Georg Fischer 578 Operating Manual

GF Piping Systems

Instruction manual

Butterfly valve Type 567/568

Observe instruction manual

The instruction manual is part of the product and an

important element within the safety concept.

• Read and observe instruction manual.

• Always keep instruction manual available close to the

product.

• Pass on instruction manual to all subsequent users of the

product.

1. Intended use

After being installed into a piping system, butterfly valves

type 567/ 568 are exclusively meant to block or convey media

within the approved pressure and temperature limits, and to

regulate the flow.

The maximum time of operation is 25 years. The valve is

intended to be used within the chemical stability of the entire

valve and all its components.

Butterfly valves are not recommended for media with

solid matters. Cavitation has to be avoided during normal

operation.

In case of degreasing or jamming media, butterfly valves

can only be used after consulting a GF Piping Systems

representative.

• Use type 567 only as intermediate butterfly valves.

• Use type 568 as intermediate or ending butterfly valve.

See «Georg Fischer‘s planning criteria» for approved

pressure areas of all approved temperatures for all housing

materials. These documents also contain the „list of

chemical resistivity“ for the different valve materials.

2. Regarding this document

This document contains all necessary information for the

installation, operation and service of the product.

2.1 Related documents

• Georg Fischer planning fundamentals

• Instruction manual for expanding the BFV 567/ 568 for

further functions:

Instruction manual GMST number

Quick Guide Electrical actuator 5886/1, 4

Pneumatic actuator PA30- PA90 5377/1, 2, 4d

Integrated Electric Feedback 5939/1, 4

Intermediate Element for BUV 567/568 5918/1, 4

These documents can be obtained from the GF Piping Systems representative or under www.piping.georgfischer.com

2.2 Abbreviations

.

Abbreviation Meaning

BFV Butterfly Valve

Type 567/ 568 Butterfly Valve 567/ 568

DN Nominal diameter

PN Pressure rate

SFA Socket flange adaptor

BFA Butt fusion flange adaptor

3. Safety and warning instructions

This manual contains warning instructions that shall warn

against injuries or material losses. Always read and observe

those warning instructions.

• Imminent danger!

DANGER

WARNING

CAUTION

NOTICE

4. Safety and responsibility

In order to provide safety in the plant, the operator is

responsible for the following measures:

• Products may only be used for its intended purpose, see

• Never use a damaged or defective product.

• Make sure that the piping system has been installed

• Products and equipment shall only be installed by persons

• Regularly train personnel in all relevant questions

The personnel is responsible for the following measures:

• Know, understand and observe the instruction manual and

The same safety guidelines apply for butterfly valves as for

the piping system into which they are built.

To operate the butterfly valves, the torques as indicated in

table 1 are sufficient.

• At high flow veloctiy we recommend to use a gear operator

• A butterfly valve is not self-locking:

Non-observance may result in major injuries

or death.

• Possible danger!

Non-observance may result in major injuries.

• Dangerous situation!

Non-observance may result in minor injuries

• Dangerous situation!

Non-observance may result in material losses.

intended purpose

Immediately sort out damaged product.

professionally and serviced regularly.

who have the required training, knowledge or experience.

regarding locally applicable regulations regarding safety at

work, environmental protection especially for pressurised

pipes.

the advices therein.

instead of a hand lever.

The actuating device shall not be disassembled, as long as

the valve is flowed or pressurised.

EC declaration of conformity

The manufacturer Georg Fischer Rohrleitungssysteme AG, 8201 Schaffhausen (Switzerland) explains that the butterfly valves types 567/ 568

according to the harmonised construction type standards EN-593

1. are pressure-maintaining components in terms of the EG Pressure

Equipment Directive 97/23™/EG and comply with the requirements of

this directive that apply to valves,

2. comply with the applicable requirements of the Construction Products

Directive 89/106/EG for valves

The Πsign on the valve proves this compliance (according to the

Pressure Equipment Directive, only valves with a ND larger than 25 shall

be indicated with Œ).

The operation of these butterfly valves is not allowed until the conformity of the entire system, in which the butterfly valves have been installed

has been explained with one of the mentioned EG Directives.

Changes to the butterfly valve that could effect the stated technical data

and the intended purpose, void this declaration of conformity. Additional

information can be found in „Georg Fischer‘s planning fundamentals“.

Schaffhausen, 01 July 2013

Antonio De Agostini

R&D Manager

Georg Fischer Piping Systems

Georg Fischer Piping Systems Ltd. CH-8201 Schaffhausen (Switzerland)

Phone +41(0)52 631 30 26 / info.ps@georgfischer.com / www.gfps.com

161.484.584 / GMST 5906/1e, 4e (07.13)

© Georg Fischer Rohrleitungssysteme AG

CH-8201 Schaffhausen/Schweiz, 2013

Printed in Switzerland

Operating torque (everage value) for opening / closing the

BFV (standard valves in new condition)

DN

Inch

Nm 5bar

Nm 10 bar

50 65 80 100 125 150 200 250

2“ 2 1⁄2“ 3“ 4“ 5“ 6“ 8“ 10“

6 8 14 19 25 33 50 70

12 17 28 38.5 50 61 90 115

300

12“

90

145

Remark: Depending on the application the operating torque

can increase up to 4 times.

CAUTION

Damage to the butterfly valves through the use

of auxiliary equipment to increase the coupling

• Operate valve only with the intended actuating means

(lever, transmission, actuator).

moment.

• If an increased actuating torque occurs, check valve for

damage/wear and tear.

When dismantling the butterfly valve, the following risks can

emerge:

WARNING

When dismantling the butterfly valve, there is a

risk of injury through the uncontrolled leakage

of the medium and/or subsequent flow of the

medium from an open pipeline and/or the butterfly valve.

If the pressure has not been relieved completely and the

pipeline has not been emptied completely, the medium can

leak uncontrollably.

There is a risk of injury depending on the type of the medium.

• Completely relieve pressure from the pipeline before

dismantling.

• In case of harmful, inflammable or explosive media,

completely empty and flush pipeline. After dismantling

the butterfly valve, also let the valve run dry while putting

it in a vertical position.

Consider possible residues.

• Guarantee the safe catching of the medium (e.g. mounting

of a catchment tank) and avoid splashing through

appropriate measures.

• Make sure that opening and closing the pipe is not done

jerkily and that pressure surges in the piping system are

avoided. This has to be observed especially when operating

the pipe with a hand lever.

5. Transport and storage

• Transport and/or store product in unopened original

packaging.

• Protect product from dust, dirt, dampness as well as

thermal and UV radiation.

• Make sure that the product has not been damaged neither

by mechanical nor thermal influences.

• Store product in the same idle position as it has been

delivered.

• Check product for transport damages prior to the

installation.

Gaskets

• All gaskets/collars (material e.g. EPDM, FPM) are

organic materials and react to environmental conditions.

Therefore, store cool, dry and dark in its original

packaging.

• Check gaskets/collars for possible ageing damages such

as tearing or rigidification prior to the installation.

• Sort out defective gaskets/collars.

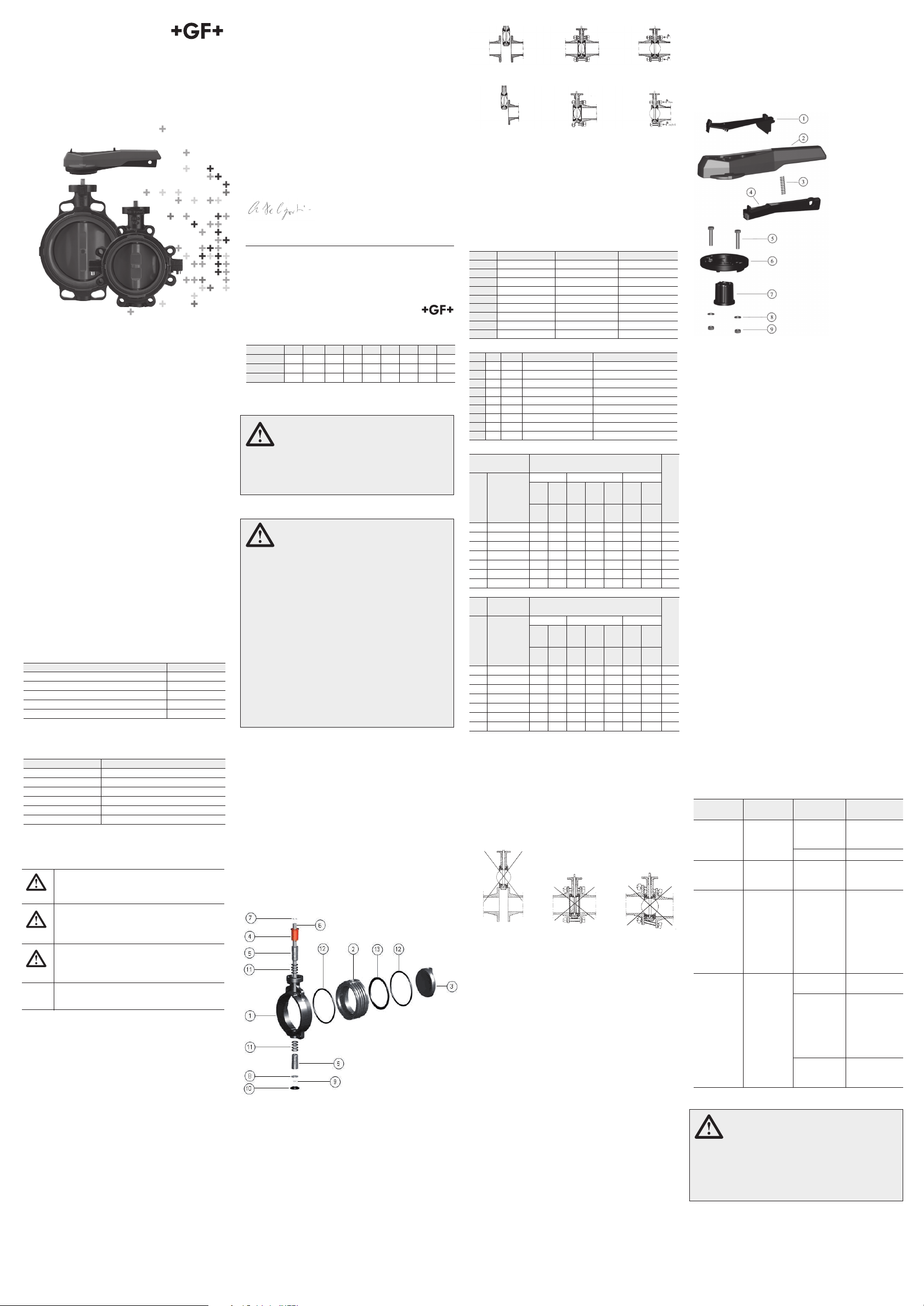

6. Design

1 Wafer housing

2 Inner body

3 Disc

4 End stop

5 Bearing bush

6 Shaft

7 Large retaining ring

8 Washer

9 Small retaining ring

10 Cap

11 O-ring

7. Installation

Installation into the pipeline

• Only use butterfly valves type 567 as intermediate butterfly

valves

• Use butterfly valves type 568 as intermediate or end

butterfly valves

As connecting part we recommend socket flange adaptor

(SFA) or butt fusion flange adaptor (BFA) with flat sealing

surface in connection with flanges of PVC-U, PP-V or PP/

steel. When SFA / BFA with serrated sealing surface are

used, in individuel cases a flat gasket needs to be added.

Prior to the installation

• Make sure that only butterfly valves are installed whose

pressure category, connection type, connection dimensions

and materials correspond to the operating conditions

• Carry out function test. To do so, close and reopen butterfly

valve.

• Only install butterfly valves without functional

disturbances.

12 Flange sealing

13 Profile sealing

AK 567: 1 2 3

AK 568: 1 2 3

• 1. Allow for sufficient spacing between the flange ends.

Note that the BFV opens counterclockwise.

During the installation

• 2: Put the valve disc at closed position.

• Move the butterfly valve with the seals (O-rings or flat

gaskets) between both flange ends

• 3: Realign the pipeline. Make sure that the disc can be fully

opened

• Fasten the butterfly valve with flange screws (see table 1)

Maximum closing torques for installing the BFV Type 567

DN Inch Nm Inch-lbs

50 2“ 30 256

65 2 ½“ 35 310

80 3“ 40 352

100 4“ 45 398

125 5“ 50 442

150 6“ 60 531

200 8“ 75 664

250 10“ 75 664

300 12“ 80 708

Indexes for fastening the BFV type 567 with flange screws

d DN Inch Schrauben gesamt Max. Drehmoment/ Nm

63 50 2 4 x M16 x 140mm 25

75 65 2 1/2 4 x M16 x 140mm 25

90 80 3 8 x M16 x 150mm 25

110 100 4 8 x M16 x 180mm 30

140 125 5 8 x M16 x 200mm 35

160 150 6 8 x M20 x 220mm 40

225 200 8 8 x M20 x 240mm 50

280 250 10 8 x M20 x 300mm 80

315 300 12 12 x M20 x 300mm 80

Indexes for fastening the BFV type 568 with flange screws

ISO BB - VSB with the various flanges

DN

Quantity of

screws

50 8xM16 55 55 50 55 50 55 50 20

65 8xM16 60 60 50 60 50 60 50 25

80 16xM16 60 65 55 60 55 65 55 15

100 16xM16 65 70 60 70 60 70 60 20

125 16xM16 70 80 70 70 70 80 70 25

150 16xM20 80 80 80 80 70 80 80 35

200 16xM20 90 90 90 90 90 90 80 45

ANSI

Quantity of

screws

2 8xUNC 5/8 55 55 50 55 50 55 50 25

2 1⁄2 8xUNC 5/8 55 60 50 60 50 60 50 25

3 8xUNC 5/8 60 65 55 60 55 65 55 25

4 16xUNC 5/8 65 70 60 60 60 70 60 30

5 16xUNC 3/4 70 80 70 70 70 80 70 35

6 16xUNC 3/4 80 80 80 80 70 80 70 40

8 16xUNC 3/4 90 90 90 90 90 90 80 50

PP PVC-U PVDF

PP-V

PP/

steel

PVC-UPP-V

L

MINLMINLMINLMINLMINLMINLMIN

BB - VSB with the various flanges

PP PVC-U PVDF

PP-V

PP/

steel

PVC-UPP-V

L

MINLMINLMINLMIN

PP/

steel

PP-V

PP/

steel

PP-V

L

MINLMINLMIN

steel

steel

in Nm

PP/

in Nm

PP/

After installing

• Do another function test also after installing.

Chamfering of the SFA / BFA

If SFA/BFA of Georg Fischer are used, chamfering is not

necessary, because the disc doesn’t touch the SFA/BFA or

the BFA already have a chamfer.

If you install a SFA/BFA of another manufacturer, please

observe that the inside diameter (Int-) of the SFA/BFA are larger than the disc outlet diameter (Q1). If necessary you may

chamfer the SFA/BFA as shown in this table below.

Possible consequences of a faulty installation:

A B C

Prior to installation

A: Not enough space between the two flanged pipe sides or

disc is open

B: The butterfly valve gets stuck in the pipeline

C: Pipeline is not well aligned or not at all

8. Disassembly/ Assembly

• Note that there are arrows ∆ on various parts of the

butterfly valves, which enable a quick and correct

assembly. Pictures according the steps, see„Quick Guide“.

8.1 Disassembly BFV 567/ 568

1. Turn disc to ca. 45°

2. Remove cap.

3. Remove the small retaining ring and take out the washer.

4. Remove the large retaining ring and take out the washer

and end stop.

5. Pull the shaft of the butterfly valve up to the upper

bearing bush.

6. Hold the shaft and turn disk to ca. 30°. Pull out shaft

completely.

7. Insert shaft from above at a 15°-position and push out

the upper bearing bush.

8. Pull the shaft of the butterfly valve up to the lower

bearing bush.

9. Hold shaft and turn disc to ca. 30°. Pull out shaft com-

pletely.

10. Insert shaft from above at a 45°-position and push out

the lower bearing bush.

11. Pull out shaft completely and remove the disc.

12. Press out the inner body from the notchless side.

8.2 Assembly BFV 567/ 568

1. Mount large safety ring, mechanical end stop and upper

bearing bush on shaft.

2. Insert inner body into the wafer housing (observe position

of arrow and cam) and move it to the limit stop

3. Insert disc in the open position of 90° (observe position

of arrow).

4. Insert shaft and move it to the limit stop. Watch at the

shape of the shaft when inserting it:

• The notch on the upper side of the shaft indicates the

position of the disc.

• In addition two chamfers at the haft are larger, which

avoids a faulty assembly

5. Insert lower bearing bush and push it into the limit stop.

6. Insert washer and secure it with the small retaining ring.

7. Mount cap and flange sealings (o-rings).

8.3 Assembly hand lever

1 Lever clip

2 Lever

3 Spring

4 Lever catch

5 Screws

6 Index plate

7 End stop

8 Washers

9 Nuts

1. Hand lever assembled by closed disc. By the indexation of the shaft and the end stop a clear assembly is

ensured.

2. With view of the moulded GF logo disc at the wafer housing, the hand lever stands in closed position of the disc

to the right direction.

Closing torque for hand lever connection 15 Nm

8.4 Turn of the hand lever

To turn the hand lever at 180 degrees take the following

steps:

1. Butterfly valve is in closed position. Washer at the hand

Max. closing torque

lever solve easily. Do not remove it completely.

2. Open the lever clip with a screwdriver. Additionally by

the dimensions DN200-300 unscrew the boltes between

handlever and end stop.

3. Bring the screwdriver between raster element and

hand lever. Afterwards move the screwdriver upwards to

unlock the end stop.

4. Take nut and washer complete from the hand lever.

5. Turn hand lever and raster element at 180 degrees. End

stop remains on the shaft.

6. Reassemble hand lever and raster element at the butterfly valve.

7. Assemble the hand lever in closed position of the disc.

Lock the hand lever clip.

8. Finish the assembly of the hand lever with nut and

washer.

9. Maintenance

Max. closing torque

During normal operation, butterfly valves do not need

servicing. But it is recommended to maintain the butterfly

valves latest after 5000 cycles. The following provisions must

be taken:

• Periodic inspection to make sure that there is no leakage

of media to the outside. If media is exiting at the flanged

connectors, they have to be tightened according to Table 2.

In case of leaks or other disturbances, Chapters 1 to 5 must

be observed.

• It is recommended to once or twice a year operate butterfly

valves that are always in the same position in order to test

their functionality.

• Depending on the operating conditions, the collars should

be periodically lubricated with grease (silicone-based).

• It is recommended that the o-rings of the bearing bushes

are checked and if necessary exchanged after each

disassembly.

10. Troubleshooting List

In case of leakage, dismount butterfly valves and replace

damaged gaskets/collars. Order spare parts for butterfly

valves with complete specifications, e.g. all details regarding

the type plates. Only use original parts of GF Piping Systems.

Problem Conse-

Cause Solution

quence

BFV does

not fit

between the

flanges

Disc cannot

be opened

Installation

not possible

Flow rate

too low

Flanges are

too close to

each other

Disc is open • Close disc

Disc touches

SFA/BFA

completely

BFV can

hardly be

opened/

closed or

cannot be

opened/

closed at all

actuating

torque too

high

Operating

conditions

such as

media,

temperature

and pressure

are possible

outside of the

specifications

Leaky BFV /

connecting

elements

Medium is

exiting

Gasket is

damaged

irregular

tightening

of the flange

screws

SFA/BFA with

fluted sealing

face

Selection of lubricants

CAUTION

Material damage due to inappropriate lubricants

that corrode the materials that butterfly valves

and/or gaskets are made of.

• Make sure that no lubricants are used that are based on

mineral oil or Vaseline (petrolatum).

• Observe special manufacturer’s notice for

paint-compatible butterfly valves.

• Lubricate all gaskets with grease based on silicone

or polycol. Other lubricants are not permissible.

10. Spare parts

Spare parts are available at your local Georg Fischer

sales company or on the Internet

at www.piping.georgfischer.com/de

The technical data are not binding. They neither

constitute expressly warranted characteristics nor

guaranteed properties nor a guaranteed durability.

They are subject to modification. Our General Terms

of Sale apply.

• Push flange

apart with

spreading tool

• Bevel SFA/

BFA according

to Table

• Replace

valve

Contact

manufacturer

• Replace

gasket

• Evenly

tighten flange

screws

criss-cross

according to

Table Screw

fixation

• Use SFA/BFA

with even

sealing face

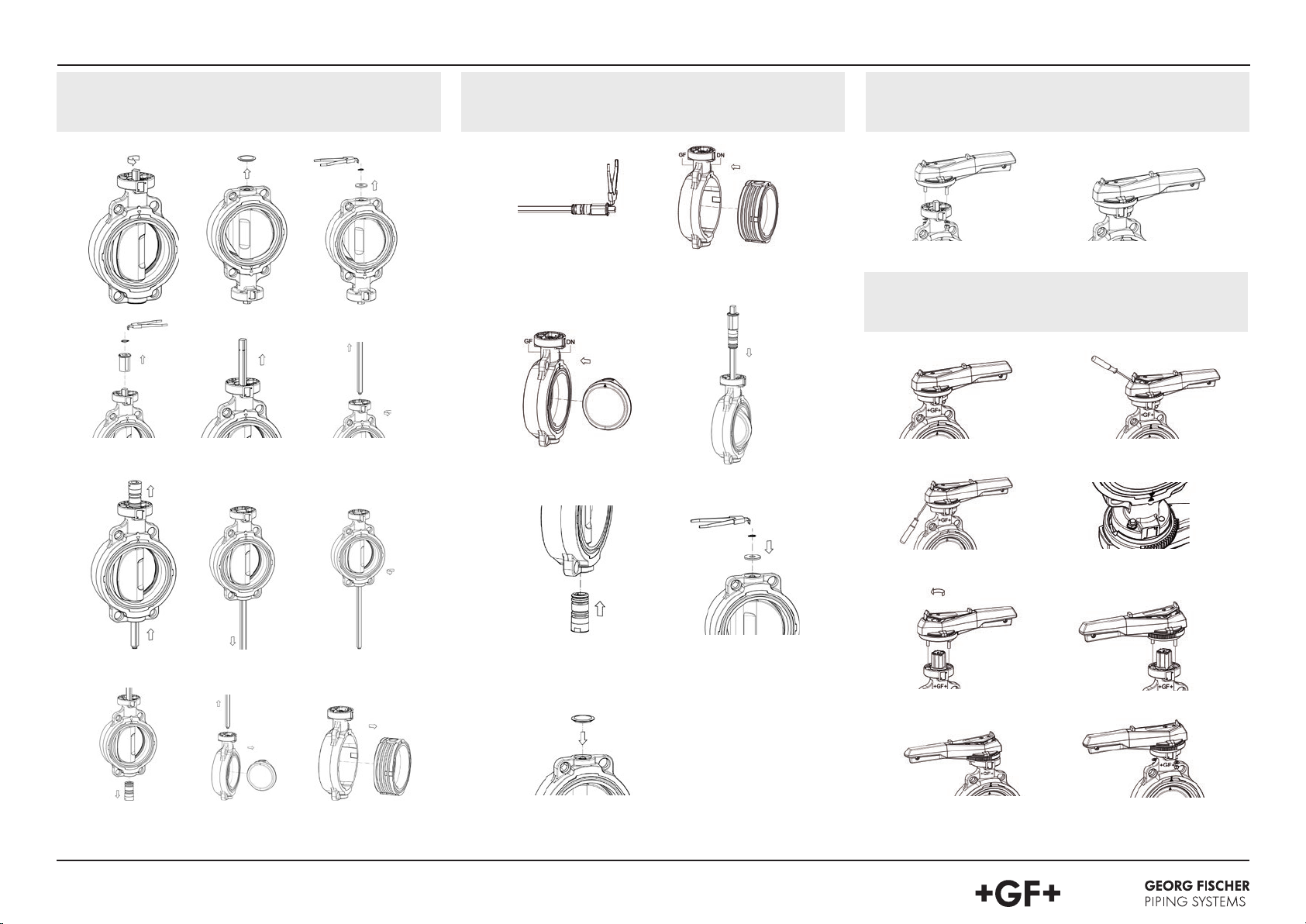

Quick Guide

Butterfly Valve Type 567/ 568

8.1 Disassembly Butterfly valve type 567/ 568

8.2 Assembly Butterfly valve type 567/ 568

8.3 Assembly hand lever

1 2 3

4 5 6

7 8 9

1 2

3 4

5 6

1 2

8.4 Turn of the hand lever

1 2

3 4

5 6

10 11 12

GFDO 6325 1_4 (06.2013)

Additional sheet for Instruction Manual „Butterfly Valve Type 567/ 568“, chapter 8

7

7 8

Loading...

Loading...