Page 1

39605 Independence, Shawnee, OK, 74804 | 1.800.654.3872 | www.gfcp.com

FAMILY: BUTT FUSION

PRODUCT: PE FITTING

TYPE: SPECIFICATION

DOC: PS-102

REV: 4

FILE:

PE BF FIT-PE3408

DATE: 4/17/2009

PAGES: 2

SCOPE:

SIZES:

REQUIREMENTS:

REFERENCE DOCUMENTS:

CERTIFICATIONS/LISTINGS:

MATERIALS:

TEST METHODS:

PRODUCT SPECIFICATION

BUTT FUSION FITTINGS (IPS)

PE3408 / PE4710 HDPE

BLACK

PRODUCT SPECIFICATIONS SHEET

BUTT FUSION FITTINGS (IPS)

PE3408 / PE4710 HDPE

BLACK

This document describes the standard specifications and features related to Georg Fischer Central Plastics' injection molded

PE4710 (formerlyPE3408) Butt Fusion Fittings for pressure piping systems.

1/2" CTS through 2" CTS. TEE, 90 DEGREE ELBOW, REDUCER, CAP,

1/2" IPS through 12" IPS. TEE, 90 DEGREE ELBOW, 45 DEGREE ELBOW, REDUCER, CAP, PURGE FITTING,

ASTM D2513 Specification for Thermoplastic Gas Pressure Pipe, Tubing, and Fittings

ASTM D3350 Specification for Polyethylene Plastic Pipes and Fittings Materials

ASTM D3261

Specification for Butt Heat Fusion Polyethylene (PE) Plastic Fittings for Polyethylene (PE) Plastics Pipe

and Tubing

PPI TR-19 Thermoplastics Piping for the Transport of Chemicals

PPI TR-31 Underground Installation of Polyolefin Pipe

PPI TR-33 Generic Butt Fusion Procedure for Polyethylene Gas Pipe

ASTM D2657 Standard Practice for Heat Fusion Joining of Polyolefin Pipe and Fittings

FM 1613 Approval Standard: Plastic Pipe and Fittings for Underground Fire Protection Service

AWWA C906 Standard for Polyethylene Pressure Pipe and Fittings, 4 in. Through 63 in., for Water Distribution

FM 1613 Approval Standard: Plastic Pipe and Fittings for Underground Fire Protection Service

ANSI/NSF 14 Plastic Piping System Components and Related Materials

PE Resin:

Pre-blended black high density virgin resin. Recognized by the Plastic Pipe Institute as having a

PE3408 / PE4710 / PE100 rating and a Hydrostatic Design Basis of 1600 psi @ 73°F. This resin has a

cell classification of 445574C* in accordance with ASTM D3350.

Note*

ASTM D1598 Time-to-Failure of Plastic Pipe Under Constant Internal Pressure.

ASTM D1599 Short-Term Hydraulic Pressure Failure of Plastics Pipe, Tubing, and Fittings.

ASTM D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

Previous editions of ASTM D3350 resulted in cell classifications of 345464C and 345564C.

Must exceed 170 hours in 80°C bath @ 670psi Hoop Stress, or

Must exceed 1000 hours in 80°C bath @ 580psi Hoop Stress, or

Must exceed 1000 hours in 23°C bath @ 1600psi Hoop Stress.

(All methods are considered equivalent)

Uniform pressurization until failure between 60 and 70 seconds from start of test. Most result in ductile failure at

a pressure great enough to create a 2520psi Hoop Stress.

Determination of diameter, wall thickness, and length dimensions including procedures for dimensioning molded

thermoplastic pipe fittings.

RP01/2013Product Specications Sheet

Page 2

39605 Independence, Shawnee, OK, 74804 | 1.800.654.3872 | www.gfcp.com

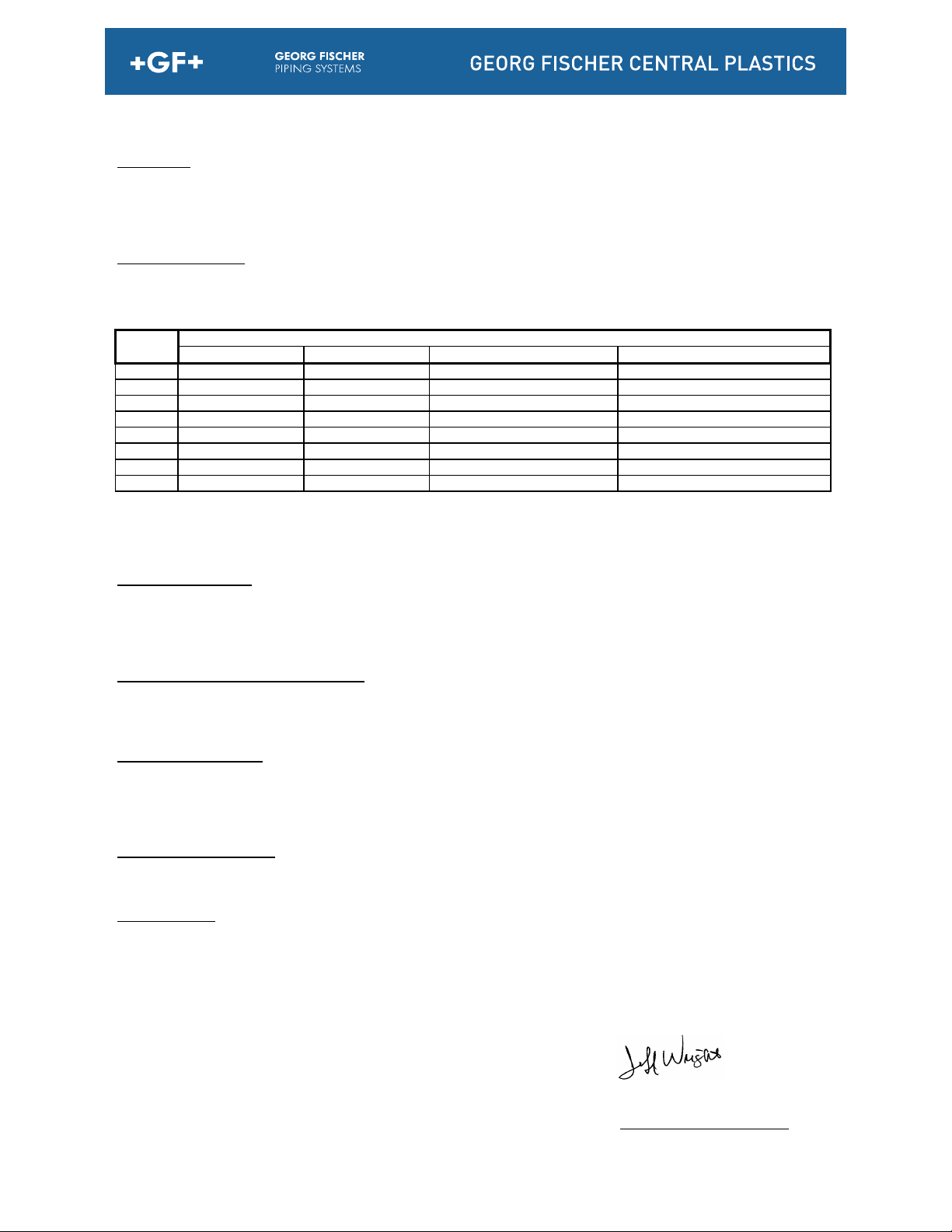

PRESSURE RATING:

7

9

11

13.5

17

21

26

32.5

PRESSURE TESTING:

MAXIMUM OPERATING TEMPERATURE:

STORAGE/SHELF LIFE:

CHEMICAL RESISTANCE:

INSTALLATION:

Natural Gas (.4 DSF) Canada

80

100

125

40

PE4710 Butt Fusion Fittings are pressure rated in accordance with industry and regulatory guidelines for natural gas or water

@73°F. Pressure ratings are subject to change depending on ambient temperatures. Pressure ratings vary according to wall

Water (.5 DSF)

Natural Gas (.32 DSF) US

SDR

Pressure Rating (PSI) @ 73° F (23° C)

80

80

65

504065

50

65

50

215*

160*

125

170*

125*

100

160

125

335

250

100

30

265

80

65

100

200

160

200

FAMILY: BUTT FUSION

PRODUCT: PE FITTING

TYPE: SPECIFICATION

DOC: PS-102

REV: 4

FILE:

PE BF FIT-PE3408

DATE: 4/17/2009

PAGES: 2

SCOPE:

SIZES:

1/2" CTS through 2" CTS. TEE, 90 DEGREE ELBOW, REDUCER, CAP,

1/2" IPS through 12" IPS. TEE, 90 DEGREE ELBOW, 45 DEGREE ELBOW, REDUCER, CAP, PURGE FITTING,

REQUIREMENTS:

ASTM D2513 Specification for Thermoplastic Gas Pressure Pipe, Tubing, and Fittings

ASTM D3350 Specification for Polyethylene Plastic Pipes and Fittings Materials

ASTM D3261

REFERENCE DOCUMENTS:

PPI TR-19 Thermoplastics Piping for the Transport of Chemicals

PPI TR-31 Underground Installation of Polyolefin Pipe

PPI TR-33 Generic Butt Fusion Procedure for Polyethylene Gas Pipe

ASTM D2657 Standard Practice for Heat Fusion Joining of Polyolefin Pipe and Fittings

CERTIFICATIONS/LISTINGS:

FM 1613 Approval Standard: Plastic Pipe and Fittings for Underground Fire Protection Service

AWWA C906 Standard for Polyethylene Pressure Pipe and Fittings, 4 in. Through 63 in., for Water Distribution

FM 1613 Approval Standard: Plastic Pipe and Fittings for Underground Fire Protection Service

ANSI/NSF 14 Plastic Piping System Components and Related Materials

MATERIALS:

PE Resin:

Note*

TEST METHODS:

ASTM D1598 Time-to-Failure of Plastic Pipe Under Constant Internal Pressure.

Must exceed 170 hours in 80°C bath @ 670psi Hoop Stress, or

Must exceed 1000 hours in 80°C bath @ 580psi Hoop Stress, or

Must exceed 1000 hours in 23°C bath @ 1600psi Hoop Stress.

(All methods are considered equivalent)

ASTM D1599 Short-Term Hydraulic Pressure Failure of Plastics Pipe, Tubing, and Fittings.

ASTM D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

FEATURES:

Uniform pressurization until failure between 60 and 70 seconds from start of test. Most result in ductile failure at

a pressure great enough to create a 2520psi Hoop Stress.

Determination of diameter, wall thickness, and length dimensions including procedures for dimensioning molded

thermoplastic pipe fittings.

PRODUCT SPECIFICATION

BUTT FUSION FITTINGS (IPS)

PE3408 / PE4710 HDPE

BLACK

Previous editions of ASTM D3350 resulted in cell classifications of 345464C and 345564C.

This document describes the standard specifications and features related to Georg Fischer Central Plastics' injection molded

PE4710 (formerlyPE3408) Butt Fusion Fittings for pressure piping systems.

Specification for Butt Heat Fusion Polyethylene (PE) Plastic Fittings for Polyethylene (PE) Plastics Pipe

and Tubing

Pre-blended black high density virgin resin. Recognized by the Plastic Pipe Institute as having a

PE3408 / PE4710 / PE100 rating and a Hydrostatic Design Basis of 1600 psi @ 73°F. This resin has a

cell classification of 445574C* in accordance with ASTM D3350.

Made in USA from pre-blended virgin materials. These fittings are availabe in various configurations and DR and are

primarily intended for use in pressure piping applications. These fittings are compatible for heat fusion to any PE material

made from a like or similar resin. Select sizes can be supplied with AWWA or FM marking. Designed for use on pipe

conforming to ASTM F714, D2513, and D3035.

thickness and the design factor for the intended application, see below for ratings:

Fitting

Water (.63 DSF)

* Subject to maximum operating pressure limits of regulatory requirements.

Minimum wall thickness for plastic piping gas distribution systems is limited to .062".

Above listed pressure ratings based on 73°F ambient temperature. Pressure ratings subject to derating depending on temperature.

Pressure testing can be conducted in accordance with the recommendations of the pipe manufacturer, or as described in

ASTM F2164 STANDARD PRACTICE FOR FIELD LEAK TESTING OF POLYETHYLENE (PE) PRESSURE PIPING

SYSTEMS USING HYDROSTATIC PRESSURE, typically 1.5 x's the rated working pressure not exceeding 8 hours in

duration for a single test.

The maximium operating temperature of PE4710 Butt Fusion Fittings is 140°F. Pressure de-rating factors should be

considered when operating systems above the 73°F stated pressure rating, to maintain the 50 year substantiated long-term

hydrostatic strength of the polyethylene material.

Black high density polyethylene resin contains a minimum of 2% of a finely dispersed concentration of carbon black which

provides protection from UV effects. Even so, it is recommended that fittings which are stored for extended periods (two

years or greater) be stored indoors in their original packaging. Fittings stored indoors in their original packaging have a

virtually unlimited shelf-life.

Polyethylene generally exhibits strong resistance to many chemical compounds. Known chemical resistance characteristics

at specified temperatures can be found in PPI Technical Report TR-19.

These fittings are compatible for heat fusion by butt, socket, or electrofusion joining products. They can be heat fusion joined

to pipe or fittings manufactured from like or similar resin. Qualified mechanical joining products can be used to join these

fittings, consult the manufacturer for recommendations. Fusion jointing should only be attempted by persons who have been

trained and have qualified joints through destructive testing.

Note: This Specification supercedes all previous Product

Specifications and is subject to change without notice.

Approved By:

Jeff Wright

Director of Product Management

RP01/2013Product Specications Sheet

Loading...

Loading...