Page 1

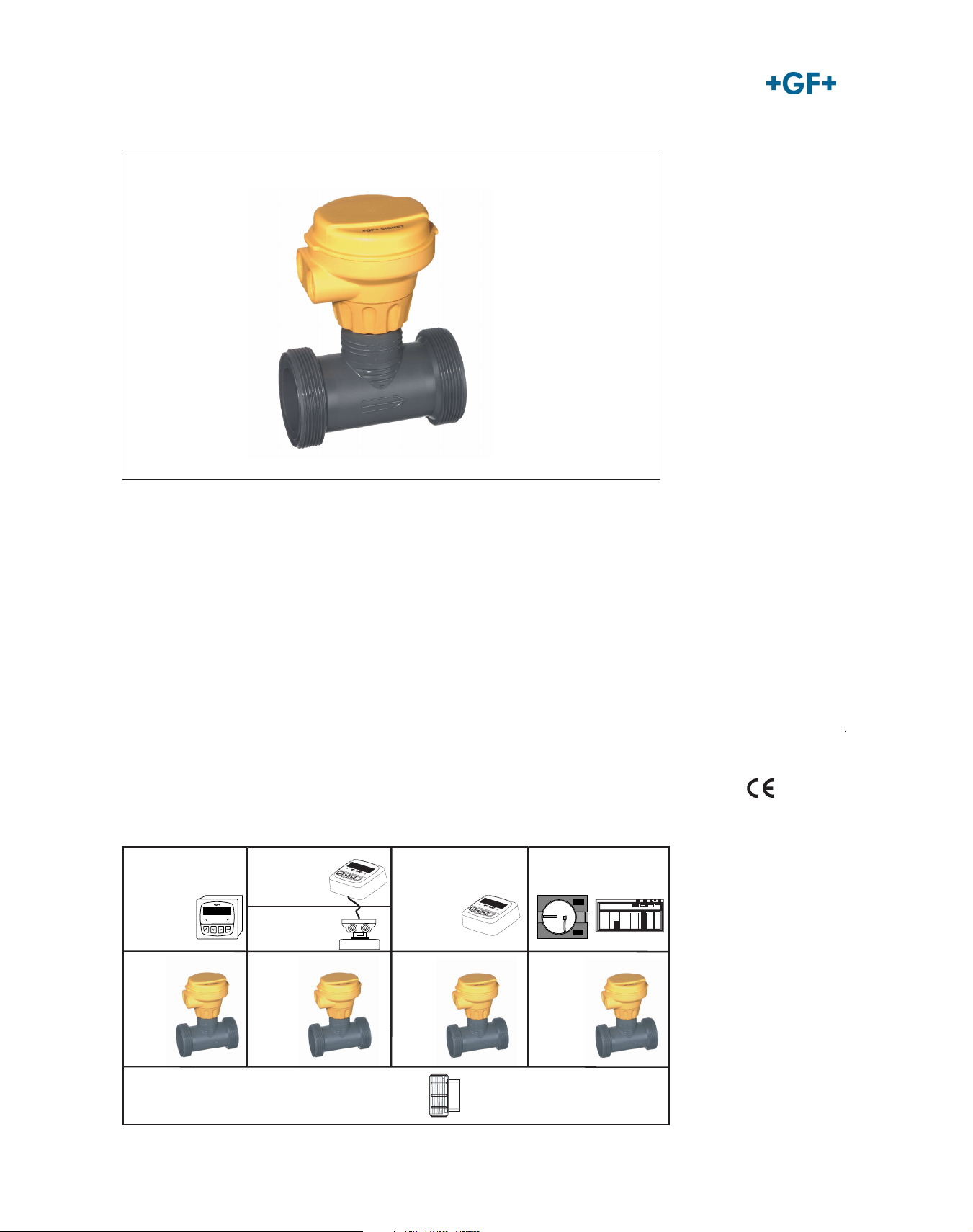

Signet 7000/7001 Vortex Flow Sensors

Blind Transmitter or Frequency Sensor

End connectors not shown.

Description

Signet Vortex Flow Sensors provide

extremely accurate and reliable flow

measurement with no moving parts.

Constructed of durable PVC, these

sensors can accommodate applications such as chemical delivery.

Each unit is injection-molded to

achieve a smooth surface finish for

cleanliness and better chemical

compatibility. This drastically reduces manufacturing inconsistencies

and in-service particulation associated with machined surfaces. End

connectors simplify installation and

allow unparalleled configuration

versatility.

The sensors feature either frequency

output or fixed 4 to 20 mA current

output, and can be used with the

comprehensive offering of Signet

flow instruments to achieve enhanced system functionality. Integral

transmitters with local displays and

many additional features are available as accessories, or select from

a wider variety of panel-mount flow

instruments.

Features

• No moving parts

• Injection-molded

construction for

excellent surfacefinish quality

• Piezo detection

• Six sizes in the

range DN 15 to DN

50 (0.5 to 2 in.)

• Vibration-noise and

reverse polarity

protected

• PVC construction

Application

• Process Flow

• Reverse Osmosis

• Process Cooling

Water

• Neutralization

Systems

• Waste Water

Effluent

• Scrubber Control

• Chemical Delivery

• Accurate Batching

• Plating rinse

• Not suitable for

gases

System Overview

Signet Flow Instrument

(sold separately)

8550 5075

8900 5500

5600

Signet

7000

Vortex Flow

Sensor

Signet

End Connectors

(sold separately)

62

Pipe, Tank, Wall MountPanel Mount Integral Mount

Signet Flow

Instrument

(sold separately)

8550

Signet Universal

Adapter Kit

(sold separately)

Signet

Vortex Flow

Sensor

7000

(3-8050)

Signet Flow Instrument

(sold separately)

8550

Signet

Vortex Flow

Sensor

Solvent Socket

7000

4 to 20 mA Input

Chart

Recorder

Signet

Vortex Flow

Sensor with

4 to 20 mA

Output

OR

7001

Programable

Logic

Controller

PLC

www.gfsignet.com

Page 2

Specifications

General

Linear Flow range:

• DN 15 to DN 20 (0.5 to 0.75 in.) sensors:

0.5 to 4 m/s (1.6 to 13 ft/s)

• DN 25 to DN 32 (1.0 to 1.25 in.) sensors:

0.4 to 4 m/s (1.3 to 13 ft/s)

• DN 40 to DN 50 (1.5 to 2.0 in.) sensors:

0.3 to 4 m/s (1.0 to 13 ft/s)

NOTE: Below these velocity ranges, Vortex

output is non-linear.

Pipe size range: 1/2 to 2 in.

Linearity: ±1% of reading @ 25 °C

Repeatability: ±0.5% of reading @ 25 °C

Reynolds Number: 7500

Enclosure

• Rating: NEMA 4X/IP65

• Material: PC/PBT blend of resins

• Seals (2): Buna-N (NBR)

Maximum vibration:

1mm or 1g double amplitude @ 500 Hz

Wetted materials

• Sensor: PVC

• Union O-Rings: FPM or EPDM

Max. Pressure/Temperature Ratings

16 bar @ 0 °C, 3.7 bar @ 60 °C

(232 psi @ 32 °F, 54 psi @ 140 °F)

Operating temperature:

0 to 65°C (32 to 149°F)

Storage temperature:

-15 to 80 °C (5 to 176 °F)

Relative humidity:

0 to 95%, non-condensing

See Temperature and Pressure graphs for

more information.

Shipping Weights:

• 3-7000-5X: 1.87 lbs.

• 3-7000-6X: 0.88 lbs.

• 3-7001-5X: 1.65 lbs.

• 3-7001-6X: 0.88 lbs.

Standards and Approvals:

• CE

• Manufactured under ISO 9001:2000

for Quality and ISO 14001:2004 for

Environmental Management

Choosing

Products

Instrument

Multi-Pa-

rameter

Flow

pH/ORP

Conductivity/

Resistivity

Pressure, Level

Temperature,

Please refer to

Wiring, Installation

and Accessories

sections for more

information.

Electrical

Reverse polarity protection.

Frequency Output Model

• Power:

3.5 to 24 VDC, regulated, 1.5 mA max.

• Output:

Open-collector NPN transistor, 10 mA

max sink, 24 VDC max pull-up voltage,

0 to 300 Hz (normal), 50% duty cycle,

non-isolated

Current Output Model

• Power:

7 to 30 VDC, regulated, 20 mA max

Current loop (2-wire)

• Loop impedance:

300Ω maximum at 12 VDC

800Ω maximum at 24 VDC

Application Tips:

• Sensor can be mounted at any angle

• A minimum back pressure is required to

prevent cavitation within the sensor. See

Installation section for more information.

• Power supplies are available and sold

separately. See individual product page.

• Be sure to select the correct output signal,

frequency or current.

Products

Other

Installation

Wiring &

Reference

Technical

Temperature/

Pressure

Graphs

of Terms

Glossary

www.gfsignet.com

63

Reference

Part No.

Index

Page 3

Dimensions

PVC Sch 80 Solvent Socket

PVC Metric Solvent Socket

Conduit port:

PG13.5 or

1/2 in. NPT

H

+GF+

XX DN XX X

XX

d

D

l

Dimension L ± 3 mm (±0.1 in.)

L

Ordering Information

PVC Sch 80 Solvent Socket

Inch size

1/2 43 1.69 128 5.04 90 3.54 117 4.61

3/4 53 2.09 144 5.67 100 3.94 120 4.72

1 60 2.36 160 6.30 110 4.33 123 4.84

1-1/4 74 2.91 168 6.61 110 4.33 127 5.00

1-1/2 83 3.27 188 7.40 120 4.72 132 5.20

2 103 4.06 212 8.35 130 5.12 139 5.47

dmmClosest

20 1/2 15 43 1.69 136 5.35 90 3.54 117 4.61

25 3/4 20 53 2.09 150 5.91 100 3.94 120 4.72

32 1 25 60 2.36 166 6.54 110 4.33 123 4.84

40 1-1/4 32 74 2.91 166 6.54 110 4.33 127 5.00

50 1-1/2 40 83 3.27 186 7.32 120 4.72 132 5.20

63 2 50 103 4.06 196 7.72 130 5.12 139 5.47

DL l H

mm inch mm inch mm inch mm inch

PVC Metric Solvent Socket

Inch sizeDNmm

DL lH

mm inch mm inch mm inch mm inch

Sensor Part Number

3-700 Vortex Flow sensor

Output - Choose one

0 Open collector output for use with the 8550, 5500, 5600, 5075, and 8900 instruments

1 Current output (4 to 20 mA) for connection to external devices

Wetted material and end fitting options - choose one

-5 PVC Sch 80, Solvent socket; purchase end connectors separately*

-6 PVC Metric, Solvent socket; purchase end connectors separately*

Size of flow chamber d/DN/inches (see Dimensions section for d/DN/inches) - Choose one

1 20 mm/15 mm/0.5 inches

2 25 mm/20 mm/ 0.75 inches

3 32 mm/25 mm/1.0 inch

4 40 mm/32 mm/1.25 inch

5 50 mm/40 mm/1.5 inch

6 63 mm/50 mm/2 inch

3-700 0 -2 3 Example Part Number

See ordering information below for available connector kits

Part Number

3-7000.391 Connector kit for the 3-7000 and 3-7001 sensors, -5, and -6 options

Wetted material and end fitting configuration - choose one

-5 PVC Sch 80, solvent socket

-6 PVC Metric, solvent socket

Size of connector - Choose one

1 20 mm/15 mm/0.5 inches

2 25 mm/20 mm/ 0.75 inches

3 32 mm/25 mm/1.0 inch

4 40 mm/32 mm/1.25 inch

5 50 mm/40 mm/1.5 inch

6 63 mm/50 mm/2 inch

*Model 7000/7001

Ordering Notes:

1) Signet Vortex Flow Sensors and End Connector

Kits are ordered separately

2) Vortex Flow Sensors are

shipped with EPDM

O-rings.

3) O-ring kits of 2 each

are available in both

materials.

3-7000.391 -2 3 Example Part Number

64

www.gfsignet.com

Page 4

Ordering Information (continued)

Choosing

Products

Mfr. Part No. Code

3-7000-51 159 000 130

3-7000-52 159 000 131

3-7000-53 159 000 132

3-7000-54 159 000 133

3-7000-55 159 000 134

3-7000-56 159 000 135

3-7000-61 159 000 136

3-7000-62 159 000 137

3-7000-63 159 000 138

3-7000-64 159 000 139

3-7000-65 159 000 140

3-7000-66 159 000 141

End Connector Kits

Mfr. Part No. Code

3-7000.391-51 159 000 581

3-7000.391-52 159 000 582

3-7000.391-53 159 000 583

3-7000.391-54 159 000 584

3-7000.391-55 159 000 585

3-7000.391-56 159 000 586

Mfr. Part No. Code

3-7001-51 159 000 172

3-7001-52 159 000 173

3-7001-53 159 000 174

3-7001-54 159 000 175

3-7001-55 159 000 176

3-7001-56 159 000 177

3-7001-61 159 000 178

3-7001-62 159 000 179

3-7001-63 159 000 180

3-7001-64 159 000 181

3-7001-65 159 000 182

3-7001-66 159 000 183

Mfr. Part No. Code

3-7000.391-61 159 000 587

3-7000.391-62 159 000 588

3-7000.391-63 159 000 589

3-7000.391-64 159 000 590

3-7000.391-65 159 000 591

3-7000.391-66 159 000 592

Instrument

Multi-Pa-

rameter

Flow

pH/ORP

Conductivity/

Resistivity

Pressure, Level

Temperature,

Universal Adapter Kit

Liquid Tight Connector Kit

1/2" NPT

PG 13.5

PG 13.5

O-Ring Kits (2 o-rings included in each kit)

Mfr. Part No. Code Description

3-7000.390-01 159 000 563 O-ring, DN15, 0.5”, EPDM

3-7000.390-02 159 000 564 O-ring, DN20, 0.75”, EPDM

3-7000.390-03 159 000 565 O-ring, DN25, 1.0”, EPDM

3-7000.390-04 159 000 566 O-ring, DN32, 1.25”, EPDM

3-7000.390-05 159 000 567 O-ring, DN40, 1.5”, EPDM

3-7000.390-06 159 000 568 O-ring, DN50, 2.0”, EPDM

Accessories and Replacement Parts

Mfr. Part No. Code Description

3-8050 159 000 184 Universal Adapter Kit

3-0000.393 159 000 618 Liquid Tight Connector Kit with PG 13.5 to NPT

Adapter

1203-1121 198 864 920 Base Seal

1223-0151 159 000 236 Cap O-ring

3-7000.390-07 159 000 569 O-ring, DN15, 0.5”, FPM

3-7000.390-08 159 000 570 O-ring, DN20, 0.75”, FPM

3-7000.390-09 159 000 571 O-ring, DN25, 1.0”, FPM

3-7000.390-10 159 000 572 O-ring, DN32, 1.25”, FPM

3-7000.390-11 159 000 573 O-ring, DN40, 1.5”, FPM

3-7000.390-12 159 000 574 O-ring, DN50, 2.0”, FPM

Graphs

Products

Other

Installation

Wiring &

Reference

Technical

Temperature/

Pressure

of Terms

Glossary

Reference

Part No.

www.gfsignet.com

Index

65

Loading...

Loading...