Page 1

Signet 7000/7001 Vortex Flow Sensors

*3-7000.090*

3-7000.090 Rev. F 10/05 English

English

1. Mounting Location ...................................................... 1

2. Installation.................................................................... 1

3. Wiring Preparation ...................................................... 2

4. Wiring Options - Frequency Output Models ............. 3

5. Calibration - Frequency Output Models .................... 3

6. Wiring Options - Current Output Models .................. 4

7. Calibration - Current Output Models ......................... 5

8. Specifi cations .............................................................. 6

9. Spare Parts .................................................................. 8

10. Sensor Ordering Tree ............................................... 10

11. End Connectors Ordering Tree ............................... 10

12. Sensor Assembly Part Numbers ..............................11

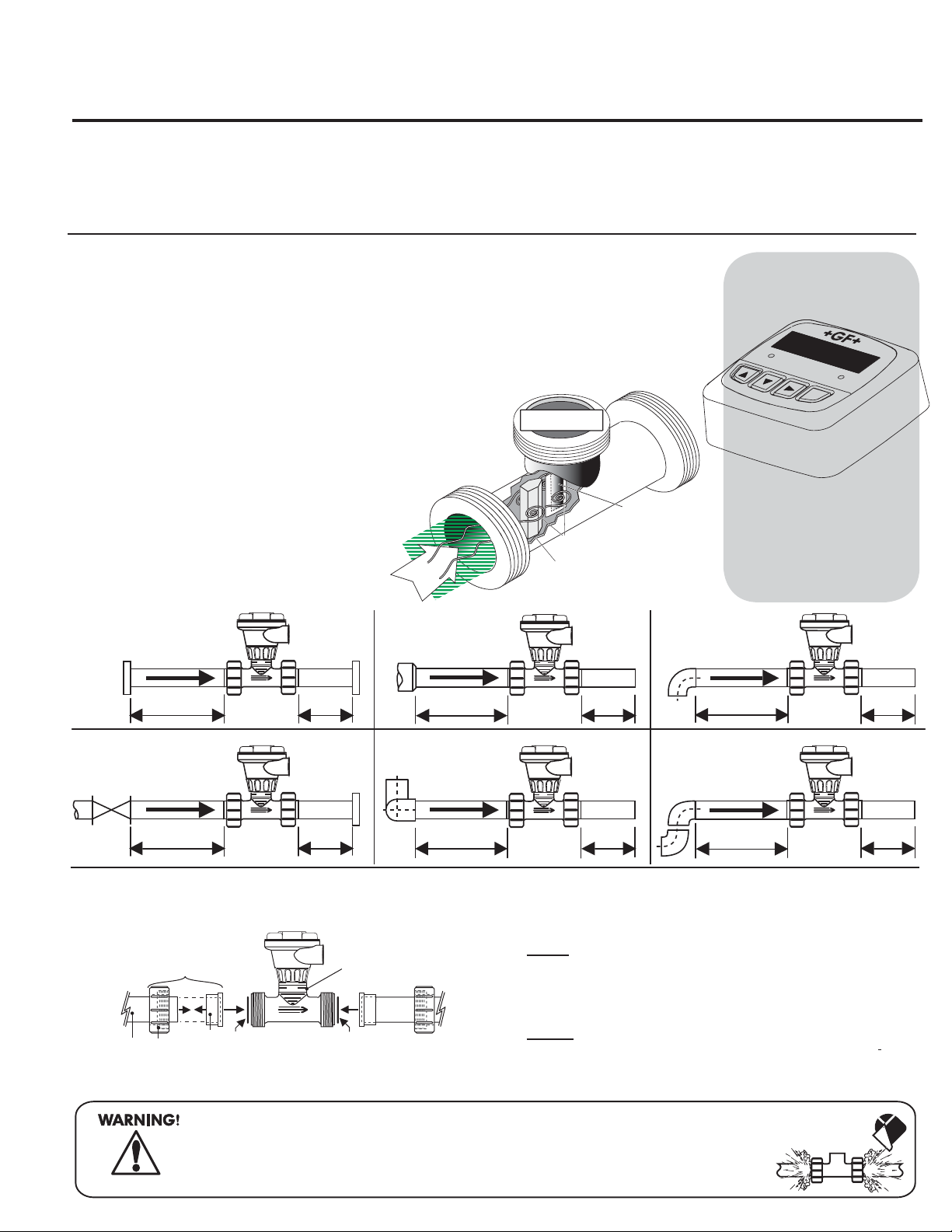

1. Mounting Location

Minimum upstream/downstream sensor mounting requirements:

• The sensor must be mounted in a rigid pipe to minimize vibration. Always maximize distance

between the sensor and pump source.

• Horizontal pipe runs: All mounting angles are acceptable. Avoid air bubbles.

• Vertical pipe runs: All mounting angles are acceptable, with upward fl ow preferred.

• A Reynold’s Number is a dimensionless number used to determine the

effects of viscosity, specifi c gravity, and velocity on fl ow

sensor performance. To maintain system accuracy, a

Reynold’s Number greater than 7,500 is required.

• Reynold's number = 3162.76 x Q x Sg/(µ x ID)

where: Q = Flow Rate in GPM;

Sg = Specifi c Gravity;

µ = Dynamic Viscosity in Centipoise;

ID = inside diameter in inches

• Minimum downstream pipe backpressure levels

(full pipes) are required to prevent cavitation

within the sensor (section 8).

Fluid flow

Sensor is shown without

its usual Cap and Adaptor

Vortices

"bluff body"

Piezoelectric

sensor

OPTION: Integral

Transmitter (local

readout)

Signet Flow

Transmitter

Order

Signet

3-8550-1,

3-8550-2, or

3-8550-3

Inlet Outlet

Flange

Valve/Gate

+GF+

XX DN XX X

XX

10 x I.D. 5 x I.D.

+GF+

XX DN XX X

XX

25 x I.D. 5 x I.D.

Reducer

25 x I.D. 5 x I.D.

2 x 90° Elbow

3 dimensions

25 x I.D. 5 x I.D.

2. Installation

• Choose a mounting location that satisfi es section 1 requirements.

Connector

Pipe Union nut

End

Connector

O-Ring

+GF+

XX DN XX X

XX

Flow

• Install sensor with arrow pointing in the direction of fl ow. These

fl ow sensors are not for bi-directional fl ow.

Sensor available in

PP, PVC, PVDF

O-Ring

+GF+

XX DN XX X

XX

90° Elbow

+GF+

XX DN XX X

XX

15 x I.D. 5 x I.D.

+GF+

XX DN XX X

XX

2 x 90° Elbow

+GF+

XX DN XX X

XX

20 x I.D. 5 x I.D.

.

2.1 Fusion Socket or Solvent Cement Socket

• Fusion socket version: available in HP PVDF, PVDF, or PP.

A George Fischer Socket Fusion Joining Machine is required to

install the end connectors on the pipeline. Refer to the joining

machine manual for installation details.

• Solvent socket version: available in PVC. Follow the PVC cement manufacturer's recommendations and instructions. Avoid

excess cement in fi tting joints to prevent port obstruction.

SAFETY INSTRUCTIONS

1. Do not remove from pressurized lines.

2. Never install sensor without O-Rings.

3. Confirm chemical compatibility before use.

4. Do not exceed maximum temperature/

pressure specifications.

5. Do not install/service without following mounting procedure.

6. Wear safety goggles and faceshield during installation/service.

7. Do not alter product construction.

8. Failure to follow safety instructions could result in severe

personal injury.

Page 2

2.2 IR/Butt Fusion Sensors

• Available in PVDF or PP. A George Fischer IR weld or Butt

Fusion Joining Machine is required to install the end connectors onto pipeline. Refer to the IR weld or butt fusion joining

machine manual for installation details.

IR/Butt Fusion

Connector Kit

+GF+

XX DN XX X

XX

2.3 BCF/IR Sensors

• A George Fischer SYGEF HP BCF/IR Fusion Joining Machine

is required to install the end connections. Refer to the SYGEF

BCF/IR fusion joining machine manual for installation details.

SAFETY INSTRUCTIONS

1. Do not remove from pressurized lines.

2. Never install sensor without O-Rings.

3. Confirm chemical compatibility before use.

4. Do not exceed maximum temperature/pressure

specifications.

5. Do not install/service without following mounting procedure.

6. Wear safety goggles and faceshield during installation/service.

7. Do not alter product construction.

8. Failure to follow safety instructions could result in severe personal injury.

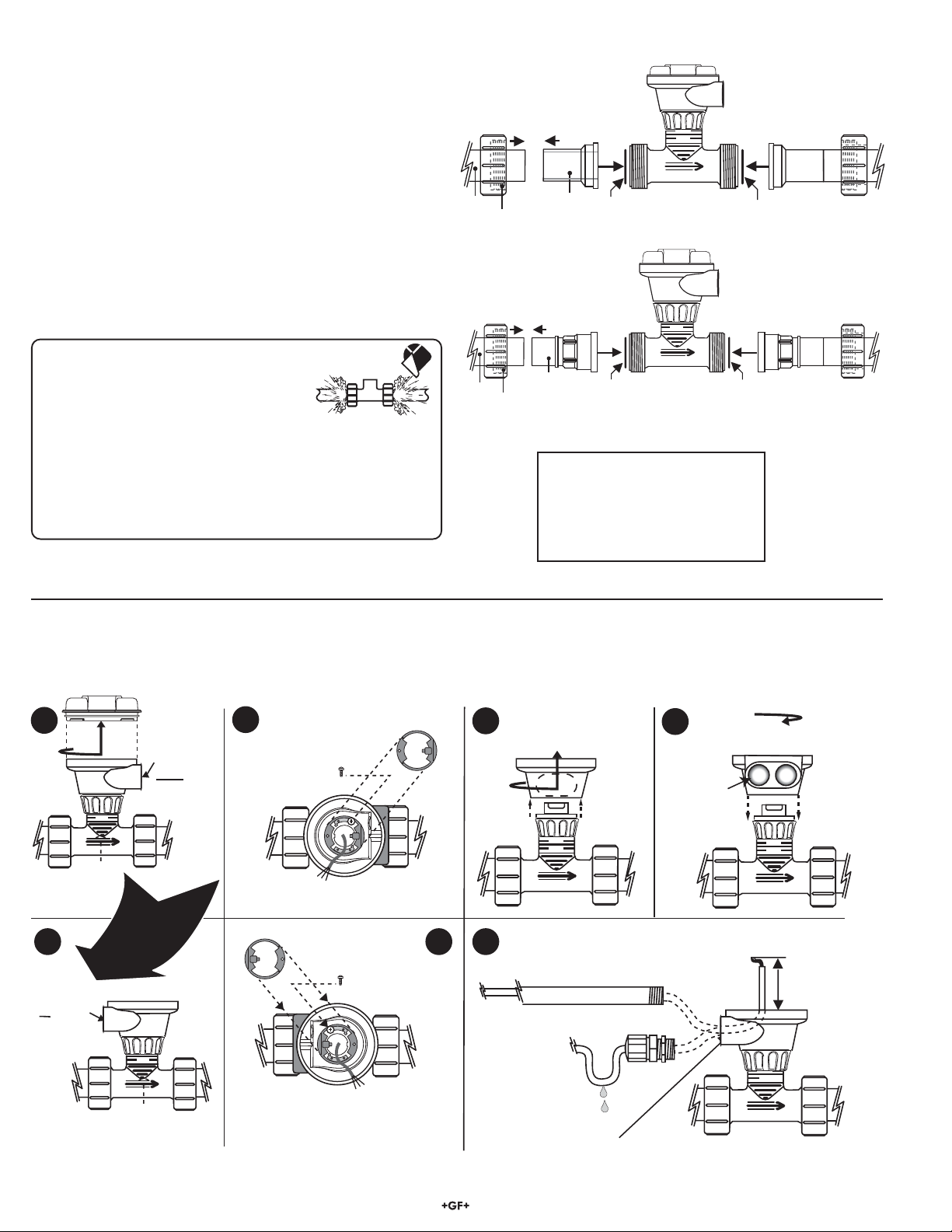

3. Wiring Preparation

Pipe

Union nut

Pipe

Union

nut

BCF/IR

Connector

End

Connector

End

O-Ring

O-Ring,

white

NOTE:

Union Connectors are sold

separately (except for HP

- High Purity.)

Flow

+GF+

XX DN XX X

XX

Flow

O-Ring

O-Ring,

white

The vortex sensor's cap base is reversible for either upstream or downstream conduit port orientation. Optional: Refer to steps (A to

F) for conduit port reversal instructions. Required: Refer to steps (A to G) for external wiring requirements.

A

+GF+

XX DN XX X

XX

Flow

Conduit port

downstream

B

1. Locking

Ring

2. Screw

Mounting base

(top)

Turn Conduit Base 1/2

C

turn to the left and lift

+GF+

XX DN XX X

XX

D

Twist Conduit Base

1/2 turn to the right

Conduit

port

+GF+

XX DN XX X

XX

change

E

Conduit

upstream

Flow

+GF+

XX DN XX X

XX

1. Insert locking ring

2. Install screw

F

G

Threaded conduit (customer supplied) OR

Watertight connector (customer supplied)

Loop cable

downward to prevent

moisture seepage

into housing

14-22

AWG.

100-150 mm

+GF+

XX DN XX X

XX

4-6 in.

PG 13.5 or 1/2 in. NPT-conduit port

2 Signet 7000/7001 Vortex Flow Sensors

Page 3

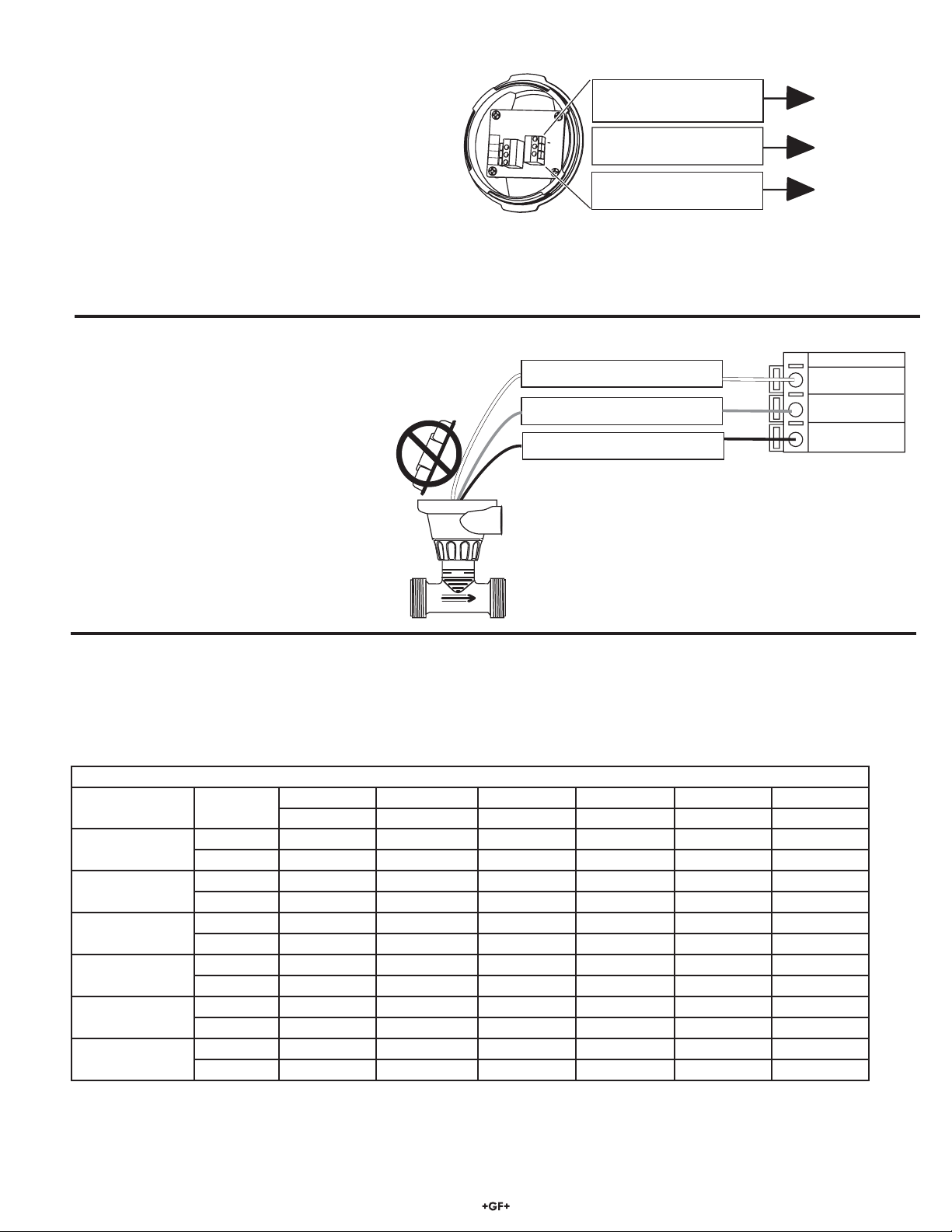

4. Wiring Options - Frequency Output Models

The open-collector frequency output requires a threewire connection between the sensor and the monitoring

device.

To wire the vortex sensor frequency output to remote

equipment:

• Cable with single twisted-pair plus shield recommend-

4-20 mA &

FREQ. OUT

W

BLACK

RED

HITE

+

F

R

E

Q

O

U

T

O

N

L

Y

ed.

• Maximum cable length 200 ft.

• Install cable through a conduit port and connect as

shown to the terminal block inside the vortex sensor

cap.

• Open collector voltage is supplied by Signet instruments.

• Use the 2535/2536 input card setting when wiring to the Signet 9010 Intelek-Pro Flow Controller

To wire the vortex sensor frequency output to a Signet 8550

Integral transmitter:

• Disconnect the sensor wires completely from the vortex sensor

cap. The cap will not be used.

• Connect the Vortex sensor to the 8550 as shown.

White Ground (frequency out)

Loop - (current output)

Red Open Collector pulse (for frequency output)

Not used for current output

Black +3.5-24 VDC +DC Voltage

-

Ground (for frequency out)

Loop - (for current output)

+

+3.5-24 VDC +DC Voltage

FREQ OUT ONLY

Open Collector pulse (for frequency output)

Not used for current output systems

Out to

remote equipment

Sensr Gnd

9

(SHIELD)

Sensr IN

8

(RED)

Sensr V+

7

(BLACK)

Signet 8550 Integral fl ow transmitter

+GF+

XX DN XX X

XX

5. Calibration - Frequency Output Models

This sensor model provides an open-collector frequency output directly proportional to the fl ow rate. The frequency output is held at

0 Hz. When the fl ow rate is below the minimum operating range (see specs.). The following K-factors represent the number of pulses

generated by the sensor for each engineering unit of water measured. If fl uids other than water are used, then custom calibration is

required.

K-Factors - ANSI & Metric Piping Systems

Sensor

Material

PVC, SCH 80

3-7000-5x

PVC, Metric

3-7000-6x

PP, Metric

3-7000-4x

PVDF, Metric

3-7000-3x

HP PVDF

BCF/IR Socket (-2x)

HP PVDF

BCF/IR Butt (-1x)

Flow

Units

U.S. Gallons 1837.39 802.34 361.30 138.76 88.296 39.133

Liters 485.44 211.98 95.455 36.660 23.328 10.339

U.S. Gallons 1248.31 538.45 243.84 114.66 61.415 29.686

Liters 329.81 140.50 64.422 30.292 16.226 7.843

U.S. Gallons 1385.46 572.51 265.76 138.41 70.719 35.096

Liters 366.04 151.26 70.213 36.568 18.684 9.272

U.S. Gallons 1381.71 582.63 265.97 111.81 50.732 25.443

Liters 365.05 153.93 70.270 29.540 13.403 6.722

U.S. Gallons 1396.90 575.71 254.11 110.86 50.431 25.537

Liters 369.07 152.10 67.137 29.288 13.324 6.747

U.S. Gallons 1400.00 575.70 254.31 110.48 51.855 25.568

Liters 369.88 152.10 67.190 29.188 13.700 6.755

d20 DN15 (-x1) d25 DN20 (-x2) d32 DN25 (-x3) d40 DN32 (-x4) d50 DN40 (-x5) d63 DN50 (-x6)

(i.d.≈0.5 inch) (i.d.≈0.75 inch) (i.d.≈1 inch) (i.d.≈1.25 inch) (i.d≈1.5 inch) (i.d≈2 inch)

K-factor Conversion Formulas:

1 U.S. gallon = 0.003785 cubic meters

1 U.S. gallon = 0.0000003069 acre feet

1 U.S. gallon = 8.3454 pounds of water

1 U.S. gallon = 3.785 liters

1 U.S. gallon = 0.8327 imperial gallons

3Signet 7000/7001 Vortex Flow Sensors

Page 4

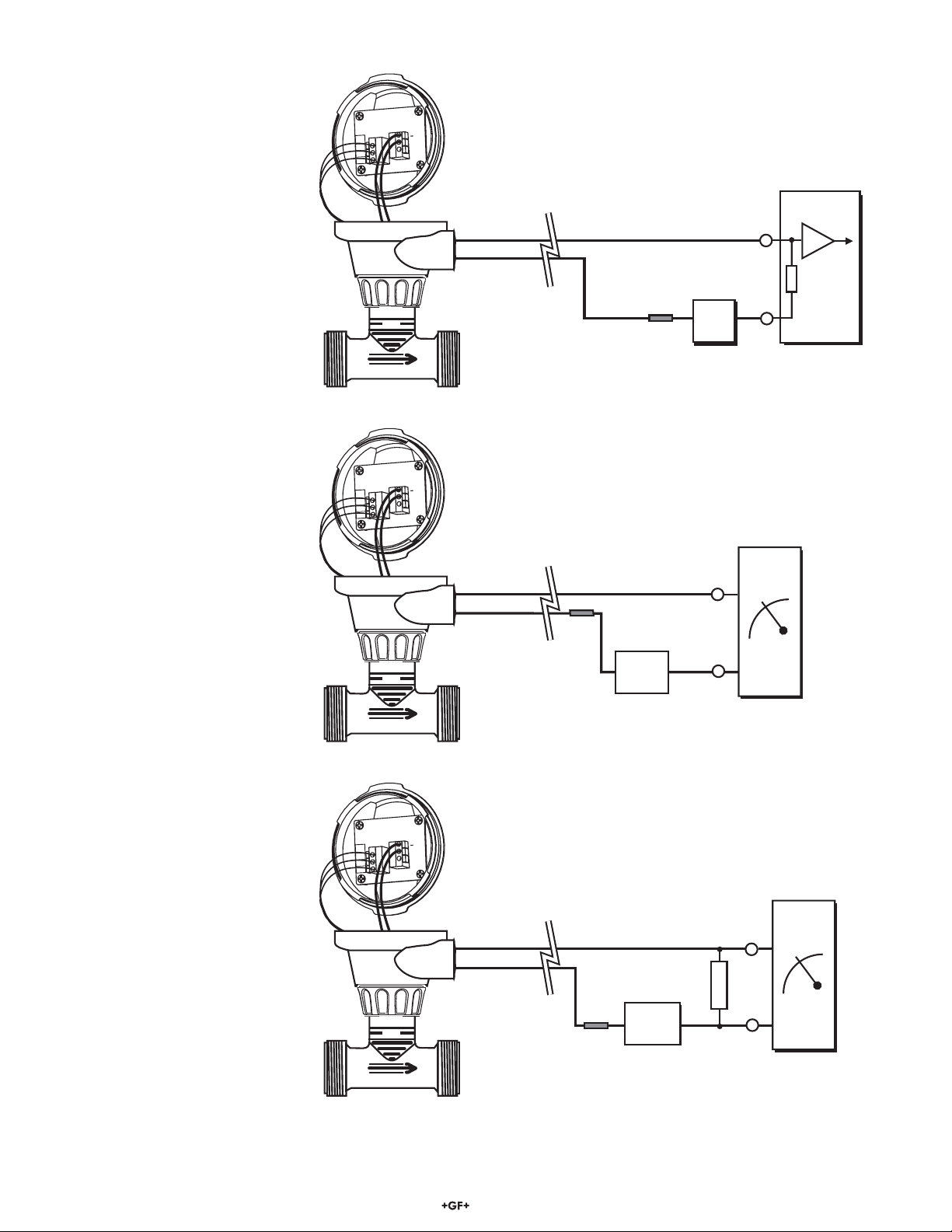

6. Wiring Options - Current Output Models

4-20 mA &

FREQ. OUT

WHITE

BLACK

+

Q

E

R

F

T

U

O

Y

L

N

RED

O

4 to 20 mA

PLC

• PLC without an internal trans-

mitter power supply

• PLC with a 4 to 20 mA indicator

4-20 mA &

FREQ. O

WHITE

BLACK

24*

VDC

4 to 20 mA

CH +

CH (gnd)

-

250Ω*

-

+

+GF+

XX DN XX X

XX

UT

RED

+

Q

E

R

F

T

U

O

LY

N

O

Fuse**

1/8A

External

power

supply

+

indicator

CH +

CH (gnd)

-

+GF+

XX DN XX X

-

+

Fuse**

1/8A

XX

External

power

supply

VDC

+

24*

4-20 mA &

UT

FREQ. O

WHITE

BLACK

RED

+

Q

E

R

F

T

U

O

Y

L

N

O

1 to 5 VDC

recorder

• PLC with a 1 to 5 VDC chart

recorder

-

+

External

power

supply

+GF+

XX DN XX X

XX

Fuse**

1/8A

* Refer to the maximum Loop Impedance for minimum operating voltage requirements in the Specifi cations section.

** 1/8 Amp. fuse recommended (customer supplied)

4 Signet 7000/7001 Vortex Flow Sensors

+

24*

VDC

-

CH +

CH -

250Ω*

(gnd)

Page 5

7. Calibration - Current Output Models

A

This sensor model outputs a 4 to 20 mA current signal directly proportional to the fl ow rate. The current output is held at 4 mA when

fl ow is less than the minimum velocity specifi cation, and increases to 20 mA at the maximum fl ow velocity specifi cation, see section 8.

Use the following formula to calculate the expected current output level at a specifi c fl ow velocity.

Fluid Velocity in pipe

Max sensor velocity (section 8)

X 16

+ 4

= Expected current

output (mA)

Example: In a pipe with a fl ow velocity of 2 m/s, the expected cur-

rent output is calculated as 12.0 mA.

2 (m/s)

4 (m/s)

X 16

+ 4

= 12.0 m

7.1 Velocity to Rate or Rate to Velocity Conversion Formulas

A. Metric Conversion Formulas V = fl owrate

EXAMPLES:

lpm to m/s: PVDF, sensor d63 with a known fl owrate V = 200 lpm (id = 55 from table below);

v(m/s) = 200 / (552 * 0.0471) = 1.40

m/s to lpm:

(optional)

B. American Conversion Formulas V = fl owrate

EXAMPLES:

gpm to ft/s: PVDF, sensor d63 with a known fl owrate V = 100 gpm (id = 55 from table below);

ft/s to gpm:

(optional)

1 lpm = 0.264 gpm 1 m/s = 3.28 ft/s

Sensors Pipe Size

PVDF / HP

PVDF

PP d20 DN15 0.50 4.98 4.00 39.66 1.64 1.32 13.12 10.48

PVC Schedule 80

PVC Metric d20 DN15 0.50 5.28 4.00 42.42 1.64 1.39 13.12 11.21

d20 DN15 0.50 4.98 4.00 39.66 1.64 1.32 13.12 10.48

d25 DN20 0.50 8.94 4.00 71.70 1.64 2.36 13.12 18.94

d32 DN25 0.40 11.76 4.00 117.78 1.31 3.11 13.12 31.12

d40 DN32 0.40 21.18 4.00 211.56 1.31 5.60 13.12 55.89

d50 DN40 0.30 26.76 4.00 356.70 0.98 7.07 13.12 94.24

d63 DN50 0.30 42.78 4.00 570.18 0.98 11.30 13.12 150.64

d25 DN20 0.50 8.94 4.00 71.70 1.64 2.36 13.12 18.94

d32 DN25 0.40 11.76 4.00 117.78 1.31 3.11 13.12 31.12

d40 DN32 0.40 18.12 4.00 181.14 1.31 4.79 13.12 47.86

d50 DN40 0.30 21.48 4.00 286.68 0.98 5.68 13.12 75.74

d63 DN50 0.30 34.62 4.00 461.88 0.98 9.15 13.12 122.03

1/2 in. 0.50 4.29 4.00 31.86 1.64 1.13 13.12 8.42

3/4 in. 0.50 7.63 4.00 57.73 1.64 2.02 13.12 15.25

1 in. 0.40 9.97 4.00 95.43 1.31 2.63 13.12 25.21

1 1/4 in. 0.40 18.70 4.00 181.14 1.31 4.94 13.12 47.86

1 1/2 in. 0.30 19.35 4.00 251.12 0.98 5.11 13.12 66.35

2 in. 0.30 32.57 4.00 425.29 0.98 8.61 13.12 112.36

d25 DN20 0.50 9.42 4.00 75.42 1.64 2.49 13.12 19.93

d32 DN25 0.40 12.72 4.00 127.44 1.31 3.36 13.12 33.67

d40 DN32 0.40 20.52 4.00 205.26 1.31 5.42 13.12 54.23

d50 DN40 0.30 23.76 4.00 316.86 0.98 6.28 13.12 83.71

d63 DN50 0.30 38.22 4.00 509.70 0.98 10.10 13.12 134.66

PVC sensor, d32 with a known fl ow velocity v = 2 m/s (id = 26 from table below);

V(lpm) = 2 * 262 * 0.0471= 63.68

v(ft/s) = 100 / (552 * 0.0038) = 8.7

PVC sensor, d32 with a known fl ow velocity v = 10 ft/s (id = 26 from table below);

V(gpm) = 10 * 262 * 0.0038 = 25.69

v (m/s) V (lpm) v (m/s) V (lpm) v (ft/s) V (gpm) v (ft/s) V (gpm)

v = known fl ow

velocity

v = known fl ow velocity

Metric Conversion Data American Conversion Data

Min Flow Max Flow Min Flow Max Flow

Scale the receiving devices such that 4 mA = zero flow and 20 mA

= full scale (max flow)

Jumps above 4 mA

up to minimum flow

reading

0

OPERATIONAL SCENARIO: At low flow (below minimum flow

rate for this sensor), sensor output is 4 mA. The instant the flow

rate exceeds the minimum, the output jumps to reflect the min.

measurable flow rate. At max. flow rate, output peaks at 20 mA.

V (lpm) to v (m/s)

v = V / (id2 * 0.0471)

V (gpm) to v (ft/s)

2

v = V / (id

* 0.0038)

Loop Range: GPM

00.000 -> 100.00

Minimum

Flow Rate

< min flow

= 4mA

(clamped at 4mA

until min. flow rate)

Flow Rate

Optional:

v (m/s) to V (lpm)

V = v * id2 * 0.0471

Optional:

v (ft/s) to V (gpm)

V = v * id2 * 0.0038

Maximum

Flow Rate

(saturates

at 20 mA)

max. flow

(100 gpm in

this example)

20 mA

Current Output

in milliAmps (mA)

4 mA

5Signet 7000/7001 Vortex Flow Sensors

Page 6

8. Specifi cations

8

p

Backpressure Calculation

• Minimum downstream pipe backpressure levels (full

pipes) are required to prevent cavitation within the

sensor. The minimum backpressure is calculated

by the following formula: 2.7 x ∆P + 1.3 x Po (∆P =

Pressure drop across sensor. Po = Water saturation

vapor pressure at operating temperature.)

1. Using Pressure Drop Graph, fi nd ∆P by locating your

maximum fl ow rate on specifi c sensor size line.

2. Using the Water Saturation Vapor Pressures Chart,

fi nd Po at operating temperature.

3. Calculate minimum back pressure needed using

formula.

conduit base

(enclosure box)

3 3/4"

Ring

Seal

Dimensions of

Adapter & Liquid

Tight Connector

as Mounted

Center

line

Adapter

NPT to

PG 13.5

Kit,Adapter, NPT to PG 13.5

3-0000.393

159.000.618

PG 13.5

Liquid

tight

Conn.

Technical Data

Wetted materials:

• Sensor: PVC, PP, PVDF, or SYGEF HP PVDF

• Union O-Rings: FPM or EPDM

Pipe size range:

• PP/PVDF, Metric: d20 to 63 mm, DN15 to 50 mm

• PVC, SCH 80: 0.5 to 2.0 in.

Flow range:

• d20 to d25 (0.5 to 0.75 in.) sensors: 0.5 to 4 m/s (1.6 to 13 ft/s)

• d32 to d40 (1.0 to 1.25 in.) sensors: 0.4 to 4 m/s (1.3 to 13 ft/s)

• d50 to d63 (1.5 to 2.0 in.) sensors: 0.3 to 4 m/s (1.0 to 13 ft/s)

NOTE: Below these velocity ranges, Vortex output is non-linear.

Enclosure:

• Rating: NEMA 4X/IP65

• Material: PC/PBT blend of resins

• Seals (2): Buna-N

Electrical:

• Accuracy: ±1% of reading @ 25°C

• Repeatability: ±0.5% of reading @ 25°C

• Immunity: EN50082-2

• Emissions: EN55011

• Reverse polarity protection

Electrical - Frequency Output Model

• Power: 3.5 to 24 VDC, regulated, 1.5 mA max

• Output type: Open-collector NPN transistor,

10 mA max sink,

24 VDC max pull-up voltage, 0 to 300 Hz (size

dependent), 50% duty cycle, non-isolated

Electrical - Current Output Model

• Power: 10 to 27 VDC, regulated, 20 mA max

Pressure Drop Graph

14.5

1.45

0.145

si bar

1.00

P)

∆

0.10

Pressure Drop (

0.01

gpm

1 10 100 1000

lpm

3.78

Sensor size:

d20 d25 d32 d40

37.8

d50 d63

Medium: W ater

@ 20 °C (68 °F)

Flo w Ra te (V)

378 37855

Water Saturation Vapor Pressures at Operation Temperatures

°C -20-100 10202530405065

°F -4 14 32 50 68 77 86 104 122 149

Po (bar) 0.001 0.003 0.006 0.012 0.023 0.32 0.042 0.074 0.123 0.25

Po (psia) 0.014 0.038 0.088 0.178 0.338 0.458 0.614 1.067 1.784 3.626

bar

psi

232

16

217.5

15

203

14

188.5

13

174

12

159.5

11

145

10

130.5

9

116

8

101.5

7

Pressure

87

6

72.5

5

58

4

43.5

3

29

2

14.5

1

0

PVC-PN16

PP-PN10

0

-58 -40 -22 -4 14 32 50 68 86 104 122 140 15

-50 -40 -30 -10 10- 20 30 40 50 60 70

0-20

PVDF-PN16

Temperature

Current loop (2-wire):

• Loop impedance: 1 Ω maximum at 7 VDC

300 Ω maximum at 12 VDC

800 Ω maximum at 24 VDC

1000 Ω maximum at 30 VDC

• 4 to 20 mA output fi xed from 0 to 13 ft/s

• Resolution: 6 µA

Environmental

Maximum media press./temp.:

• PVDF: 16 bar @ 0°C, 9.8 bar @ 65°C

(232 psi @ 32°F, 144 psi @ 149°F)

• PP: 10 bar @ 0°C, 2.9 bar @ 65°C

(145 psi @ 32°F, 42 psi @ 149°F)

• PVC: 16.2 bar @ 0°C, 3.7 bar @ 60°C

(235 psi @ 32°F, 54 psi @ 140°F)

• Ambient temp.: 0 to 65°C (32 to 149°F)

• Storage temp.: -15 to 80°C (5 to 176°F)

• Relative humidity: 0 to 95%, non-condensing

• Max. vibration: 1 mm or 1g double amplitude @ 500 Hz

Standards and Approvals

• Manufactured under ISO 9001 and ISO 14001

• CE

6 Signet 7000/7001 Vortex Flow Sensors

Page 7

Dimensions

HP BCF/IR True Union

H

+GF+

XX DN XX X

XX

e

l

L

Conduit port:

PG13.5 or

1/2 in. NPT

HP BCF/IR True Union

d C losest DN D L l H e

mm in c h s i z e mm mm in c h mm inc h mm i n c h mm i n c h mm

20 1/ 2 15 47 1.85 226 8.90 90 3.54 117 4.61 1.9

25 3/ 4 20 57 2.24 236 9.29 100 3.94 120 4.72 1.9

32 1 25 64 2.52 248 9.76 110 4.33 123 4.84 2.4

40 1-1/4 32 78 3.07 286 11.26 110 4.33 127 5.00 2.4

d

D

50 1-1/2 40 89 3.50 298 11.73 120 4.72 132 5.20 3.0

63 2 50 109 4.29 317 12.48 130 5.12 139 5.47 3.0

• HP BCF/IR True Union supplied with white FPM o-rings.

• All HP Sensors are 100% cleaned, inspected and double-bagged in

heat-sealed PA6/PE liners.

HP Socket Fusion True Union

PVDF Socket Fusion

PP Socket Fusion

Conduit port:

PG13.5 or

1/2 in. NPT

H

+GF+

XX DN XX X

XX

d

D

l

Dimension L ± 3 mm (±0.1 in.)

L

PVDF Butt Fusion / IR

PP Butt Fusion / IR

Conduit port:

PG13.5 or

H

+GF+

XX DN XX X

XX

e

l

1/2 in. NPT

L

Dimension L ± 3 mm (±0.1 in.)

Shown with Butt Fusion/IR connectors

PVC Sch 80 Solvent Socket;

PVC Metric Solvent Socket

Conduit port:

PG13.5 or

1/2 in. NPT

H

+GF+

XX DN XX X

XX

d

D

l

Dimension L ± 3 mm (±0.1 in.)

L

HP Socket Fusion True Union; PVDF and PP, Socket Fusion

d C losest DN D L l H

mm I nc h s i z e mm mm inc h mm i nc h mm inc h mm i nc h

20 1/2 15 47 1.85 128 5.04 90 3.54 117 4.61

25 3/4 20 57 2.24 142 5.59 100 3.94 120 4.72

32 1 25 64 2.52 156 6.14 110 4.33 123 4.84

40 1-1/4 32 78 3.07 160 6.30 110 4.33 127 5.00

50 1-1/2 40 89 3.50 176 6.93 120 4.72 132 5.20

63 2 50 109 4.29 194 7.64 130 5.12 139 5.47

• HP Socket Fusion True Union supplied with black FPM o-rings.

• All HP Sensors are 100% cleaned, inspected and double-bagged in

heat-sealed PA6/PE liners.

PVDF & PP Butt Fusio n/ IR c onnectors

d C losest DN D L l H e

mm Inc h siz e mm mm i n c h mm inch mm i nc h mm inch mm

20 1/2 15 47 1.85 196 7.72 90 3.54 117 4.61 1.9

25 3/4 20 57 2.24 212 8.35 100 3.94 120 4.72 1.9

32 1 25 64 2.52 228 8.98 110 4.33 123 4.84 2.4

D

40 1-1/4 32 78 3.07 234 9.21 110 4.33 127 5.00 2.4

50 1-1/2 40 89 3.50 250 9.84 120 4.72 132 5.20 3.0

63 2 50 109 4.29 266 10.47 130 5.12 139 5.47 3.0

PVC Sch 80 Solvent Socket

DLlH

Inch size mm inch mm inch mm inch mm inch

1/2 43 1.69 128 5.04 90 3.54 117 4.61

3/4 53 2.09 144 5.67 100 3.94 120 4.72

1 60 2.36 160 6.30 110 4.33 123 4.84

1-1/4 74 2.91 168 6.61 110 4.33 127 5.00

1-1/2 83 3.27 188 7.40 120 4.72 132 5.20

2 103 4.06 212 8.35 130 5.12 139 5.47

PVC Metric Solvent Socket

d C losest DN D L l H

mm Inch siz e mm mm i nc h mm inch mm i n c h mm i nc h

20 1/2 15 43 1.69 136 5.35 90 3.54 117 4.61

25 3/4 20 53 2.09 150 5.91 100 3.94 120 4.72

32 1 25 60 2.36 166 6.54 110 4.33 123 4.84

40 1-1/4 32 74 2.91 166 6.54 110 4.33 127 5.00

50 1-1/2 40 83 3.27 186 7.32 120 4.72 132 5.20

63 2 50 103 4.06 196 7.72 130 5.12 139 5.47

7Signet 7000/7001 Vortex Flow Sensors

Page 8

9. Spare Parts

For retrofit of earlier Signet

part numbers 152.xxx.xxx,

use 3-8055.

Conduit Base Kit

3-8054

159.000.619

Ring Nut

3-8050.562-2

159.000.621

screw

locking ring

conduit base

(enclosure box)

base seal

End

Union

conn.

nut

PG 13.5 Liquid tight Conn.

threaded

plug

Adapter NPT to PG 13.5

Ring Seal

+GF+

XX DN XX X

XX

O-Ring (see table below)

End Connector Kit (see table on next page)

NOTE: For Sensor part num-

bers, see pages 10

and 11

Kit,Adapter, NPT to PG 13.5

3-0000.393

159.000.618

Spare O-Rings

Description “Size

(mm)”

Material “Mfr. Part No.

(2 pieces)”

“Code

(1 piece. order 2 pcs.)”

O-Ring(s) [1 or 2 pieces] d20 EPDM 3-7000.390-01 748.410.038

O-Ring(s) [1 or 2 pieces] d25 EPDM 3-7000.390-02 748.410.044

O-Ring(s) [1 or 2 pieces] d32 EPDM 3-7000.390-03 748.410.195

O-Ring(s) [1 or 2 pieces] d40 EPDM 3-7000.390-04 748.410.052

O-Ring(s) [1 or 2 pieces] d50 EPDM 3-7000.390-05 748.410.134

O-Ring(s) [1 or 2 pieces] d63 EPDM 3-7000.390-06 748.410.135

O-Ring(s) [1 or 2 pieces] d20 FPM (Viton) 3-7000.390-07 749.410.038

O-Ring(s) [1 or 2 pieces] d25 FPM (Viton) 3-7000.390-08 749.410.044

O-Ring(s) [1 or 2 pieces] d32 FPM (Viton) 3-7000.390-09 749.410.195

O-Ring(s) [1 or 2 pieces] d40 FPM (Viton) 3-7000.390-10 749.410.052

O-Ring(s) [1 or 2 pieces] d50 FPM (Viton) 3-7000.390-11 749.410.134

O-Ring(s) [1 or 2 pieces] d63 FPM (Viton) 3-7000.390-12 749.410.135

O-Ring(s) [1 or 2 pieces] d20 FPM white 3-7000.390-13 749.410.005

O-Ring(s) [1 or 2 pieces] d25 FPM white 3-7000.390-14 749.410.006

O-Ring(s) [1 or 2 pieces] d32 FPM white 3-7000.390-15 749.410.120

O-Ring(s) [1 or 2 pieces] d40 FPM white 3-7000.390-16 749.410.062

O-Ring(s) [1 or 2 pieces] d50 FPM white 3-7000.390-17 749.410.172

O-Ring(s) [1 or 2 pieces] d63 FPM white 3-7000.390-18 749.410.054

8 Signet 7000/7001 Vortex Flow Sensors

Page 9

9. Spare Parts (continued)

Spare End Connectors

Mfr. Part No. Code

Size END CONNECTOR Material

Complete Kit:

2 ring nuts

2 end connectors

End Connector

Single piece

d20 PVDF, Metric, Butt Fusion, 1/2” 3-7000.391-11 735.608.606 735.690.406

d25 PVDF, Metric, Butt Fusion, 3/4” 3-7000.391-12 735.608.607 735.690.407

d32 PVDF, Metric, Butt Fusion, 1” 3-7000.391-13 735.608.608 735.690.408

d40 PVDF, Metric, Butt Fusion, 1 1/4” 3-7000.391-14 735.608.609 735.690.409

d50 PVDF, Metric, Butt Fusion, 1 1/2” 3-7000.391-15 735.608.610 735.690.410

d63 PVDF, Metric, Butt Fusion, 2” 3-7000.391-16 735.608.611 735.690.411

d20 PVDF, Metric, Fusion Socket, 1/2” 3-7000.391-21 735.600.106 735.690.406

d25 PVDF, Metric, Fusion Socket, 3/4” 3-7000.391-22 735.600.107 735.690.407

d32 PVDF, Metric, Fusion Socket, 1” 3-7000.391-23 735.600.108 735.690.408

d40 PVDF, Metric, Fusion Socket, 1 1/4” 3-7000.391-24 735.600.109 735.690.409

d50 PVDF, Metric, Fusion Socket, 1 1/2” 3-7000.391-25 735.600.110 735.690.410

d63 PVDF, Metric, Fusion Socket, 2” 3-7000.391-26 735.600.111 735.690.411

Union Nut

Single piece

d20 PP Metric, Butt Fusion, 1/2”: 3-7000.391-31 727.608.506 727.690.406

d25 PP Metric, Butt Fusion, 3/4” 3-7000.391-32 727.608.507 727.690.407

d32 PP Metric, Butt Fusion, 1” 3-7000.391-33 727.608.508 727.690.408

d40 PP Metric, Butt Fusion, 1 1/4” 3-7000.391-34 727.608.509 727.690.409

d50 PP Metric, Butt Fusion, 1 1/2” 3-7000.391-35 727.608.510 727.690.410

d63 PP Metric, Butt Fusion, 2” 3-7000.391-36 727.608.511 727.690.411

d20 PP Metric, Fusion Socket, 1/2” 3-7000.391-41 727.600.106 727.690.406

d25 PP Metric, Fusion Socket, 3/4” 3-7000.391-42 727.600.107 727.690.407

d32 PP Metric, Fusion Socket, 1” 3-7000.391-43 727.600.108 727.690.408

d40 PP Metric, Fusion Socket, 1/1/4” 3-7000.391-44 727.600.109 727.690.409

d50 PP Metric, Fusion Socket, 1 1/2” 3-7000.391-45 727.600.110 727.690.410

d63 PP Metric, Fusion Socket, 2” 3-7000.391-46 727.600.111 727.690.411

d20 PVC Sch80, 1/2” 3-7000.391-51 721.602.006 721.690.006

d25 PVC Sch80, 3/4” 3-7000.391-52 721.602.007 721.690.007

d32 PVC Sch80, 1” 3-7000.391-53 721.602.008 721.690.008

d40 PVC Sch80, 1 1/4” 3-7000.391-54 721.602.009 721.690.009

d50 PVC Sch80, 1/1/2” 3-7000.391-55 721.602.010 721.690.010

d63 PVC Sch80, 2” 3-7000.391-56 721.602.011 721.690.011

d20 PVC Metric, 1/2” 3-7000.391-61 721.600.106 721.690.006

d25 PVC Metric, 3/4” 3-7000.391-62 721.600.107 721.690.007

d32 PVC Metric, 1” 3-7000.391-63 721.600.108 721.690.008

d40 PVC Metric, 1 1/4” 3-7000.391-64 721.600.109 721.690.009

d50 PVC Metric, 1 1/2” 3-7000.391-65 721.600.110 721.690.010

d63 PVC Metric, 2” 3-7000.391-66 721.600.111 721.690.011

9Signet 7000/7001 Vortex Flow Sensors

Page 10

10. Sensor Ordering Tree

• To select a replacement sensor:

a) determine if your sensor has a pulse (frequency) or

current output;

b) determine material type and confi guration;

c) determine size.

OUTPUT

0 Frequency Output

1 Current Output (4 to 20 mA)

+GF+

XX DN XX X

+GF+

XX

XX DN XX X

XX

IndustrialHigh Purity (HP)

-

3

11. End Connectors Ordering Tree

3- 0 .

7

0

o-

0

MAT'L./CONFIG.

SYGEF HP-PVDF BCF/IR

*

Butt Fusion True

1

(end connectors included)

SYGEF HP-PVDF BCF/IR

*

Socket Fusion True

2

(end connectors included)

3

PVDF

4

PP

PVC Sch 80

5

Solvent Socket

PVC Metric

6

Solvent Socket

End connector kit options for these sensors

are ordered separately. Use selection tree

below to determine part number

70

0391-

Union

Union

m

m

s

SIZE

d DN Å inches

1 20mm 15mm 1/2

2 25mm 20mm 3/4

3 32mm 25mm 1

4 40mm 32mm 1 1/4

5 50

6 63

*SYGEF¨ HP is the George Fischer

High Purity PVDF formulation and process.

mm

40mm 1 1/2

mm

50mm 2

s

MAT'L./CONFIG.

1

PVDF Metric, Butt Fusion

2

PVDF Metric, Fusion Socket

3

PP Metric, Butt Fusion

4

PP Metric, Fusion Socket

PVC Sch 80

5

PVC Metric

6

10 Signet 7000/7001 Vortex Flow Sensors

1 d20 1/2"

2 d25 3/4"

3 d32 1"

4 d40 1 1/4"

5 d50 1 1/2"

6 d63 2"

SIZE

Page 11

12. Sensor Assembly Part Numbers

Electrical Materials/Confi guration Size (mm) ≈Size (in.) Mfr. Part No. Code

Frequency

3-7000

HP Union BCF/IR True Union

(High Purity Polyvinylidene Fluoride

Bead and Crevice Free /

/ Infra-Red welded)

(shipped with white FPM O-rings)

HP PVDF Socket Fusion True Union

(shipped with FPM O-rings)

PVDF

(shipped with FPM O-rings)

Polypropylene

(shipped with FPM O-rings)

PVC Sch 80 Solvent Socket

(shipped with EPDM O-rings)

PVC Metric Solvent Socket

(shipped with EPDM O-rings)

d20 0.50 3-7000-11 159 000 106

d25 0.75 3-7000-12 159 000 107

d32 1.00 3-7000-13 159 000 108

d40 1.25 3-7000-14 159 000 109

d50 1.50 3-7000-15 159 000 110

d63 2.00 3-7000-16 159 000 111

d20 0.50 3-7000-21 159 000 112

d25 0.75 3-7000-22 159 000 113

d32 1.00 3-7000-23 159 000 114

d40 1.25 3-7000-24 159 000 115

d50 1.50 3-7000-25 159 000 116

d63 2.00 3-7000-26 159 000 117

d20 0.50 3-7000-31 159 000 118

d25 0.75 3-7000-32 159 000 119

d32 1.00 3-7000-33 159 000 120

d40 1.25 3-7000-34 159 000 121

d50 1.50 3-7000-35 159 000 123

d63 2.00 3-7000-36 159 000 123

d20 0.50 3-7000-41 159 000 124

d25 0.75 3-7000-42 159 000 125

d32 1.00 3-7000-43 159 000 126

d40 1.25 3-7000-44 159 000 127

d50 1.50 3-7000-45 159 000 128

d63 2.00 3-7000-46 159 000 1299

d20 0.50 3-7000-51 159 000 130

d25 0.75 3-7000-52 159 000 131

d32 1.00 3-7000-53 159 000 132

d40 1.25 3-7000-54 159 000 133

d50 1.50 3-7000-55 159 000 134

d63 2.00 3-7000-56 159 000 135

d20 0.50 3-7000-61 159 000 136

d25 0.75 3-7000-62 159 000 137

d32 1.00 3-7000-63 159 000 138

d40 1.25 3-7000-64 159 000 139

d50 1.50 3-7000-65 159 000 140

d63 2.00 3-7000-66 159 000 141

11Signet 7000/7001 Vortex Flow Sensors

Page 12

12. Sensor Part Numbers (continued)

Electrical Materials/Confi guration Size (mm) ≈Size (in.) Mfr. Part No. Code

Current

3-7001

HP Union BCF/IR True Union

(High Purity Polyvinylidene Fluoride

Bead and Crevice Free /

/ Infra-Red welded)

(shipped with white FPM O-rings)

HP PVDF Socket Fusion True Union

d20 0.50 3-7001-11 159.000.148

d25 0.75 3-7001-12 159.000.149

d32 1.00 3-7001-13 159.000.150

d40 1.25 3-7001-14 159.000.151

d50 1.50 3-7001-15 159.000.152

d63 2.00 3-7001-16 159.000.153

d20 0.50 3-7001-21 159.000.154

d25 0.75 3-7001-22 159.000.155

(shipped with FPM O-rings)

d32 1.00 3-7001-23 159.000.156

d40 1.25 3-7001-24 159.000.157

d50 1.50 3-7001-25 159.000.158

d63 2.00 3-7001-26 159.000.159

PVDF

(shipped with FPM O-rings)

Polypropylene

d20 0.50 3-7001-31 159.000.160

d25 0.75 3-7001-32 159.000.161

d32 1.00 3-7001-33 159.000.162

d40 1.25 3-7001-34 159.000.163

d50 1.50 3-7001-35 159.000.164

d63 2.00 3-7001-36 159.000.165

d20 0.50 3-7001-41 159.000.166

d25 0.75 3-7001-42 159.000.167

d32 1.00 3-7001-43 159.000.168

d40 1.25 3-7001-44 159.000.169

d50 1.50 3-7001-45 159.000.170

(shipped with FPM O-rings)

PVC Sch 80 Solvent Socket

d63 2.00 3-7001-46 159.000.171

d20 0.50 3-7001-51 159.000.172

d25 0.75 3-7001-52 159.000.173

d32 1.00 3-7001-53 159.000.174

d40 1.25 3-7001-54 159.000.175

d50 1.50 3-7001-55 159.000.176

(shipped with EPDM O-rings)

PVC Metric Solvent Socket

d63 2.00 3-7001-56 159.000.177

d20 0.50 3-7001-61 159.000.178

d25 0.75 3-7001-62 159.000.179

d32 1.00 3-7001-63 159.000.180

d40 1.25 3-7001-64 159.000.181

(shipped with EPDM O-rings)

d50 1.50 3-7001-65 159.000.182

d63 2.00 3-7001-66 159.000.183

George Fischer Signet, Inc. 3401 Aerojet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

3-7000.090 Rev.F 10/05 English © George Fischer Signet, Inc. 2002 Printed in U.S.A. on recyclable paper

Loading...

Loading...