Georg Fischer 8900 Specifications

Let Us Configure It for You!

Use the Signet 8900 Configurator

to tailor controllers to your needs

and receive them fully-assembled

and ready to install...

For Example: to order an 8900 with (2)

inputs, AC powered, (4) Dry contact relays,

and (2) active 4-20 mA outputs —

Use part number

3-8900-L - 2 - AC - 4D - 2A

Inputs

Two Inputs 2

Four Inputs 4

Six Inputs 6

Power

100 to 240 VAC AC

12 to 24 VDC DC

Relays

None 0

Two Dry Contact Relays 2D

Four Dry Contact Relays 4D

Two Solid State 2S

Four Solid State 4S

Two Dry Contact, Two Solid State 4DS

Outputs

None 0

Two Active 2A

Four Active 4A

Two Passive 2P

Four Passive 4P

Two VDC 2V

Four VDC 4V

Two Active and Two Passive 4AP

Two Active and Two Voltage 4AV

Two Passive and Two Voltage 4PV

3-8900-L

Input Power Relay Output

Parameter

Instruments

Protocol

Communication

FlowConductivity/

pH/ORP Multi-

Resistivity

Level

Pressure,

Temperature,

Oxygen

Turbidity ChlorineDissolved

Other

Products

& Wiring

Installation

Technical

Reference

Graphs

Pressure

Temperature/

37www.gfpiping.com

T

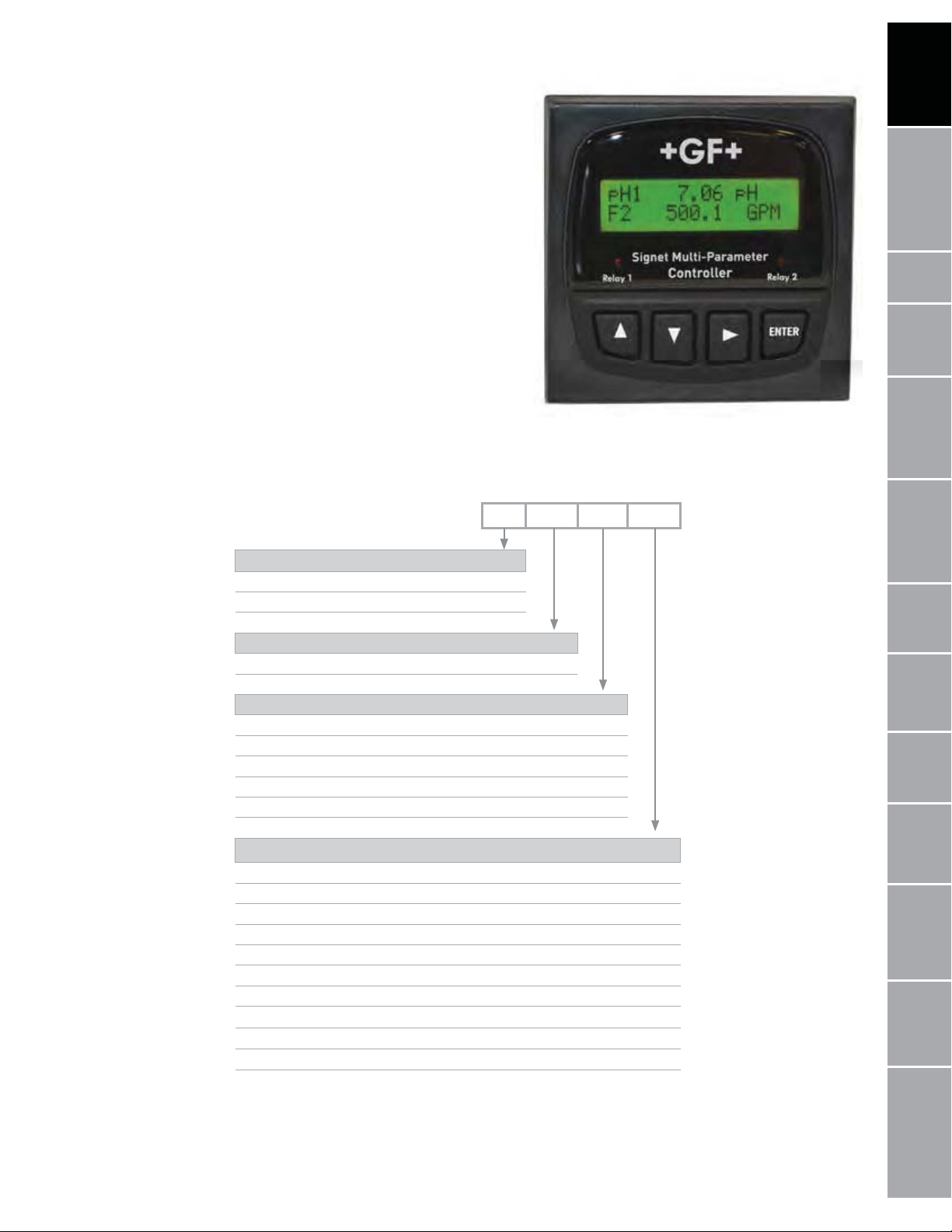

Signet 8900 Multi-Parameter Controller

Features

Member of the ProcessPro® Family of Instruments

The Signet 8900 Multi-Parameter Controller takes

the concept of modularity to the extreme. Each

8900 is field commissioned with the users specified

combination of inputs, outputs, and relays using

simple-to-install modular boards into the base unit.

Configure the system by selecting either two, four,

or six input channels which accepts any of the Signet

sensors listed below, and/or other manufacturer’s

sensors via a 4 to 20 mA signal converter (Signet

Model 8058). To complete your unit, choose a power

module with universal AC line voltage or 12 to 24 VDC

±10%, regulated.

• Measures Flow, pH, ORP, Conductivity, Pressure,

Level and Temperature

• Multi-language display

• ¼ DIN enclosure

• Up to 4 analog outputs

• Up to 8 relays

• 12 to 24 VDC or 100 to 240 VAC ±10%,

regulated power

• Digital communication allows for extended cable

lengths and easy wiring

• Accepts 3rd party 4 to 20 mA output devices

when used with 8058 signal converter

• Available with 2 to 6 channels

• Simultaneous BTU Calculations with

Heating & Cooling Totalizers per calculation

MEASURING EQUIPMEN

77CJ

If more features are needed, analog output and relay

modules are available and easily installed. Plus, the

8900 will support four additional relays via an external

relay module. There are other notable features that

the 8900 offers. For instance, digital input to the 8900

enables longer cable runs and simplified wiring with

minimal noise interference. Advanced relay logic

allows users to select up to 3 measurement sources

to trigger 1 relay. Derived measurements include

difference, sum, ratio, percent recovery, percent

rejection, percent passage and BTU. The menu system

can be programmed to display in multi-languages

including English, German, French, Spanish, Italian,

and Portuguese.

Applications

• RO/DI System Control

• Media Filtration

• Pure Water Production

• Demineralizers

• Chemical Processing

• Metal & Plastics Finishing

• Fume Scrubbers

• Proportional Chemical Addition

• Cooling Tower & Boiler Protection

• Wastewater Treatment

• Aquatic Animal Life Support Systems

• Rinse Tank

38 www.gfpiping.com

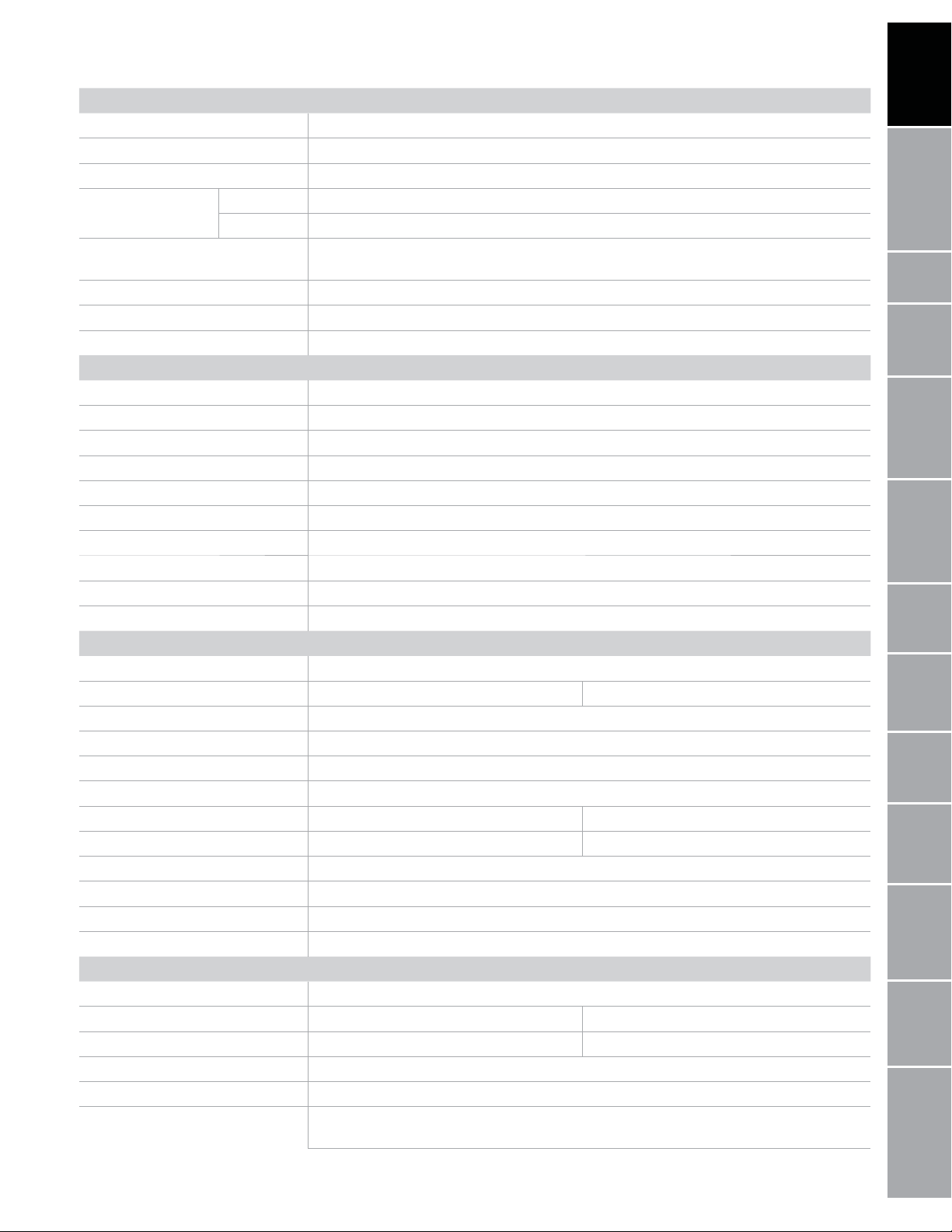

Specifications

General

Compatibility Modular (completely field-commissionable)

No. of Input Channels 2, 4, or 6

Compatible Sensors See System Overview

3

Input Signal Types Digital (S

Frequency 0.5% of reading

Measurement Types Flow, pH, ORP, Conductivity/Resistivity, Pressure, Temperature, Level, or 3rd party

Derived Measurements Sum, dierence, ratio, % recovery, % reject, % passage, power (BTU)

No. of Relays Supported Available: 2, 4, 6 or 8 (8 dry-contact or 4 solid state and 4 dry- contact)

No. of Analog Outputs Available in pairs: 2 or 4 (active and/or passive 4 to 20 mA); and/or 2 (0 to 5/10 VDC)

Enclosure and Display

Enclosure Rating NEMA 4X/IP65 (front face only)

Case Material PBT

Panel Gasket Silicone Sponge

Window Self-healing polyurethane-coated polycarbonate

Keypad 4-buttons, highly tactile and audible injection-molded silicone rubber seal

Display Alphanumeric 2 x 16 back-lit LCD

Update Rate 1 second

Accuracy Sensor dependent

LCD Contrast 4 settings

Languages Available English, French, Spanish, German, Italian and Portuguese

Display Ranges (see sensor specifications for actual measurement limits)

pH -2.00 to 15.00 pH

pH Temperature -40 °C to 150 °C -40 °F to 302 °F

ORP -9999 to +9999 mV

Flow Rate 0.0000 to 999999 units per second, minute, hour or day

Totalizer 0.00 to 99999999 units

Conductivity 0.0000 to 999999 μS, mS, PPM & PPB (TDS), kΩ, MΩ

Conductivity Temperature -99.9 °C to 250 °C -148 °F to 482 °F

Temperature -99.9 °C to 999.9 °C -148 °F to 999.9 °F

Pressure -99.99 to 9999 psi, kPa, bar

Level -99999 to 99999 m, cm, ft, in., %

Volume -99999 to 999999 m

Other (4 to 20 mA) -99999 to 999999 user selectable units

Environmental

Ambient Operating Temperature

Backlit LCD -10 °C to 55 °C 14 °F to 131 °F

Storage Temperature -15 °C to 80 °C 5 °F to 176 °F

Relative Humidity 0 to 95%, non-condensing

Maximum Altitude 2,000 m (6,560 ft)

L) Serial ASCII, TTL level 9600 bps

devices with a 4 to 20 mA output

3

, ft3, in3, cm3, gal, L, kg, lb, %

4,000 m (13,123 ft); use only DC power supply and, if applicable, solid state relays to

maintain UL safety standard up to this altitude

Parameter

Instruments

Protocol

Communication

FlowConductivity/

pH/ORP Multi-

Resistivity

Level

Pressure,

Temperature,

Oxygen

Turbidity ChlorineDissolved

Other

Products

& Wiring

Installation

Technical

Reference

Graphs

Pressure

Temperature/

39www.gfpiping.com

Loading...

Loading...