Page 1

Instruction Manual

Electrical Actuator Unit Type EA 20

GEORGE FISCHER …

Page 2

The technical data are not

binding. They are not warranted characteristics and are

subject to change. Please

consult our General Conditions of Supply.

46

GEORGE FISCHER …

Page 3

Table of Contents

Page

1. General 48

2. Design of the actuator 49

2.1 Mains voltage selection 50

2.2 Wiring diagram of the standard version 51

3. Design of the actuated valve 52

3.1 Ball valve Type @@5 (multi port mixing valve/L-port) 52

3.2 Ball valve Type @@@ – @@3 53

4. Installation of the actuator 54

5. Specifications 55

5.1 Actuator unit 55

5.2 Block diagram 56

5.3 Dimensions 56

6. Assembly and wiring of the modular components 57

6.1 Intermediate position 58

6.2 Mechanical limit switch 59

6.3 Inductive limit switch 60

6.4 Potentiometer 61

6.5 Operating time adjustment module (Vario) 62

6.6 Heating element 63

7. Troubleshooting guide 64

8. Individual Parts/Spare Parts 65

GEORGE FISCHER …

47

Page 4

1. Introduction

This instruction manual contains all the information

regarding design, installation and start-up procedure for the electrical actuator unit Type EA 20.

Warnings:

≠ Do not work on this unit before disconnecting it

from the mains!

≠ The actuator is factory preset to a mains volta-

ge of 230 V AC. By all means refer to Item 2.1.

≠ Electric actuators do not have a safety position.

In case of a mains breakdown, the actuator

resp. the valve remains in its actual position.

≠ Any work done on the actuator may only be

carried out by authorized and trained personnel.

≠ These products are according to the Machine

Guidelines 98/37/EG (ancient 89/392/EWG),

not regarded as machines; they are, however,

built into installations which are regarded as

machines.

Note

We distinctly emphasize that operation is

prohibited until it has been confirmed that the

machine (plant) into which the products have

been built corresponds to the conditions of the

EC Machine Guidelines 98/37/EG (ancient

89/392/EWG).

48

GEORGE FISCHER …

Page 5

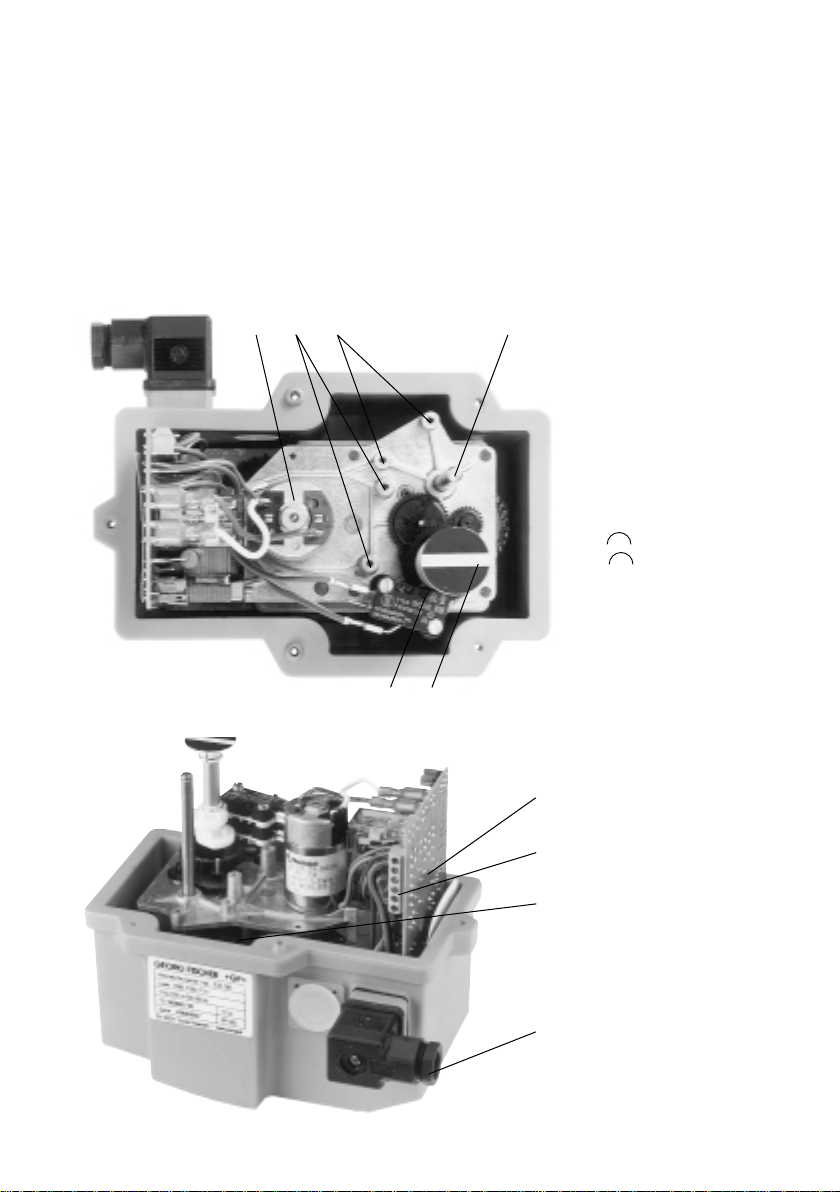

2. Design of the actuator

The standard version of the electrical actuator

EA 20 consists of the following elements: spurwheel gear, DC motor, power supply board as

well as components for limit positioning. For special applications, the actuator can be equipped with

additional modular components (see Item 6).

5

4

3

2

1 Limit Switch S1 und S2

2 Spindle for additional

switching cams

3 Mounting space for addi-

tional limit switches

4 Mounting space for po-

tentiometer and/or operating time adjustment

module

5 DC motor

6 Visual position indicator

valve closes

왔

valve opens

왔

61

1 Spur-wheel gear

2 Unit plug

3 Connector terminal strip

4

3

for external connections

max. 1,5 mm

4 Electrical supply unit

2

GEORGE FISCHER …

1

2

49

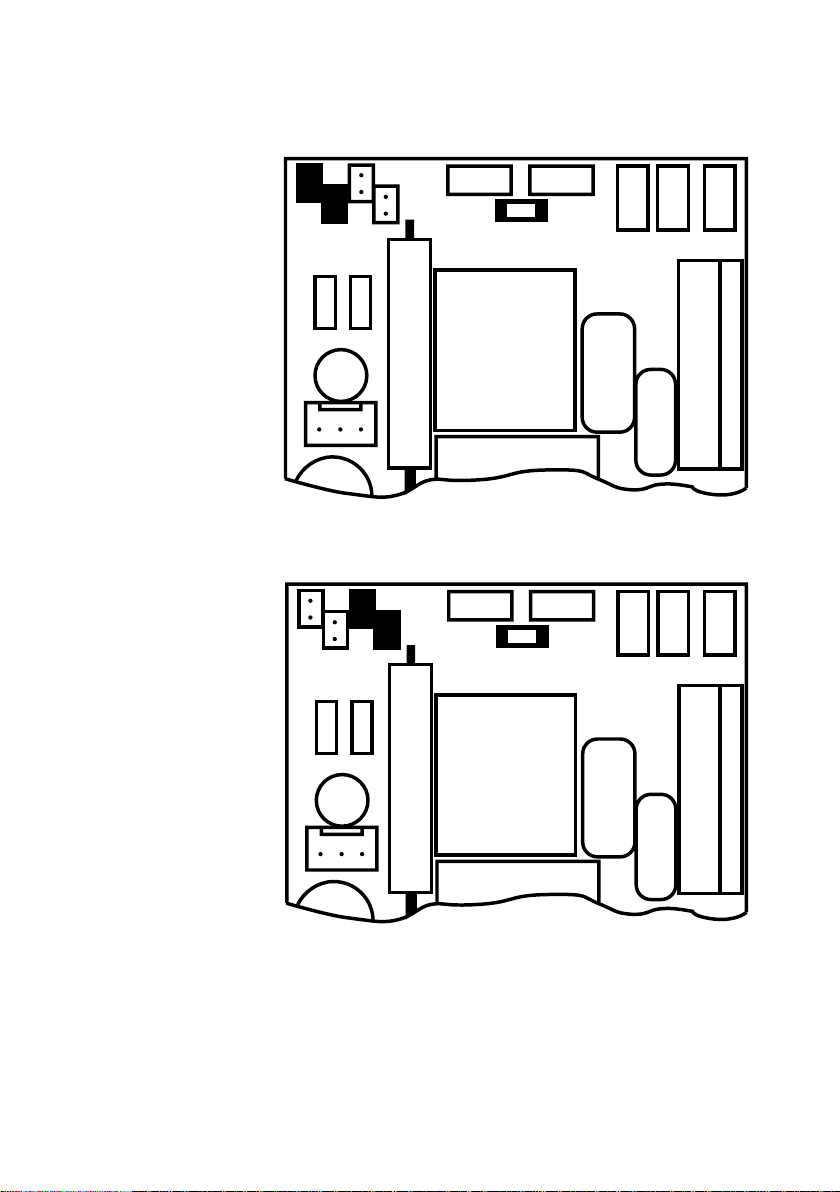

Page 6

230 V, 50–60 Hz

왗왘

The actuator is factory preset

for 230 V 앑

@@5 V, 50–60 Hz

Selecting @@5 V 앑

can be done by changing

the corresponding jumpers as

shown in the diagram

2.1 Mains Voltage Selection

왗왘

50

Do not work unit when under voltage!

GEORGE FISCHER …

Page 7

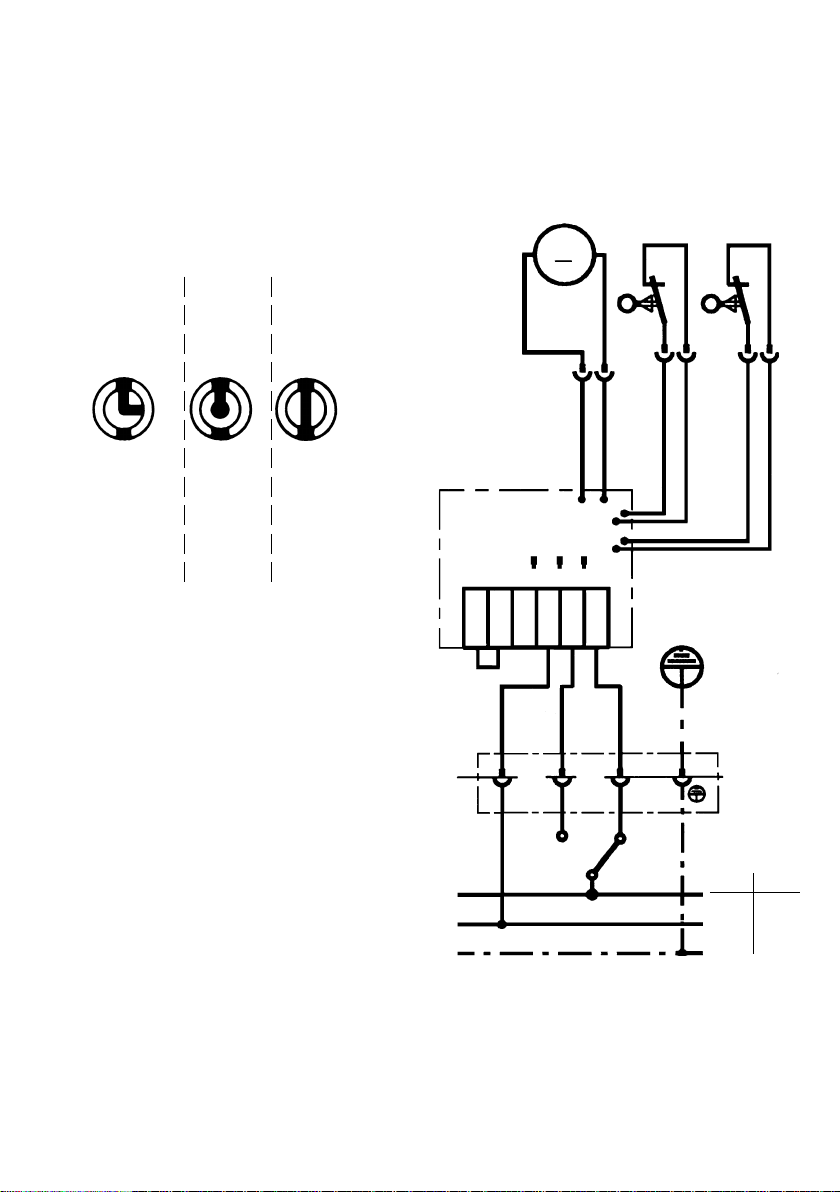

2.2 Wiring Diagram

Standard Version

Position indicator

3/2-way

Multiport

mixing valve

A

BBB

B–C

A–C

L-port

A

C

2/2-way

A

C

B closed

C open

As a component the

electrical actuator unit

EA 20 is delivered in

position <open> (A–B)

M

black

3

white

M2

F E D

red

2

brown

C

654321

open

S1

1

green

M1

S1

S2

green

1

close

S2

1

2

green

red

Connect earth

conductor to

transformer

green/

yellow

2

red

Do not use S1 and S2 for electric position

feedback.

GEORGE FISCHER …

«closed»

B

«open»

A

DC AC

+L1

–N

PE

51

Page 8

3. Design of Actuated Valve

The electrical actuator Type EA 20 can be mounted on a valve via a suitable intermediate housing.

The actuators are delivered ex factory in the

<open> position. Pictured below under 3.1 and 3.2

are the assembly parts necessary for the automatic ball valve Type 111–113 and Type 115 from

George Fischer. Both end positions are preset in

the factory. It is necessary to readjust them after

the customer has assembled the unit (see Item 4).

3.1 Ball valve Type @@5

L-port Multiport mixing valve

DN @0–50 DN @0–50

1. Type EA 20 Actuator unit

2. Coupling, Screws

3. Ball valve bracket

DN 10–32 (L-port)

4. Ball valve bracket

DN 40–50 (L-port)

DN 10–50 (Multiport

mixing valve)

5. 3-way ball valve Type 343

52

1

2

3

4

5

1

2

4

5

GEORGE FISCHER …

Page 9

3.2 Ball valve Types @@@–@@3

With manual override Without manual override

Actuator unit

Type EA 20

Coupling lever

Manual override lever

Intermediate housing

Ball valve bracket Type @26,

top half

Bracket clamps

Wedge

Screws

Coupling pieces

Ball valve Type 346

Ball valve bracket

Type @26, bottom half

Wedge

Procedure

(Ball valve with manual override)

≠ Screw the top half of the ball valve bracket to

the actuator, together with the intermediate

housing, manual override lever and coupling

lever

≠ Fit the ball valve into the bottom half of bracket

≠ Place the actuator with the top half of the

bracket on the ball valve, install the bracket

clamps and fix with wedges.

GEORGE FISCHER …

53

Page 10

S2

S1

4. Installation of the actuator

Warning:

Before the actuator is connected to the mains, the

following must be checked:

≠ is the actuator adjusted to the correct mains

voltage

(see Item 2.@)

≠ are the electrical connections correct

(see Item 2.2)

Adjustments

If a complete actuated valve is being supplied by

George Fischer, no further adjustments are necessary. If the customer assembles the unit or if a

repair has been done, the end positions must be

checked and if necessary adjusted.

Adjustments can only be done on dismounted

valves.

Limit switch positions:

Switch S1 opens at «open» position

Switch S2 opens at «closed» position

(see diagram in the margin)

54

Procedure

Both switching cams S1 and S2 are to be adjusted

so that the actuating angle is less than 90° 쏝) .

Drive the actuator until one limit switch, is operated. The end positions can be adjusted by moving

the switching cams, as the actuator follows them.

GEORGE FISCHER …

Page 11

5. Specifications

5.1 Actuator unit

Nominal voltage @@5/ 230 V, 50–60 Hz

Power consumption @2 W

Protection IP 65 in accordance with DIN 40050

Duty cycle @00% at 25 °C / 70% at 50 °C, 20 min

Overload protection Dependent on current and time

Electric connection Cable plug 3 P+E in accordance with

Control time 6 s / 90° 쏝)

Angle of operation max. 270°, set to 90°

Continuous torque @2 Nm

Peak torque 25 Nm

Operating temperature –@0° to +50 °C

Permissible humidity 0–98%, non-condensing

Body material PP fiberglass reinforced

Position indicator visual, integrated

1)

The overload protection is designed to protect

(switchable)

24 V = / 24 V, 50–60 Hz

48 V, 50–60 Hz on request

(automatic reset)

DIN 43650

additional cable connections PG @@

external screws rust-proof

1)

2)

both motor and power supply board. If the overload protection device has triggered, it will reset

automatically when the unit has cooled down

sufficiently and the actuator will operate again.

2)

For temperatures below –@0 °C the heating element Nr. @98 @90 @42/ . . @43 should be installed

(see Item 6.6).

GEORGE FISCHER …

55

Page 12

5.2 Block Diagram

open

L

closed

1

2

S1

S2

input voltage

selection

230 V

115 V

power supply

overload protection

M

N

3

5.3 Dimensions

230 V

115 V

reversing circuit

84,5

@48

56

61

@46

85

64

45

@@7

@8@

GEORGE FISCHER …

Page 13

6. Assembly and Connection

of Modular Components

The electrical actuator EA 20 is equipped with

fastening points which allow for additional modular components to be mounted.

The configuration of these points is described

under Section 2. The electrical connection is made

by means of a second cable plug or a threaded

cable joint Pg @@ (depending on the number of

connecting wires). The respective kits are prepared

for installation, the electric cables are cut to size

and packaged accordingly.

In the following sections, the corresponding assembly points and the wiring are illustrated.

GEORGE FISCHER …

57

Page 14

6.1 Intermediate position

h

l

Description Technical Data Code

Set of 2 additional auxiliary switches 250 V 앑, @0 A @99 @90 @4@

for intermediate position

1 Additional switching cams

2 Limit switches S3, S4

1

2

Adjust the central position

1. Adjust the «Open» A and «Open» B

(fine adjustment by moving the cams

with a small screw driver).

2. Move the actuator to position C

(from B outgoing).

3. Move the cam S3 by rotating clockwise to the change over point.

4. Move the cam S4 by rotating anticlockwise to the change over point.

5. Connect the D/E and connections

according to diagram.

Note:

Do not insert the connections D/E and

F yet.

Caution:

Connections to S3 and S4 are under

supply voltage.

58

Wiring diagram Nr. @99 @90 @4@

orizonta

version

A

B

vertical

version

A

B

C

C

32

black

from

from

B

A

S3

S4

1212

black

grey

6 5 4 N 2 1

grey

1

M

white

F E D

B C A

GEORGE FISCHER …

A

S1

DC AC

+L1

–N

B

S2

PE

Page 15

6.2 Mechanical limit switches

Description Technical Data Code

Kit with 2 additional auxiliary switches 250 V 앑, @0 A @99 @90 @38

Kit with 4 additional auxiliary switches 250 V 앑 , @0 A @99 @90 @39

Kit with 2 additional auxiliary switches 4–30 V = @99 @90 @49

with gold contacts 1–@00 mA

1

1 Additional switching

cames

2

2 Limit switches S5, S6 or

S5 to S8

Wiring diagram Wiring diagram

Nr. @99 @90 @39 Nr. @99 @90 @38 /@49

S7 S6 S5 S6 S5

S8

14 2 14 2 14 2 14 2 14 2 14 2

M

S2

S1

black

white

black

schwarz

weiss

schwarz

red

rot

M

S1 S2

6

GEORGE FISCHER …

ED

54321

N

321

BA BA

DC AC

+L1

–N

PE

F

654321

EDF

N

DC AC

+L1

–N

PE

59

Page 16

6.3 Inductive limit switches

The mechanical installation of these switches is

identical to those under 6.2.

An additional metal operator must be mounted so

that the active surface of the inductive switch can

be activated.

Description Technical Data Code

Kit with 2 additional auxiliary switches 9,6–55 V = @99 @90 @46

inductive, with LED NPN 0,2 A

Kit with 2 additional auxiliary switches 9,6–55 V = @99 @90 @47

inductive, with LED PNP 0,2 A

Kit with 2 additional auxiliary switches 5–24 V = @99 @90 @48

inductive Namur @0 mA

Wiring Diagram Wiring Diagram

Nr. @99 @90 @46 NPN Nr. @99 @90 @48

Nr. @99 @90 @47 PNP

S6 S5

–+A

rot

red

white

black

weiss

schwarz

3

+

–

60

M

BA

S1 S2

DC AC

+L1

–N

PE

black

white

schwarz

weiss

321

––

++

black

schwarz

–+A + – +–

green

white

weiss

grün

schwarz

black

21

S6

S6

+ NPN

+ NPN

– PNP

– PNP

654321

S5

S5

F

ED

N

white

weiss

654321

M

F

ED

N

BA

S1 S2

DC AC

+L1

–N

GEORGE FISCHER …

PE

Page 17

6.4 Potentiometer

The potentiometer must be mounted on closed

valves. Before mounting, the potentiometer must

be turned to the end position, so that 0–액 is

measured between the red and the white connecting wires.

Description Technical Data Code

Potentiometer kit 1–k액 @99 @90 @40

Wiring Diagram

Nr. 199 190 140

GEORGE FISCHER …

CCW CW

2

1

red

white

rot

weiss

321

3

black

schwarz

654321

M

F

ED

N

BA

S1 S2

DC AC

+L1

–N

PE

61

Page 18

6.5 Operating time adjustment module

왗왘

왔

(Vario)

T = @0–80 seconds, Nr. @99 @90 @44

(The vario drives the motor stepwise.)

Description Technical Data Code

Operating time adjustment module @0–80 s @99 @90 @44

1 Potentiometer for time

adjustment

time is reduced

time is extended

왔

1

2 The operating time adjust-

ment module is connected

electrically to this plug (2)

on the power supply unit.

62

2

GEORGE FISCHER …

Page 19

6.6 Heating element

Description Technical Data Code

Heating element 100–120 V, 50–60 Hz @99 @90 @42

200–240 V, 50–60 Hz

Heating element 24 V = / 앑 @99 @90 @43

1

3

Wiring Diagram

Nr. 199 190 142

Nr. 199 190 143

rot

white

weiss

red

2

1 Heating cartridge

2 Temperature switch

Switching point on: 0 °C

Switching point off: + 5 °C

3 Mounting bracket

S1 S2

GEORGE FISCHER …

213

F

ED

654321

N

B

A

DC AC

+L1

–N

PE

63

Page 20

7. Troubleshooting Guide

Problem

Motor does not run

Motor only runs in one

direction

Transformer gets very

hot

Overload protection

triggers (self resetting)

Possible Error

no mains voltage

(terminal 1, 2, 3)

internal wiring error

switching cams S1 and

S2 adjusted incorrectly

throw-over relay does

not function

wrong input voltage

selected

friction torque of valve

too high

defective motor

duty rating too high

Solution

find customer's error

check actuator

see Item 4

replace power supply

board

see Item 2.@

clean and lubricate

valve

replace motor

increase cycle time

apply measures to

decrease ambient

temperature

Valve does not close or

open correctly

64

switching cams S1 and/

or S2 not adjusted

For customer service please consult the specialist

at your nearest George Fischer sales office.

see Item 4

GEORGE FISCHER …

Page 21

8. Individual Parts / Spare Parts

Description Code

1 Unit plug, complete @98 000 147

2 Gear box and motor (irrespective of voltage) @98 800 972

3 Power supply unit

1@5/ 230 V 앑/ 50–60 Hz @98 150 586

24 V = / 앑 @98 150 587

48 V 앑 @98 150 588

Electrical Actuator, complete

1@5/ 230 V 앑/ 50–60 Hz @98 150 431

24 V = / 앑 @98 150 433

48 V 앑 / 50–60 Hz @98 150 450

Cover set consisting of: @98 000 138

1 cover 1 clamp

1 showcase inspection glass 1 seal

1 O-Ring 5 PT-screws

Sealing set consisting of: @98 000 139

4 screw 1 sealing ring

5 PT screw 4 spring washer

1 shaft seal 1 O-Ring

Limit switch set consisting of: @98 000 140

2 limit switches

4 screws

4 washers

Position indicator @98 800 899

2

dDN Intermediate Intermediate Ball valve

mm mm Zoll manual override manual override Type @26

16 10

20 15

25 20

32 25 1 198 000 102 198 000 112 161 126 008

40 32 1

50 40 1

63 50 2 198 000 105 198 000 115 161 126 011

GEORGE FISCHER …

element with element without bracket

3

/8 198 000 100 198 000 110 161 126 005

1

/2 198 000 100 198 000 110 161 126 005

3

/4 198 000 101 198 000 111 161 126 007

1

/2 198 000 103 198 000 113 161 126 009

3

/4 198 000 104 198 000 114 161 126 010

3

1

65

Page 22

GEORGE FISCHER …

A Georg Fischer Rohrleitungssysteme GmbH, Sandgasse 16, 3130 Herzogenburg

Tel. +43(0)2782/8 56 43-0, Fax +43(0)2782/8 51 56, e-mail: office@georgfischer.at

AUS George Fischer Pty. Ltd., 4 Jacks Road, South Oakleigh, Victoria 3¢67

Tel. +61(0)3/95 63 88 99, Fax +61(0)3/95 63 89 66, e-mail: sales@georgefischer.com.au

B/L Georg Fischer NV/SA, Digue du Canal 109-¢¢¢ — Vaartdijk 109-¢¢¢, 1070 Bruxelles/Brüssel

Tél. +32(0)2/556 40 20, Fax +32(0)2/524 34 26, e-mail: info.be@be.piping.georgfischer.com

CH Georg Fischer Rohrleitungssysteme (Schweiz) AG, Amsler-Laffon-Strasse ¢, Postfach, 8201 Schaffhausen

Tel. +41(0)52/631 30 26, Fax +41(0)52/631 28 97, e-mail: info@rohrleitungssysteme.georgfischer.ch

CHINA Georg Fischer Piping Systems Ltd. Shanghai, No. 2Ý8 Kang Qiao Dong Rd., Shanghai 201319

Tel. +86(0)2¢/58 13 33 33, Fax +86(0)2¢/58 13 33 66, e-mail: gfsro@public.shanghai.cngb.com

D Georg Fischer GmbH, Daimlerstraße 6, 73095 Albershausen

Tel. +49(0)7161/302-0, Fax +49(0)7161/30 2 2 59 , e-m ail: info@georgfischer.de, Internet: http://www.rls.georgfischer.de

Georg Fischer DEKA GmbH, Postfach 1145, 35228 Dautphetal, Tel. +49(0)6468/91 51-0, Fax +49(0)6468/91 52 21/22

e-mail: info@dekapipe.de

DK/IS Georg Fischer A/S, Klintehøj Vænge 17, 3460 Birkerød, Tel. +45 45 81 19 75, Fax +45 45 81 16 22

E Georg Fischer S.A., Sistemas de tuberías para la industria, Alcalá, 85, 2

Tel. +34(0)9¢/781 98 90, Fax +34(0)9¢/426 08 23, e-mail: info@georgfischer.es

F George Fischer S.A., 105–1¢3, rue Charles Michels, 93208 Saint-Denis Cedex 1

Tél. +33(0)1/49 22 ¢3 4¢, Fax +33(0)¢/49 22 ¢3 00, e-mail: info@georgefischer.fr

GB George Fischer Sales Limited, Paradise Way, Coventry, CV2 2ST, Tel. +44(0)2476/535 535, Fax +44(0)2476/530 450

e-mail: info@georgefischer.co.uk, Internet: http://www.georgefischer.co.uk

I Georg Fischer S.p.A., Via Sondrio 1, 20063 Cernusco S/N (MI), Tel. +3902/92 18 61, Fax +3902/92 14 07 85

e-mail: office@piping.georgfischer.it

J Kubota George Fischer Ltd., 2-47, Shikitsuhigashi, 1-chome, Naniwa-ku, Osaka 556-8601

Tel. +81(0)6/6648 25 62, Fax +81(0)6/66 48 25 65, e-mail: kgf-yosi@kubota.co.jp

N Georg Fischer AS, Rudsletta 97, ¢35¢ Rud, Tel. +47(0)67/¢7 ¢7 40, Fax +47(0)67/¢3 92 92

NL Georg Fischer N.V., Lange Veenteweg 19, Postbus 35, 8160 AA Epe

Tel. +31(0)578/678222, Fax +31(0)578/621768, e-mail: info.vgnl@nl.piping.georgfischer.com

Internet: http://www.georgfischer.nl

PL Georg Fischer Sp. z o.o., ul. Radiowa 1A, 01-485 Warszawa, Tel. +48(0)22/638 91 39, Fax +48(0)22/638 00 94

S/FIN Georg Fischer AB, Box113, 12523 Älvsjö-Stockholm, Tel. +46(0)8/727 47 00, Fax +46(0)8/749 23 70

e-mail: info@georgfischer.se, Internet: http://www.georgfischer.se

SGP George Fischer Pte. Ltd., ¢5 Kaki Bukit Road 2, KB Warehouse Complex, 4¢7 845 Singapore/Singapore

Tel. +65(0)7/47 06 ¢¢, Fax +65(0)7/47 05 77, e-mail: info@georgfischer.com.sg

USA George Fischer Inc., 2882 Dow Avenue, Tustin, CA 92780-7285

Tel. +1(0)714/7 31 88 00, Toll Free 800/854 40 90, Fax +1(0)714/7 3¢ 46 88

e-mail: info@us.piping.georgefischer.com, Internet: http://www.us.piping.georgefischer.com

Export Georg Fischer Rohrleitungssysteme AG, Ebnatstrasse ¢¢¢, Postfach, CH-820¢ Schaffhausen

Tel. +41(0)52/63¢ ¢¢ ¢¢, Fax +41(0)52/63¢ 28 93/631 28 58

e-mail: export@piping.georgfischer.com, Internet: http://www.piping.georgfischer.com

@98.@50.439

Fi 1944/@,2,4h (3.0@) 4000 © Georg Fischer Rohrleitungssysteme AG, CH-820@ Schaffhausen/Schweiz, @996 Printed in Switzerland

a

, 28009 Madrid

Loading...

Loading...