Page 1

Instruction Manual

Controller Type PE 22

¥ ‡

¥ ‡

33

Page 2

The technical data are not

binding. They are not

warranted characteristics

and are subject to change.

Please consult our General

Conditions of Supply.

Important Information

≠ Electrostatic discharges caused by touching the

printed circuit boards can cause the destruction

of individual components. Please take

appropriate precautions antistatic workplaces,

metallic connections to a water pipe, etc.

≠ In order to obtain the required protection

against physical contacts in accordance to DIN/

EN 60355-@, the external cable installation has

to be duly isolated and protected against

physical contacts.

Warnings:

≠ Any work done on the actuator may only be

carried out by authorized and trained personnel.

≠ These products are according to the Machine

Guidelines 98/37/EG (ancient 89/392/EWG), not

regarded as machines; they are, however, built

into installations which are regarded as machines.

Note

We distinctly emphasize that operation is

prohibited until it has been confirmed that the

machine (plant) into which the products have

been built corresponds to the conditions of the

EC Machine Guidelines 98/37/EG (ancient

89/392/EWG).

34

¥ ‡

Page 3

Contents

Page

1. General features 36

2. Specifications 37

3. Installation and assembly of the PE 22 37

3.1 Installation in electric actuator

EA 20, EA 30 37

3.2 Installation in electric actuator

EA 41, EA 50 39

4. Connection diagram for use as a positioner 41

5. Connection diagram for use as a process controller 41

6. Wiring of the PEV 122 supply unit

in the EA 41, EA 50 42

7. Block diagram of the PE 22 43

8. Balancing/adjusting the PER 22 43

9. Adjustments 45

10. Order Numbers 47

¥ ‡

35

Page 4

Controller Type PE 22 for installation in electric actuators

EA 20/EA 30 and EA 4@/EA 50

1. General Features

Electrically powered valves are increasingly being

driven by external reference inputs.

With the PE 22 Controller, the EA 20, EA 30, EA 4@

and EA 50 electric actuators can be employed as

follows:

≠ as a continuously adjustable positioner from

0. . .90° or 0. . .180°; in the process the aperture

angle of the valve is measured continuously and

compared with the setpoint

≠ as a process controller in conjunction with an

external sensor and a reference input.

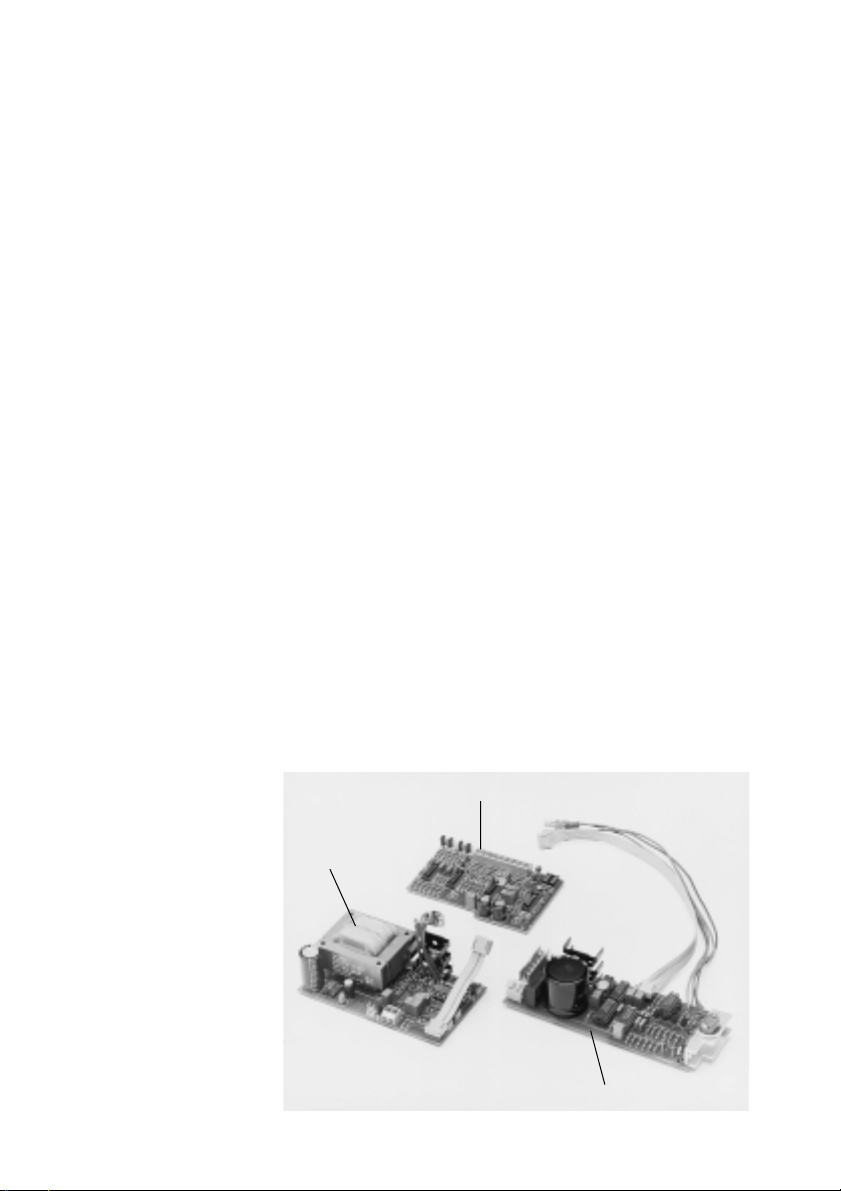

The PE 22 Controller comprises two parts (PEV 22/

PEV @22 and PER 22) and is preferably installed in

the actuator in the factory; it can, however, also

be supplied in kit form (Fig. @).

Fig. 1

36

PER 22 for EA 20, EA 30, EA 41 and EA 50

PEV 22 for

EA 20, EA 30

PEV 122 for EA 41, EA 50

¥ ‡

Page 5

2. Specifications

Connected voltage 1@5/230 V, 50–60 HZ

(switchable)

24 V 앑/=

Setpoint 0–5/10 V=/4–20 mA

Actual value, external

(process controller) 0–5/10 V=/4–20 mA

Actual value, internal

(potentiometer) 0–5/10 V=(90/180°)

Range when used

as positioner 0–90°/0–180°

Control PI, proportional range

characteristics continuously adjustable

when used as 8 to 210%, reset time

process controller continuously adjustable:

1,2 s to1,9 min

Duty cycle 100% at 25°C ambient

temperature for the EA 20/EA 30

50% at 25°C ambient

temperature for the EA 41/EA 50

Ambient temperature –10 to +50°C

conditions relative humidity 0 to 90%

3. Installation and assembly of the PE 22

Before installation and assembly starts,

the actuator must be moved to the <closed>

position.

3.1. Installation in electric actuator EA 20 and EA 30

3.1.1 Adjustment to mains voltage

Jumpers JP1 (230 V) and JP2 (@@5 V) on the PEV 22

supply unit must be plugged in according to the mains

voltage available (Fig. 2). As delivered: 230 V. JP@ is

plugged in on the 24 V version.

¥ ‡

37

Page 6

JP1

JP2

Bild 2

38

23 1

3.1.2 Mounting and connecting the PEV 22

supply unit

≠ separate actuator from mains

≠ detach electrical connections

≠ remove existing supply unit

≠ install PEV 22 supply unit and bolt on securely

≠ attach connecting cable (green = 1)

(black = N)

≠ connect earth to transformer (1)

3.1.3 Installing the PER 22 control unit

≠ bolt on PER 22 securely as illustrated (2+3)

≠ plug in the ribbon cable connection

¥ ‡

Page 7

3.2 Installation in electric actuator EA 4@/EA 50

3.2.1 Adjustment to mains voltage

≠ wire up as shown in Fig. 8

≠ Connector terminal: 1 = 115 V / 2 = 230 V / N = Neutral

Connector terminal

3.2.2 Mounting and connecting the PEV @22

supply unit

≠ separate actuator from mains

≠ detach electrical connections

≠ remove existing supply unit

≠ fit the PEV @22 in the same way (see Fig. 3)

≠ wire up as shown in Fig. 8

Fitting the PEV @22

printed circuit board

¥ ‡

Fig. 3

39

Page 8

Fig. 4

3.2.3 Installing the PER 22 control unit

≠ slide the printed circuit board into the groove

provided, as shown in Fig. 5

≠ secure it with the bracket and bolts provided

(Fig. 4 + 5)

≠ plug in the ribbon cable connection

Fastening bolts

Fig. 5

40

¥ ‡

Page 9

4. Connection diagram when used

as a positioner with internal actual value sensor

(potentiometer @99 @90 @40)

Fig. 6

M

1 S2 1 S1

closed

242

red

PS2 S2 PS1 S1

PEV 22

PEV @22*

M1

M2

1N

Ph

+

@234

L@ N PE

connection

mains

EA 20, EA 30

+ @0 V/

0 V 0 V

5 mA

black

red

2

3

@99 @90 @40

actual value

internal potentiometer

EA 41, EA 50

white

1

open

4

green

PER 22

JP4

N

@@0–@20 V 앑,

–

200–240 V앑, 24 V 앑/ =

JP9

34 56 789 @0@@

connecting

cable

+–+–

0–5 V/@0 V =

4–20 mA

inputs for external

setpoint

5. Connection diagram when used

as a process controller with 4–20 mA or 0–5/@0 V

external actual value sensor (e.g. transmitter)

Fig. 7

red

1 S2 1 S1

closed

242

open

EA 20, EA 30

4

green

EA 41, EA 50

PS2 S2 PS1 S1

PEV 22

PEV @22*

M

M1

M2

1N

PH

+

@234

L@ N PE

mains

connection

* see Fig. 8

¥ ‡

JP4

N

@@0–@20 V 앑,

–

200–240 V앑, 24 V 앑/ =

JP9

34 56 789 @0@@

connecting

cable

0–5 V/@0 V =

+

––

inputs for external

setpoint

PER 22

+ @0 V/

0 V 0 V

5 mA

+

4–20 mA

+

+– –

0–5 V/@0 V =

4–20 mA

inputs for external

actual value

41

Page 10

6. Wiring of the PEV @22 supply unit in

the EA 4@/ EA 50

Fig. 8.1

Fig. 8.2

EA 41

115/230 V

EA 41

24 V⫽/앑

Transformer

T1

brown

grey

black

1N21011121314

115 V

230 V

32

14

L1+N-PE

M

open

S2

S1

green

S1S2

PS1

JP4

white

white

closed

1

2

3

4

5

6

red

PS2

PEV 122

M1

M

M2

open

S2

closed

red

1

2

3

PS2

S2

4

5

6

PS1

PEV @22

Connection

cable

S1

green

S1

JP4

M1

M2

1

N

42

connection

cable

L1+N–PE

mains connection

¥ ‡

Page 11

7. Block diagram ot the PE 22

1

3

4

5

6

7

8

9

10

11

1

3

I

U

+ @5 V

PER 22

1

1

3

I

U

5

4

24

6/1

1

7

6/2

8

max.

min.

2910

U

f

910

U

f

PEV 22

PEV 122

+ 24 V

+ 15 V

– 15 V

=

앑

11

12

11

13

M1

M2

S1

PS1

S2

PS2

1

2

8. Balancing/adjusting the PER 22

8.1 Adjusting the input signals

Various operating conditions can be adjusted

on control unit PER 22 by means ot the jumpers

(JP@–JP8) provided.

JP1

JP2

JP3

JP4

JP5

JP6

JP7

JP8

3 4567 8 91011

P3

P2

P1

JP9

1 Amplifier

2 Inverting amplifier

3 Current-voltage converter

4 Filter

5 Setpoint smoothing

6 Adder

7 Integrator

8 Limiter

9 Voltage-frequency

converter

10 Monostable multivibrator

11 Logic

12 Motor driver H bridge

13 Power supply unit

¥ ‡

43

Page 12

8.1.1 Used as a positioner with integrated

potentiometer

Jumper plugged in

Actual value

Rotation 90° JP5, JP7

Rotation 180° JP5, JP8

Setpoint 0– 5 V JP1, JP3

0–10 V JP1, JP4

4–20 mA JP2, JP3

8.1.2 Used as a process controller with

external sensor

Jumper plugged in

Actual value 0– 5 V JP5, JP7

Setpoint 0– 5 V JP1, JP3

0–10 V JP5, JP8

4–20 mA JP6, JP7

0–10 V JP1, JP4

4–20 mA JP2, JP3

8.2 Installing the internal potentiometer for

actual value feedback

Important: Ensure that during installation (with

valve closed) the potentiometer is at the left-hand

stop when viewed from above (turn counter-clockwise), i.e. the resistance between the red and

white wires must be 0 Ohm.

(See EA 20/EA 30/EA 41/EA 50 Instruction

Manual).

44

¥ ‡

Page 13

9. Adjustments

9.@ Used as positioner with internal potentiometer

Potentiometers P@ and P2 (Fig. @0) must be turned

clockwise as far as the stop (max. 28 revs.).

This is already set in the factory.

The regulating speed of the valve can be adjusted

between 7 and @5 s by means of potentiometer P3.

Time

shorter

왗

Turn

counterclockwise

(CCW)

Potentiometer

P3

P3 P1 P2

9.2 Used as a process controller

Adjusting the parameters.

The parameters are set as follows in the factory:

Proportional range maximum (2@0%)

Reset time maximum (1.9 min)

Turn

clockwise

(CW)

Fig. 10

왘

Time

longer

¥ ‡

45

Page 14

The controller thus displays a predominantly proportional action.

Three potentiometers are provided on the control

unit (PER 22) for special adjustments:

P@ for adjusting reset time

P2 for adjusting the proportional range

P3 for delaying the setpoint (remains at left-hand

stop)

If the setscrew is turned counter-clockwise:

≠ the reset time is shortened (I component is

increased)

≠ the proportional range is diminished (P compon-

ent is reduced)

Control parameters

␣

P max.

l min.

Start Flow

Set 50%

Osc?

No

Set 20%

Osc?

No

20%

Yes

액

Yes

Yes

No

Red P

Reduce P

component

Red P

Inc. I

Increase I

component

Start of adjustment

Basic setting:

maximum P component (P2)

Basic setting:

maximum I component (P1)

Setpoint: 50%

Start flow

Control circuit

oscillating?

Setpoint: 20%

Start flow

Control circuit

oscillating?

Acutal value = 20%?

End of adjustment

46

¥ ‡

Page 15

10. Order Numbers

Article Code

EA 20 actuator with integrated PE 22 as positioner

(including @99 @90 @40)

@@5/230 V, 50–60 Hz @98 @50 434

24 V=/앑 @98 @50 435

EA 20 actuator with integrated PE 22 as processor controller

(without @99 @90 @40)

@@5/230 V, 50–60 Hz @98 @50 436

24 V=/앑 @98 @50 437

EA 30 actuator with integrated PE 22 as positioner

(including @99 @90 @40)

@@5/230 V, 50–60 Hz @98 @50 7@2

24 V=/앑 @98 @50 7@3

EA 30 actuator with integrated PE 22 as processor controller

(without @99 @90 @40)

@@5/230 V, 50–60 Hz @98 @50 7@4

24 V=/앑 @98 @50 7@5

EA 41 actuator with integrated PE 22 as positioner

(including @99 @90 @40)

@@5/230 V, 50–60 Hz @98 @50 70@

24 V=/앑 @98 @50 702

EA 41 actuator with integrated PE 22 as process controller

(without @99 @90 @40)

@@5/230 V, 50–60 Hz @98 @50 703

24 V=/앑 @98 @50 704

EA 50 actuator with integrated PE 22 as positioner

@@5/230 V, 50–60 Hz @98 @50 706

24 V=/앑 @98 @50 707

EA 50 actuator with integrated PE 22 as process controller

@@5/230 V, 50–60 Hz @98 @50 708

24 V=/앑 @98 @50 709

PE 22 in kit form

PER 22 controller PCB @99 @90 225

PEV 22 supply unit: @@5/230 V, 50–60 Hz @99 @90 236

24 V=/앑 @99 @90 237

PEV @22 supply unit: @@5/230 V, 50–60 Hz @99 @90 229

24 V=/앑 @99 @90 230

Potentiometer @99 @90 140

¥ ‡

47

Page 16

¥ ‡

A Georg Fischer Rohrleitungssysteme GmbH, Sandgasse 16, 3130 Herzogenburg

Tel. +43(0)2782/8 56 43-0, Fax +43(0)2782/8 51 56, e-mail: office@georgfischer.at

AUS George Fischer Pty. Ltd., 4 Jacks Road, South Oakleigh, Victoria 3¢67, Tel. +61(0)3/95 63 88 99, Fax +61(0)3/95 63 89 66

e-mail: sales@georgefischer.com.au

B/L Georg Fischer NV/SA, Digue du Canal 109-¢¢¢ — Vaartdijk 109-¢¢¢, 1070 Bruxelles/Brüssel

Tél. +32(0)2/556 40 20, Fax +32(0)2/524 34 26, e-mail: info.be@be.piping.georgfischer.com

BR George Fischer Ltda, Av. das Nações Unidas 21689, CEP 04795-100 São Paulo, SP, Brasil

Tel. +55(0)11/247 13 11, Fax +55(0)11/247 60 09

CH Georg Fischer Rohrleitungssysteme (Schweiz) AG, Amsler-Laffon-Strasse ¢, Postfach, 8201 Schaffhausen

Tel. +41(0)52 631 30 26, Fax +41(0)52 631 28 97, e-mail: info@rohrleitungssysteme.georgfischer.ch

CHINA Georg Fischer Piping Systems Ltd. Shanghai, No. 2Ý8 Kang Qiao Dong Rd., Shanghai 201319

Tel. +86(0)2¢/58 13 33 33, Fax +86(0)2¢/58 13 33 66, e-mail: gfsro@public.shanghai.cngb.com

Georg Fischer Piping Systems (Trading) Ltd. Shanghai, No 516 Fute Bei Road, Waigaoqiao Free Trade Zone, 200131 Pudong,

Shanghai, Tel. +86(0)21/5868 0278, Fax +86(0)21/5868 0264, e-mail: gftrade@sh.cngb.com

D Georg Fischer GmbH, Daimlerstraße 6, 73095 Albershausen, Tel. +49(0)7161/302-0, Fax +49(0)7161/3 0 2 25 9

e-mail: info@georgfischer.de, Internet: http://www.rls.georgfischer.de

Georg Fischer DEKA GmbH, Postfach 1145, 35228 Dautphetal, Tel. +49(0)6468/91 51-0, Fax +49(0)6468/91 52 21/22

e-mail: info@dekapipe.de

DK/IS Georg Fischer A/S, Klintehøj Vænge 17, 3460 Birkerød, Tel. +45 45 81 19 75, Fax +45 45 81 16 22

E Georg Fischer S.A., Sistemas de tuberías para la industria, Alcalá, 85, 2

Tel. +34(0)9¢/781 98 90, Fax +34(0)9¢/426 08 23, e-mail: info@georgfischer.es

F George Fischer S.A., 105–1¢3, rue Charles Michels, 93208 Saint-Denis Cedex 1

Tél. +33(0)1/49 22 ¢3 4¢, Fax +33(0)¢/49 22 ¢3 00, e-mail: info@georgefischer.fr

GB George Fischer Sales Limited, Paradise Way, Coventry, CV2 2ST, Tel. +44(0)2476/535 535, Fax +44(0)2476/530 450

e-mail: info@georgefischer.co.uk, Internet: http://www.georgefischer.co.uk

GR Georg Fischer S.p.A., Athens Branch, 101, 3rd September Str., 10434 Athen

Tel. +30(0)1/882 0491, Fax +30(0)1/881 0291, e-mail: dderv_piping_gf@oneway.gr

I Georg Fischer S.p.A., Via Sondrio 1, 20063 Cernusco S/N (MI)

Tel. +3902/92 18 61, Fax +3902/92 14 07 85, e-mail: office@piping.georgfischer.it

ID George Fischer Representative Office, c/o Wisma Aria, 3rd Floor, Jl. H.O.S. Cokroaminoto 81, Jakarta 10310, Indonesia,

Tel. +62(0)21/391 48 62, Fax +62(0)21/391 48 63

IND George Fischer Piping Systems Ltd, India Branch Office, Solitaire Corporate Park, 532, Building No. 5, 3rd Floor, Chakala,

Ghatkopar Link Road, Andheri (E), 400 093 Mumbai, Tel. +91(0)22/820 2362, Fax +91 22-820 2462, e-mail: wpfunder@vsnl.net

J Georg Fischer Ltd, 2-47, Shikitsuhigashi 1-chome, Naniwa-ku, 556-8601 Osaka

Tel. +81(0)6/664 82 59 4, Fax +81 6-664 82 56 5, e-mail: kgf-yosi@kubota.co.jp

N Georg Fischer AS, Rudsletta 97, ¢35¢ Rud, Tel. +47(0)67¢ 7¢7 40, Fax +47(0)67¢ 392 92

NL Georg Fischer N.V., Lange Veenteweg 19, Postbus 35, 8160 AA Epe, Tel. +31(0)578/678222, Fax +31(0)578/621768

e-mail: info.vgnl@nl.piping.georgfischer.com, Internet: http://www.georgfischer.nl

PL Georg Fischer Sp. z o.o., ul. Radiowa 1A, 01-485 Warszawa, Tel. +48(0)22/638 91 39, Fax +48(0)22/638 00 94

RO Georg Fischer Rohrleitungssysteme AG, Rep. Office Romania, 11 Barbu Delavrancea, 70000 Bucharest - Sector 1

Tel. +40(0)1/222 91 36, Fax +40(0)1/222 91 77, e-mail: office@georgfischer.ro

RU Georg Fischer Piping Systems Ltd, Moscow Representative Office, Sheremetievskaya ul., 47, 127521 Moscow,

Tel. +7 095/219 9604, Fax +7 095/232 3625, e-mail: lazer@orc.ru

S/FIN Georg Fischer AB, Box113, 12523 Älvsjö-Stockholm, Tel. +46(0)8/506 77 500, Fax +46(0)8/749 23 70

e-mail: info@georgfischer.se, Internet: http://www.georgfischer.se

SGP George Fischer Pte. Ltd., ¢5 Kaki Bukit Road 2, KB Warehouse Complex, 4¢7 845 Singapore/Singapore

Tel. +65(0)7/47 06 ¢¢, Fax +65(0)7/47 05 77, e-mail: info@georgfischer.com.sg

USA George Fischer Inc., 2882 Dow Avenue, Tustin, CA 92780-7285, Tel. +1(0)714/731 88 00, Toll Free 800/854 40 90

Fax +1(0)714/7 3¢ 46 88, e-mail: info@us.piping.georgefischer.com, Internet: http://www.us.piping.georgefischer.com

Export Georg Fischer Rohrleitungssysteme AG, Ebnatstrasse ¢¢¢, Postfach, CH-820¢ Schaffhausen, Tel. +41(0)52 63¢ ¢¢ ¢¢

Fax +41(0)52 63¢ 28 93/631 28 58, e-mail: export@piping.georgfischer.com, Internet: http://www.piping.georgfischer.com

@98.@50.442

Fi @99@/ @,2,4d (3.00) @000 © Georg Fischer Rohrleitungssysteme AG, CH-820@ Schaffhausen/Schweiz, @996 Printed in Switzerland

a

, 28009 Madrid

Loading...

Loading...