Due to the unique material characteristics of polyethylene, heat fusion allows successful joining of pipe and fittings into a single leak-free system with no connections to

Products

corrode or loosen.

Conventional Fusion

“The basic principle of heat fusion (in this case butt,

saddle or socket fusion) is to heat and melt the joint

surfaces and force the melted surfaces together, which

causes the materials to mix and fuse into a monolithic

joint.” AWWA PE Pipe - Design and Installation, Manual of

Water Supply Practices M55

Georg Fischer Central Plastics has been actively involved

in the research and development of innovative joining

methods for polyethylene piping systems since the early

1960’s. Recognized as an industry leader in the world of

manufactured Polyethylene (PE) fittings; Georg Fischer

Central Plastics offers our customers the broadest and

most complete line of Butt, Saddle, and Socket fusion fittings. All designed, manufactured and tested in Shawnee,

Oklahoma. under ISO 9001 standards and serviced by an

experienced staff of the most knowledgeable and customer friendly professionals you could hope to find.

geothermal, irrigation and other industries; Georg Fischer

Central Plastics is helping to ensure that your conventional fusion job is done right - the first time.

With an extensive and state of the art in-house testing

facility, Georg Fischer Central Plastics performs the following tests on all of our Butt, Saddle, and Socket fittings.

> ASTM D 1599 - Minimum Hydraulic Burst Pressure

Test.

> ASTM D 1598 -Sustained Pressure Test Results.

> ASTM D638 Tensile Strength Test.

> PE3408/PE4710 Fittings are tested to the require-

ments of AWWA C906 (where applicable)

> PE3408/PE4710 FM Tested and Approved (where

applicable)

Bringing unrivaled knowledge, experience and

manufacturing capabilities to industries throughout the

world, Georg Fischer Central Plastics delivers innovative and cost effective pipe joining solutions right to your

door step. Servicing the polyethylene fitting needs in

natural gas, potable water, municipal wastewater, oil

and gas gathering, mining, landfill, telecommunications,

6

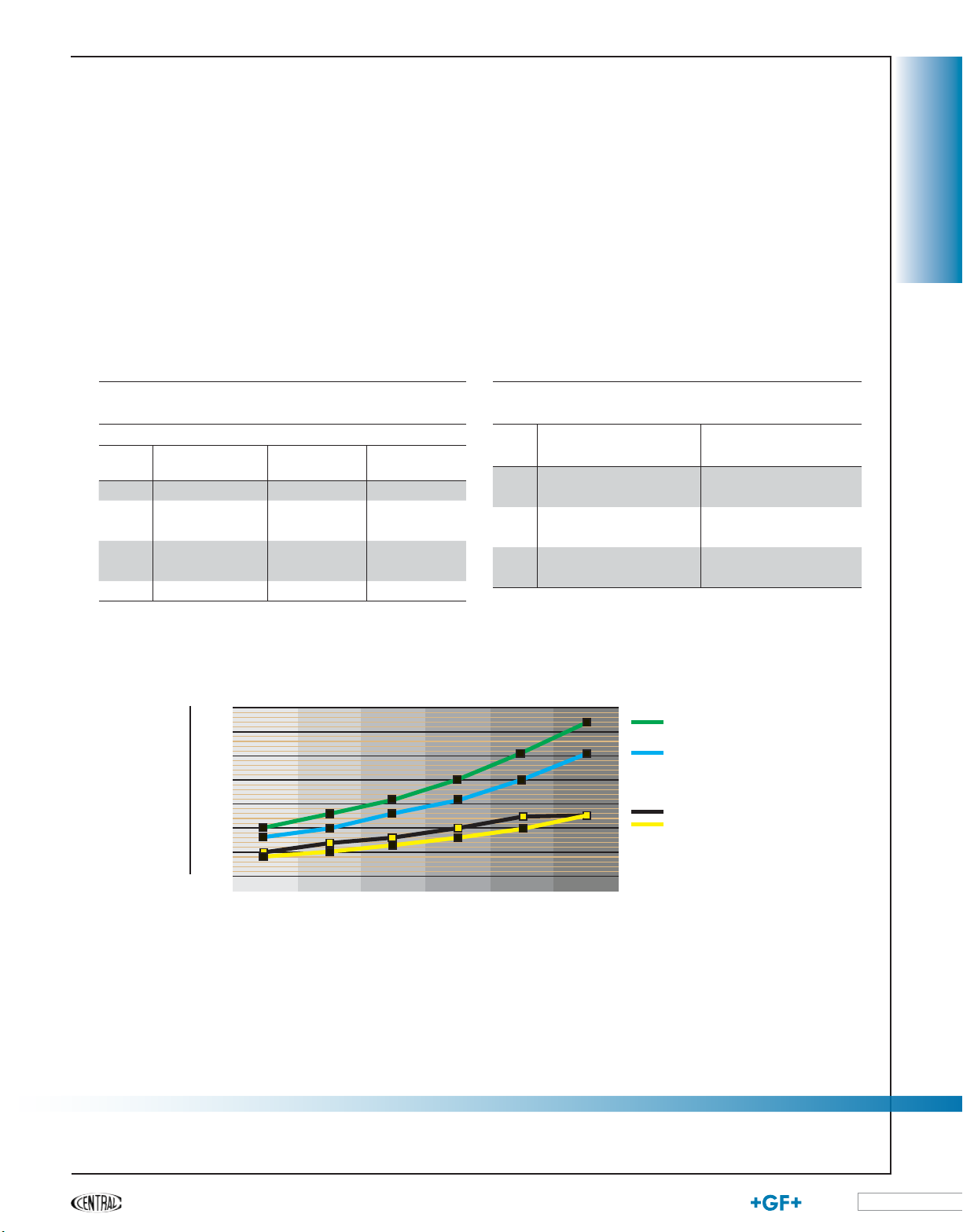

Conventional Fusion: Allowable Operating Pressures

Conventional Fusion

The following charts represent the Allowable Operating Pressure for fittings manufactured from three grades of polyethylene resin used in our products. These values represent the most common Standard Dimension Ratios (SDR) used

in the industries that we ser vice and are further divided based on the design factors determined by each of their related

governing authorities.

> .32 for natural gas distribution systems regardless of resin used

> .50 for water applications for PE3408 resins

> .63 for water applications for PE4710 resins

NOTE: For other fluids, temperatures, chemicals and environmental considerations additional design factors may be required. (i.e.

Canadian gas utilities use a .40 design factor for their natural gas applications.)

DOT Allowable Operating Pressure for

Natural Gas Plastic Pipe Systems

.32 design factor @ 73°F

SDR

21 40 50 50

17 50 64 64

13.5 64 80 80

11 80 100 100

9 100 125** 125**

7 125** 125** 125**

** DOT Regulations only allow a 125 psig max for natural gas

plastic pipe systems regardless of the materials Maximum

Allowable Operating Pressure (MAOP).

PE2406/PE2708

DOT Allowable

PE3408

DOT Allowable

PE4710

DOT Allowable

SDR

21 80 100

17 100 130

13.5 130 160

11 160 200

9 200 255

7 265 335

}

Allowable Operating Pressure for

Municipal & Industrial Applications

PE3408

.50 design factor @ 73°F

All design factors are assuming a standard

operating temperature

of 73°F

PE4710

.63 design factor @ 73°F

Products

PSIG

350

300

250

200

150

100

50

0

Allowable Operating Pressures

SDR 17 SDR 13.5 SDR 11 SDR 9 SDR 7SDR 21

Standard Dimension Ratio

NOTE: Operating Pressure for Conventional Tapping Tees and

Conventional Branch Saddles are determined by the material used, the

outlet SDR and the governing regulations.

Water PE4710

Water PE3408/3708

Gas PE3408/3708 & PE4710

Gas PE2406/2708

7

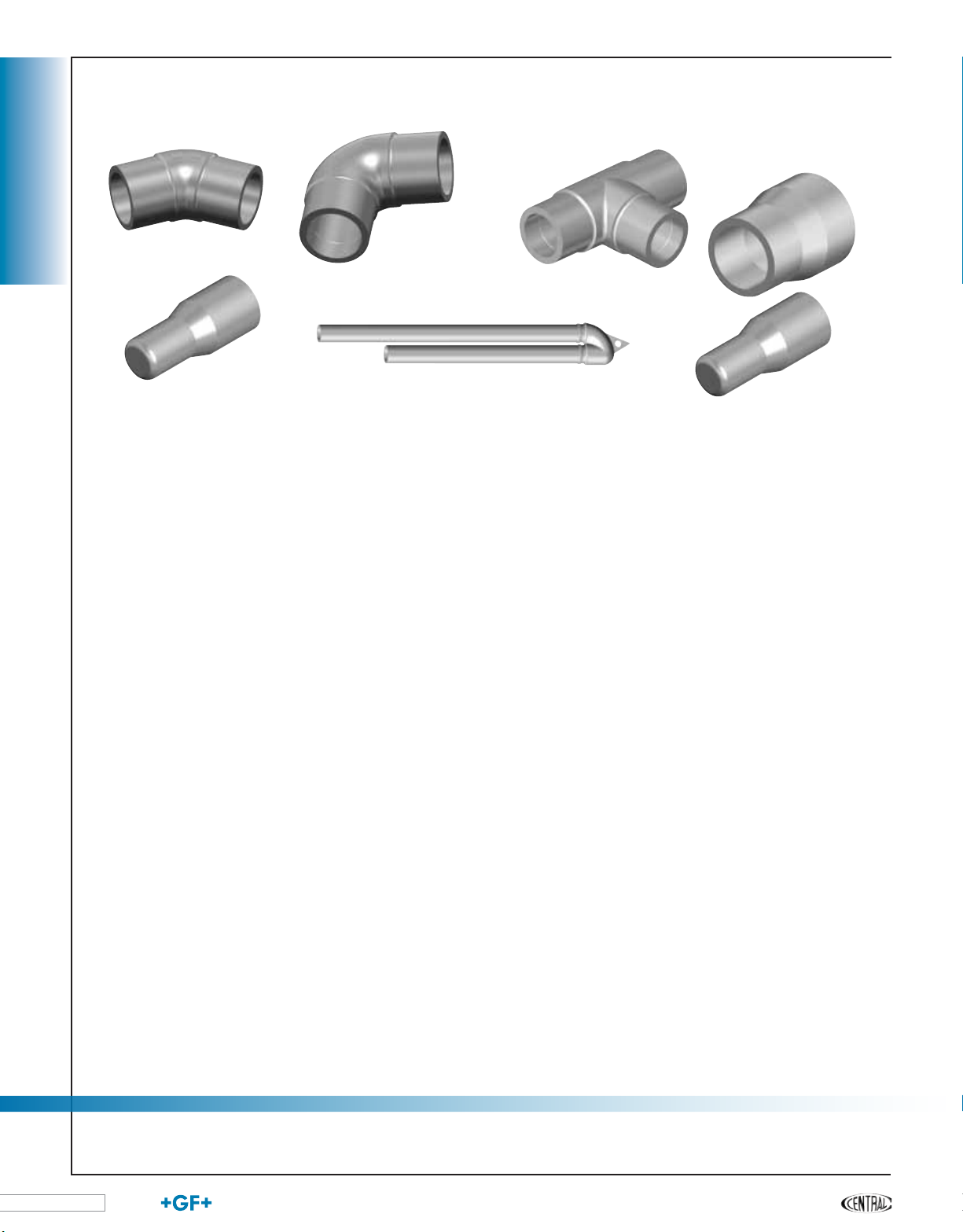

Conventional Fusion: Butt Fusion Fittings

Products

Conventional Fusion

GF Central’s Molded PE2406/PE2708 Butt fittings are

manufactured and tested to the requirements of ASTM

D2513 and ASTM D3261 and are sized for use with pipe

conforming to ASTM D2513 and with Butt fittings conforming to ASTM D3261. GF Central’s PE2406 /PE2708

Butt fittings are molded from a virgin yellow medium

density resin in accordance with the material specifications listed in ASTM D3350 with a designation of PE2406/

PE2708. All Georg Fischer Central Plastics PE2406/

PE2708 Butt Fittings are compatible for heat fusion with

any pipe or fitting manufactured from a like or similar

resin. GFCP’s PE2406/PE2708 fittings have been qualified

for fusion using PPI generic fusion procedures.

Georg Fischer Central’s Molded PE3408/PE4710 Butt fittings are manufactured and tested to the requirements

of ASTM D2513, ASTM D3261, and ANSI/AWWA C906 for

use with outside diameter controlled pipe and fittings

conforming to ASTM D2513, ASTM D3035, ASTM F-714.

Georg Fischer Central’s PE3408/PE4710 Butt fittings are

molded from an NSF listed resin in accordance with the

material specifications listed in ASTM D3350 with a designation of PE3408/PE4710. GFCP PE3408/PE4710 Butt

fittings are manufactured and tested to the requirements

of ASTM D2513 and ASTM D3261 (where applicable) and

are compatible for heat fusion with any pipe and or fitting

manufactured from a like or similar resin. GF Central’s

PE3408/PE4710 fittings have been qualified for fusion

using PPI generic fusion procedures.

FEATURES

> Pressure rated for natural gas and potable water

applications.

> IAPMO Approved (where applicable).

> CSA Approved (where applicable).

> PE3408/PE4710 FM Approved (where applicable).

> PE3408/PE4710 fittings are tested to the requirements

of AWWA C906.

> Can be joined by butt, socket , electrofusion or

mechanical methods.

> Can be heat fused with all conventional and electrofu-

sion fusion methods.

8

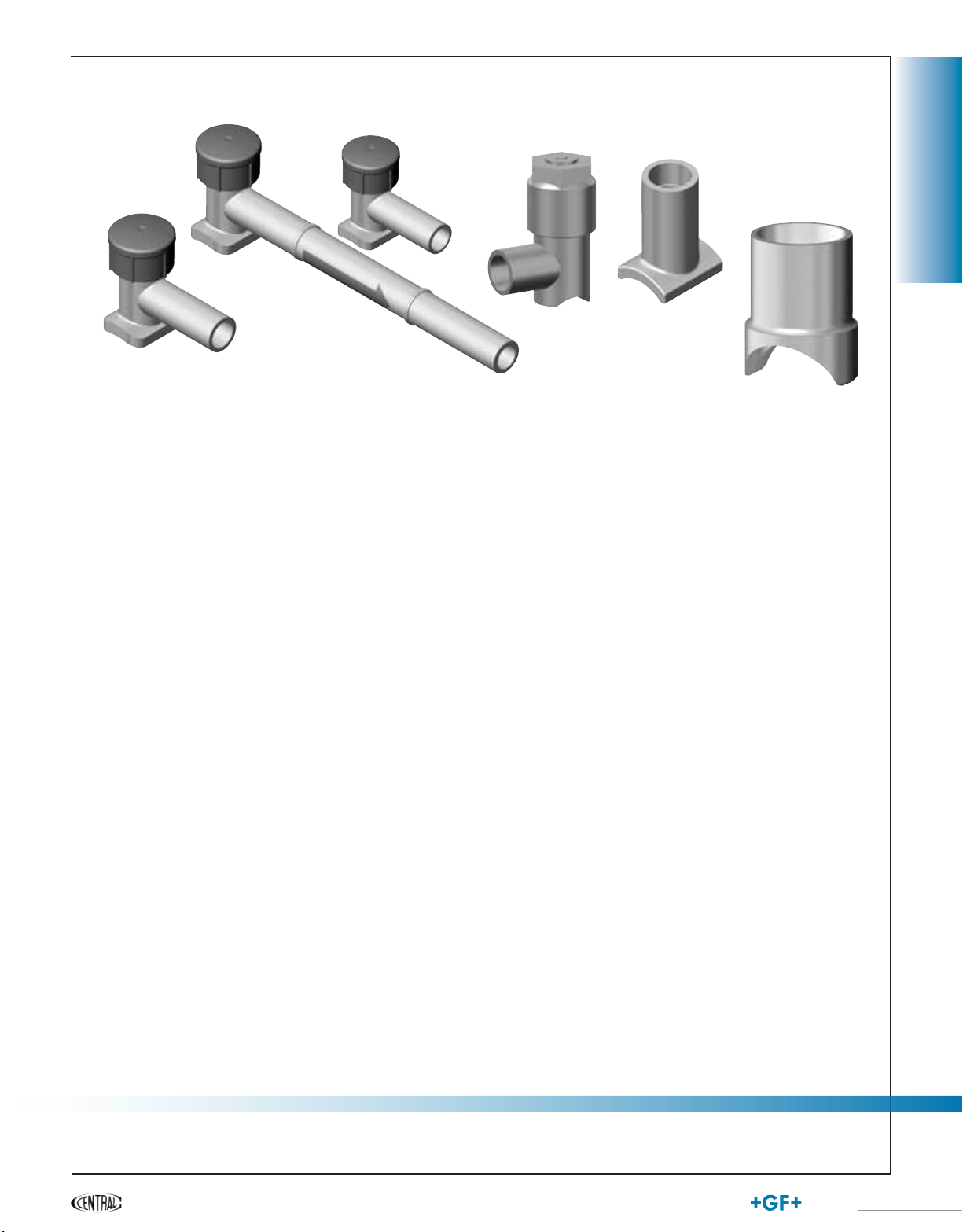

Conventional Fusion: Saddle Fusion Fittings

Conventional Fusion

Products

Georg Fischer Central’s Molded PE2406/PE2708 SideWall Tapping Tees, Service Saddles, and Branch Saddles

are manufactured and tested to the requirements of ASTM

D2513 and ASTM D3261 and are sized for use with pipe

conforming to ASTM D2513 and with Butt fittings conforming to ASTM D3261 as applicable. GF Central’s PE2406/

PE2708 Side-Wall Tapping Tees, Service Saddles and

Branch Saddles are molded from a virgin yellow medium

density resin in accordance with the material specifications listed in ASTM D3350. All Georg Fischer Central

Plastic’s PE2406/PE2708 Side-Wall Tapping Tees, Service

Saddles and Branch Saddles are compatible for side-wall

fusion with any pipe or fitting manufactured from a like or

similar resin. Georg Fischer Central’s PE2406/PE2708

fittings have been qualified for fusion using PPI generic

fusion procedures.

GF Central’s Molded PE3408/PE4710 Side-Wall Tapping

Tees, Service Saddles, and Branch Saddles are manufactured and tested to the requirements of ASTM D2513,

ASTM D3261 and ANSI/AWWA C906 for use with outside

diameter controlled pipe and fittings conforming to ASTM

D2513, ASTM D3035, ASTM F-714 and with Butt fittings

conforming to ASTM D3261. Georg Fischer Central’s

PE3408/PE4710 Side-Wall Tapping Tees, Service Saddles

and Branch Saddles are molded from an NSF listed resin

in accordance with the material specifications listed in

ASTM D3350. All GF Central Plastic’s PE3408/PE4710

Side-Wall Tapping Tees, Service Saddles, and Branch

Saddles are manufactured and tested to the requirements

of ASTM D2513 and ASTM D3261 (where applicable) and

are compatible for side-wall fusion with any pipe and or

fitting manufactured from a like or similar resin. Georg

Fischer Central’s PE3408/PE4710 fittings have been qualified for fusion using PPI generic fusion procedures.

AVAILABLE FEATURES

> Pressure rated for natural gas and potable water

applications.

> IAPMO Approved (where applicable).

> CSA Approved (where applicable).

> PE3408/PE4710 are tested to the requirements of

AWWA C906.

> Can be heat fused to pipe wall using conventional side-

wall fusion methods.

> Outlets can be heat fused using conventional and elec-

trofusion fusion methods.

9

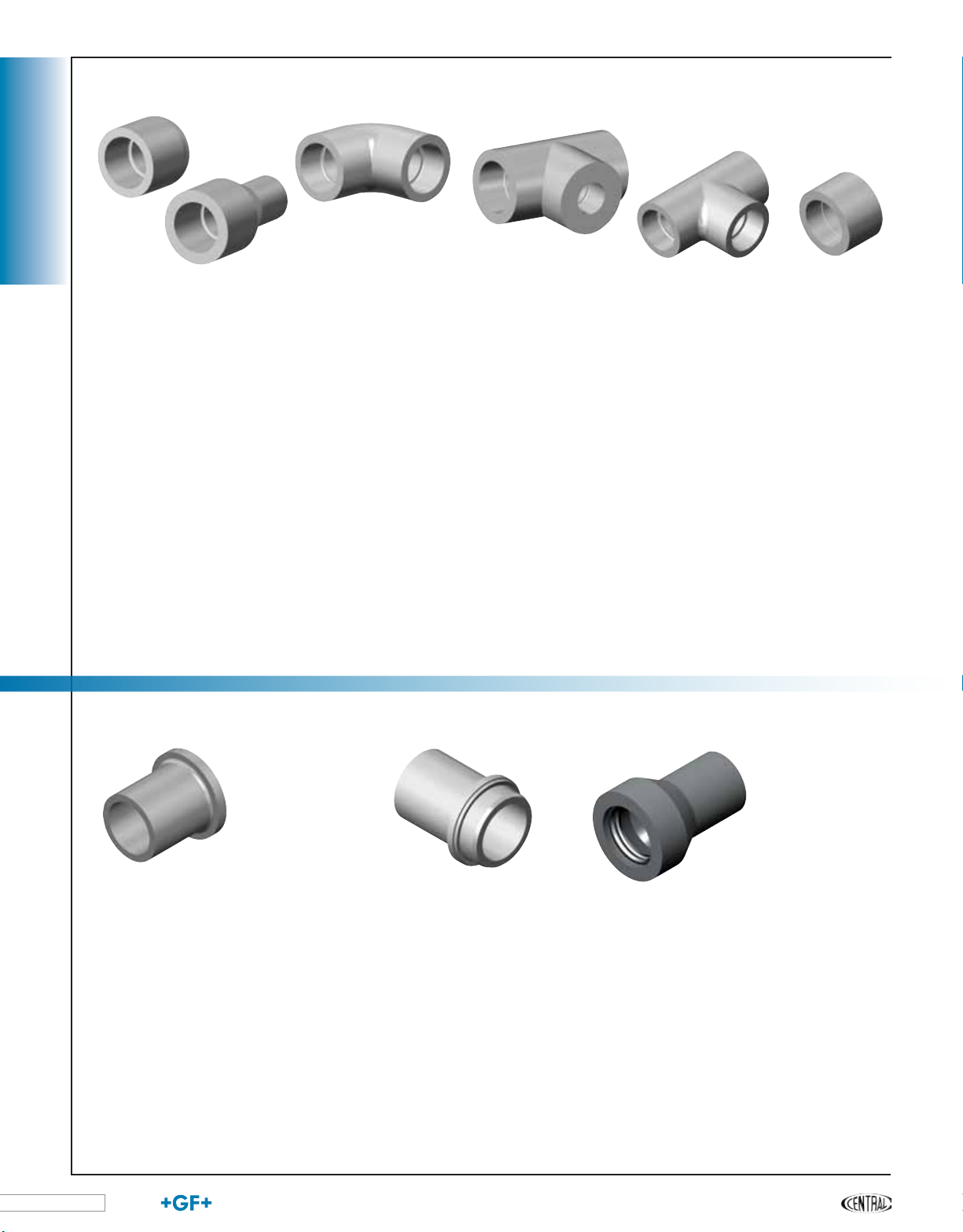

Conventional Fusion: Socket Fusion Fittings

Products

Conventional Fusion

Georg Fischer Central’s Molded PE2406/PE2708 Socket

Fusion fittings are manufactured and tested to the

requirements of ASTM D2513 and ASTM D2683 and are

sized for use with pipe conforming to ASTM D2513. GF

Central’s PE2406/PE2708 Socket fittings are molded from

a virgin yellow medium density resin in accordance with

the material specifications listed in ASTM D3350. All

Georg Fischer Central Plastic’s PE2406/PE2708 Socket

Fusion Fittings are compatible for heat fusion with any

pipe or fitting manufactured from a like or similar resin.

Georg Fischer Central’s PE2406/PE2708 fittings have

been qualified for fusion using ASTM D2657 generic fusion

procedures.

Georg Fischer Central’s Molded PE3408/PE4710 Socket

Fusion fittings are fully manufactured and tested to the

requirements of ASTM D2513 and ASTM D2683 and are

manufactured for use with outside diameter controlled

pipe and fittings conforming to ASTM D2513 and ASTM

F-714. GF Central’s PE3408/PE4710 Socket fittings are

molded from a virgin black high density resin in accordance with the material specifications listed in ASTM

D3350. All GF Central Plastic’s PE3408/PE4710 Fusion

fittings are manufactured and tested to the requirements

of ASTM D2513 and ASTM D2683 and are compatible for

heat fusion with any pipe and or fitting manufactured

from a like or similar resin. GF Central’s PE3408/PE4710

fittings have been qualified for fusion using ASTM D2657

generic fusion procedures.

AVAILABLE FEATURES

> Pressure ratings up to SDR7 on most sizes.

> IAPMO Approved (where applicable).

> CSA Approved (where applicable).

> Can be used with all socket fusion methods.

Conventional Fusion: PE Adapters

Flange Adapter

MJ Adapter

Georg Fischer Central’s PE3408/PE4710 Flange Adapters

and MJ Adapters are manufactured and tested to the

requirements of ASTM D3261 and ASTM D3261 and ANSI/

AWWA C906 for use with pipe conforming to ASTM

D2513/3035, F-714 and with Butt fittings conforming to

ASTM D3261 as applicable. Georg Fischer Central’s

PE3408/PE4710 Flange Adapters and MJ Adapters are

molded from an NSF listed resin in accordance with the

material specifications listed in ASTM D3350. All GF

Central Plastic’s PE3408/PE4710 Flange Adapters and MJ

Adapters are compatible for heat fusion with any pipe or

fitting manufactured from a like or similar resin.

10

FEATURES

> Pressure rated for municipal and trial applications.

> PE3408/PE4710 FM Approved (where applicable).

> PE3408/PE4710 fittings are tested to the requirements

of AWWA C906.

> Can be heat fused using conventional and electrofu-

sion fusion methods.

> Can be beveled for butterfly valves when requested.

> MJ Adapters can be provided with stiffeners when

requested.

Gasketed Adapter

Conventional Fusion: General Equipment Information

Conventional Fusion

Products

Georg Fischer Central Plastics has been a manufacturer

of polyethylene fusion equipment since the early days of

plastic product development and to this day we continue

to manufacture a line of quality fusion equipment. Our

equipment includes:

BS-4 BUTT FUSION MACHINE – capable of butt fusing ½”

thru 4” pipe and fittings. This compact machine is manufactured using structural aluminum castings for stability,

yet is still light weight - ONLY 34 POUNDS. Extra wide

grooved pipe clamps and liners help to assure alignment

on coiled and out-of-round pipe. The precision ground

guide bars are in the center line of pipe to maintain equal

load balance and proper alignment. Clamp knobs are

stainless steel with thrust bearings. A pressure control

knob allows operator to lock position during cooling time

for better joint integrity.

BS-4 ELECTRIC TRIMMER with adjustable trimming

stops. The chain driven 110 or 220 volt BS-4 Electric

Trimmer utilizes a 1/2 hp, 620 watt, 5.63 amp motor. The

main spindle turns on sealed ball bearings for longer life.

Trimmer blades are made of hardened stainless steel for

longer wear, better edge and rust free operation.

MANUAL TRIMMER – is typically used in conjunction with

the Central Gas Fired Heating Tool and allows quality

fusion in remote areas. The manual trimmer can be used

in lieu of electric trimmer.

BUTT, SOCKET AND SADDLE HEATING TOOLS

> Versatile heating tools capable of Socket, Saddle or

Butt Fusion

> Interchangeable Heater Faces – Heating tools are

interchangeable with most conventional heater faces

currently in the field.

> Central Quality – GF Central’s heater face coating is

designed to provide durability and long wear.

> Portable – Lightweight for easy handling.

> Recessed Thermometer – Easy to read dial thermom-

eter recessed in the handle.

> Gas Fired Tools – Economical tools for quick line

repairs. No generator is required – simply heat

desired temperature with a conventional gas torch.

AVAILABLE FUSION EQUIPMENT ACCESSORIES

> Butt Fusion Heater Faces

> Socket Heater Faces

> Tapping Tee Faces

> High-Volume Multi-Saddle Faces

> Branch Saddle Faces

> BS-4 Butt Fusion Machine Liner Kits

> Special Liner Kits

> Socket Fusion Depth Gauges

> Socket Fusion Cold Rings

> Socket Fusion Fitting Holders

> Socket Fusion Chamfer Tools

> Squeeze-Off Tools

On March 8, 2007, GF Central Plastics officially expanded

the breadth of our fusion equipment product offering

through the acquisition of

Georg Fischer Connectra LLC

The inclusion of Connectra fusion products will now allow

Georg Fischer Central Plastics to offer a more comprehensive line of fusion equipment with Butt Fusion capabilities up to 42”.

11

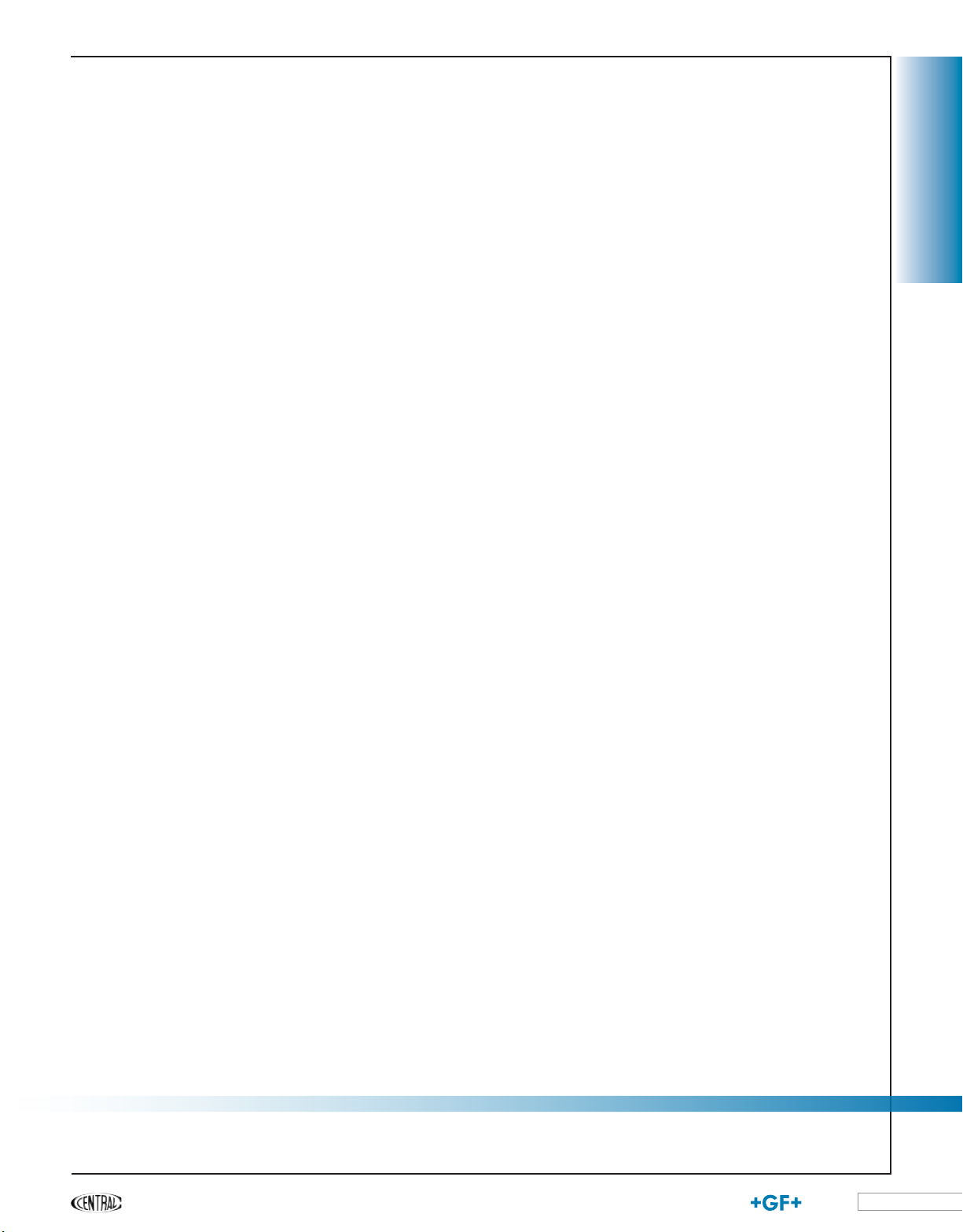

Butt Fittings: 45° Butt Elbow

Products

Conventional Fusion

45° IPS ELBOW DIMENSIONS

Nominal Size A B L

3” IPS 3.13 5.00 *

4” IPS 3.00 5.00 *

6” IPS 4.38 7.00 *

8” IPS 6.00 11.00 *

Call for availability of other sizes and dimensions.

10” IPS 6.00 13.25 *

12” IPS 7.50 15.75 *

(PE2406/PE2708) 45° IPS BUTT ELBOWS

Size SDR Part Number Pack. Qty. Wt. CSA

3” IPS DR 11/11.5 6910559 10 1.79 -

4” IPS DR 13.5 6911526 10 2.52 -

4” IPS DR 11/11.5 6911483 10 2.67 YES

6” IPS DR 13.5 6910456 10 6.50 -

6” IPS DR 11/11.5 691060625000 2 7.15 YES

8” IPS DR 13.5 6910568 2 18.40 YES

8” IPS DR 11/11.5 6910482 2 20.23 YES

10” IPS DR 13.5 6910964 1 36.50 -

10” IPS DR 11 6910954 1 36.50 -

12” IPS DR 13.5 6910967 1 61.50 -

12” IPS DR 11 6910960 1 61.50 -

(PE3408/PE4710) 45° IPS BUTT ELBOWS

Size SDR Part Number Pack. Qty. Wt. AWWA

2” IPS DR 7 10007359 10 1.33 YES

3” IPS DR 17 10004085 10 1.57 YES

3” IPS DR 11 10002941 10 1.80 YES

3” IPS DR 9/9.3 10004087 10 1.62 YES

3” IPS DR 7 10007360 10 2.97 YES

4” IPS DR 17 10004091 10 2.64 YES

4” IPS DR 11 10002942 10 2.90 YES

4” IPS DR 9/9.3 10004094 10 2.79 YES

4” IPS DR 7 10007361 10 3.03 YES

6” IPS DR 17 10004098 2 7.43 YES

6” IPS DR 11 10002943 2 7.09 YES

6” IPS DR 9 10004101 2 7.14 YES

6” IPS DR 7 10007362 2 11.74 YES

8” IPS DR 17 10004106 2 19.60 YES

8” IPS DR 11 10002944 2 20.90 YES

8” IPS DR 9 10004107 2 19.90 YES

10” IPS DR 17 10004073 1 38.00 YES

10” IPS DR 11 10004070 1 41.50 YES

10” IPS DR 9 10004074 1 47.50 YES

12” IPS DR 17 10004082 1 60.00 YES

12” IPS DR 11 10004078 1 64.00 YES

12” IPS DR 9 10004083 1 67.50 YES

12

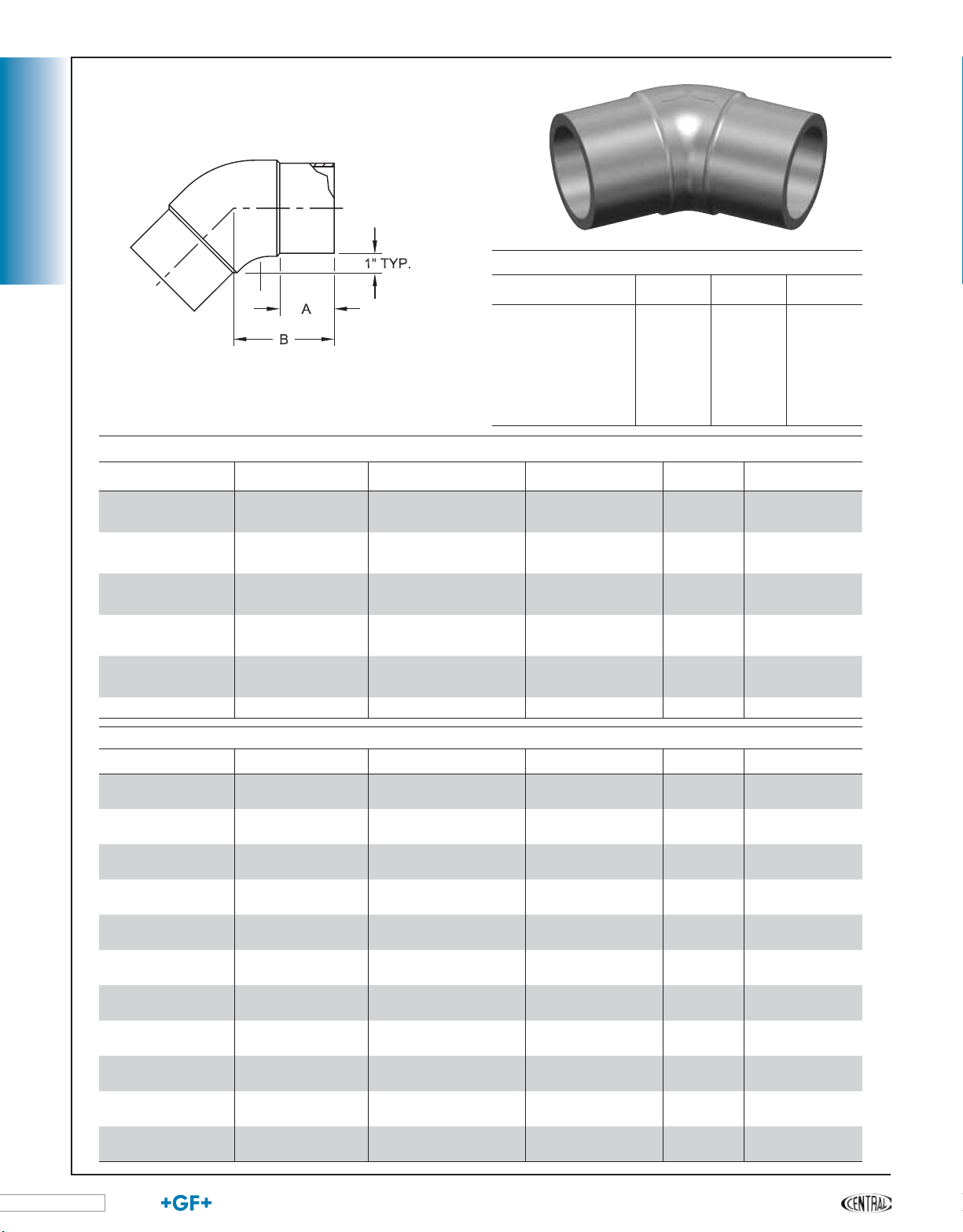

Butt Fittings: 45° Butt Elbow (DIPS)

Nominal Size A

4” DIPS 4.10 6.05 *

6” DIPS 5.10 7.16 *

8” DIPS 5.17 8.32 *

10” DIPS 6.00 13.25 *

12” DIPS 7.50 15.88 *

(PE3408/PE4710) 45° DIPS BUTT ELBOWS

45° DIPS ELBOW DIMENSIONS

B

Conventional Fusion

Products

L

Size SDR Part Number Pack. Qty. Wt. AWWA

4” DIPS DR 17 call - - -

4” DIPS DR 11 10004088 10 3.45 YES

4” DIPS DR 9 call - - -

6” DIPS DR 17 call - - -

6” DIPS DR 11 10004095 2 8.88 YES

6” DIPS DR 9 call - - -

8” DIPS DR 17 call - - -

8” DIPS DR 11 10004103 2 14.60 YES

8” DIPS DR 9 call - - -

10” DIPS DR 17 call - - -

10” DIPS DR 11 10004069 1 43.00 YES

10” DIPS DR 9 call - - -

12” DIPS DR 17 call - - -

12” DIPS DR 11 10004076 1 68.00 YES

12” DIPS DR 9 call - - -

Call for availability of other sizes and dimensions.

13

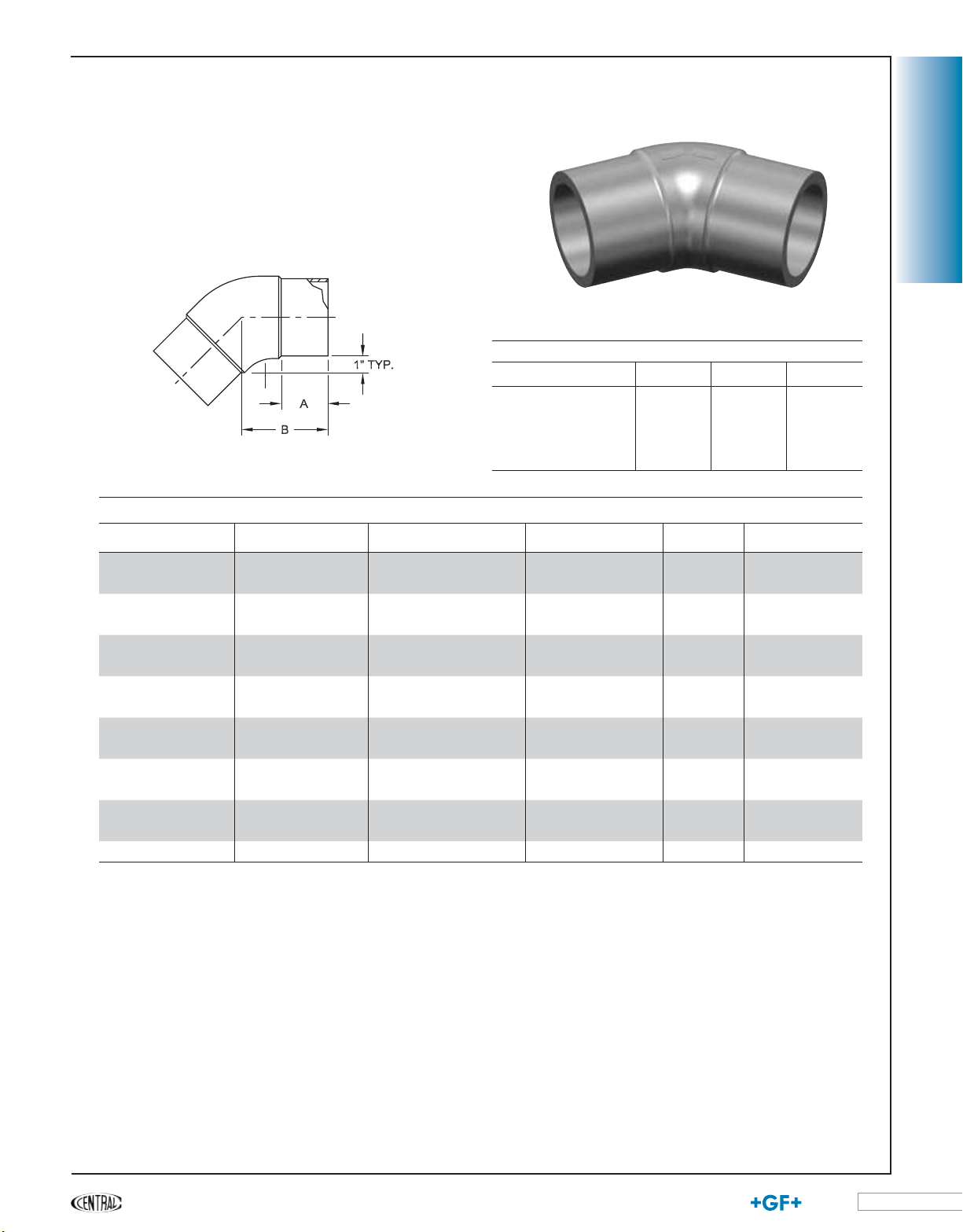

Butt Fittings: 90° Butt Elbow

Products

Conventional Fusion

90° CTS & IPS ELBOW DIMENSIONS

Nominal Size A

¾” IPS 2.63 4.00 *

1” CTS 2.25 3.69 *

1” IPS 2.63 4.00 *

1¼” IPS 2.63 4.00 *

1½” IPS 2.63 4.00 *

2” IPS 2.81 4.50 *

3” IPS 3.00 5.13 *

4” IPS 3.00 5.75 *

6” IPS 4.38 9.00 *

8” IPS 6.00 12.00 *

10” IPS 6.00 13.25 *

12” IPS 7.50 15.88 *

B

L

(PE 2406/PE2708) 90° CTS & IPS BUTT ELBOWS

Size SDR Part Number Pack Qty. Wt. CSA IAPMO

¾” IPS DR 11 6916262 100 0.09 YES ¾” IPS DR 9.3 6910068 100 0.14 YES YES

1” CTS 0.101 WALL 6912014 100 0.13 - 1” IPS DR 11 6911354 50 0.13 YES 1” IPS DR 9.3 6910067 100 0.19 - 1¼” IPS DR 9.3 6910056 40 0.29 YES YES

1½” IPS DR 11 6911356 10 0.34 YES 1½” IPS DR 9.3 6910265 10 0.39 - YES

2” IPS DR 11 6912133 8 0.68 YES YES

3” IPS DR 11/11.5 6911433 10 1.64 YES YES

4” IPS DR 13.5 6911424 10 3.07 - 4” IPS DR 11/11.5 6912158 1 3.11 - 6” IPS DR 13.5 6910455 1 10.00 - 6” IPS DR 11/11.5 691060623000 1 10.00 YES YES

6” IPS DR 11/11.5 10009792 1 10.00 - 8” IPS DR 13.5 6910499 1 20.90 YES 8” IPS DR 11.5/11.5 6910480 1 20.90 YES 10” IPS DR 13.5 6910963 1 34.00 - 10” IPS DR 11 6910952 1 36.50 - 12” IPS DR 13.5 6910966 1 55.50 - 12” IPS DR 11 6910958 1 57.30 - -

14

Butt Fittings: 90° Butt Elbow

(PE3408/PE4710) 90° IPS BUTT ELBOWS

Size SDR Part Number Pack Qty. Wt. AWWA

¾” IPS DR 11 10004109 100 0.15 YES

¾” IPS DR 9.3 10004110 100 0.15 YES

1” IPS DR 11 10004111 100 0.14 YES

1” IPS DR 9.3 10003813 100 0.19 YES

1¼” IPS DR 11 10002945 100 0.26 YES

1¼” IPS DR 9.3 10004112 100 0.29 YES

1½” IPS DR 11 10004113 40 0.34 YES

1½” IPS DR 9.3 10004114 80 0.37 YES

2” IPS DR 17 10004130 10 0.59 YES

2” IPS DR 11 10002946 10 0.74 YES

2” IPS DR 9/9.3 10004131 10 0.66 YES

2” IPS DR 7 10007363 0.89 YES

3” IPS DR 17 10008763 10 1.54 YES

3” IPS DR 11 10007745 10 1.75 YES

3” IPS DR 9/9.3 10004133 10 1.67 YES

3” IPS DR 7 10007364 10 2.35 YES

4” IPS DR 17 10003465 10 3.15 YES

4” IPS DR 11 10001630 10 3.61 YES

4” IPS DR 9/9.3 10004137 10 3.12 YES

4” IPS DR 7 10007365 10 3.97 YES

6” IPS DR 17 10008764 2 9.96 YES

6” IPS DR 11 10007785 2 9.76 YES

6” IPS DR 9/9.3 10004148 2 9.37 YES

6” IPS DR 7 10007366 2 12.87 YES

8” IPS DR 17 10008766 2 21.10 YES

8” IPS DR 11 10007788 2 21.40 YES

8” IPS DR 9 10004155 2 20.20 YES

10” IPS DR 17 10004119 1 33.00 YES

10” IPS DR 11 10004116 1 35.80 YES

10” IPS DR 9 10004121 1 43.50 YES

12” IPS DR 17 10004127 1 56.50 YES

12” IPS DR 11 10003853 1 59.70 YES

12” IPS DR 9 10003928 1 71.00 YES

Conventional Fusion

Products

Call for availability of other sizes and dimensions.

15

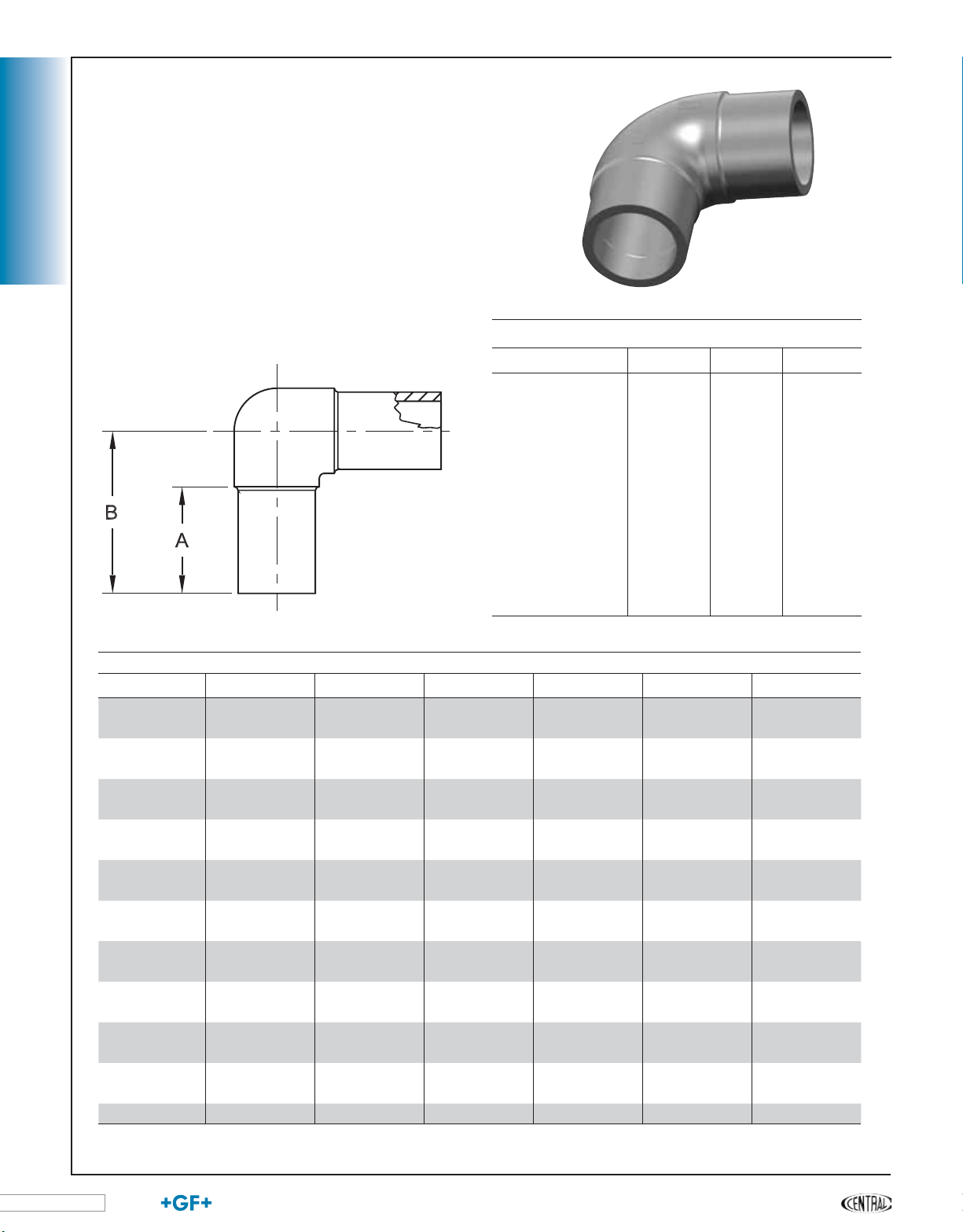

Butt Fittings: 90° Butt Elbow (DIPS)

Products

Conventional Fusion

90° DIPS ELBOW DIMENSIONS

Nominal Size A

4” DIPS 4.10 7.82 *

6” DIPS 5.10 9.67 *

8” DIPS 5.17 11.58 *

10” DIPS 6.00 13.25 *

12” DIPS 7.50 15.88 *

(PE3408/PE4710) 90° DIPS BUTT ELBOWS

Size SDR Part Number Pack Qty. Wt. AWWA

4” DIPS DR 17 call - - YES

4” DIPS DR 11 10004134 10 4.30 YES

4” DIPS DR 9 call - - 6” DIPS DR 17 10004140 2 10.50 YES

6” DIPS DR 11 10004139 2 10.50 YES

6” DIPS DR 9 call - - 8” DIPS DR 17 10004150 - - YES

8” DIPS DR 11 10004149 2 19.40 YES

8” DIPS DR 9 call 2 21.00 YES

10” DIPS DR 17 call - - 10” DIPS DR 11 10004115 1 39.00 YES

10” DIPS DR 9 call - - 12” DIPS DR 17 call - - 12” DIPS DR 11 10004123 1 62.50 YES

12” DIPS DR 9 call - - -

B

L

Call for availability of other sizes and dimensions.

16

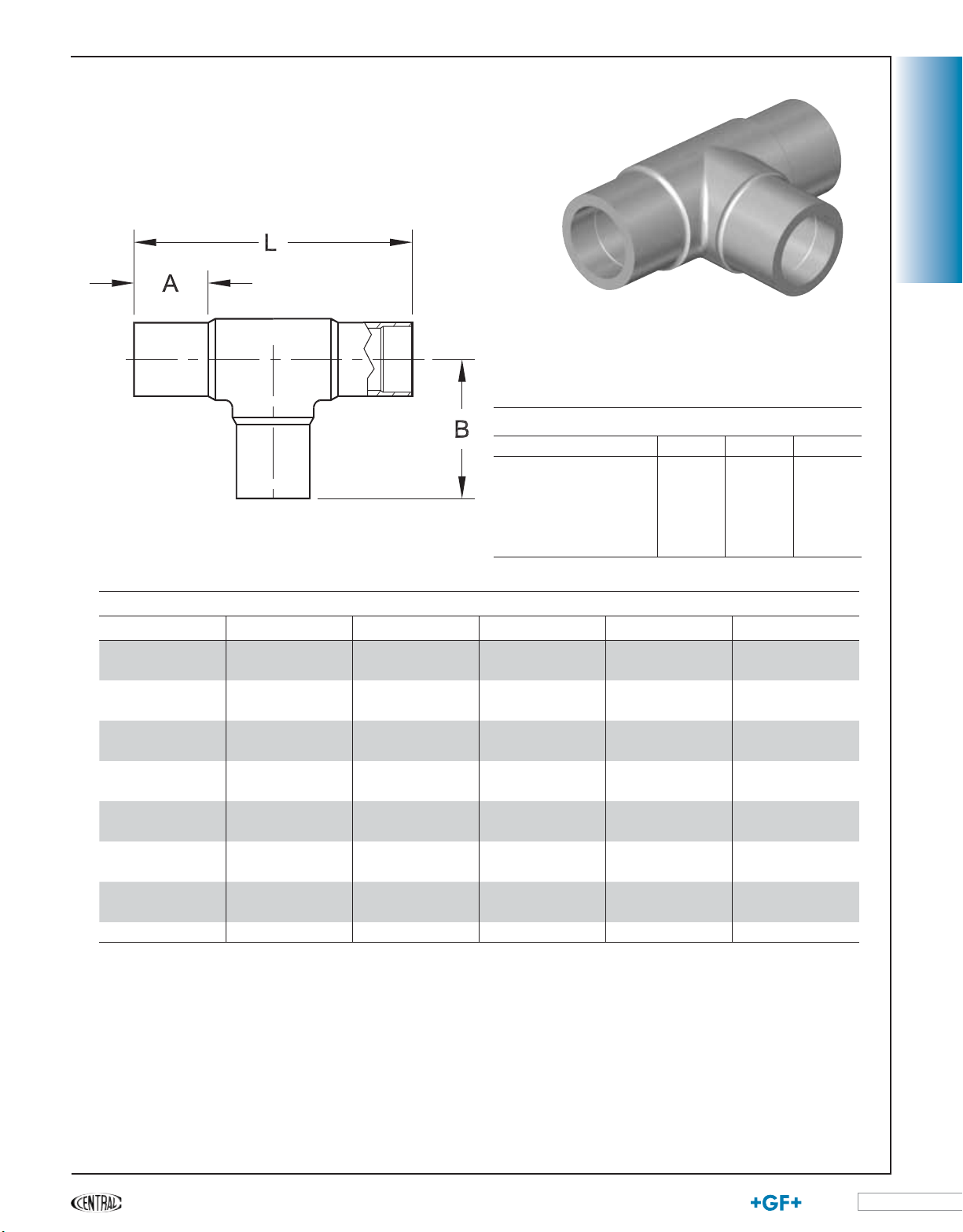

Butt Fittings: Butt Tee

Call for availability of other sizes and dimensions.

Conventional Fusion

Products

CTS & IPS BUTT TEE DIMENSIONS

Nominal Size A B L

¾” CTS 1.75 2.85 5.70

¾” IPS 1.75 3.06 6.12

1” CTS 2.25 3.62 7.25

1” IPS 1.75 3.19 6.38

1¼” IPS 1.88 3.38 6.76

1½” IPS 2.30 4.25 8.50

2” IPS 2.54 4.61 9.28

3” IPS 2.90 5.13 10.26

4” IPS 2.90 5.60 11.20

6” IPS 4.38 9.00 18.00

8” IPS 6.00 12.00 24.00

10” IPS 6.00 13.25 26.50

10” IPS 6.00 13.25 26.50

12” IPS 7.50 15.88 31.75

(PE 2406/PE2708) CTS & IPS BUTT TEES

Size SDR Part Number Pack Qty. Wt. CSA IAPMO

½” CTS .090 WALL 6911493 100 0.04 YES -

¾” CTS .090 WALL 6912139 100 0.12 - -

¾” IPS DR 11 6910216 100 0.00 YES -

1” CTS 0.101 WALL 6911790 50 0.16 - -

1” IPS DR 11 6910217 100 0.20 YES -

1¼” IPS DR 10 6910215 50 0.41 - -

1½” IPS DR 11 6910226 40 0.49 YES -

2” IPS DR 11 6912135 10 0.88 YES YES

3” IPS DR 11/11.5 6911434 10 2.15 YES YES

4” IPS DR 13.5 6911441 8 3.50 - -

4” IPS DR 11/11.5 6912160 10 4.46 YES YES

6” IPS DR 13.5 6910454 1 13.70 - -

6” IPS DR 11/11.5 691060624000 1 13.80 YES YES

8” IPS DR 13.5 6910569 1 29.30 YES -

8” IPS DR 11/11.5 6910476 1 30.30 YES -

10” IPS DR 13.5 6910962 1 49.50 - -

10” IPS DR 11 6910950 1 51.50 - -

12” IPS DR 13.5 6910965 1 81.00 - -

12” IPS DR 11 6910956 1 81.00 - -

17

Butt Fittings: Butt Tee

Products

Conventional Fusion

(PE3408/PE4710) CTS & IPS BUTT TEES

Size SDR Part Number Pack Qty. Wt. AWWA

½” CTS .090 WALL 10004229 100 0.08 YES

¾” IPS DR 11 10003969 100 0.13 YES

1” CTS .101 WALL 10002906 50 0.18 1” IPS DR 11 10003838 100 0.19 YES

1¼” IPS DR 11 10003815 50 0.42 YES

1½” IPS DR 11 10004230 40 0.49 YES

1½” IPS DR 9.3 10003931 40 0.49 YES

2” IPS DR 11 10002956 10 0.99 YES

2” IPS DR 9.3/9.3 10004250 10 0.91 YES

2” IPS DR 7 10007367 10 1.15 YES

3” IPS DR 17 10008631 10 2.01 YES

3” IPS DR 11 10007746 10 2.30 YES

3” IPS DR 9/9.3 10004253 10 2.31 YES

3” IPS DR 7 10007368 10 3.05 YES

4” IPS DR 17 10003478 8 4.50 YES

4” IPS DR 11 10000853 8 4.50 YES

4” IPS DR 9 10002073 10 5.40 YES

4” IPS DR 7 10007369 10 5.18 YES

6” IPS DR 17 10008765 1 13.50 YES

6” IPS DR 11 10007787 1 14.13 YES

6” IPS DR 9 10004263 1 15.10 YES

6” IPS DR 7 10007370 1 16.96 YES

8” IPS DR 17 10008767 1 29.90 YES

8” IPS DR 11 10007789 1 30.51 YES

8” IPS DR 9 10004273 1 28.00 YES

10” IPS DR 17 10004237 1 46.50 YES

10” IPS DR 11 10004233 1 56.50 YES

10” IPS DR 9 10004238 1 59.00 YES

12” IPS DR 17 10004246 1 74.50 YES

12” IPS DR 11 10004242 1 79.30 YES

12” IPS DR 9 10004247 1 82.30 YES

Call for availability of other sizes and dimensions.

18

Butt Fittings: Butt Tee (DIPS)

DIPS BUTT TEE DIMENSIONS

Nominal Size A

4” DIPS 4.10 7.85 15.63

6” DIPS 5.10 9.67 19.34

8” DIPS 5.17 11.58 23.15

10” DIPS 6.00 13.25 26.50

12” DIPS 7.50 15.88 31.76

B

L

Conventional Fusion

Products

(PE3408/PE4710) DIPS BUTT TEES

Size SDR Part Number Pack Qty. Wt. AWWA

4” DIPS DR 17 call - - YES

4” DIPS DR 11 10004254 5 6.20 YES

4” DIPS DR 9 call - - YES

6” DIPS DR 17 10004258 1 15.15 YES

6” IPS DR 11 10004257 1 15.19 YES

6” DIPS DR 9 call - - YES

8” DIPS DR 17 10004267 1 27.70 YES

8” DIPS DR 11 10004266 1 30.00 YES

8” DIPS DR 9 call - - YES

10” DIPS DR 17 call - - YES

10” DIPS DR 11 10004232 - 53.98 YES

10” DIPS DR 9 call - - YES

12” DIPS DR 17 call - - YES

12” DIPS DR 11 10004240 1 88.00 YES

12” DIPS DR 9 call - - YES

Call for availability of other sizes and dimensions.

19

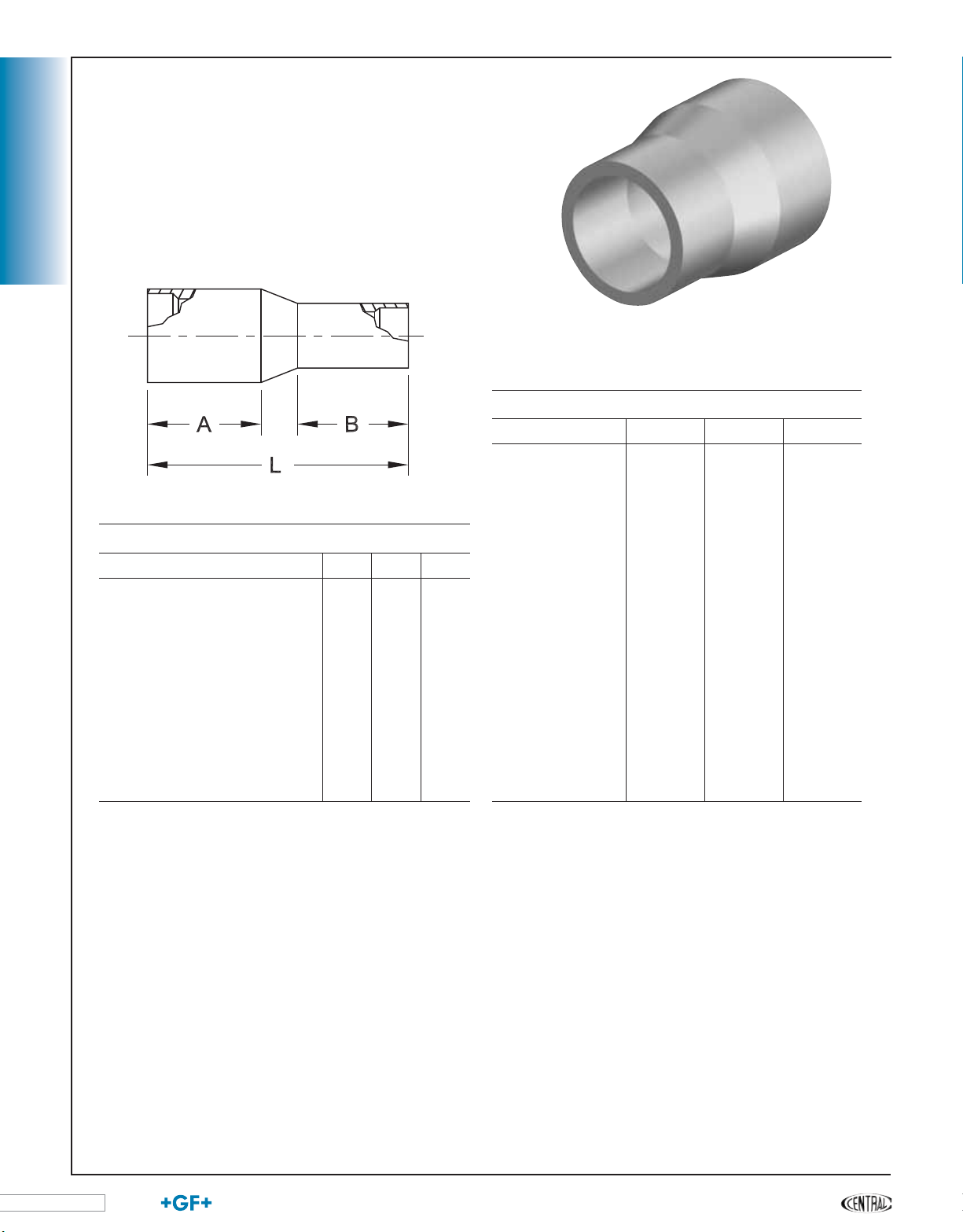

Butt Fittings: Butt Reducers

Products

Conventional Fusion

IPS BUTT REDUCER DIMENSIONS

B

L

CTS BUTT REDUCER DIMENSIONS

Nominal Size A

1” CTS × ½” CTS 1.79 2.00 4.00

1” IPS × ½” CTS 1.44 1.80 4.50

1” IPS × ¾” CTS 1.50 1.80 4.50

1” IPS × 1” CTS 1.60 2.25 4.50

1¼” CTS × 1” IPS 1.50 2.00 3.84

1¼” IPS × 1¼” CTS 2.50 2.50 5.75

2” IPS × 1¼” CTS 2.49 2.88 6.31

2” IPS × 1½” CTS 2.19 2.29 5.00

2” IPS × 2” CTS 2.75 3.00 6.00

2” IPS × 2” CTS 2.75 3.00 6.00

B

L

Nominal Size A

1” × ½” 1.50 1.25 4.00

1” × ¾” 1.50 1.75 4.50

1¼” × 1” 1.86 1.92 4.25

1½” × ¾” 2.50 2.40 5.69

1½” × 1” 2.50 2.28 5.75

2” × 1” 2.49 2.88 6.31

2” × 1¼” 3.15 2.56 6.44

2” × 1½” 2.50 2.72 6.00

3” × 2” 3.22 2.50 6.65

4” × 2” 3.00 3.00 11.87

4” × 2” 2.75 2.75 7.16

4” × 3” 3.13 3.13 8.62

6” × 4” 4.22 3.75 9.13

8” × 6” 5.00 4.64 10.70

10” × 8” 6.63 6.25 14.98

12” × 10” 6.63 6.25 14.88

Call for availability of other sizes and dimensions.

20

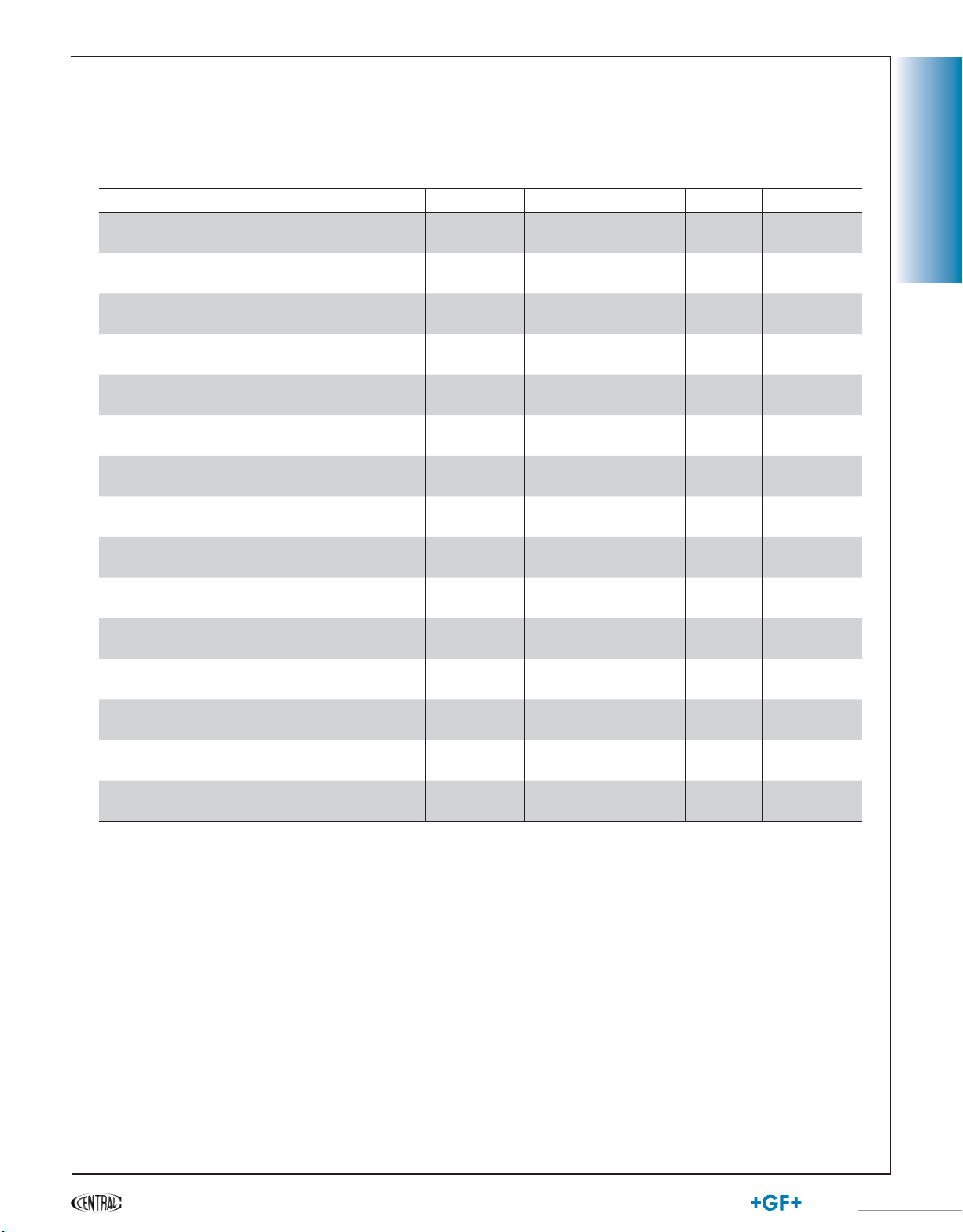

Butt Fittings: Butt Reducers

(PE 2406/PE2708) REDUCERS

Size SDR Part Number Pack Qty. Wt. CSA IAPMO

1” CTS × ½” CTS .101 WALL × .090 WALL 6911789 100 0.05 - 1” IPS × ½” CTS DR 9.3 × .090 WALL 6911893 100 0.06 - 1” IPS × ½” IPS DR 9.3 6911248 100 0.06 - 1” IPS × ¾” CTS DR 9.3 × .090 WALL 6911234 100 0.07 - 1” IPS × ¾” IPS DR 9.3 6910223 100 0.10 - 1” IPS × 1” CTS DR 9.3 × .090 WALL 6911238 100 0.09 - 1” IPS × 1” CTS DR 9.3 × .101 WALL 6911719 100 0.09 - 1¼” CTS × 1” IPS .090 WALL × DR 9.3 6911245 100 0.07 - 1¼” IPS × 1” CTS DR 10 × .102 WALL 10000725 100 0.10 - 1¼” IPS × 1” IPS DR 10 × DR 11 6910218 100 0.10 - 1½” IPS × ¾” IPS DR 9.3 6910073 100 0.22 - 1½” IPS × 1” IPS DR 11 6910227 100 0.20 YES 1½” IPS × 1¼” IPS DR 11 6911809 100 0.17 - 2” IPS × 1” IPS DR 11 6910081 100 0.29 YES YES

2” IPS x 1” IPS DR 11 10009614 100 0.29 - 2” IPS × 1¼” CTS DR 11 × .090 WALL 6912314 100 2.40 - 2” IPS × 1¼” IPS DR 11 × DR 10 6910022 100 0.32 YES YES

2” IPS × 1½” IPS DR 11 6910228 50 0.31 YES 3” IPS × 2” IPS DR 11/11.5 × DR 11 691030221000 10 0.68 YES YES

4” IPS × 2” IPS DR 11/11.5 × DR 11 6910025 10 1.01 YES YES

4” IPS × 3” IPS DR 11/11.5 691040321000 10 0.95 YES YES

4” IPS × 2” IPS DR 13.5 × DR 11 6910625 10 1.09 - 4” IPS × 3” IPS DR 13.5 × DR 11 6910646 10 1.03 - 6” IPS × 4” IPS DR 11/11.5 691060421000 5 3.33 YES YES

6” IPS × 4” IPS DR 13.5 × DR 11 6911477 5 2.99 - 6” IPS × 4” IPS DR 13.5 6911600 5 3.09 - 8” IPS × 6” IPS DR 11 × DR 11/11.5 6912389 6 5.31 - 8” IPS × 6” IPS DR 11/11.5 691080621000 6 5.86 YES 8” IPS × 6” IPS DR 13.5 × DR 11 6911107 6 6.06 - 8” IPS × 6” IPS DR 13.5 6910451 6 6.20 YES -

Conventional Fusion

Products

Call for availability of other sizes and dimensions.

21

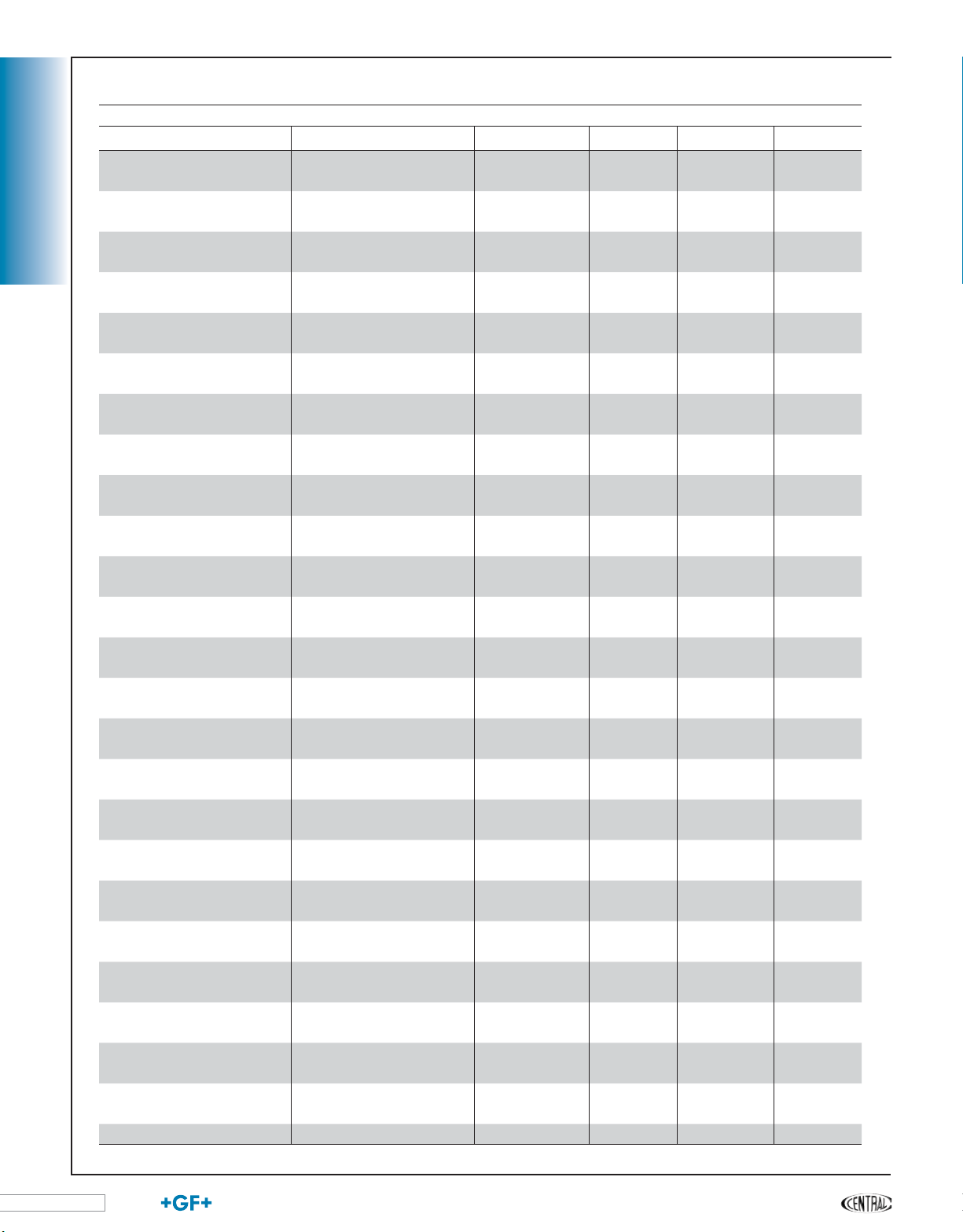

Butt Fittings: Butt Reducers

(PE3408/PE4710) CTS & IPS REDUCERS

Size SDR Part Number Pack Qty. Wt. AWWA

¾” IPS × ¾” CTS DR 11 × .090 WALL 10004186 100 0.03 1” CTS × ½” CTS .101 WALL × .090 WALL 10004187 100 0.04 YES

Products

Conventional Fusion

1” IPS × ½” CTS DR 9.3 × .090 WALL 10004189 50 0.09 YES

1” IPS × ¾” CTS DR 11 × .090 WALL 10004188 100 0.07 YES

1” IPS × ½” IPS DR 9.3 10004190 100 0.07 YES

1” IPS × ¾” CTS DR 9.3 × .090 WALL 10004191 100 0.09 YES

1” IPS × ¾” IPS DR 9.3 10004192 100 0.09 YES

1” IPS × 1” CTS DR 9.3 × .090 WALL 10004194 100 0.10 YES

1” IPS × 1” CTS DR 9.3 × .121 WALL 10004195 100 0.10 YES

1¼” CTS × 1” IPS .090 WALL × DR 9.3 10003945 100 0.07 YES

1¼” IPS × 1” IPS DR 11 10004197 100 0.11 YES

1¼” IPS × 1¼” CTS DR 9.3 × .090 WALL 10003946 100 0.15 YES

1½” IPS × ¾” IPS DR 9.3 10003947 100 0.18 YES

1½” IPS × 1” IPS DR 11 10004198 100 0.16 YES

1½” IPS × 1” IPS DR 9.3 10004199 100 0.19 YES

2” IPS × 1” IPS DR 11 10007485 100 0.29 YES

2” IPS × 1¼” CTS DR 11 × .090 WALL 10004200 100 0.30 YES

2” IPS × 1¼” IPS DR 11 10007479 100 0.33 YES

2” IPS × 1½” IPS DR 11 10003814 50 0.30 YES

2” IPS × 2” CTS DR 11 × .193 WALL 10004202 20 0.57 YES

3” IPS × 2” IPS DR 11 10007480 10 0.65 YES

3” IPS × 2 IPS DR 9 10004208 10 1.21 YES

3” IPS × 2” IPS DR 9/9.3 10004209 10 1.15 YES

3” IPS × 2” IPS DR 7 10007371 10 1.62 YES

4” IPS × 2” IPS DR 17 10004212 10 0.89 YES

4” IPS × 2” IPS DR 11 10007481 10 1.02 YES

4” IPS × 2” IPS DR 9/9.3 10004215 10 0.89 YES

4” IPS × 2” IPS DR 7 10007372 10 2.38 YES

4” IPS × 3” IPS DR 17 10004213 10 0.98 YES

4” IPS × 3” IPS DR 11 10007482 10 1.18 YES

4” IPS × 3” IPS DR 9/9.3 10004216 10 1.73 YES

4” IPS × 3” IPS DR 7 10007373 10 2.78 YES

6” IPS × 4” IPS DR 17 10008769 5 3.30 YES

6” IPS × 4” IPS DR 11 10007784 5 3.26 YES

6” IPS × 4” IPS DR 9 10004221 5 3.67 YES

6” IPS × 4” IPS DR 7 10007374 5 6.00 YES

8” IPS × 6” IPS DR 17 10004224 5 5.41 YES

8” IPS × 6” IPS DR 11 10007483 6 6.13 YES

8” IPS × 6” IPS DR 9 10004227 6 7.69 YES

8” IPS × 6” IPS DR 7 10007375 6 10.68 YES

10” IPS × 8” IPS DR 17 10007440 1 15.61 YES

10” IPS × 8” IPS DR 11 10007439 1 16.40 YES

10” IPS × 8” IPS DR 9 10000627 1 18.00 YES

12” IPS × 8” IPS DR 17 10008803 1 17.00 YES

12” IPS × 8” IPS DR 11 10008804 1 20.20 YES

12” IPS × 8” IPS DR 9 10008805 1 23.00 YES

12” IPS × 10” IPS DR 17 10007445 1 21.00 YES

12” IPS × 10” IPS DR 11 10007444 1 24.20 YES

12” IPS × 10” IPS DR 9 10000628 1 27.00 YES

Call for availability of other sizes and dimensions.

22

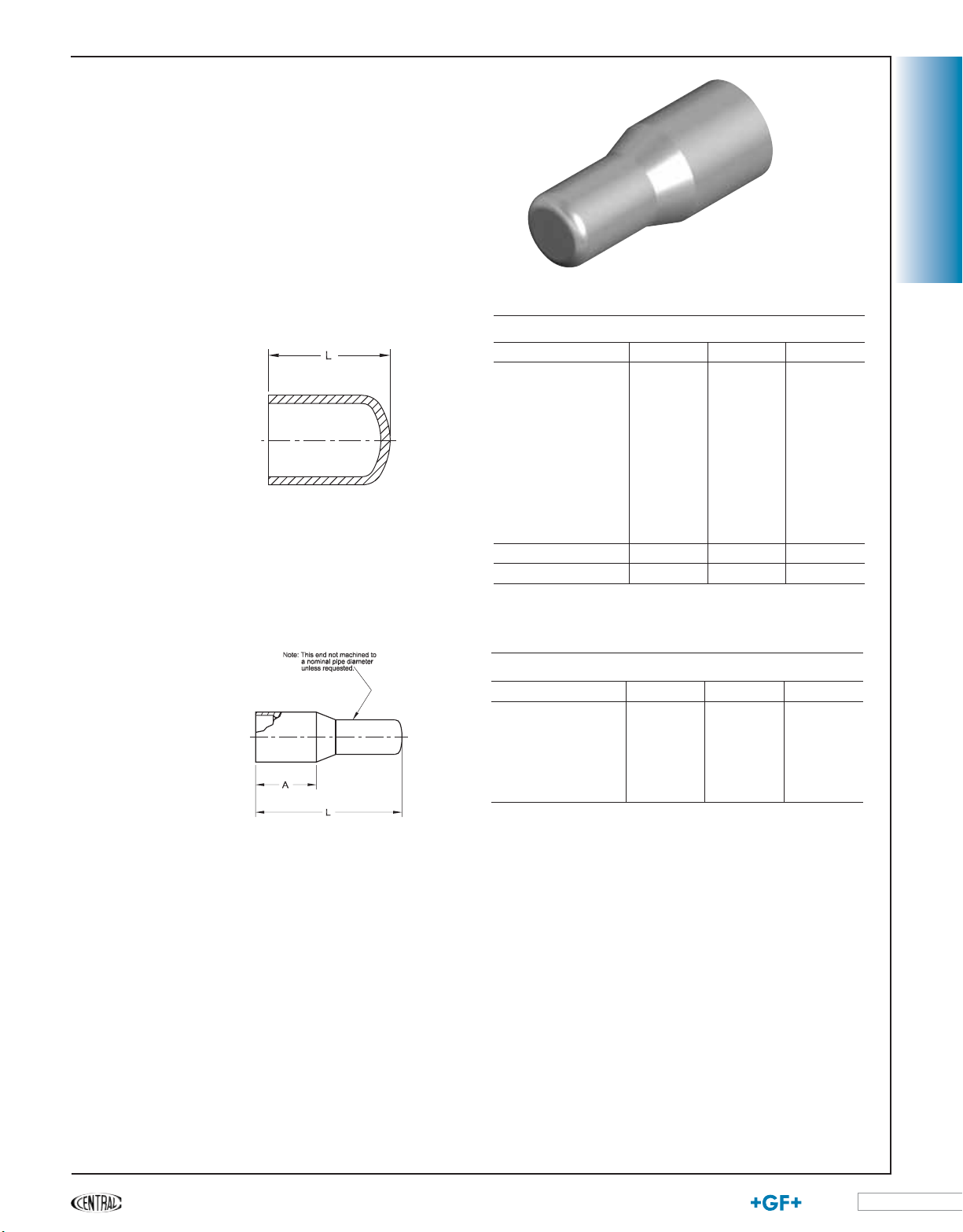

Butt Fittings: Butt Cap

Style 1

Conventional Fusion

Products

Style 2 shown here.

STYLE 1 END CAP DIMENSIONS

Nominal Size A B L

½” CTS * * 1.65

½” IPS * * 2.07

¾” CTS * * 2.14

¾” IPS * * 2.04

1” CTS * * 2.18

1” IPS * * 2.09

1¼” IPS * * 3.25

1½” IPS * * 2.58

2” IPS * * 2.72

10” IPS * * 10.06

12” IPS * * 11.95

Style 2

STYLE 2 END CAP DIMENSIONS

Nominal Size A B L

2” IPS 3.13 * 7.00

3” IPS 2.88 * 7.43

4” IPS 3.00 * 7.75

6” IPS 4.22 * 10.25

8” IPS 5.14 * 12.41

Call for availability of other sizes and dimensions.

23

Butt Fittings: Butt Cap

Call for availability of other sizes and dimensions.

(PE2406/PE2708) CTS & IPS BUTT CAPS

Size SDR Part Number Pack. Qty. Wt. CSA IAPMO Cap Style

½” CTS .090 WALL 6911497 100 0.01 YES - Style 1

Products

Conventional Fusion

½” IPS DR 9.3 6910631 100 0.02 - - Style 1

¾” CTS .090 WALL 6912138 100 0.02 - - Style 1

¾” IPS DR 11 6910221 100 0.03 YES - Style 1

1” CTS .101 WALL 6912470 100 0.03 - Style 1

1” IPS DR 11 6910220 100 0.04 YES - Style 1

1¼” IPS DR 10 6910052 50 0.12 YES - Style 1

1½” IPS DR 11 6910225 50 0.11 - - Style 1

2” IPS DR 11 691022200000 40 0.38 YES YES Style 2

2” IPS DR 11 6912474 40 0.17 - - Style 1

3” IPS DR 11 691032200000 10 0.90 YES YES Style 2

4” IPS DR 13.5 6910624 10 1.45 - Style 2

4” IPS DR 11 691042200000 10 1.37 YES YES Style 2

6” IPS DR 13.5 6910452 5 3.56 - - Style 2

6” IPS DR 11/11.5 691062200000 5 4.19 YES YES Style 2

8” IPS DR 13.5 6910453 6 6.95 YES - Style 2

8” IPS DR 11 691082200000 6 7.82 YES YES Style 2

10” IPS DR 13.5 10002781 1 11.75 - - Style 1

10” IPS DR 11 6912345 1 11.92 - - Style 1

12” IPS DR 13.5 6912347 1 20.18 - Style 1

12” IPS DR 11 6912346 1 20.78 - - Style 1

(PE3408/PE4710) IPS BUTT CAPS

Size SDR Part Number Pack. Qty. Wt. AWWA Cap Style

½” CTS .090 WALL 10004157 100 0.01 YES Style 1

¾” IPS DR 11 10003713 100 0.05 YES Style 1

1” CTS .101 WALL 10003122 100 0.03 YES Style 1

1” IPS DR 11 10003837 100 0.04 YES Style 1

1¼” IPS DR 11 10001876 50 0.10 YES Style 1

1½” IPS DR 11 10004159 50 0.10 YES Style 1

1½” IPS DR 9.3 10003942 50 0.18 YES Style 1

2” IPS DR 11 10007419 40 0.16 YES Style 1

2” IPS DR 11 10004165 40 0.16 YES Style 2

2” IPS DR 7 10007376 10 0.32 YES

3” IPS DR 17 10004168 10 0.87 YES Style 2

3” IPS DR 11 10002937 10 0.80 YES Style 2

3” IPS DR 9.3 10003671 10 0.57 YES Style 2

3” IPS DR 7 10007377 10 0.66 YES

4” IPS DR 17 10004171 10 1.30 YES Style 2

4” IPS DR 11 10002938 10 1.40 YES Style 2

4” IPS DR 9 10004173 10 2.50 YES Style 2

4” IPS DR 7 10007378 10 1.76 YES

6” IPS DR 17 10008768 5 3.98 YES Style 2

6” IPS DR 11 10007786 5 4.36 YES Style

6” IPS DR 9 10004179 5 5.61 YES Style 2

6” IPS DR 7 10007379 5 2.92 YES

8” IPS DR 17 10004182 6 7.14 YES Style 2

8” IPS DR 11 10007484 6 7.46 YES Style

8” IPS DR 9 10004184 6 8.15 YES Style 2

10” IPS DR 11 10004161 1 11.75 YES Style 1

12” IPS DR 11 10004163 1 21.10 YES Style 1

24

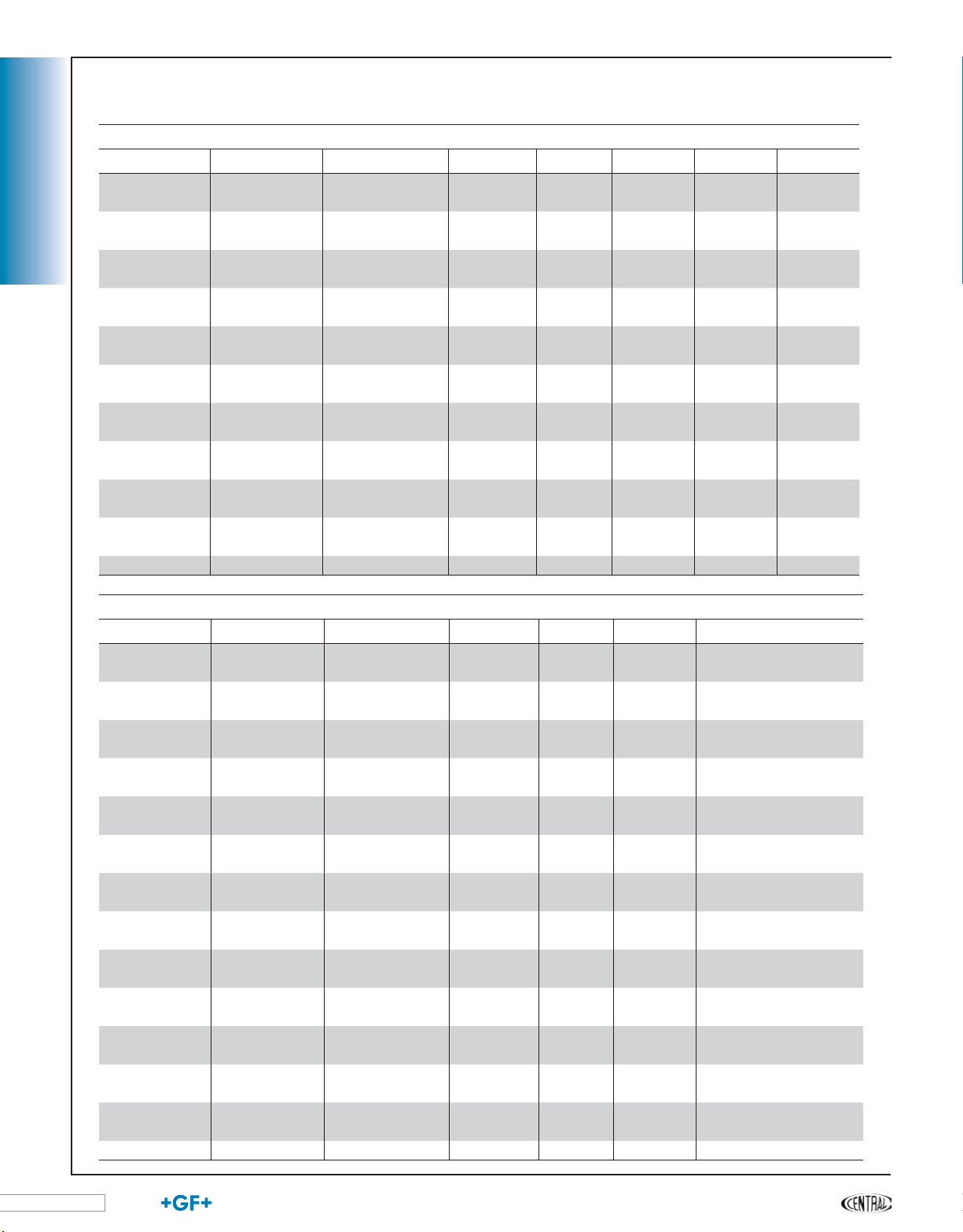

Butt Fittings: Purge Caps

Conventional Fusion

Products

PURGE CAP DIMENSIONS

Nominal Size A L

2” IPS (DR 11) 2.50 4.78

3” IPS (DR 11) 2.49 3.72

4” IPS (DR 11) 2.75 4.31

6” IPS (DR 11) 4.08 10.46

8” IPS (DR 11) 5.14 12.41

(PE 2406/PE 2708) SOCKET FUSION PURGE CAPS

Main Size Outlet Size Part Number Pack. Qty. Wt. CSA

2” IPS 1/2” CTS 6912391 25 0.29 4” IPS 1/2” CTS 6912393 10 1.06 6” IPS 1/2” CTS 10003172 5 3.00 6” IPS 1” CTS 6912394 5 4.00 8” IPS 1” CTS 6912395 6 9.10 -

(PE 2406/PE 2708) BUTT FUSION PURGE CAPS

Size Outlet Size Part Number Pack. Qty. Wt. CSA IAPMO

2” IPS 1/2” CTS 6912400 15 0.48 YES 4” IPS 1/2” CTS 6912402 10 1.05 YES 6” IPS 1” CTS 6912403 10 5.00 YES 8” IPS 1” CTS 6912404 10 9.80 YES -

Call for availability of other sizes and dimensions.

25

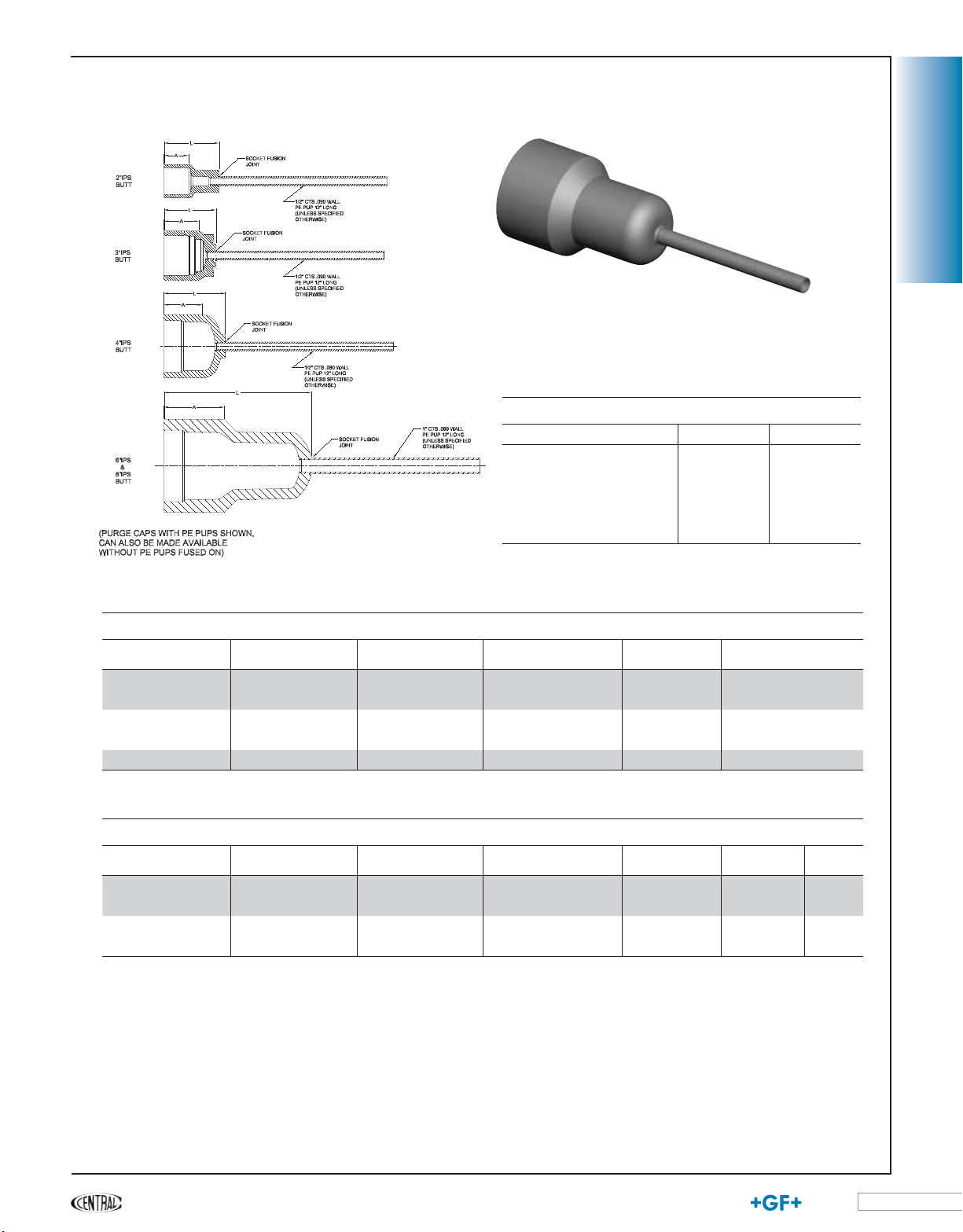

Butt Fittings: Purge Points

Products

Conventional Fusion

(PE2406/PE2708) PURGE POINTS

Size Part Number Pack. Qty. Wt.

1¼” IPS 6911803 10 .37

2” IPS 6912107 40 .48

(PE3408/PE4710) PURGE POINTS

Size Part Number Pack. Qty. Wt.

1¼” IPS 10004308 10 0.37

2” IPS 10004307 40 0.50

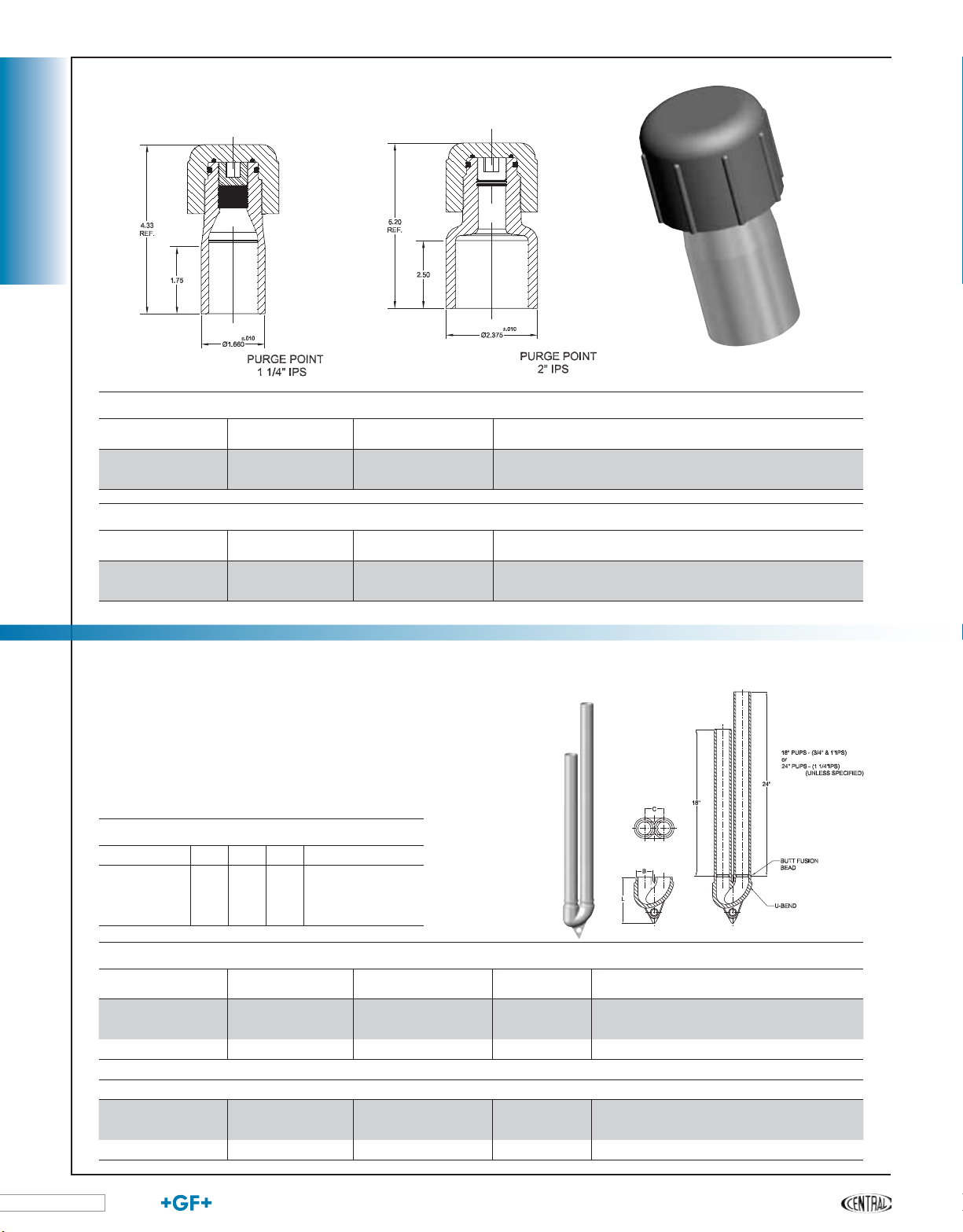

Butt Fittings: Geo-Loops (U-Bends)

*Available in PE3408/PE4710 only.

U-BEND DIMENSIONS

Nominal Size A B C L

¾” IPS * 1.05 1.75 3.84

1” IPS * 1.31 1.82 3.84

1¼” IPS * 1.66 1.91 4.55

(PE 3408/PE4710) U-BENDS with pups

Size SDR Part Number Pack. Qty. Wt.

¾” IPS DR 11 10004317 15 1.24

1” IPS DR 11 10004318 15 1.43

1¼” IPS DR 11 10004319 15 1.82

(PE 3408/PE4710) U-BENDS

¾” IPS DR 11 10004311 100 .125

1” IPS DR 11 10004310 100 .125

1¼” IPS DR 9.3 10004309 100 .28

26

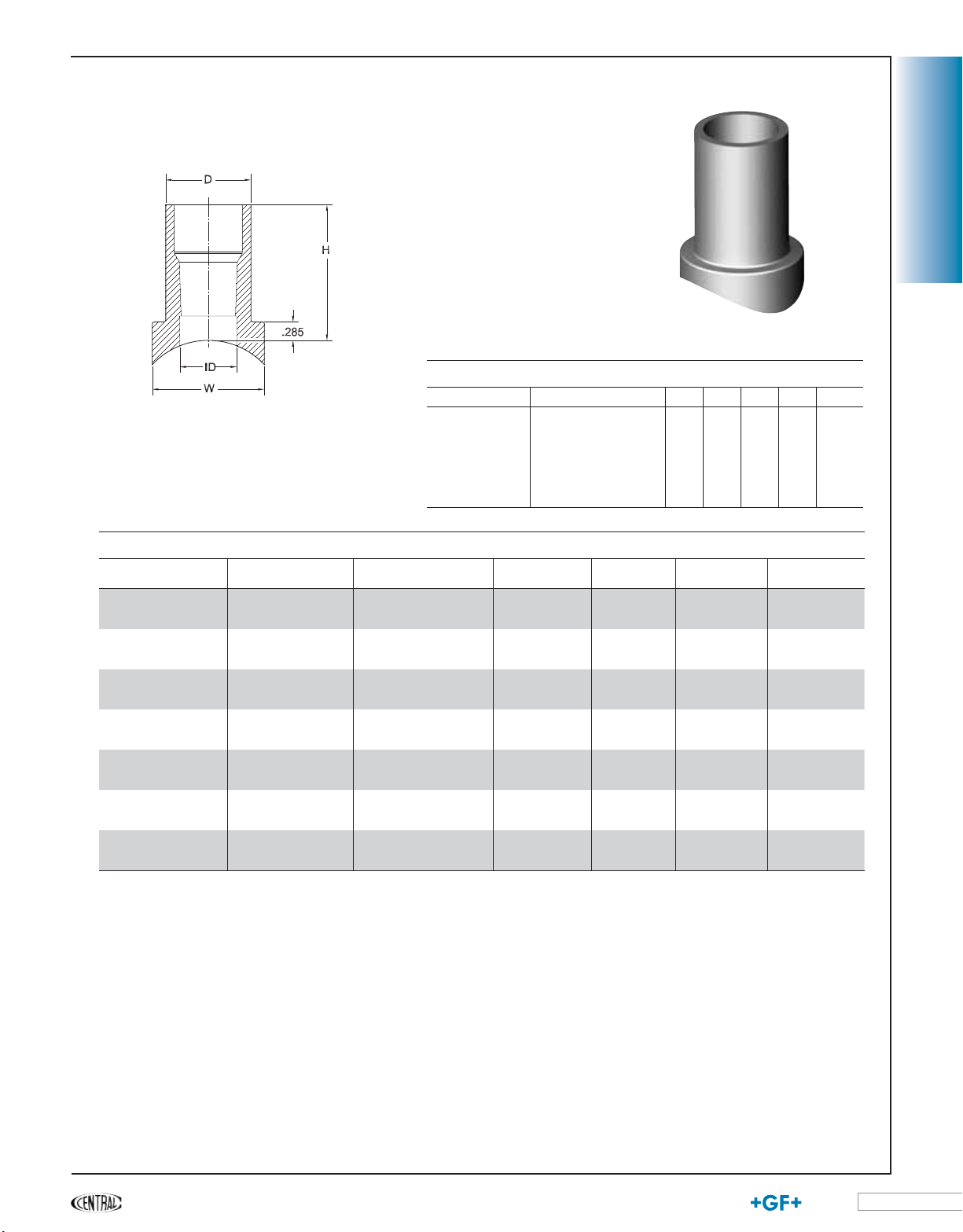

Saddle Fittings: Service Saddles w/Butt Outlet

SERVICE SADDLE w/ROUND BASE DIMENSIONS

IPS Main Size Nominal Outlet Size H W ID D L

3”–6” ½” IPS * * * * *

1¼”–4” ¾” IPS 1.81 1.73 0.66 1.05 *

1¼”–6” 1” IPS 1.81 1.73 0.88 1.31 *

6” 1¼” IPS * * * * *

2”–6” 1½” IPS 2.66 2.13 1.62 1.90 *

Conventional Fusion

Products

(PE3408/PE4710) SERVICE SADDLES w/ BUTT OUTLET

Outlet Size SDR Base Size Part Number Pack. Qty. Wt. AWWA

½” IPS SDR 11 1¼” IPS call - - ½” IPS SDR 11 1½” IPS call - - ½” IPS SDR 11 2” IPS call - - ½” IPS SDR 11 3” IPS call - - ½” IPS SDR 11 4” IPS call - - ½” IPS SDR 11 6” IPS call - - ½” IPS SDR 11 8” IPS call - - ½” IPS SDR 9.3 1¼” IPS call - - ½” IPS SDR 9.3 1½” IPS call - - ½” IPS SDR 9.3 2” IPS call - - ½” IPS SDR 9.3 3” IPS call - - ½” IPS SDR 9.3 4” IPS call - - ½” IPS SDR 9.3 6” IPS call - - ½” IPS SDR 9.3 8” IPS call - - -

Also available with 12” sleeves.

Call for availability of other sizes and dimensions.

27

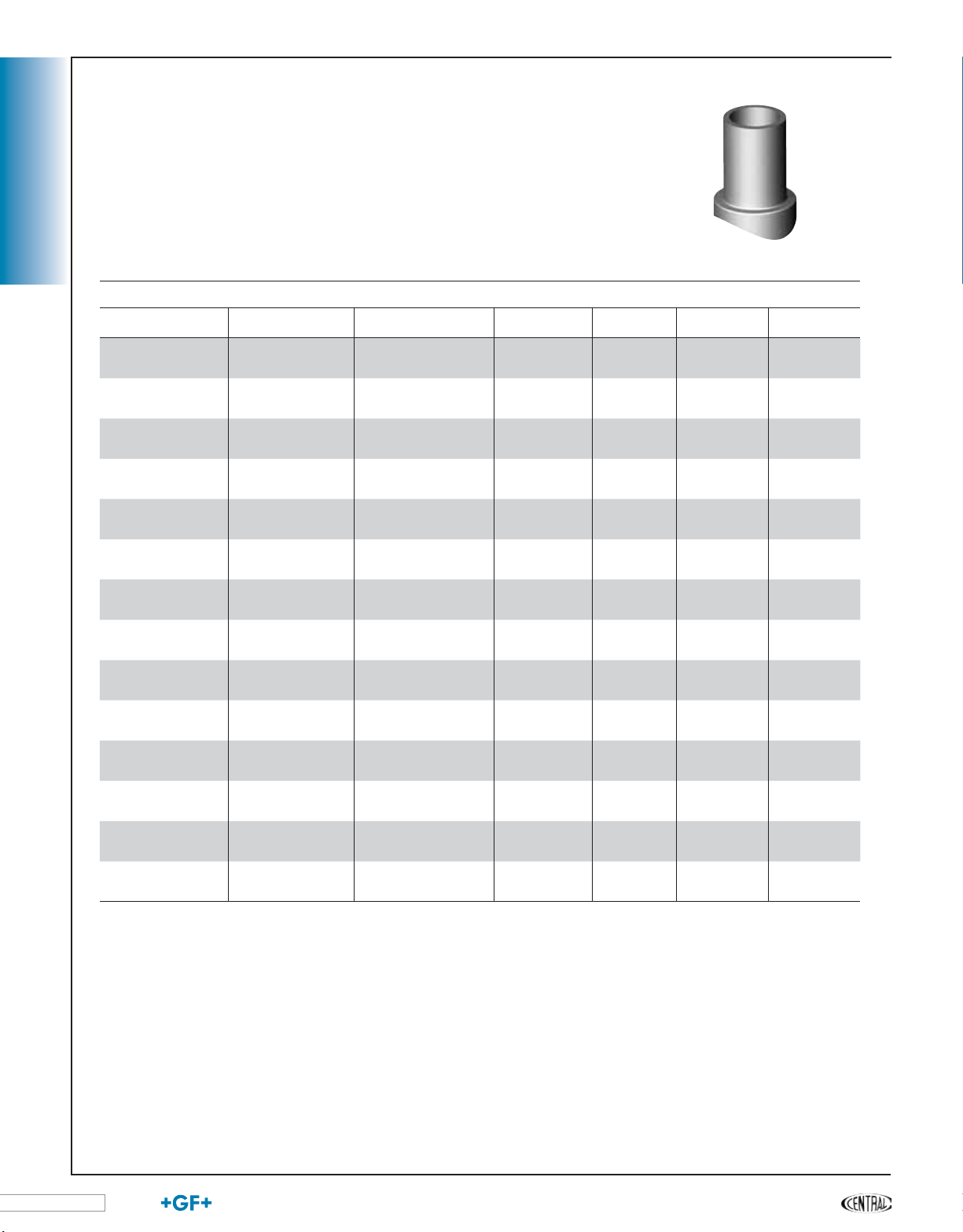

Saddle Fittings: Service Saddles w/Butt Outlet

Products

Conventional Fusion

(PE3408/PE4710) SERVICE SADDLES w/BUTT OUTLET

Outlet Size SDR Base Size Part Number Pack. Qty. Wt. AWWA

¾” IPS SDR 11 1¼” IPS 10004961 100 0.08 YES

¾” IPS SDR 11 1½” IPS 10004968 100 0.06 YES

¾” IPS SDR 11 2” IPS 10004977 100 0.06 YES

¾” IPS SDR 11 3” IPS 10004988 100 0.05 YES

¾” IPS SDR 11 4” IPS 10004999 100 0.07 YES

¾” IPS SDR 11 6” IPS call - - ¾” IPS SDR 11 8” IPS call - - ¾” IPS SDR 9.3 1¼” IPS 10004962 100 0.08 YES

¾” IPS SDR 9.3 1½” IPS 10004969 100 0.13 YES

¾” IPS SDR 9.3 2” IPS 10004978 100 0.06 YES

¾” IPS SDR 9.3 3” IPS 10004989 100 0.05 YES

¾” IPS SDR 9.3 4” IPS 10005000 100 0.07 YES

¾” IPS SDR 9.3 6” IPS call - - ¾” IPS SDR 9.3 8” IPS call - - 1” IPS SDR 11 1¼” IPS 10004965 100 0.07 YES

1” IPS SDR 11 1½” IPS 10004972 100 0.08 YES

1” IPS SDR 11 2” IPS 10004981 100 0.07 YES

1” IPS SDR 11 3” IPS 10004992 100 0.06 YES

1” IPS SDR 11 4” IPS 10005003 100 0.06 YES

1” IPS SDR 11 6” IPS 10005012 100 0.06 YES

1” IPS SDR 11 8” IPS call - - 1” IPS SDR 9.3 1¼” IPS 10004966 100 0.07 YES

1” IPS SDR 9.3 1½” IPS 10004973 100 0.08 YES

1” IPS SDR 9.3 2” IPS 10004982 100 0.07 YES

1” IPS SDR 9.3 3” IPS 10004993 100 0.06 YES

1” IPS SDR 9.3 4” IPS 10005004 100 0.06 YES

1” IPS SDR 9.3 6” IPS

1” IPS SDR 9.3 8” IPS call - - -

call

- - -

Also available with 12” sleeves.

Call for availability of other sizes and dimensions.

28

Loading...

Loading...