Page 1

Signet 9900 Transmitter

*3-9900.090*

3-9900.090 Rev. H 08/17

Quick Start

Look for the

Quick Start

icon to quickly

set up your

new 9900.

English

Operating Instructions

Your new Signet 9900 Transmitter needs to be calibrated and the

sensor needs to be initialized prior to use. The following steps

outline the recommended procedure to start up a new system.

1. Module Installation (page 3)

2. Installation (page 7)

3. Wiring (page 8)

4. Sensor Wiring (page 11)

5. Power Wiring (page 17)

6. Relay and Open Collector Wiring (page 18)

7. Relay Functions (page 19)

8. Operation (page 23)

9. Menu System (page 25)

Panel Mount

Field Mount

• English

• Deutsch

• Français

• Español

• Italiano

• 中文

Description

The 9900 Transmitter, a member of Signet's line of SmartPro® instruments,

provides a single-channel interface for all Flow, pH/ORP, Conductivity/Resistivity,

Salinity, Pressure, Temperature, Level, Dissolved Oxygen, Turbidity, Batch and

other applications.

The 9900 is available in either Panel or Field Mount. Both versions run on

10.8 to 35.2 VDC power (24 VDC nominal), and can power certain sensors on

loop power (see NOTE on page 11).

The 9900 Transmitter, also allows third-party 4 to 20 mA signals to be used as an

input (optional Signet 8058 i-Go® Signal Converter required, sold separately).

Compatibility

The 9900 is compatible with all GF Signet

products listed in the column to the right.

pH and ORP electrodes require the

Signet 2750/2751 DryLoc® Sensor

Electronics (sold separately).

Conductivity/Resistivity or Salinity

measurement requires either the optional

Direct Conductivity/Resistivity Module

(part number 3-9900.394) or the Signet

2850 Conductivity/Resistivity Sensor

Electronics (sold separately).

NOTE: If using the 2850, use the onechannel Digital (S3L) models. The twochannel model 3-2850-63 may be used

with only one channel connected. Do

not use with both channels connected.

The 4 to 20 mA models 3-2850-52 and

3-2850-62 are incompatible with the 9900.

Turbidity measurement using Signet 4150

or Dissolved Oxygen measurement using

Signet 2610-31 requires Signet 8058 i-Go

Signal Converter (sold separately).

Flow

515*/8510*, 525*, 2000,

2100, 2507, 2536*/8512*,

2537, 2540*, 2551, 2552

pH/ORP

2724-2726 with 2750*/2751

2734-2736 with 2750*/2751

2756-WTx–2757-WTx with

3719 and 2750*/2751

2764-2767 with 2750*/2751

2774-2777 with 2750*/2751

Conductivity/Resistivity, Salinity

2819-2823 with

2850 or Cond/Res Module

2839-2842 with

2850 or Cond/Res Module

Level, Temperature, Pressure

2250*, 2350*, 2450*

Turbidity

4150 requires 8058

Dissolved Oxygen

2610-41 direct to 9900

2610-31 requires 8058

* Can be run on Loop Power

(see NOTE on page 11)

Page 2

Warranty Information Table of Contents

Refer to your local Georg Fischer Sales offi ce for the

most current warranty statement.

All warranty and non-warranty repairs being returned

must include a fully completed Service Form and

goods must be returned to your local GF Sales offi ce or

distributor.

Product returned without a Service Form may not be

warranty replaced or repaired.

Signet products with limited shelf-life (e.g. pH, ORP,

chlorine electrodes, calibration solutions; e.g. pH buffers,

turbidity standards or other solutions) are warranted out

of box but not warranted against any damage, due to

process or application failures (e.g. high temperature,

chemical poisoning, dry-out) or mishandling (e.g. broken

glass, damaged membrane, freezing and/or extreme

temperatures).

Product Registration

Thank you for purchasing the Signet line of Georg

Fischer measurement products.

If you would like to register your product(s), you can now

register online in one of the following ways:

• Visit our website www.gfsignet.com.

Under Service and Support click Product

Registration Form

• If this is a pdf manual (digital copy), click here

Safety Information

Follow instructions carefully to avoid personal injury.

This unit is designed to be connected to equipment

which can be hazardous to persons and property if

used incorrectly.

Read and understand all associated equipment

manuals and safety warnings before using with this

product.

Remove power to unit before wiring connections.

Wiring connections to this product should only be

performed by qualifi ed personnel.

Do not use unit if front panel is cracked or broken.

Warning / Caution / Danger

Indicates a potential hazard. Failure to follow all warnings

may lead to equipment damage, injury, or death.

Electrostatic Discharge (ESD) / Electrocution Danger

Alerts user to risk of potential damage to product by ESD,

and/or risk of potential of injury or death via electrocution.

Personal Protective Equipment (PPE)

Always utilize the most appropriate PPE during installation

and service of Signet products.

NOTE / Technical Notes

Highlights additional information or detailed procedure.

General Information .........................................................2

Dimensions ......................................................................3

Module Installation ...........................................................3

Plug-In Modules .........................................................4

Relay Module .............................................................4

Direct Conductivity/Resistivity Module .......................5

H COMM Module .......................................................5

Batch Module .............................................................6

4 to 20 mA Output Module .........................................6

Installation ........................................................................7

Wiring ...............................................................................8

Signal Type: Frequency .............................................9

Signal Type: Digital (S

3

L) ...........................................9

Signal Type: 4 to 20 mA ...........................................10

Terminal Identifi cation ..............................................10

Sensor Wiring ...........................................................11

Power Wiring ............................................................17

Relay and Open Collector Wiring ............................18

Relay Functions .............................................................19

Relay and Open Collector Outputs ................................19

Operation .......................................................................23

Menu System .................................................................25

System Setup Menu .................................................25

Common Menus .............................................................27

LOOP Menu .............................................................27

RELAY Menu ............................................................28

OPTION Menu .........................................................30

Sensor-Specifi c Menus ..................................................31

Flow ..........................................................................31

pH .............................................................................33

ORP ..........................................................................35

Conductivity/Resistivity ............................................37

Pressure ...................................................................39

Level/Volume ............................................................40

Temperature .............................................................42

4 to 20 mA ................................................................43

Salinity ......................................................................45

Dissolved Oxygen ....................................................47

Troubleshooting .............................................................49

Appendix ........................................................................51

Averaging .................................................................51

LOG Current Loop Output .......................................51

Custom Measurements ............................................52

Calibration Procedures - pH.....................................56

Calibration Procedure - ORP ...................................58

Calibration Procedure - Conductivity/Resistivity ......60

Calibration Procedure - Flow ...................................61

Calibration Error Messages .....................................62

USP Limits ................................................................63

H COMM Module Overview .....................................64

H COMM Module Installation ...................................65

H COMM Module Wiring ..........................................65

H COMM Module Operation ....................................67

HART Commands ....................................................68

Unit Codes ...............................................................69

Specifi cations .................................................................70

Maintenance ...................................................................71

Ordering Information ......................................................72

2

9900 Transmitter

Page 3

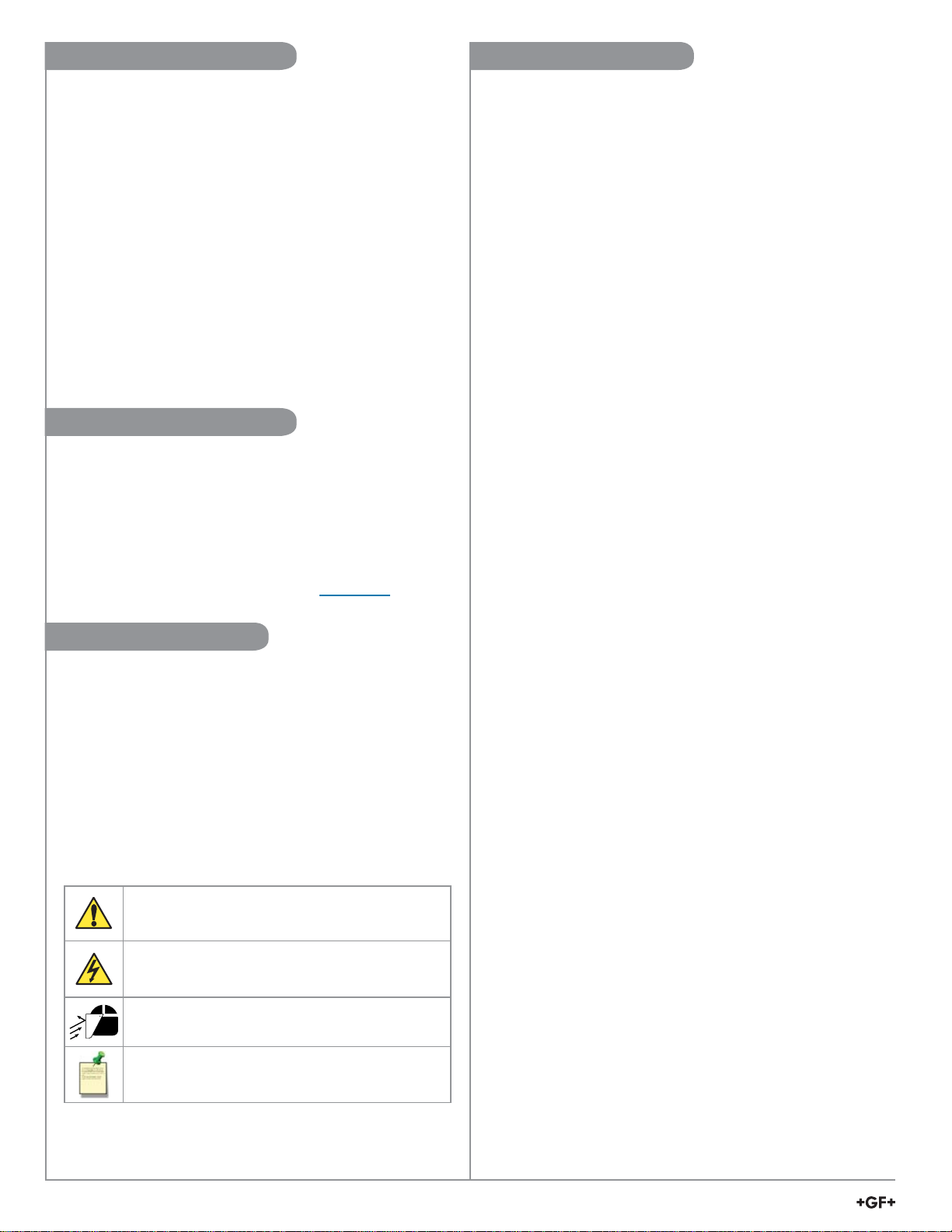

Dimensions Module Installation

Panel Mount

3-9900-1P

29.97 mm

(1.18 in.)

8.13 mm

(0.32 in.)

99.06 mm

(3.90 in.)

91.44 mm

(3.60 in.)

99.06 mm

(3.90 in.)

Top ViewSide View

54.10 mm

(2.13 in.)

Base Unit

3-9900.393 Relay Module

5A 30 VDC

5A VAC

Rating:

~

Relay Module

(Panel Mount

Only)

H COM

Conductivity/

Resistivity

H COMM

Module

DC Power

Loop Voltage

3-9900.394

Cond/Res Module

Module

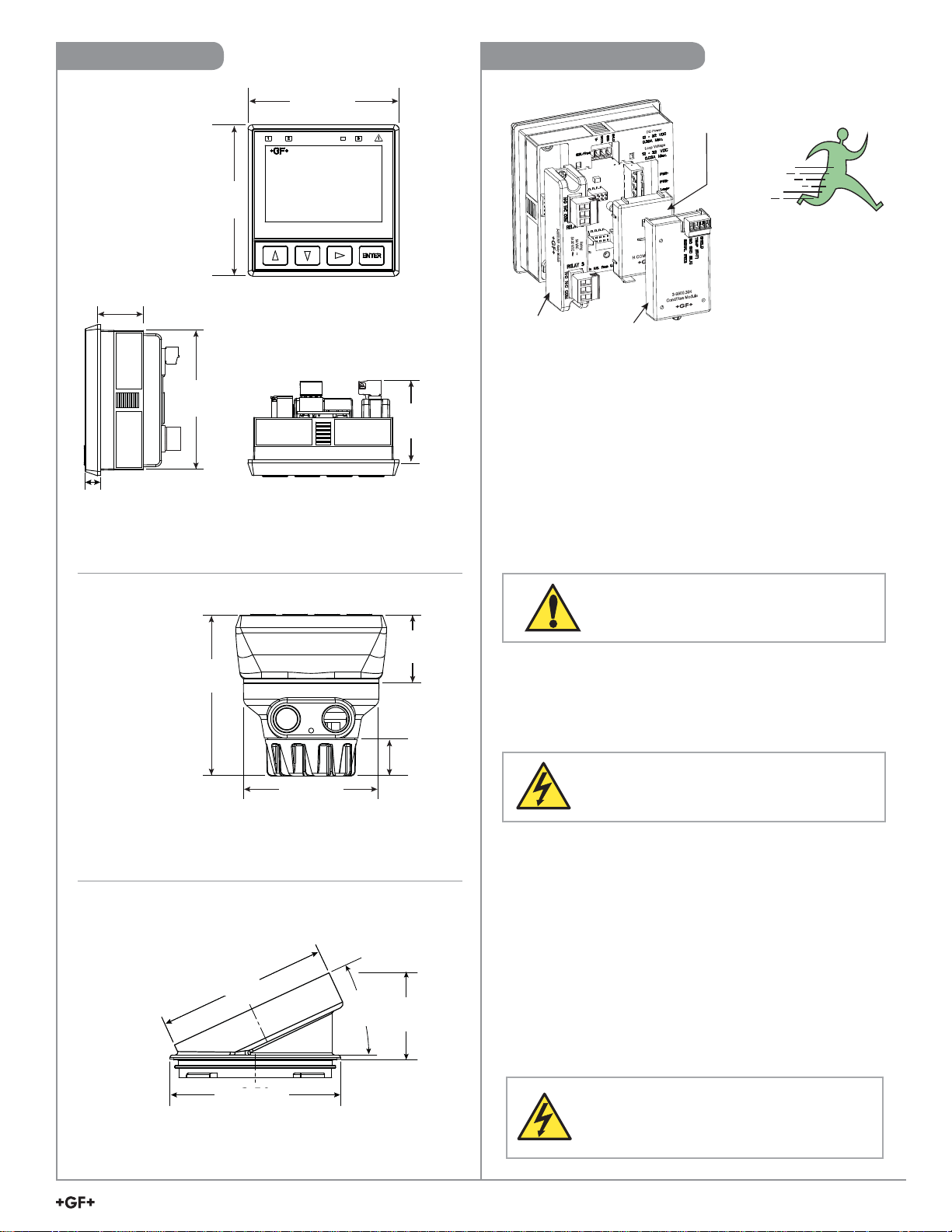

If the 9900 Base Unit will be mounted in a panel, the

plug-in modules may be installed either before or after

the base unit is mounted. If the 9900 Base Unit will be

mounted using the wall mount accessory kit (3-9900.392),

install plug-in modules fi rst.

If installing both the Conductivity/Resistivity

(Cond/Res) and the H COMM Modules, install the

H COMM Module fi rst, then the Cond/Res Module on

top of it (see illustration on page 5).

Field Mount

3-9900-1

107 mm

(4.21 in.)

88.90 mm

(3.50 in.)

44.45 mm

(1.75 in.)

24.13 mm

(0.95 in.)

(3-8051-X shown)

NOTE: 3-8051-X Integral Mounting Kit sold separately.

3-9900.396 Angle Adjustment Adapter Kit

88.90 mm

(3.50 in.)

25°

Ref.

0.68 mm

(0.27 in.)

CAUTION

Exercise care when installing modules.

Do not bend connecting pins.

To install modules:

Remove power from the 9900. Carefully align pins and

connectors (do not bend connecting pins) and push

module fi rmly into place, then attach with screw(s)

(except H COMM Module).

CAUTION

LOOP as well as DC power MUST be removed

BEFORE installing H COMM Module.

To remove modules:

Remove power from the 9900.

For Relay, Cond/Res, and 4 to 20 mA Output Modules,

unplug connectors, remove screw(s), and carefully pull

module straight out from the base unit. Do not bend the

connecting pins.

For H COMM Module, squeeze the tabs on the bottom

edge, grasp the module and pull straight out. Do not bend

the connecting pins.

For Batch Module, remove the Relay module. Loosen

bottom screw of Batch module. Carefully grip and squeeze

the tabs at the top of the module to release. Pull module

away from the unit. Do not bend the connecting pins.

88.90 mm

3.50

(3.50 in.)

WARNING

Relays may be connected to external

high-voltage power sources or multiple power

sources creating an electrocution hazard.

9900 Transmitter

3

Page 4

Plug-In Modules

Optional modules and accessories are available for the 9900:

a. Base Unit (required)

b. Slot for optional H COMM Module

c. Slot for optional Conductivity/Resistivity, Batch, or 4 to 20 mA Output Module

d. Slot for optional Relay Module (not available on fi eld mount)

Each item is ordered separately.

Modules are fi eld-replaceable at any time.

See Module Installation (pg. 3) and Ordering Information (pg. 72) sections for more details.

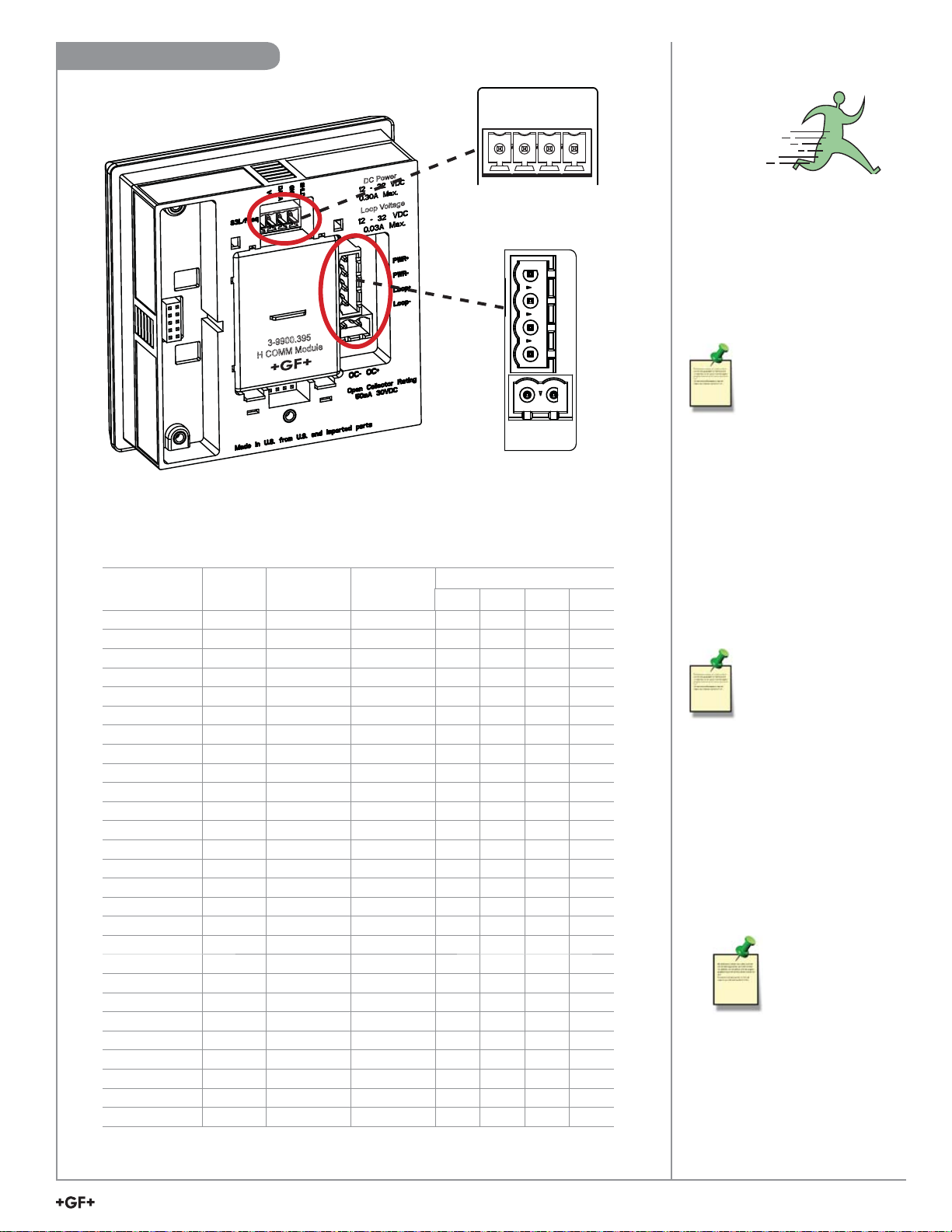

3-9900.395

H COMM Module

DC Power

Loop Voltage

a.

9900 Module

H COMM* XXXX

Relay XXXX

Conductivity/

Resistivity

Batch XXX

4-20mA

Output*

9900 Generation

I II III IV

XXXX

XX

CAUTION

Avoid Electrostatic

Discharge (ESD).

Minimize handling of the plug-in modules to

reduce the possibility of damage due to ESD.

Handle modules by the edges.

Never touch any exposed circuitry or contacts.

Wear an anti-static wristband or stand on an

anti-static mat, or keep one hand touching a

properly grounded pipe or other piece of properly

grounded metal when handling modules.

*Able to run on Loop power

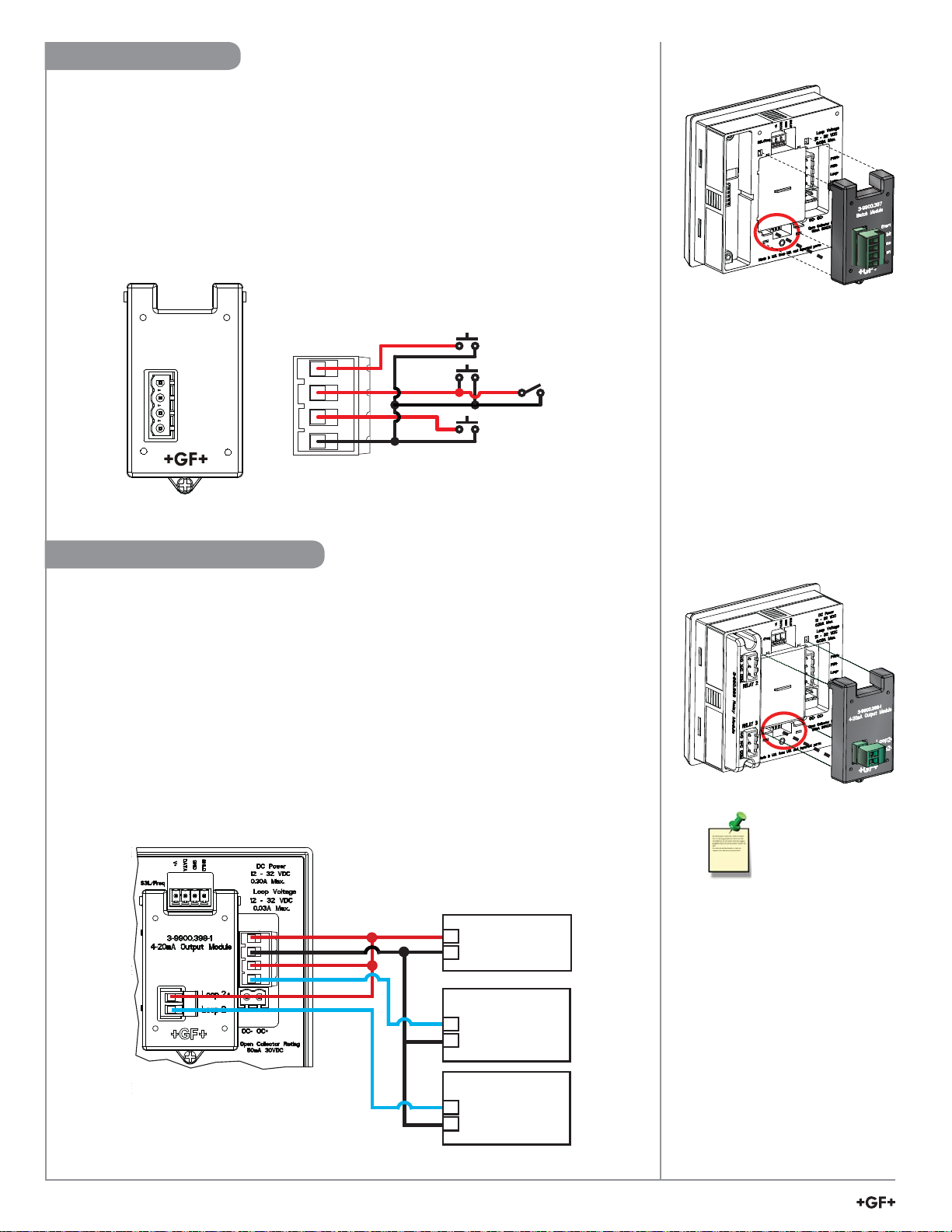

Relay Module

(Panel Mount installations only)

Mfr. Part No. Code Description

3-9900.393 159 001 698 Relay Module - Two dry-contact relays

In addition to the standard programmable Open Collector output in the base unit, the

Panel Mount version of the 9900 has a slot for an optional Relay Module, which adds two

programmable dry-contact relays. The Open Collector output in the base unit uses the Relay

1 setting in the menus. If the optional Relay Module is installed, these are assigned to relays

2 and 3 in the menus.

Dry-contact relays are electromechanical switches with a moving contact armature.

They are suitable for many general-purpose applications, AC or DC, including AC loads up to

250 V. Install RC Filter Kits, 3-8050.396, on relays used to switch motor or inductive loads.

Two (2) SPDT dry-contact relay (DCR) inputs

User programmable

250 V, 5 A maximum resistive loading (AC).

Can switch line voltage (typically 120 to 240 VAC)

Can switch DC voltage (< 30 VDC @ 5A)

Larger voltage and current ratings than Open Collector outputs.

For wiring information, refer to the Relay and Open Collector Wiring section, page 18.

d.

3-9900.393 Relay Module

5A 30 VDC

5A VAC

Rating:

~

b.

c.

DC Power

Loop Voltage

NOTE:

The Relay Module requires 10.8-35.2 VDC, 300 mA power connection to DC PWR Terminals.

The Relay Module cannot be used with loop power.

The two red Mechanical Relay Indicator LEDs on the front panel of the 9900 show the

status of relays 2 and 3. (Status of all relays and Open Collector is available at all times

in a single screen in View mode.)

Hysteresis and time delay are adjustable for each relay.

CAUTION

Switching active loads (usually inductive) can cause contact arcing suffi cient

to damage the relays.

The RC Filter Kit or “snubber” (part number 3-8050.396) is available as an

accessory to reduce or eliminate these damaging effects. Recommended for

inductive loads greater than 50 VAC (remote relays, solenoids, pumps, etc.)

4

9900 Transmitter

CAUTION

DO NOT bundle

Relay Module wiring

with other wiring.

Doing so may cause

injury and/or damage

to 9900 Transmitter,

Relay Module, and

Batch Module.

Page 5

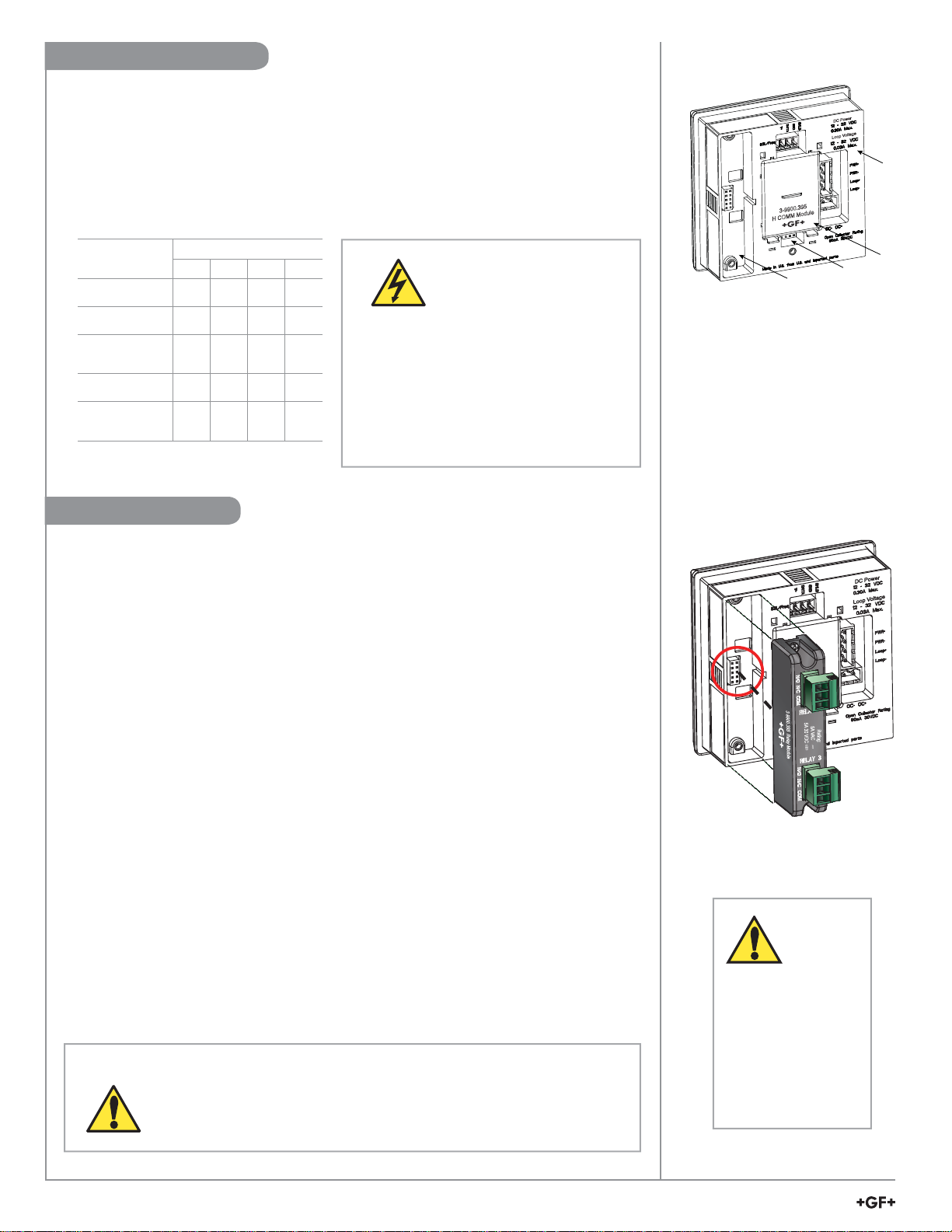

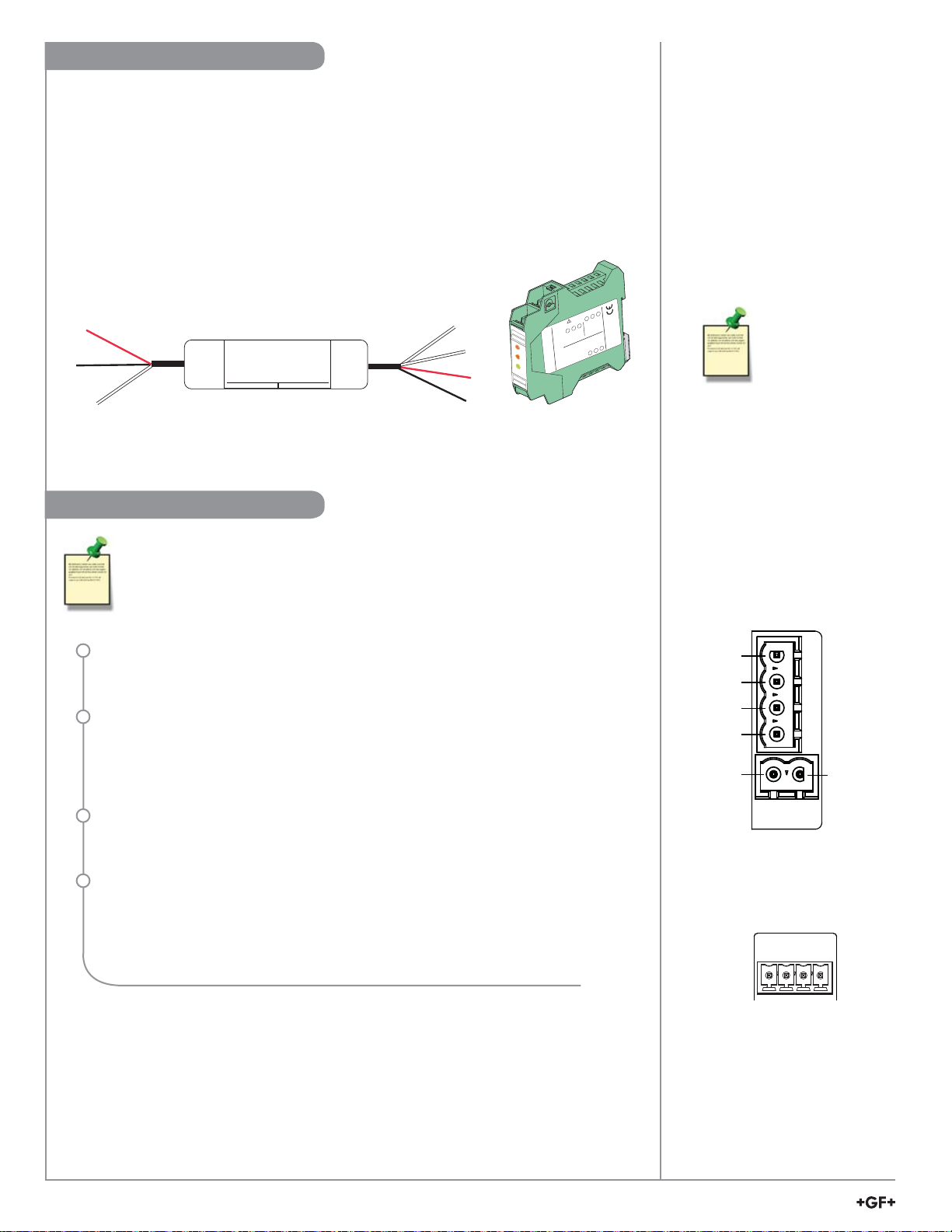

Direct Conductivity/Resistivity Module

Mfr. Part No. Code Description

3-9900.394 159 001 699 Direct Conductivity/Resistivity Module

The Direct Conductivity/Resistivity (Cond/Res) Module interfaces Signet 2818-2823 and

2839-2842 Conductivity electrodes directly to the 9900. (Conductivity/Resistivity and Salinity

measurements may also be performed via the 2850 Sensor Electronics connected through

the 9900 Digital (S

Provides fi ltering and conditioning.

Sensor cable length can be extended to 30 m (100 ft).

2839 - 2842 sensors come with a cell constant certifi cate to improve the accuracy of

the sensor measurements (see page 38).

Signet Conductivity Module cannot operate when using loop power and requires an

external DC power supply to be used with the 9900 Transmitter (see Power Wiring, pg. 17).

3

L) input.)

Red

Black

White

Shield

SHIELD (SILVER)

ISO GND (BLK)

SIGNAL (RED)

TEMP (WHT)

DC Power

Loop Voltage

2818 Sanitary 2819-

2821

2822 2823 2839-

2842

H COMM Module

Mfr. Part No. Code Description

3-9900.395 159 001 697 H COMM Module

The H COMM Module enables communication between the 9900 and a HART®-enabled

device. The HART (Highway Addressable Remote Transducer) Protocol superimposes digital

signals on top of the 4 to 20 mA analog signal.

Refer to the 9900 H COMM Module Instruction Sheet 3-9900.094 for further details.

NOTE:

With H COMM Module installed, a minimum of 24 V is required for loop-powered systems.

NOTE:

The black rubber jumper adjacent to the power terminal should only be removed when both

the H COMM Module is utilized and the required sensor cable length is over 304 m (1000 ft).

See Appendix for H COMM Module Overview, Installation, Wiring, Operation,

HART Commands, and Unit Code information. (See page 64-69)

H COMM Module

DC Power

Loop Voltage

NOTE:

The H COMM Module

can run on Loop Power.

TEMP (WHT)

ISO GND (BLK)

SIGNAL (RED)

Cond/Res Module

3-9900.395

H COMM Module

SHIELD

HART® is a registered trademark of the HART Communication Foundation, Austin, Texas, USA.

Any use of the term HART hereafter in this document implies the registered trademark.

9900 Transmitter

5

Page 6

Batch Module

Mfr. Part No. Code Description

3-9900.397 159 310 163 Batch Module

Convert a 9900-1P Transmitter (Generation II** or later) into a Batch Controller system by

utilizing a Batch Module (3-9900.397) and a Relay Module (3-9900.393).

Optional Module Wiring:

Wire an external button or keypad (customer supplied) to stop, start or resume

a batch remotely.

*Wire an external input that can inhibit a batch from starting.

Full 9900-1BC Batch Controller System manual available at www.gfsignet.com

3-9900.397

Batch Module

Stop/Inhibit

Resume

Common

Start

Common

Start

Stop

Inhibit*

Resume

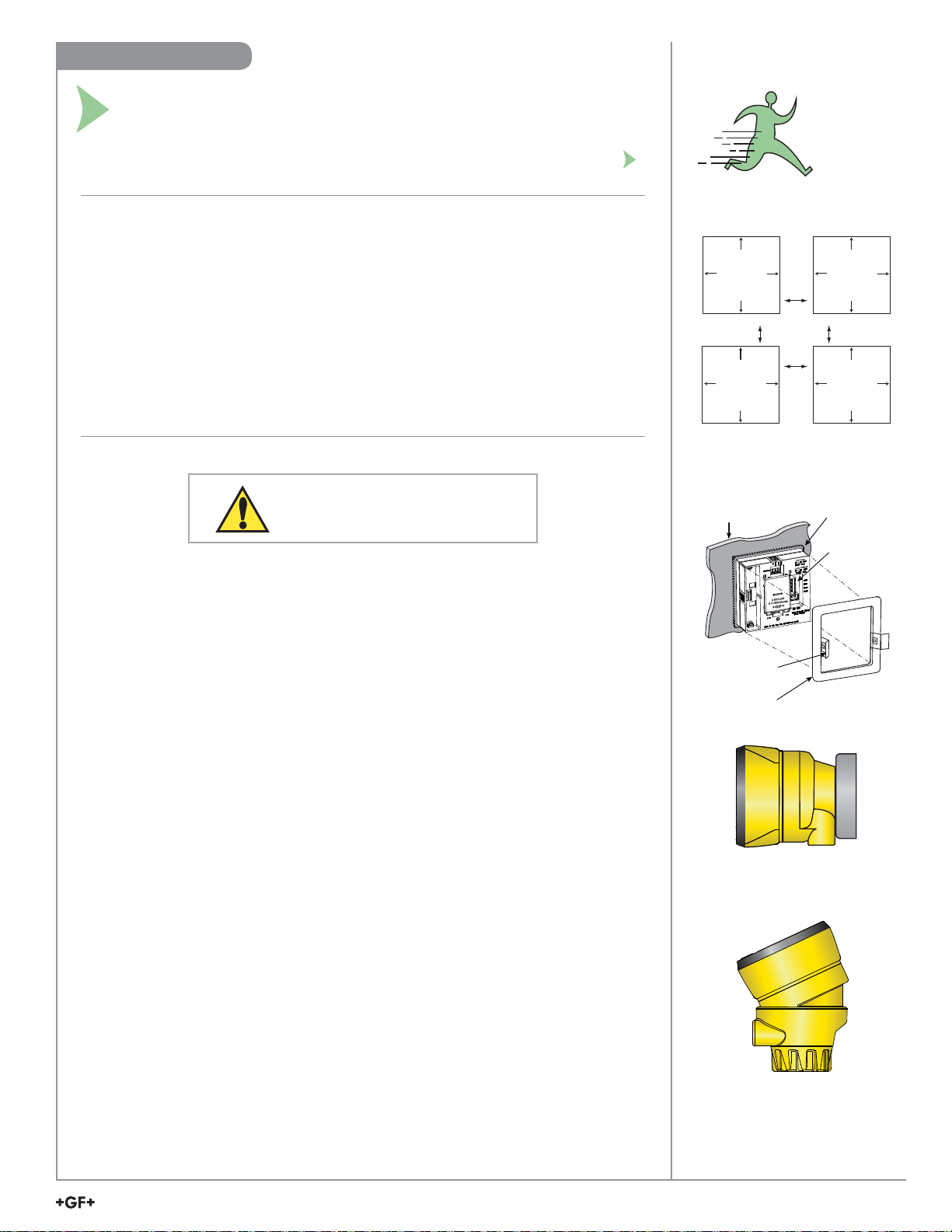

4 to 20 mA Output Module

Mfr. Part No. Code Description

3-9900.398-1 159 001 784 4 to 20 mA Output Module

The optional 4 to 20 mA Output Module adds an additional 4 to 20 mA loop output to a

Signet 9900 Transmitter (Panel or Field Mount). Requires the 9900 Generation III** or later.

Features:

4 to 20 mA Output Module can be powered using Loop Power or DC Power in the

9900 base unit.

Independent settings for the loop currents of the Output Module and 9900 base unit

(Error, Loop Adjustments, etc.).

The Primary or Secondary (if applicable) measurement of a compatible sensor can

be selected as the loop source.

The same source (Primary or Secondary measurement) can be used for Loop 1 in

the 9900 base unit and Loop 2 in the Output Module.

** NOTE:

Verify 9900 Transmitter

generation in the

OPTIONS Menu.

NOTE:

The 4 to 20 mA Output,

PWR+

PWR–

Loop+

Loop–

Loop2+

Loop2–

Red

Black

Blue

+

–

+

–

Power Supply

10.8 to 35.2 VDC

PLC or Recorder

Loop 1 Input

4 to 20 mA

Direct Conductivity, and

Batch Modules share the

same installation site on

the 9900 base units.

Only one of these

modules can be used

per 9900 Transmitter.

NOTE:

PLC or Recorder

Blue

+

Loop 2 Input

–

4 to 20 mA

6

9900 Transmitter

The Output Module can

run on Loop Power.

Page 7

Installation

System Start-up: Step 1

Prepare the transmitter installation location. If the back of the transmitter is diffi cult to

access when installed, wire the removable terminal blocks fi rst, then install it completely.

Next step: Wiring (see page 8).

For future reference, for each installation, it is recommended to record the part number

and serial number of each of the components listed here:

Facility Tag Number or System ID (user assigned):__________________

Base unit 3-9900-____ S/N ___________________

Relay Module 3-9900.393 S/N ___________________

Cond/Res Module 3-9900.394 S/N ___________________

H COMM Module 3-9900.395 S/N ___________________

Batch Module 3-9900.397 S/N ___________________

4 to 20 mA

Panel Mount Installation

Tools and Equipment Required

Fine-tooth fi le

¼ DIN punch or jigsaw suitable for cutting panel opening to within 1 mm (0.04 in) tolerance.

¼ DIN punches are available and recommended for creating clean, precise openings

quickly and easily in most instrument panels.

If a punch is not available, a jigsaw or other cutting tool can be used.

An adhesive template is provided to help guide the cutting process.

De-burr and smooth the opening with a fi le.

Output Module 3-9900.398-1 S/N ___________________

Do not mount in direct sunlight.

Panel Cutout

92 x 92 mm

_

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

panel

Quick-clip

mounting

bracket

minimum

clearance

25 mm

(1 in.)

3-9900.395

H COMM Module

gasket on

front side

of panel

DC Power

Loop Voltage

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

terminal

blocks

1. The panel mount transmitter is designed for installation using a ¼ DIN punch.

Recommended clearance on all sides between instruments is 25 mm (1 in).

2. Place gasket on instrument, and install in panel.

3. Slide mounting bracket over back of instrument until bracket snaps into latches on

sides of instrument.

To remove:

1. Secure instrument temporarily with tape from front or grip from rear of instrument.

DO NOT RELEASE.

2. Press bracket clips outward and remove.

Field Mount Installation

Field mounting requires a separate mounting kit. The 3-8050 Universal Mount Kit, the

3-8051 or 3-8052 Integral Mount Kits, and the 3-9900.396 Angle Adjustment Adapter Kit

enable the transmitter to be installed virtually anywhere. Detailed instructions for fi eld

installation options are included with the 3-8050, 3-8051 and 3-8052 adapter kits

(see Ordering Information section).

For Field Mount installations with a Cond/Res Module, the 3-9900.396 Angle Adjustment

Adapter is required along with a 3-8050 or 3-8052 adapter kit to allow for suffi cient

clearance for the wiring.

Field Mount with

3-8050 Universal Mount Kit

Field Mount with

3-8051 Integral Mount Kit

and Angle Adjustment Adapter

9900 Transmitter

7

Page 8

Wiring

System Start-up: Step 2

Wire the transmitter for all connections with the power off. Keep any 4 to 20 mA and

relay-actuated output devices that are connected to it offl ine at this time.

Connect the sensors (page 11), power (page 17) and relay(s) (page 18).

Next step: Relay Functions (see page 19).

Wiring Tips:

Do not route the sensor, DC power, or 4 to 20 mA cables in conduit containing

AC power wiring. Electrical noise may interfere with sensor signal.

Routing the sensor cable in grounded metal conduit can help prevent electrical noise

and mechanical damage.

Seal the cable entry points to prevent moisture damage.

Only one wire should be inserted into a terminal.

Splice double wires outside the terminal or use appropriate wire ferrule,

not to exceed 2 mm (0.08 in) diameter.

All wiring connections to the 9900 are made via removable terminals.

In general:

The Power, Loop and Open Collector plugs and the Relay Module plug accept

12 to 28 AWG wire.

The S3L/Freq plug and the Cond/Res Module plug accept 16 to 28 AWG wire.

Strip 7 mm (0.28 in.) of insulation from wire tips and tin bare ends to eliminate fraying.

Insert wire tip or ferrule completely into the terminal and secure with the screw.

Do not allow any AC leads that may be connected to the internal relays to come in

contact with low voltage wiring.

Tools Required

Phillips screwdriver

Flat-head screwdriver

Wire strippers

For Field Mount

installations, refer to

the wiring diagram

inside the Field

Mount housing.

CAUTION:

Avoid Electrostatic Discharge (ESD)

Minimize handling of plug-in modules to reduce the

possibility of damage due to ESD.

Handle modules by the edges. Never touch any exposed

circuitry or contacts.

Wear an anti-static wristband or stand on an anti-static mat,

or keep one hand touching a properly grounded pipe or other

properly grounded piece of metal when handling modules.

8

9900 Transmitter

Page 9

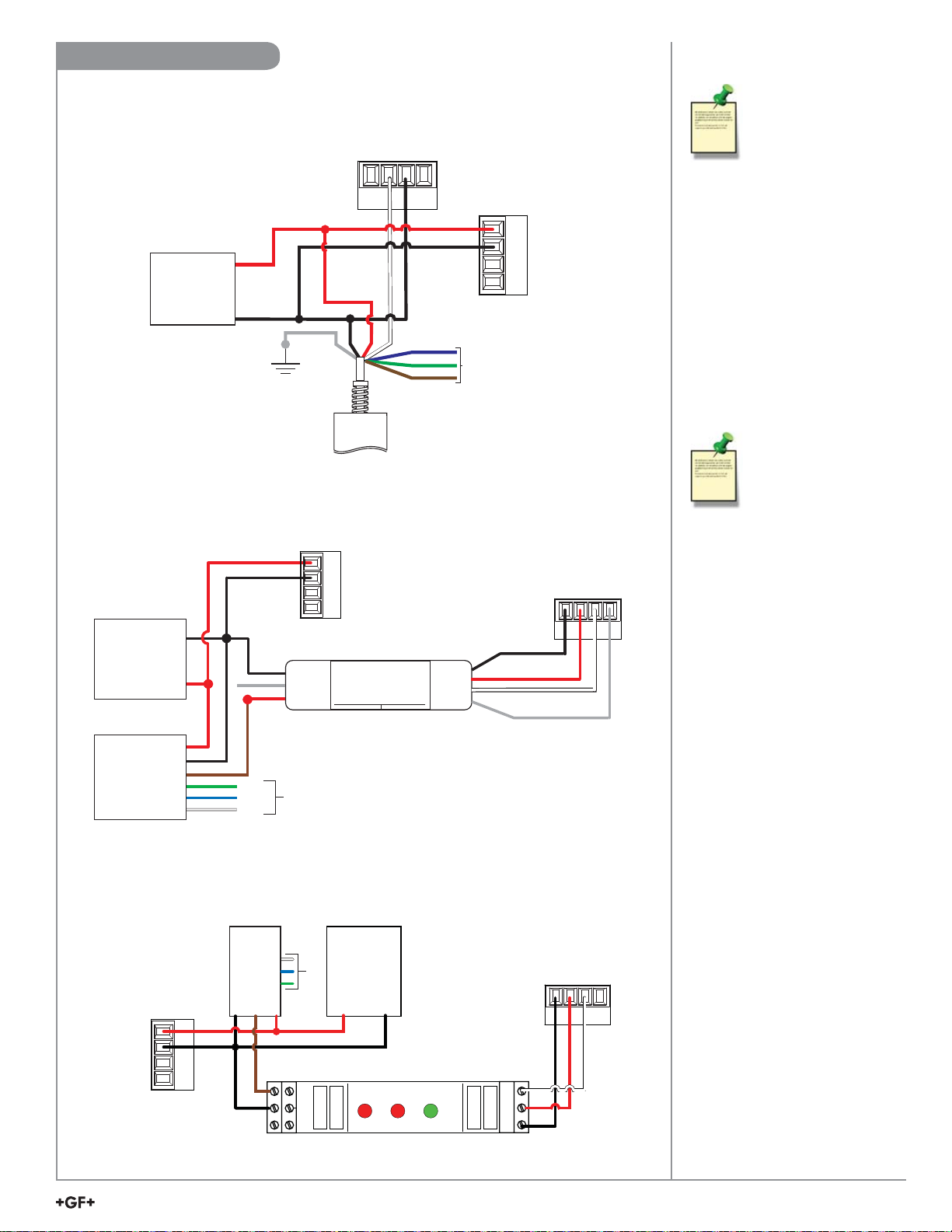

Signal Type: Frequency

Signet fl ow sensors 515/8510, 525, 2000, 2100, 2507, 2536/8512 and 2540 provide a

frequency output. (Flow sensors 2551 and 2552 can be confi gured with either Digital (S

or Frequency outputs, see page 13.)

The maximum allowable cable length for sensors with frequency output is dependent upon

the output signal strength of the sensors themselves, and the degree to which the signals

are susceptible to EMI or "noise." This is largely a function of whether the sensors are

self-powered (515/8510 and 525), or powered by an external source.

The input terminals on the 9900 carry frequency data signals from the sensor.

Do not route sensor or output cables in conduit containing AC power wiring.

Electrical noise may interfere with sensor signal.

Routing cable in grounded metal conduit will help prevent electrical noise and

mechanical damage.

Seal cable entry points to prevent moisture damage.

Only one wire should be inserted into a terminal. Splice double wires outside the terminal.

In case of noise interference, ground the sensor SHIELD wire to a local earth ground

at a point near the sensor.

Consult the sensor manual for additional wiring information.

3

L)

Signal Type: Digital (S3L)

The input terminals on the 9900 carry Digital (S3L) serial data from the sensor.

Do not route sensor or output cables in conduit containing AC power wiring.

Electrical noise may interfere with sensor signal.

Routing cable in grounded metal conduit will help prevent electrical noise and

mechanical damage.

Seal cable entry points to prevent moisture damage.

Only one wire should be inserted into a terminal. Splice double wires outside the terminal.

The TOTAL cable length from I/O devices to the transmitter must not exceed 305 m (1000 ft).

In case of noise interference, ground the sensor SHIELD wire to a local earth ground

at a point near the sensor.

Consult the sensor manual for additional wiring information.

The maximum cable length of the Digital (S3L) bus varies depending on the types

of sensors connected and the size of the conductors in the cable. For best results,

determine the maximum cable length for the system before routing cables.

There are several methods that can help route the digital cables and remain within the

distance limitations.

Flow sensor

models with

Frequency

Output

515/8510 X

525 X

2000 X

2100 X

2507 X

2536/8512 X

2537 X

2540 X

2551 X

2552 X

In case of noise

interference, connect

the cable shield to

earth ground.

Maximum total cable length

of the Digital (S3L) Bus:

The quality of the cable

used in the bus determines

the maximum length of all

branches combined.

The maximum cable length

may not exceed

305 m (1000 ft),

regardless of current

requirements.

Maximum

Cable Length

60 m

(200 ft)

305 m

(1000 ft)

9900 Transmitter

9

Page 10

Signet 8058 i-Go™

4-20 mA to S

3

L Converter

+GF+

4-20 mA input S3L Output

Input

4-to-20 mA

Output

S

3

L

White

Shield

Shield

Black

Black

Red

Red

Signal Type: 4 to 20 mA

When connecting a non-Signet sensor to the 9900, the sensor’s 4 to 20 mA signal must be

converted to Digital (S

and converts it into Digital (S

1. Wire the 8058 between the 4 to 20 mA loop source and the 9900 Digital (S

3

L). The 8058 i-Go Signal Converter accepts any 4 to 20 mA signal

3

L).

3

L) input

terminals (see page 14).

2. In the 9900 INPUT TYPE menu (see System Setup Menu discussion, page 25),

specify 4 to 20 mA INPUT.

3. Set additional labels and abbreviations as described on pgs. 42-43.

X

A

M

C

1

2

D

V

5

+

3

3

1

p

1 -

o

p

o

o

4

L

o

/C

5

6

/C

Input

N

4-20 mA

L Converter

3

3

S L

Output

4-20mA to S

8058 i-Go™

+GF+

L

+

N

2

-

p

2

o

p

o

o

L

o

L

C

D

3

V

9 GND

8 S L

7 +5

8058-1

+

G

3 2 1

6 5 4

S

ig

n

N/C

7 8 9

F

+

L

o

o

p

1

P

W

R

L

o

o

p

2

P

W

R

S

3

L

D

A

TA

e

t 80

5

8

8058-2

Terminal Identifi cation

3-8058.610D

For the 8058-2,

connect Channel 1

ONLY

The 9900 requires regulated 10.8 to 35.2 VDC (24 VDC nominal)

from an external power supply (not supplied).

Maximum current draw is:

200 mA = 9900 without Relay module

300 mA = 9900 with Relay module

Terminals 1-2: DC Power

Required by the instrument

10.8 to 35.2 VDC input power to sensors, relays and the LCD backlight

Terminals 3-4: Loop Power (may also be used for system power)

10.8 to 35.2 VDC

NOTE: Backlight, LEDs and optional Relay Module do not operate on

loop power. Any connected sensors or sensor electronics that cannot

operate on loop power will also be inoperative.

Terminals 5-6: Open Collector

Software selectable for Normally Open or Normally Closed.

May be disabled (Off) if not used.

Terminals 7-10: Digital (S

3

L)/Frequency Input

7: V+: +5 VDC out to sensor (black wire)

8: DATA: Input signal from sensor (red wire)

9: GND: Sensor ground (white wire)

10: SHLD: Cable shield

Power

1

2

3

4

5

OC- OC+

Digital (S3L)/Freq

SHLD

DATA

GND

V+

PWR+

PWR–

Loop+

Loop–

6

10

9900 Transmitter

10978

Page 11

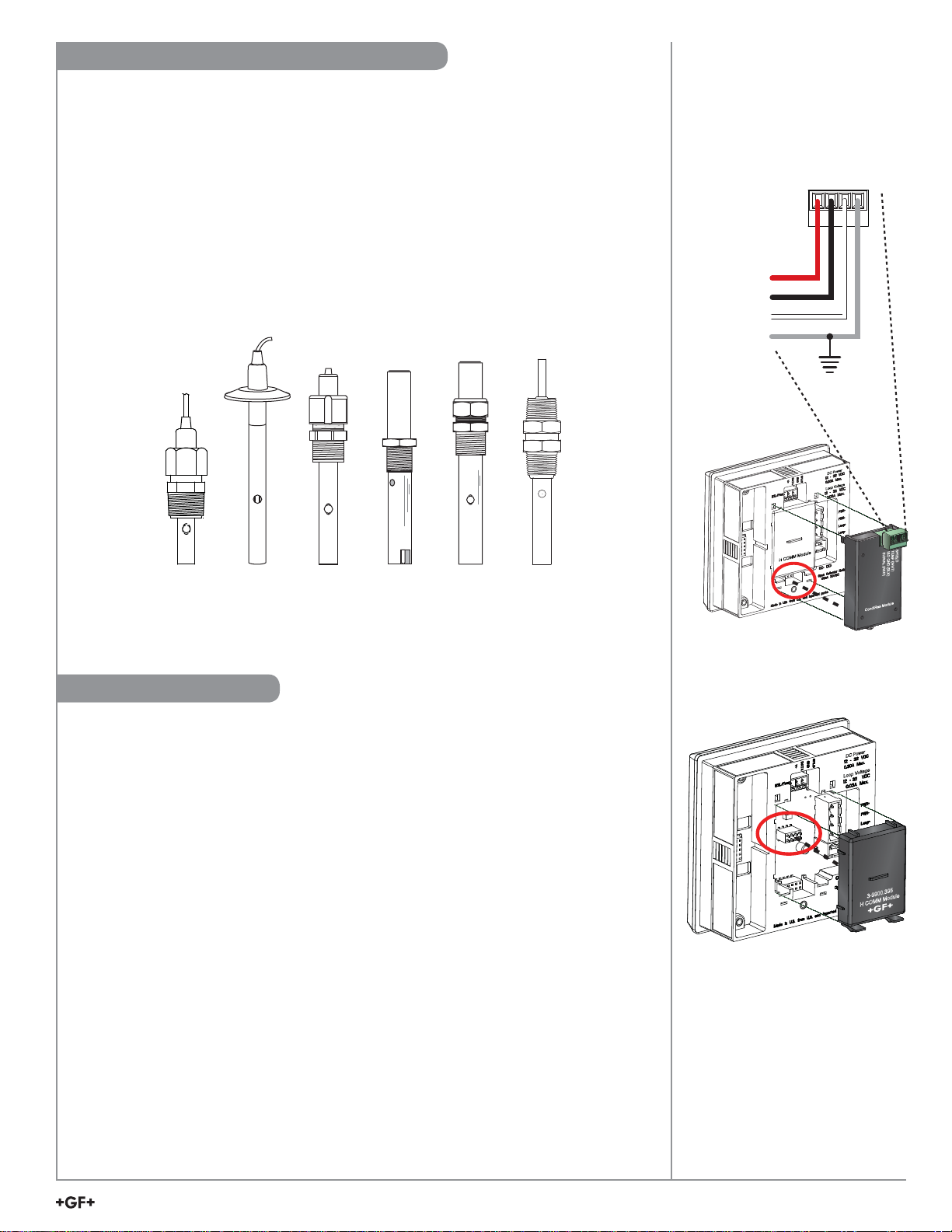

Sensor Wiring

3-9900.395

H COMM Module

DC Power

Loop Voltage

Connect sensor wires here as

shown in the following fi gures.

Connect power and open

collector wires here as

shown on pages 17 and 18.

Loop powered systems

cannot power both an

H COMM Module and

pH sensor.

If using both an H COMM

Module and pH sensor,

DC power is required.

Sensor model

Freq

Output

Digital (S3L)

Output

Run on

Loop Power

9900 Generation

I II III IV

515/8510 X X XXXX

525 X X XXXX

2000 X XXXX

2100 X XXXX

2250 X X XXXX

2350 X X XXXX

2450 X X XXXX

2507 X XXXX

2536/8512 X X XXXX

2537-5 X XXXX

2540 X X XXXX

2551 X X XXXX

Loop Power can be

used ONLY for the

following sensors:

515/8510, 525,

2250, 2350, 2450,

2536/8512, 2540, 8058

and pH/ORP sensors

with 2750; all other

measurement sensors

require DC power.

2552 X X XXXX

2610-41 XXX

2610 + 8058 X XXXX

2724-2726 X XXXX

2734-2736 X XXXX

2750 X X* XXXX

2751 X XXXX

2756-2757 X XXXX

2764-2767 X XXXX

Advanced 2751

features require

Gen 4 or greater

2774-2777 X XXXX

2819-2823 X XXXX

2839-2842 X XXXX

2850 X XXXX

4150 + 8058 X XXXX

U1000 X XXXX

* A minimum of 24 VDC Loop Power is required for the 2750.

9900 Transmitter

11

Page 12

Sensor Wiring

NOTE: Loop Power cannot be used to power Signet models 2000, 2100, 2507, 2537,

2551 or 2552 Flow sensors.

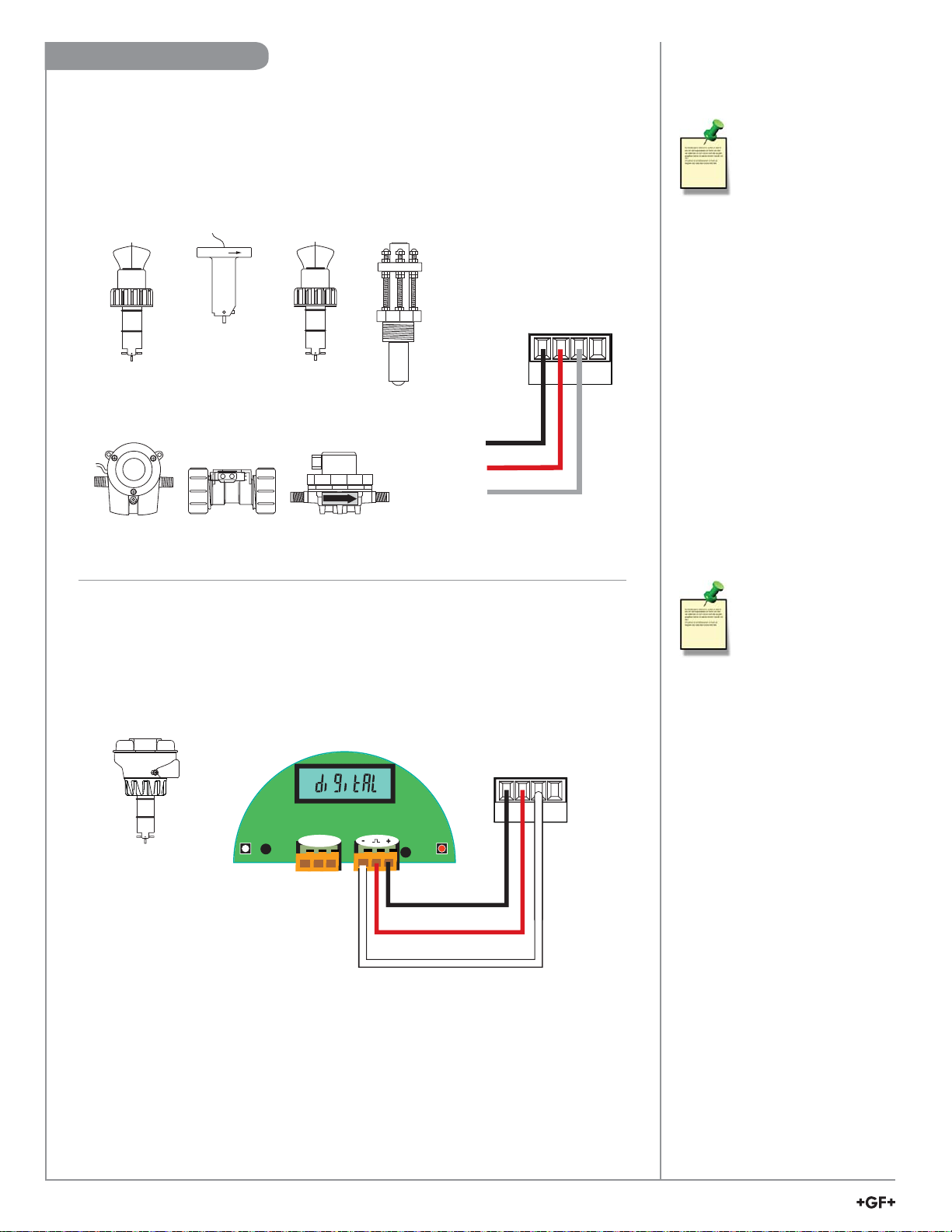

Wiring for:

515/8510

525 2536/8512 2540

FLOW

2000 2100 2507

Wiring for:

FLOW

Black

Red

Shield

Frequency

SHLD

DATA

GND

V+

No connection

Technical Notes:

• See corresponding product

manuals for maximum cable

length.

• Maintain cable shield through

cable splice.

• Route sensor cable away

from AC power lines.

• 515/8510 and 525

installations, connect the

silver (shield) wire to earth

ground in case of EMI noise

interference.

2537-5

Technical Notes:

• Wiring terminals on the 2537

9900 S

V+

3

L Inputs

SHLD

DATA

GND

are rated for 16 to 22 AWG

wires.

• The cable must be

7 mm to 10 mm in diameter

(0.275 in. to 0.394 in.) to seal

properly in the liquid-tight

connector.

Blk Red Shld

S1

-

+

S2

• The conduit ports have

½-inch NPT threads.

After routing the cables,

seal the port with a liquid-

Black

Red

White

tight conduit connector

(3-9000.392-1) or with

conduit.

• The 2537 models can

connect to the 9900 via a

relay frequency signal or with

a Digital (S3L) output. Signet

recommends installing the

Digital (S3L) output model

(2537-5) because Digital

3

L) is more accurate.

(S

• See 2537 instruction manual

for additional installation

information.

12

9900 Transmitter

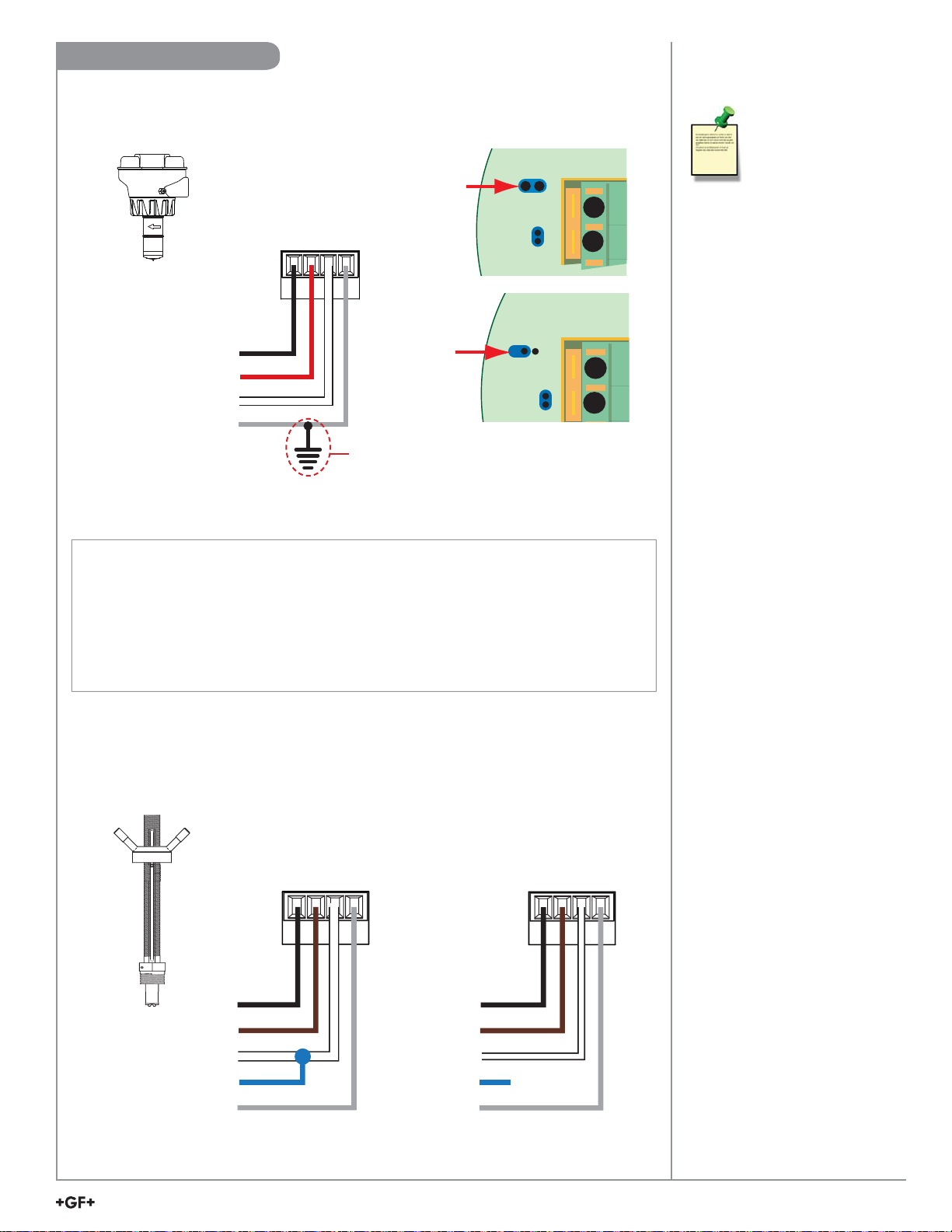

Page 13

Sensor Wiring

Wiring for:

2551-XX-11

Blind Magmeter

Black

Red

White

Shield

V+

DATA

SHLD

GND

Frequency

3

S L

4

3

4

2551 Technical Notes:

• When the blue jumper

illustrated here is placed over

both pins, the 2551-XX-11

(Blind Magmeter) outputs

an open collector frequency

signal. When the jumper is

removed (or placed over

one pin for storage) the

2551-XX-11 outputs a digital

3

(S

L) signal (recommended).

3

Only in case of EMI interference.

See Frequency Output Technical

Notes (2551 & 2552) at right

Input Wiring for 2551 and 2552 sensors

• Either Frequency or Digital (S3L) may be used.

• Signet recommends confi guring these sensors with the Digital (S3L) output

because it is more accurate and will also display reverse fl ow (negative numbers).

• Input type is selected by choosing between “SENSOR FREQ” and "SENSOR S3L" in

the FLOW sensor type INPUT menu (see page 32).

• Loop Power cannot be used to power these sensors.

Wiring for:

2552

Frequency9900 S3L Inputs

V+

DATA

SHLD

GND

V+

DATA

SHLD

GND

Frequency Output Technical

Notes (2551 & 2552):

• The frequency output will

be displayed as positive

fl ow regardless of the fl ow

direction.

• 5 VDC power required by

the 2551 & 2552 is supplied

by the 9900. No additional

power is required.

• Connect the silver wire

(shield) to earth ground

in case of EMI noise

interference.

• If EMI noise interference

continues, disconnect silver

wire (shield) from 9900

2552 Technical Notes:

• The 2552 outputs an open

collector frequency signal that

can be connected to the 9900.

Black

Brown

White

Blue

Shield

Black

Brown

White

Blue

Shield

No

X

connection

9900 Transmitter

13

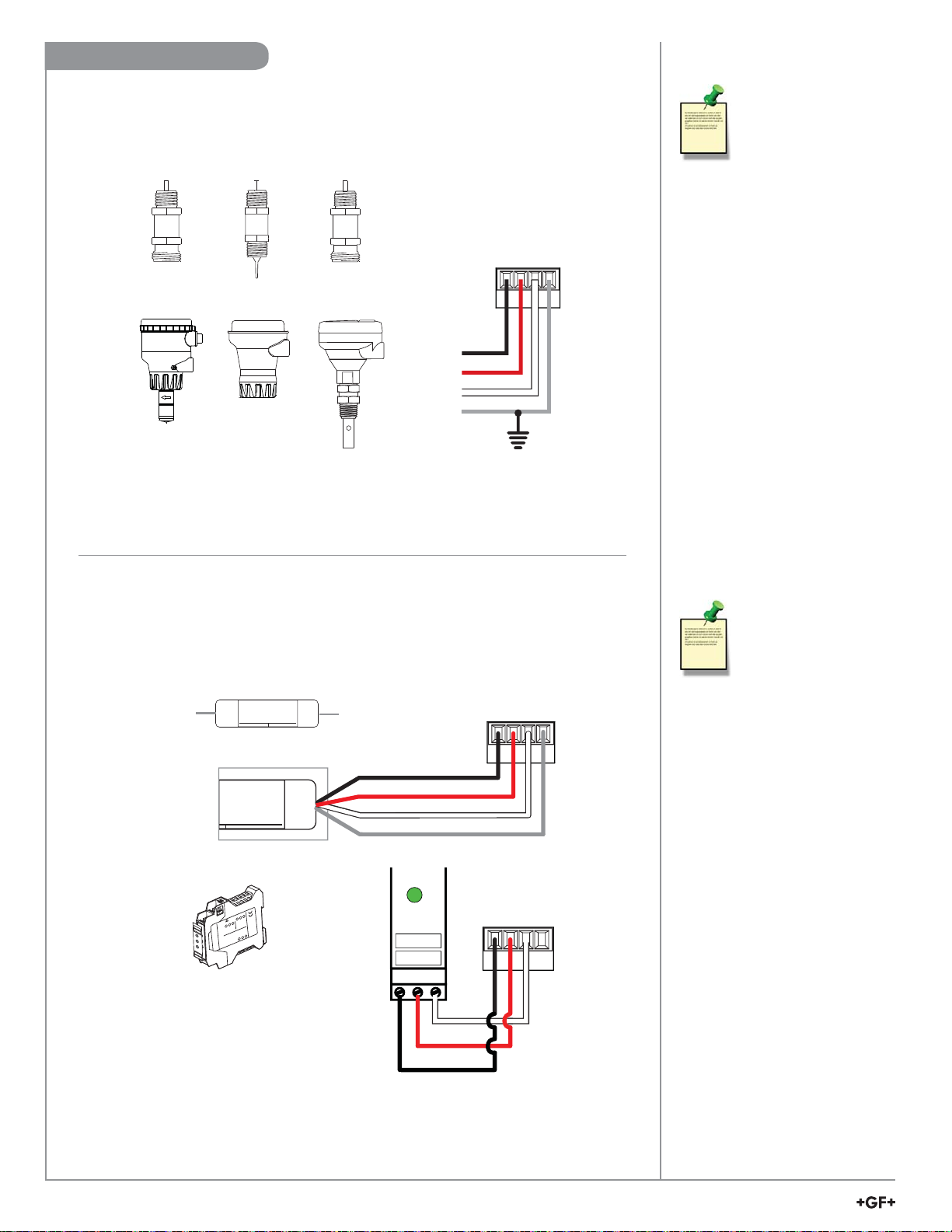

Page 14

Sensor Wiring

Wiring for:

2250 2350 2450

2551* 2750/2751 2850

* 2551-XX-21, -41

Display Magmeter

Wiring for:

9900 S

V+

Black

Red

White

Shield

NOTE: The 2850 has no SHIELD wire.

3

L Inputs

SHLD

DATA

GND

Technical Notes:

• Use three conductor shielded

cable for sensor cable splices

up to 305 m (1000 ft) max.

• Maintain cable shield through

cable splice.

• Route sensor cable away

from AC power lines.

• Connect the silver (shield)

wire to earth ground in case

of EMI noise interference.

Technical Notes:

• The 2850 has no SHIELD wire.

• To work correctly with the

9900, the 2850 must be set

for the custom cell constant or

the actual probe cell constant

and the 9900 set for a 1.0 cell

constant.

8058-1

8058-1

close-up

8058-2

4-to-20 mA

+GF

+

3 2 1

6 5 4

L

L Converter

o

o

p

3

1

PWR

L

o

op2

PWR

4-20mA to S

8058 i-Go™

S

3

L

DA

+GF+

Sign

TA

et 8058

N/C

7 8 9

+GF+

Input

4-20 mA to S

4-20 mA input S3L Output

Signet 8058 i-Go™

4-20 mA to S3L Converter

S3L Output

MAX

DC

V

35

Loop1 + 1

Loop1 - 2

N/C 3

Loop2+ 4

Loop2 - 5

Input

N/C 6

3-8058.610D

4-20 mA

3

9 GND

8 S L

7 +5VDC

3

S L

Output

Signet 8058 i-Go™

3

L Converter

L

3

S

Output

L

3

S

Output

8058-2

close-up

Black

Red

White

Shield

N/C

7 8 9

9900 S3L Inputs

9900 S

3

S L

DATA

WHITE

RED

BLACK

V+

V+

DATA

SHLD

DATA

GND

3

L Inputs

SHLD

GND

Technical Notes:

• The cable length from the

8058 to the 9900 must not

exceed 60 m (200 ft).

• When using the 8058-2,

connect the loop source to

Channel 1 input ONLY.

• See the 8058 manual for

more information.

14

9900 Transmitter

Page 15

Sensor Wiring

Wiring for:

2610-41

24 VDC

Power Supply

7310-XXXX

2610-31 via 8058-1

24 VDC

Power Supply

7310-XXXX

V–

V+

V+

V-

RED

BLACK

SHIELD

BLACK

SHIELD

(no connection)

REDRED

4-20 mA

Input

RED

9900 S3L Inputs

DATA

GND

V+

WHITE

Blue

Green

Brown

3-2610-41

PWR+

PWR–

LOOP+

LOOP–

+GF+

4-20 mA input S3L Output

Signet 8058 i-Go™

4-20 mA to S

8058-1

3

L Converter

SHLD

9900 Power Inputs

RED

BLACK

No connection

L

3

S

Output

PWR+

PWR–

LOOP+

LOOP–

BLACK

RED

WHITE

SHIELD

Technical Notes:

The wiring of the 3-2610-41

is non-standard:

• RED is 12 to 24 VDC

• WHITE is Data

• BLACK is VDC Ground

• A jumper MUST be installed

between PWR- and S3L GND.

9900 S3L Inputs9900 Power Inputs

V+

DATA

GND

SHLD

Technical Notes:

• 3-2610-31 Dissolved Oxygen

Sensor can be connected

to the 9900 only via a

3-8058-1 or 3-8058-2 i-Go

Signal Converter.

• Program the 9900 for the

2610 DO sensor via the

4 to 20 mA sensor settings

on the 9900 (see page 44).

• See the 2610 manual for

more information.

DO Sensor

3-2610-31

2610-31 via 8058-2

9900 Power Inputs

PWR+

PWR–

LOOP+

LOOP–

RED

BLACK

BROWN

GREEN

BLUE

WHITE

DO

Sensor

1

3-2610-31

BROWN

No connection

Power Supply

7310-XXXX

No connection

3 2 1

6 5 4

+GF+ SIGNET

24 VDC

+

PWR

Loop1

-

Loop2

PWR

Technical Notes:

• The cable length from the

8058 to the 9900 must not

exceed 60 m (200 ft).

9900 S3L Inputs

V+

DATA

GND

SHLD

Technical Notes:

• When using the 8058-2 with

the 9900, connect the loop

power supply to 8058-2

Loop 1 inputs ONLY as

shown in the fi gure.

• See the 8058 manual for

more information.

BLACK

WHITE

RED

3

S L

DATA

N/C

7 8 9

9900 Transmitter

15

Page 16

Sensor Wiring

Wiring for: 4150

via 8058-1

+

EMCF1

RLY2

TB2

TB4

ISL 1

ALARM2 ALARM1

NC

COMNONC

+

24 VDC

+

COM

L5

L7

SHLD

RED

ORG

L3

BLK

Q2

R2

D2

R3

R4

TB1

TB3

NO

SHLD

+–

BA

4-20mA/

RS-485

L7

L4

Q1

R1

RLY1

L2

WHT

BRN

GRN

YEL

9900

S3L Inputs

SHLD

DATA

GND

V+

+

D1

Black

Red

White

Shield

Signet Turbidimeter

ENTER

Connect 4 to 20 mA wires to

S

L

+

3

Output

terminal board TB3 as shown in

the fi gure.

Refer to the latest revision of

L1

+

3

L Converter

3

Signet 8058 i-Go™

4-20 mA to S

+GF+

L Output

4-20 mA input S

Input

4-20 mA

the Signet 4150 Turbidimeter

Manual (3-4150.090) for further

information.

Power

Connection

via 8058-2

+

EMCF1

TB2

+

24 VDC

+

Power

Connection

RLY2

ISL 1

ALARM2 ALARM1

NC

COMNONC

TB4

COM

RED

L5

ORG

L3

BLK

L7

SHLD

Q2

R2

D2

R3

R4

TB1

TB3

NO

SHLD

+–

BA

4-20mA/

RS-485

L7

L4

Q1

R1

RLY1

L2

WHT

BRN

GRN

YEL

Black

Shield

Red

Technical Notes:

• All of the electrical

connections to the

instrument are made

through the terminal box.

The connections are labeled

within the terminal box and

are self-descriptive.

Technical Notes:

+

D1

When using the 8058-2, connect the

loop source to Channel 1 input ONLY.

• A plug is inserted into the

RS-485 cable bulkhead

when shipped to ensure a

watertight seal. Remove

and discard this plug when

cabling to this connection.

• The bulkhead will accept

cable diameters from

5.8 mm (0.23 in.) up to

+

10 mm (0.34 in.).

The terminals are designed to

L1

+

+GF+ SIGNET

3 2 1

6 5 4

Loop1

PWR

Loop2

PWR

S L

DATA

9900

3

L Inputs

S

SHLD

DATA

3

GND

V+

accept wires in the range of

14-28 AWG. All wires should

be stripped to a length of

6 mm (0.25 in.).

• Ensure that the watertight

seal is maintained after the

terminal box has been wired

for operation. If any of the

bulkheads are not tightened

N/C

7 8 9

properly around a cable

or plug, the ratings of the

instrument will be jeopardized

and there is a possibility of

Black

Red

White (Gnd)

Red (S3L)

Black (5 VDC)

creating a shock hazard.

• Do not run 4 to 20 mA cables

in the same conduit as power.

16

9900 Transmitter

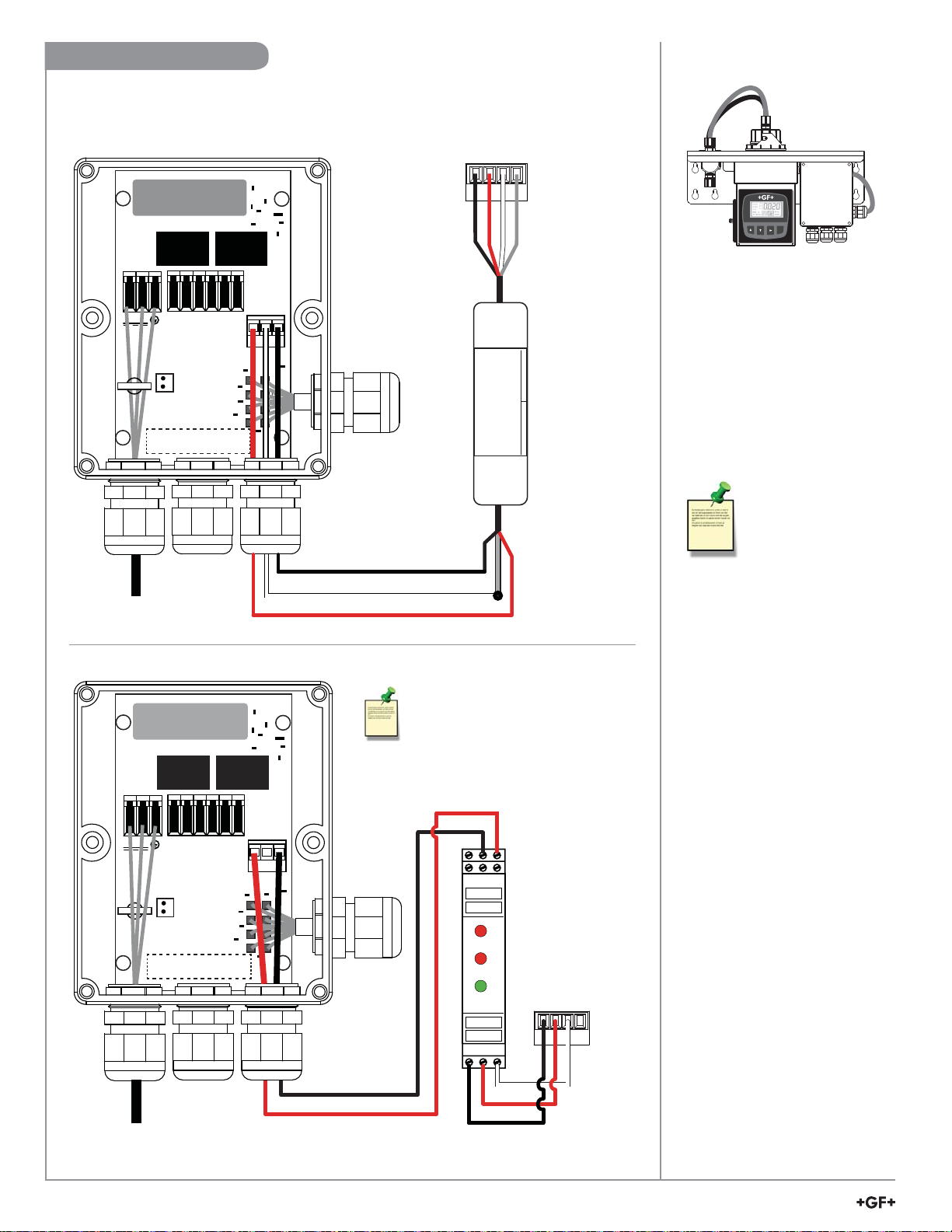

Page 17

Power Wiring

CAUTION!

DO NOT connect your 9900 to AC power.

The 9900 MUST be powered by

10.8 to 35.2 VDC ONLY.

Stand-alone application, no current loop used

ProcessPro

(for reference only)

Transmitter

Terminals

System Pwr Loop -

System Pwr Loop +

AUX Power -

AUX Power +

4

3

2

1

Black

Red

Connection to a PLC/Recorder, separate supply

ProcessPro

(for reference only)

Transmitter

Terminals

4

System Pwr Loop -

System Pwr Loop +

AUX Power -

AUX Power +

4

3

3

2

2

1

1

AUX power required for all 8750-2 systems

Blue

Black

Red

–

+

Power

Supply

12 to 24 VDC

PLC or Recorder

+

Loop Input

–

4 to 20 mA

–

+

Power

Supply

12 to 24 VDC

PWR +

PWR –

Loop +

Loop –

PWR +

PWR –

Loop +

Loop –

9900

Terminals

9900

Terminals

9900

Red

Black

9900

Blue

Red

Black

+

–

+

–

+

–

Power Supply

10.8 to 35.2 VDC

Power Supply

10.8 to 35.2 VDC

PLC or Recorder

Loop Input

4 to 20 mA

System Pwr Loop System Pwr Loop +

AUX Power -

AUX Power +

ProcessPro

(for reference only)

Transmitter

Terminals

4

3

2

1

Black

Red

Loop Powered

+

–

–

+

Power

Supply

12 to 24 VDC

PLC or Recorder

Loop Input

4 to 20 mA

9900

9900

Terminals

PWR +

PWR –

Loop +

Loop –

NOTE: Loop Power

cannot be used to power

certain Signet sensors.

See table on page 11.

Red

Black

+

Power Supply

–

10.8 to 35.2 VDC

PLC or Recorder

–

Loop Input

+

4 to 20 mA

9900 Transmitter

17

Page 18

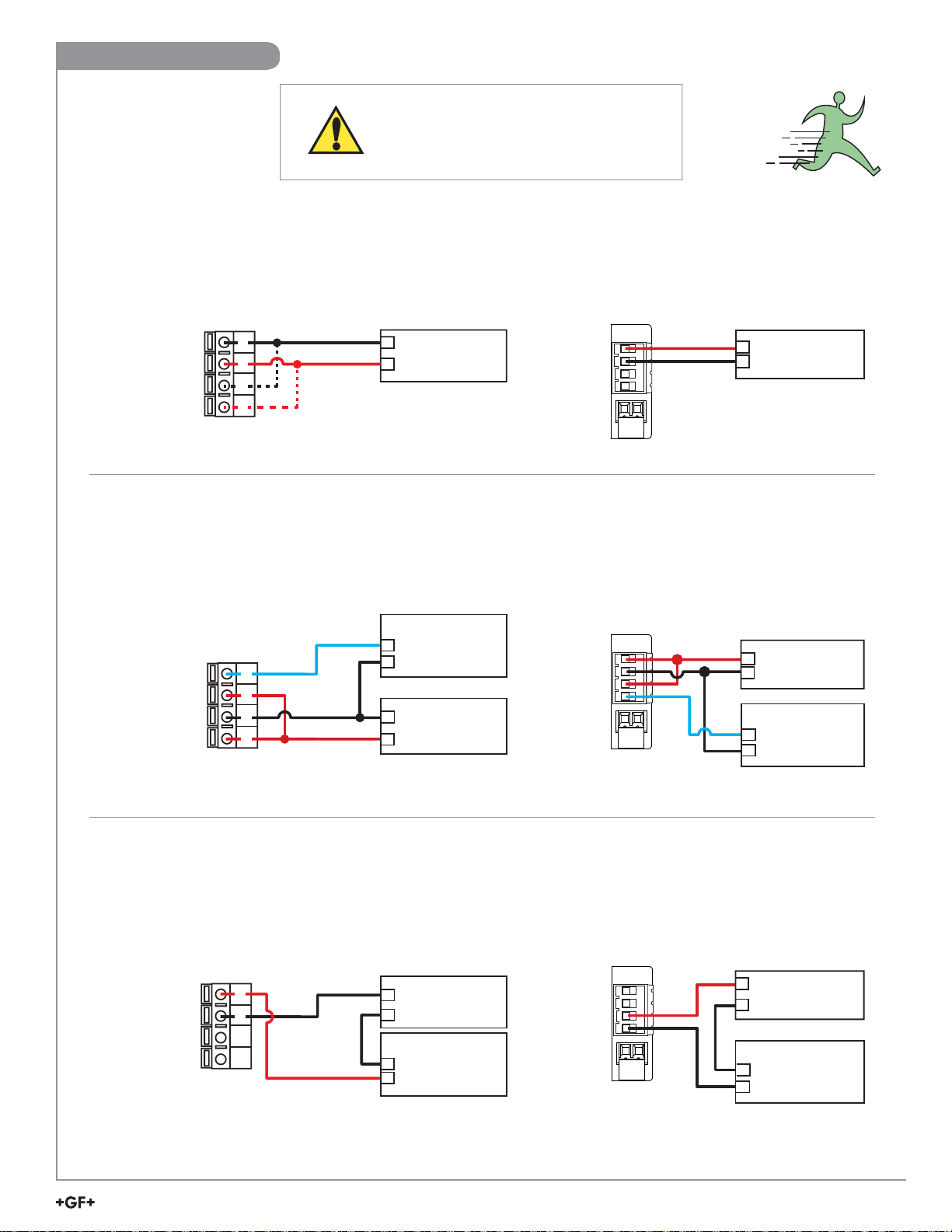

Relay and Open Collector Wiring

Open Collector wiring

NPN Style Wiring

Pull-Up Resistor

..ȍ:

PWR +

PWR –

Loop +

Loop –

OC –

OC+

If PLC needs 0 logic input when relay is

not energized, set NORMAL to CLOSED

in the RELAY menu when using the Open

Collector (R1) with NPN style wiring.

9WR9

Gnd

Input

Gnd

Power

Supply

PLC

PNP Style Wiring

3:5

3:5±

Loop +

/RRS±

2&±

with NORMAL set to OPEN.

PWR +

PWR –

Loop +

Loop –

OC – OC+

OC+

Pull-Down Resistor

..ȍ:

Alarm

Input

PLC

Gnd

9WR9

Power

Supply

Gnd

V+

Gnd

Power

Supply

• The 9900 Open Collector (R1) output provides high-speed switching capability.

Signal frequencies can reach 400 pulses per minute.

• The 9900 Open Collector (R1) output connection is dependent upon the type of circuit being controlled by the output.

• Most indicating instruments or control system inputs require a signal voltage of 0 to 5 V (TTL or CMOS logic levels) or 0 to 24 V.

Therefore, the 9900 Open Collector output circuits must be equipped with a pull-up or pull-down resistor (not supplied), and a

quality regulated 5 to 24 V (depending on the application) power supply (not supplied) is recommended to function properly.

Relay Module wiring

The alarm is OFF during normal operation,

and will go ON when relay energizes

according to 9900 Relay settings.

The valve is ON during normal operation,

and will go OFF when relay energizes

according to 9900 Relay settings.

RELAY 2RELAY 3

NO

NC

NO

NC

ALARM!

C

AC or DC

power

C

AC or DC

power

18

NO = normally open (closes when energized)

NC = normally closed (opens when energized)

9900 Transmitter

Valve

Flow

Page 19

Relay Functions

System Start-up: Step 3

Set your relay functions to your own application requirements.

Next step: System Setup (see page 25).

Once a setting is saved it becomes immediately active.

1. Go to the Relay Menu (RELAY fl ashing on screen, press ENTER).

2. If prompted, select desired source.

3. Press to relay MODE selection screen.

4. If necessary, press and then or to select R1 MODE LOW.

Press ENTER to confirm.

5. Press to R1 SET LOW. Press to enter GPM value of 5.5.

6. Press ENTER to save.

7. Scroll to the R1 HYSTERESIS menu.

8. Press to edit.

9. Set the hysteresis for this relay. This affects the turn off only: 2.5 gpm.

10. Press ENTER.

11. Scroll down to the R1 ON DELAY menu.

12. Press to edit.

13. Set the turn-on delay in seconds for the relay: 15.0.

14. Press ENTER.

15. Exit to View Mode.

Relay function can be tested in the RELAY menu.

Example: Set a relay R1 to turn

on at a low setpoint of 5.5 gpm

with a time delay of 15 seconds

and turn off at 8.0 gpm.

Remember,

SET LOW + hysteresis = OFF point:

5.5 + 2.5 = 8.0

Relay and Open Collector Outputs

RELAY HIGH and LOW Settings

Depending on the desired function of the circuit attached to the Open Collector (R1) output, it may be necessary to have the

Open Collector turned “on” or “off” when the criteria for the activation of this output are met.

If the 9900 is set to operate in RELAY LOW mode, when the user-defi ned condition for the activation is met (e.g. exceeding an

alarm limit) the Open Collector switch is turned “on.” If wired as standard “NPN-style” output (see previous page) the logic level of

the attached control system or PLC input consequently becomes “low” logic level (when NORMAL is set to OPEN).

If a high input logic level is required for activation, it can be accomplished in one of three ways.

In order of preference,

1. Change the Open Collector (Relay 1) output function to “high” in the instrument's RELAY menu, or

2. Wire the Open Collector (R1) output “PNP” style as described on the previous page, or

3. Set the Open Collector (R1) to NORMAL CLOSED in the RELAY menu.

Fail-Safe Behavior

No matter the setting, the Open Collector output turns off if the 9900 loses power. This must be taken into account when evaluating

system failure consequences. If the system layout requires a “closed” or “on” condition for the output in case of power loss, a

mechanical dry-contact relay (NC contacts) must be used instead of the Open Collector (R1) output.

Voltage and Current Limitation

The supply voltage in the Open Collector output circuit MUST be limited to the specifi ed maximum Open Collector voltage

(see operating manual for specifi c instrument). The use of a quality 5 to 24 V (depending on the application) regulated power supply

(not supplied) is recommended.

The current through the Open Collector switch also must be limited. Typical Open Collector outputs allow only for 10 to 50 mA

switch current. Exceeding this current limit can burn out the Open Collector output components immediately.

Load and Pull-Up/Down Resistor Considerations

By utilizing basic arithmetic and Ohm’s Law, the safe limits of load resistance can be determined. When the Open Collector switch is

closed, almost the entire supply voltage is applied to the load (e.g., the pull-up or pull-down resistor, the alarm horn input, a potential

power relay coil or annunciator lamp).The resulting current through the load and through the Open Collector switch, as well, can be

calculated as:

(Current)

= (Supply Voltage) / (Load Resistance)

9900 Transmitter

19

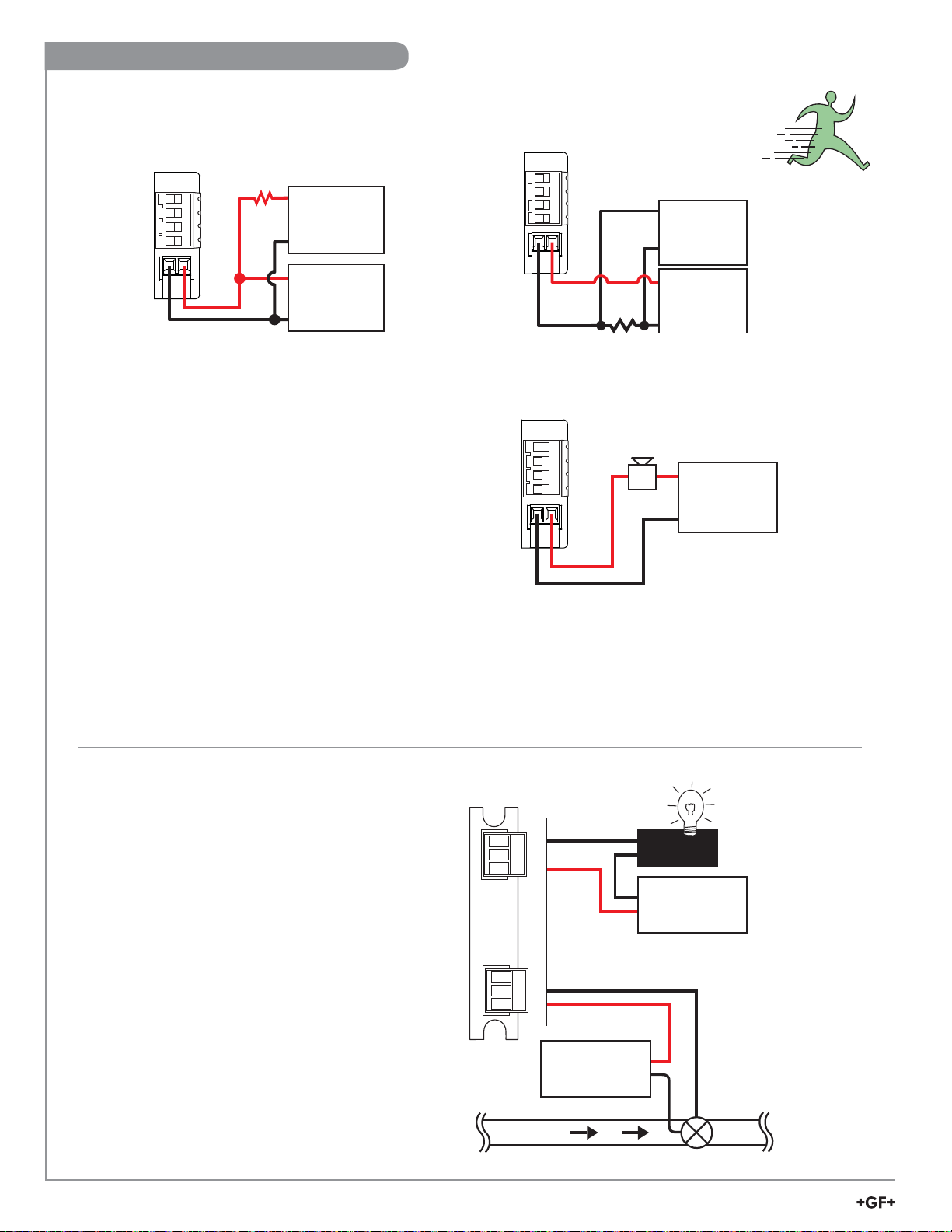

Page 20

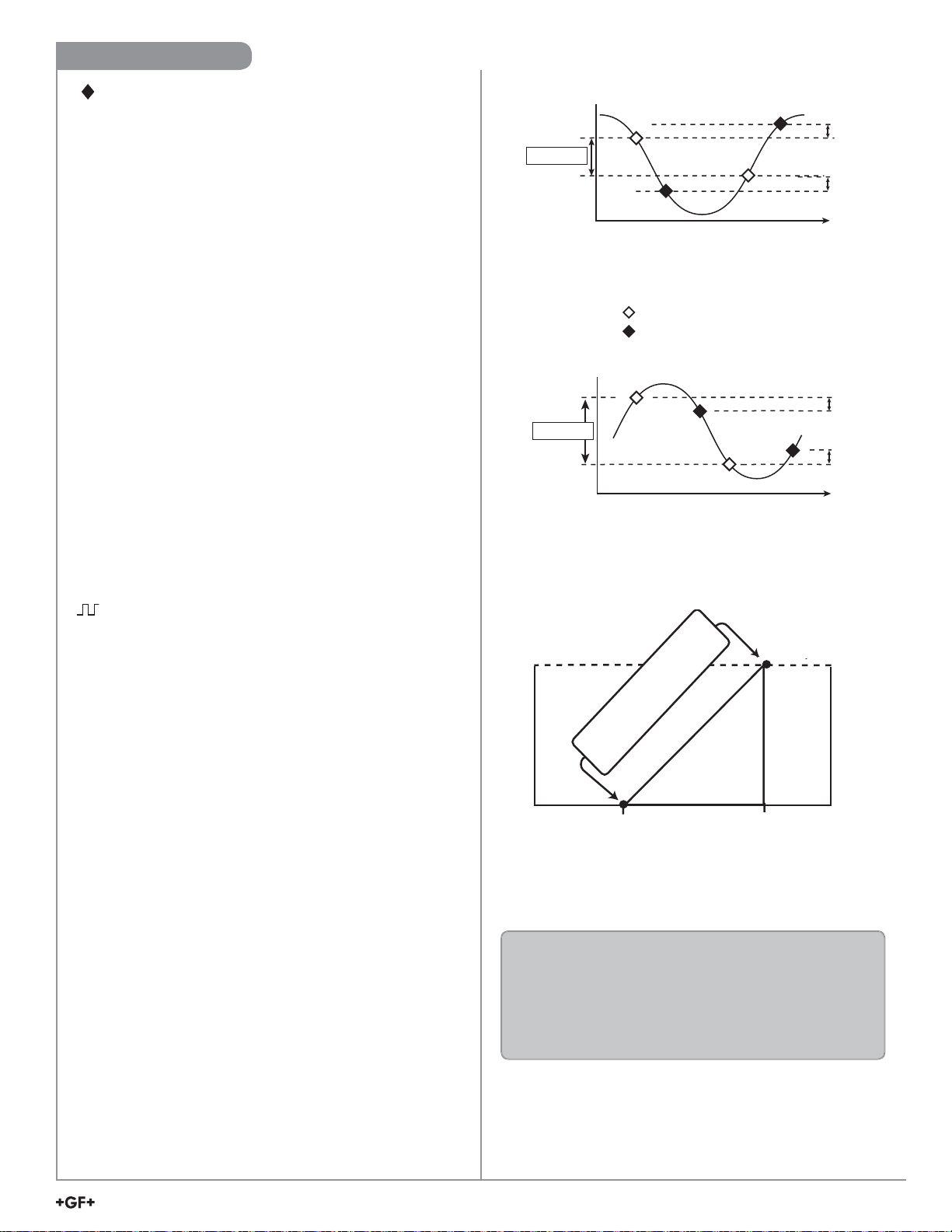

Hysteresis

Time

Low Setpoint

Process

Hysteresis

Time

High Setpoint

Process

Relay energized

Relay de-energized

Relay Outputs

The 9900 open collector and relays are selectable and

confi gurable and can be used as switches that respond when

the process value moves above or below a user-defi ned

setpoint or it can be used to generate a pulse at a rate

proportional to the process value.

They can be used for Low Alarm, High Alarm or Proportional

Pulse triggering related to the process value. All relay

functions are set up in the RELAY menus.

Open Collector Output

Longer life than a mechanical relay

No moving parts

Faster ON/OFF switching capabilities than mechanical relays

Can switch DC voltage only (< 30 VDC)

Not recommended for use with inductive loads.

Low Setpoint:

Relay is on when the measured value is less than the setpoint.

High Setpoint:

Relay is on when the measured value is higher than the setpoint.

Cycle Time

Process

High Setpoint

Hysteresis

Relay energized

Relay de-energized

CAUTION!

If power is lost to the 9900 Transmitter during a

cycle, the Cycle Time will reset. If the condition

still exists after power is restored, the relay will be

energized for the complete Cycle Time.

Time

Cycle High/Low:

The relay can stay energized for a set length of time after the

process value goes above (or below) the setpoint.

The relay will stay on for the CYCLE TIME and then turn off,

even if the process value is still above (or below) the setpoint.

The cycle will not repeat until the process value goes below

(or above) the setpoint minus the hysteresis after the relay

times out.

In FLOW, Cycle High activates the relay each time the volume

reaches the SET VOLUME setpoint (see page 28).

NOTE: To reset the timer (or volume in Flow): in the RELAY

menu, select TEST RELAY function. The timer will reset to 0

if the condition no longer exists when the TEST is performed.

The timer will restart if the condition still exists.

20

9900 Transmitter

Page 21

Time

High Limit

Hysteresis

Low Limit

Process

Window

10

5

Open Collector Output Rate:

0 to 100 Pulses/min.

Pulse rate

0 pulses

100 puls

Relay energized

Relay de-energized

Time

High Limit

Hysteresis

Low Limit

Process

Window

Hysteresis

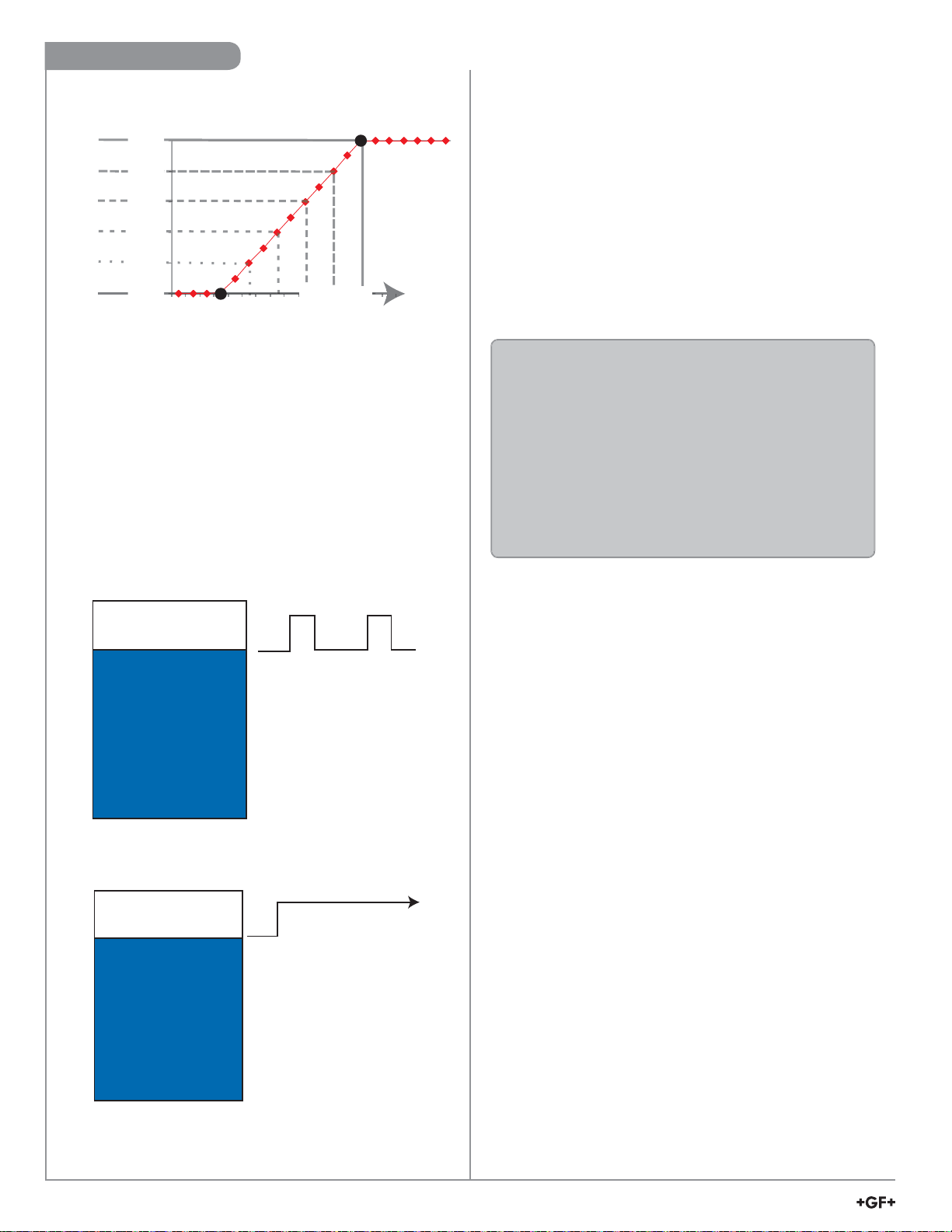

Relay Outputs

Window In/Out:

Relay is on when the value is higher or lower than the high or

low setpoint.

WINDow IN = relay on if measurement is inside the window

of two setpoints. Measurement inside the two setpoints is

abnormal condition.

WINDow OUT = relay on if measurement is outside the

window of two setpoints.

Window IN example

Proportional Pulse Operation:

The transmitter can output a pulse at the rate defi ned by the

settings in the CAL menu and the sensor input. The maximum

pulse output from the relays is 300 pulses per minute.

Example usage would be to control solenoid-operated

dosing pumps.

For example: As the process value drops below the setpoint,

the output will start pulsing in relation to the process value,

the maximum pulse endpoint and the programmed

pulses/minute. The pulse rate will change as the process

value changes and approaches the programmed endpoint.

This functionality can be used to precisely control the process.

The starting point, endpoint and maximum pulse rate are

select able in the RELAY menus.

NOTE: Relay LEDs are not lit in PULSE mode.

Window OUT example

100 pulses

Starting point Endpoint

In the example:

• The output will be 0 pulses/min. when value is less

than 5.

• The output will be 50 pulses/min. when value is 7.5.

• The output will be 100 pulses/min. when value is

greater than 10.

9900 Transmitter

21

Page 22

y

Relay Outputs

100%

80%

60%

40%

Relay Pulse Width

20%

(as a % of Relay period)

0%

alwa

Relay is

s OFF

PWM

Minimum

PWM

Maximum

Range

Process value

Relay is

always ON

• Pulse Width Modulation

PWM automatically varies the ratio of ON time to OFF time

proportional to minimum and maximum range settings.

The relay period is the sum of the time a relay is ON and the

time it is OFF.

Relay pulse width is the time the relay is ON.

The 9900 must be programmed with the relay period, and with

the low and high setpoints.

NOTE: The PWM mode is not used for Pressure applications.

NOTE: Relay LEDs are not lit in PWM mode.

Example:

• The pulse width will be 0% of the relay period

(relay always OFF) when the process value is

less than the minimum range.

• The pulse width will be 100% of the relay period

(relay always ON) when the process value is

greater than the maximum range.

• The pulse width will be 60% of the relay period when

the process value is at 60% of the span between the

minimum and maximum range.

• Volumetric Pulse

A pulse is generated each time a specifi ed volume of fl uid is

registered. For fl ow inputs only.

NOTE: Relay LEDs are not lit in VOLUMETRIC PULSE mode.

• Totalizer Volume

Relay activates and latches when a specifi ed volume of fl uid is

registered. For Flow inputs only.

Total Volume mode counts the TOTALIZER Units until the

setpoint volume is reached, then turns on the relay until the

resettable totalizer is reset.

If the Resettable Totalizer reading is greater than the setpoint,

the relay will be turned on immediately. The relay will be off

when the totalizer is reset to zero.

This mode is useful to trigger a reminder when a process is

due, as for a backwash cycle or fi lter change.

22

9900 Transmitter

Page 23

Operation

Open Collector (R1)

Indicator LED

Mechanical Relay (R2)

Indicator LED

Backlight Sensor

(do not block)

Mechanical Relay (R3)

Indicator LED

Warning LED

Bar Graph

Units of Measure

(GPM, pH, sec, %, etc.)

Value

Label

Menu Indication

Menu Navigation Keys

ENTER

All possible segments shown in this illustration. The instrument's software controls which segments are shown at

any particular time. Only the bar graph and GF logo are visible when the unit is turned off.

3

Warning LED will be lit when No Sensor or Wrong Sensor is detected in Digital (S

UP, DOWN keys

Scroll through Menu options or adjust values during editing

Press both together to exit a menu or escape without saving

RIGHT key

Select item or character to edit

L) mode.

ENTER

ENTER key

Access menus

Save changes

9900 Transmitter

23

Page 24

Operation

3s

ENTER

Edit

or or

ENTER

Input Edit

Input Edit Choices

(Password may

be required)

Keypad Functions

The four buttons of the keypad are used to navigate display modes

according to the descriptions in this table. Notice that the function

of each button may change depending on the display mode.

System Setup: Menu Navigation

This basic operating procedure repeats throughout the 9900 program:

1. Press ENTER for 3 seconds to enter MENU mode.

2. Press to move to the desired menu then press ENTER to

select it. (Password may be required.)

3.

Press or to select the desired menu item for editing.

4. Press to edit the value/selection.

5. Press ENTER to store the new value/selection.

6. Press or to select another menu item if desired.

Repeat steps 3-5 as required.

7. Press + to select a different menu to edit.

Repeat steps 2-5 as required.

8. When fi nished editing all menus, press + again to return to

normal operation.

The menu is constructed in a loop, so you can move forward and

backward to select an item. After any item is saved (by pressing

ENTER), the display will return to the previous menu.

24

9900 Transmitter

+

Return to

View Mode

2x

Or

or

ENTER

Saves Changes

+

Select another

Menu Item

Page 25

Menu System

System Setup Menu

All of the basic system setup functions are automated in the

9900 for many sensors and sensor electronics. This includes

identifying the sensor connected to the 9900, and confi guring

the display for the sensor. After installation and wiring is

completed, apply power to the 9900.

When the 9900 is fi rst powered on, it will attempt to determine

the sensor type connected when ENTER is pressed (unit will

display LOOKING FOR).

If no sensor is attached to the 9900, the words “TYPE” and

“FLOW” are displayed.

If the 9900 does not identify your sensor type correctly,

use the and keys to select your sensor type.

As you scroll through the available sensor types, press to

select the desired sensor and then press ENTER.

You may change sensor type after initial

power-on (if the sensor type is changed

after your 9900 is already in service).

Enter the INPUT menu, scroll to TYPE,

press , and scroll to select the desired sensor type

(you may be prompted for your password).

Press ENTER. The bottom line will display ALL SETTINGS

WILL BE RESET. ARE YOU SURE? The top line of the

display will blink NO (unless switching from Factory mode).

Press or to select YES.

Press ENTER again to finalize your selection.

ENTER

Sensor Choices

NOTE: User is strongly discouraged from changing the

sensor type away from the correct sensor.

ENTER

NOTE:

The 9900 displays the BATCH instrument type

ONLY if the Batch Module is installed.

9900 Transmitter

25

Page 26

Menu System

VIEW Mode Overview

The top level of menus is referred to as the VIEW Mode. This view displays measurement

values as well as current outputs and relay status. The radial bar graph represents the

measurement value that is also displayed in the 7-segment numeric fi eld below the bar

graph. The bar graph is primarily used to display the full scale range of the sensor, but can

be scaled via a menu item.

During normal operation, the 9900 displays the VIEW mode.

To select a display, press the or arrow keys.

The display selections scroll in a continuous loop.

Changing the display selection does not interrupt system operations.

No password is necessary to change display selection.

Output settings cannot be edited from the View Mode.

The display will return to the VIEW mode if no button is pressed for 10 minutes.

MENU Mode Overview

The MENU mode enables the user to view and confi gure all menu items.

The fi ve menus available are: CAL, INPUT, LOOP, RELAY, and OPTION.

MENU Mode is entered by pressing and holding ENTER for three seconds.

The button is used to change the position of the blinking cursor.

When the desired menu is blinking, press ENTER.

In the selected menu, use the and keys to navigate through the menu.

Use the , and keys to edit the selected item

(see Menu Navigation discussion, page 24).

Error Handling

Errors occurring while in the

VIEW Mode show a specifi c

message (e.g., CHECK SENSOR).

This message is displayed every

10 seconds and stays on for 5

seconds. Once the error is

resolved or cleared, the error

message stops.

Scrolling

In some cases, more than one

message or measurement may

need to be displayed. This is

accomplished by alternating the

message portions across the

screen.

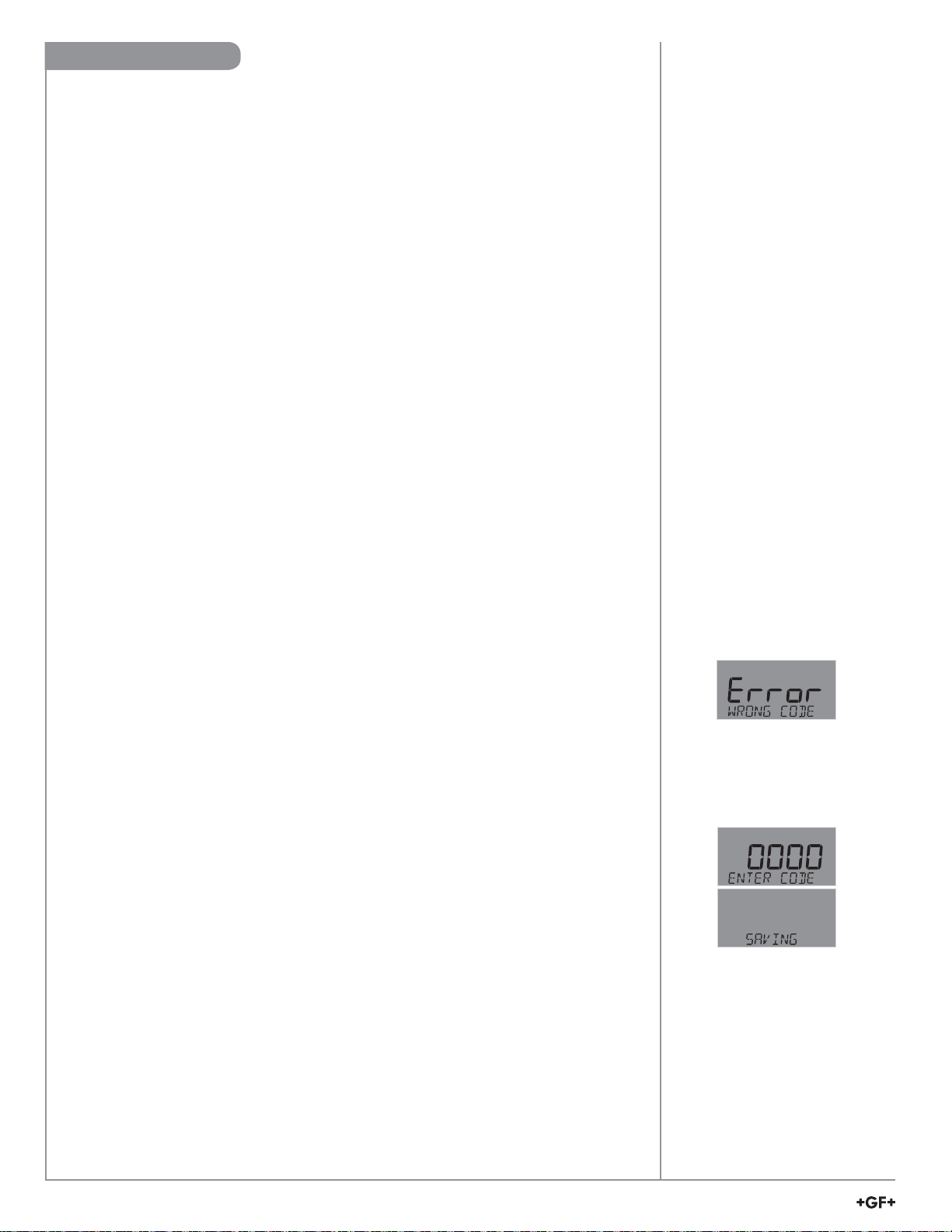

To save the new selection, press the ENTER key. A message displaying “Saving…” will be

displayed for 3 seconds. After this message is displayed, the newly selected value will be

displayed, if applicable.

Password Overview

The password is often required to start editing. Once entered correctly, this password will

not be needed for subsequent edits. However, once the menu system is exited,

the password will again be required when edit mode is re-entered.

Your choice of password (STD or CODE) is selected in the Options Mode.

STD

The standard (STD) password is , pressed in sequence. This password is

designed to protect the 9900 from unintentional changes. It is best suited for systems

where a group of people need to be able to change settings.

CODE

The CODE default setting is 0000, adjustable to any 4-digit numerical code up to

9999. Using a personal code provides the maximum degree of security.

This code can be modifi ed in the Options mode.

In the MENU mode, if the

wrong code or password is

entered, an ERROR message

is displayed.

To change your CODE, go

to OPTIONS mode, enter

your desired code and press

ENTER. (The STD password

cannot be changed.)

26

9900 Transmitter

Page 27

Common Menus

System Start-up: Step 4

Customize your 9900 to your own installed sensors.

Common Menus

The menu system shares certain modes between sensor types.

The following describes the EDIT Mode menus found in common between most sensor types.

NOTE:

Menu and Mode displays shown are examples only.

Your displays may vary.

INPUT Menu

(ALL) Manually select Sensor Type (See page 25 for further instruction).

Allows user to reset 9900 Transmitter to Factory settings.

Note: User is strongly discouraged from changing the sensor type away from the correct sensor.

The following can individually be set for each current loop

LOOP Menu

(Loop1 = 9900 base unit, Loop2 = Output Module)

(pH, COND/RES, LEVEL, SALINITY, DO only)

Set LOOP output source; select between Primary and Secondary measurements of applicable sensor.

Secondary measurements: DO, pH, COND/RES, and SALINITY = TEMP; LEVEL = VOL.

(COND/RES only) Select LIN/LOG. Default = LIN.

See LOG Current LOOP Output discussion in Appendix.

(ALL) Set value corresponding to desired 4 mA output. 5 digits max. Default = 0 (ORP = -999).

(ALL) (Not shown in COND/RES LOG Mode)

Set value corresponding to desired 20 mA output. 5 digits max.

Defaults = 100 (Flow, Cond/Res, Temp), 14 (pH), 1000 (ORP), 10 (Lvl/Prs), 5 (4 to 20 mA), 80 (Sal).

(ALL) Set desired LOOP output value when sensor error (e.g., bad sensor, broken wire) is detected.

Select (3.6 mA, 22 mA). Default = 22.

(ALL) Allows fi ne-tuning to compensate for errors in other equipment connected to the 9900.

Adjust the minimum and maximum current output. The display value represents the precise current output.

Adjustment limits: from 3.80 mA minimum to 5.00 mA maximum. Default = 4.00 mA.

(ALL) Allows fi ne-tuning to compensate for errors in other equipment connected to the 9900. Adjust

the minimum and maximum current output. The display value represents the precise current output.

Adjustment limits: from 19.00 mA minimum to 21.00 mA maximum. Default = 20 mA.

(ALL) Press or to manually order any output current value from 3.8 mA to 21.00 mA to test the

output of LOOP.

9900 Transmitter

27

Page 28

Common Menus

RELAY Menu

The following can individually be set for each relay (R1 = open collector, R2/R3 = Relay Module)

(pH, LEVEL/VOL, COND/RES, SALINITY and DO only.) Select source for each of R1, R2 and R3 outputs.

Choose pH/TEMP, LEVEL/VOLUME, COND/TEMP, SAL/TEMP, (DO)PPM/TEMP.

Defaults = pH, COND, LEVEL, SAL, PPM.

(ALL) Set Open Collector (R1) as Normally Open or Normally Closed. Default = OPEN.

(ALL) Select the desired mode of operation for the open-collector (R1) output (OFF, LOW, HIGH,

WINDow IN, WINDow OUT, CYC LOW (except FLOW), CYC HIGH, PROP PuLSe, VOL PuLSe, PWM,

TOTAL, USP, ERROR mode) (See chart on page 29). Default = OFF. Continue stepping through to

select R2 and R3 output modes. When MODE is set to ERROR, delays energizing relay until after

ON DELAY time expires if sensor problem is detected. See Cycle High/Low discussion on page 20.

(ALL) (Shown if LOW, WIND IN/OUT or CYC LOW mode)

Relay turns on if process measurement goes lower than this value. Set desired value.

NOTE: The corresponding indicator lights do not light up in PROP PLS and PWM modes.

The LEDs light up only when the Test Relay options are selected.

(ALL) (Shown if HIGH or WIND IN/OUT mode)

Relay turns on if process measurement goes higher than this value. Set desired value.

NOTE: The corresponding indicator lights do not light up in PROP PLS and PWM modes.

The LEDs light only when the Test Relay options are selected.

(FLOW only) (Shown if CYC HIGH or VOL PLS mode)

Amount of accumulated fl ow that must be counted before a pulse is sent out.

Relay turns on if fl ow volume exceeds this value. Set desired value. Default = 100.00.

(ALL) (Shown if LOW, HIGH, WIND IN/OUT, CYC LOW/HIGH or USP mode)

Hysteresis prevents the system from chattering around the set point.

Set amount (in units of measure from INPUT Mode) to add to SET LOW or SET HIGH values.

(COND/RES only) (Shown only in USP mode)

Relay turns on if USP value drifts by this value away from USP limit.

See USP Limits discussion in the Appendix.

(ALL) (Shown if Low, High, WIND IN/OUT, CYC LOW/HIGH or Error mode)

Set seconds (up to 9999.9) to wait before activating relay.

(ALL except PRESSURE) (Shown only if PROP PLS mode)

Set minimum setpoint value for proportional pulsing.

(ALL except PRESSURE) (Shown only if PROP PLS mode)

Set maximum setpoint value for proportional pulsing.

(ALL except PRESSURE) (Shown only if PROP PLS mode)

Set desired maximum pulse rate (300 max)

NOTE: Pulse width fi xed at 100 ms.

(ALL except PRESSURE and FLOW) (Shown only if PWM mode)

Set minimum value for pulse width modulation.

(ALL except PRESSURE and FLOW) (Shown only if PWM mode)

Set maximum value for pulse width modulation.

NOTE: Defaults for most relay functions are dependent upon sensor type and are not listed here.

28

9900 Transmitter

Page 29

Common Menus

RELAY Menu

The following can individually be set for each relay (R1 = open collector, R2/R3 = Relay Module)

(ALL) (Shown only if CYC LOW/HIGH mode)

Set time in seconds (up to 99999) for relay to remain on. See discussion on page 20.

(FLOW only) (Shown only if VOL PULS mode)

Amount of accumulated fl ow that must be counted before a pulse is sent out. Set value.

(FLOW only) (Shown only if VOL PULS mode)

(ALL except PRESSURE and FLOW) (Shown only if PWM mode)

Set time value for one complete pulse cycle. (relay ON time + relay OFF time).

(FLOW only) (Shown only if TOTAL) Resettable value that, when exceeded, turns relay on.

Must reset Totalizer (in VIEW Mode) to clear relay. Set maximum value.

(ALL) Press or to turn relay on or off for testing purposes.

Can also be used to reset or latch/unlatch the relay. Does NOT reset the Totalizer.

Set time value for one pulse width

.

Available Relay Modes by Sensor Type

Flow pH ORP Cond/Res Pressure Lvl/Vol Temp

Off XXX X XXX X XX

LowXXX X XXX X XX

High X X X X X X X X X X

Wind In X X X X X X X X X X

Wind Out X X X X X X X X X X

Cyc Low X X X X X X X X X

Cyc High X X X X X X X X X X

Prop Pulse X X X X X X X X X

Vol Pulse X

PWM X X X X X X X X

Total X

USP X*

Error X X X X X X X X X X

* In USP Relay Mode in Conductivity, Relay Source must be set to COND, TEMP COMP must be set to NONE

and Unit Of Measure must be set to S.

4 to 20 mA

Salinity DO

9900 Transmitter

29

Page 30

Common Menus

OPTION Menu

Adjust the LCD contrast for best viewing for your environment.

A setting of 1 is lowest contrast, 5 is highest. Default = 3.

Select backlight level (OFF, LOW, HIGH, AUTO). Default = AUTO.

NOTE: No backlight when operating on loop power.

Enter 5 digit value to represent bar at minimum.

Default = 0 (ORP = -999).

Enter 5 digit value to represent bar at maximum.

Defaults = 100 (Flow, Cond/Res, Temp), 14 (pH), 1000 (ORP), 10 (Lvl/Prs), 5 (4 to 20 mA),

80 (Sal), 20 (DO)

(ALL) Set the decimal to the best resolution for your application.

The display will automatically scale up to this resolution.

Select -----., ----.-, ---.--, --.---, or -.---- (varies by parameter). Default = ----.-.

(pH, COND/RES, TEMP, SAL, DO only)

Set the Temperature decimal to the best resolution for your application.

The display will automatically scale up to this resolution. Select -----., ----.-, or ---.--. Default = ----.-.

(FLOW only) Set the decimal to the best resolution for the Permanent Totalizer display.

The display will automatically scale up to this resolution. Select -----., ----.-, ---.-- or --.---.

Default = ----.-

(COND/RES only) Displays mS or S as set in COND UNITS in INPUT Mode.

Set ON/OFF. Default = OFF.

(FLOW only) Locks the TOTALIZER output. Select OFF, ON (Does not affect Permanent Totalizer).

Default = OFF.

(ALL) Select STD, CODE.

Default = STD.

(ALL) Enter desired password code. 4-character entry not displayed, ---- displayed instead.

(Shown if type = CODE.)

(ALL) Enter 13-character string, if desired.

Default = Blank.

Enables Remote Setup to confi gure the 9900 via a computer and the optional 0252 Confi guration tool.

Press and select YES to enable. REMOTE SETUP flashes when mode is enabled.

NOTE: Communication with 0252 tool is automatic when 9900 is in FACTORY state (Enter flashing).

Refer to the 0252 Configuration Tool manual, 3-0252.090, included with your configuration tool.

30