Instruction Manual

Model LC-2x4

4 Channel VW Datalogger

No part of this instruction manual may be reproduced, by any means, without the written consent of Geokon, Inc.

The information contained herein is believed to be accurate and reliable. However, Geokon, Inc. assumes no responsibility

for errors, omissions or misinterpretation. The information herein is subject to change without notification.

Copyright © 2007 - 2018 by Geokon, Inc.

(Doc Rev W, 11/14/2018)

Warranty Statement

Geokon, Inc. warrants its products to be free of defects in materials and workmanship, under

normal use and service for a period of 13 months from date of purchase. If the unit should

malfunction, it must be returned to the factory for evaluation, freight prepaid. Upon examination

by Geokon, if the unit is found to be defective, it will be repaired or replaced at no charge.

However, the WARRANTY is VOID if the unit shows evidence of having been tampered with

or shows evidence of being damaged as a result of excessive corrosion or current, heat, moisture

or vibration, improper specification, misapplication, misuse or other operating conditions outside

of Geokon's control. Components which wear or which are damaged by misuse are not

warranted. This includes fuses and batteries.

Geokon manufactures scientific instruments whose misuse is potentially dangerous. The

instruments are intended to be installed and used only by qualified personnel. There are no

warranties except as stated herein. There are no other warranties, expressed or implied, including

but not limited to the implied warranties of merchantability and of fitness for a particular

purpose. Geokon, Inc. is not responsible for any damages or losses caused to other equipment,

whether direct, indirect, incidental, special or consequential which the purchaser may experience

as a result of the installation or use of the product. The buyer's sole remedy for any breach of this

agreement by Geokon, Inc. or any breach of any warranty by Geokon, Inc. shall not exceed the

purchase price paid by the purchaser to Geokon, Inc. for the unit or units, or equipment directly

affected by such breach. Under no circumstances will Geokon reimburse the claimant for loss

incurred in removing and/or reinstalling equipment.

Every precaution for accuracy has been taken in the preparation of manuals and/or software,

however, Geokon, Inc. neither assumes responsibility for any omissions or errors that may

appear nor assumes liability for any damages or losses that result from the use of the products in

accordance with the information contained in the manual or software.

TABLE OF CONTENTS

1. INTRODUCTION .................................................................................................................................................. 1

2. GETTING STARTED ............................................................................................................................................ 2

TRANSDUCER INSTALLATION .............................................................................................................................. 2

2.1

2.1.1 Cable Gland Models (8002-4-1, 8002-4-2, 8002-4-3) ............................................................................... 2

2.1.2 10-pin Bulkhead Models (8002-4A-1, 8002-4A-2, 8002-4A-3) .................................................................. 3

BATTERY INSTALLATION .................................................................................................................................... 4

2.2

ACCESSORIES ...................................................................................................................................................... 4

2.3

EARTH GROUND INSTALLATION ......................................................................................................................... 4

2.4

SOFTWARE INSTALLATION AND SETUP ............................................................................................................... 5

2.5

2.5.1 LogView Installation .................................................................................................................................. 5

2.5.2 Launching LogView .................................................................................................................................... 5

2.5.3 LogView Workspaces ................................................................................................................................. 6

2.5.4 Adding Projects to LogView Workspaces ................................................................................................... 7

2.5.5 Adding Dataloggers to LogView Projects .................................................................................................. 8

2.5.6 LC-2x4 Connection (8002-4-1, RS-232) ....................................................................................................10

2.5.7 LC-2x4 Connection (8002-4-2, USB) ........................................................................................................10

2.5.8 LC-2x4 Connection 8002-4-3 (RS_485) ....................................................................................................10

2.5.9 Connecting to a Datalogger with LogView ...............................................................................................11

2.5.10 Determining COM Port Numbers ...........................................................................................................12

COMMUNICATION SETUP EXAMPLE USING HYPERTERMINAL ...........................................................................13

2.6

3. COMMAND LIST .................................................................................................................................................17

3.1

“BRNNN”- SET OR DISPLAY THE CURRENT BAUD RATE ....................................................................................17

“C” - DISPLAY CURRENT CLOCK SETTINGS .......................................................................................................17

3.2

“CSMM/DD/YY/HH:MM:SS” - SET THE INTERNAL CLOCK ...................................................................................17

3.3

“DEFAULT” – LOAD FACTORY DEFAULT SETTINGS ........................................................................................17

3.4

“DF” - DISPLAY OR SET DATE FORMAT .............................................................................................................18

3.5

“DL” – DISPLAY CURRENT MODE .....................................................................................................................18

3.6

“DNNNN” - DISPLAY ARRAYS FORWARD FROM USER POSITION ........................................................................18

3.7

“E” - LOW POWER SLEEP MODE ........................................................................................................................19

3.8

“GNN/C/TT/SZZZZZZ/SFFFFFF/SOOOOOO” OR “GNN/C/TT/SAAAAAA/SBBBBBB/SCCCCCC” – GAGE SETTINGS .....20

3.9

“IDDDDDDDDDDDDDDDDD” - DISPLAY OR SET DATALOGGER ID ...................................................................24

3.10

“L” - DISPLAY LOG INTERVALS .......................................................................................................................24

3.11

“LN/LLLLL/III” - DEFINE LENGTH AND ITERATION OF INTERVAL .....................................................................25

3.12

“LD” - DISABLE LOG INTERVALS ....................................................................................................................26

3.13

“LE” - ENABLE LOG INTERVALS ......................................................................................................................26

3.14

“M” - DISPLAY CURRENT MONITOR MODE SETTING .......................................................................................26

3.15

“MD” - DISABLE MONITOR MODE ...................................................................................................................26

3.16

“ME” - ENABLE MONITOR MODE ....................................................................................................................26

3.17

“MXS” – DISPLAY MULTIPLEXER STATUS ......................................................................................................27

3.18

“MXN” – SET THE MAXIMUM NUMBER OF CHANNELS ....................................................................................27

3.19

“N” - DISPLAY NEXT MEASUREMENT CYCLE ..................................................................................................27

3.20

“NA” - DISPLAY NETWORK ADDRESS .............................................................................................................28

3.21

“NADDD” - SET NETWORK ADDRESS ..............................................................................................................28

3.22

“ND” - NETWORK DISABLE .............................................................................................................................29

3.23

“NE” - NETWORK ENAB LE ...............................................................................................................................29

3.24

“NS” - DISPLAY NETWORK STATUS .................................................................................................................29

3.25

“PNNNN” - SET USER POSITION MEMORY POINTER .........................................................................................30

3.26

“R” - RESET MEMORY POINTERS .....................................................................................................................30

3.27

“RESET” - REBOOT THE LC-2 MICROPROCESSOR ...........................................................................................30

3.28

“S” – DISPLAY STATUS ....................................................................................................................................30

3.29

“SCNNNNN” - SET SCAN INTERVAL .................................................................................................................31

3.30

“SS” - DISPLAY SYSTEM STATUS .....................................................................................................................31

3.31

“SPHH:MM” - STOP LOGGING ..........................................................................................................................32

3.32

“SR” - SYNCHRONIZE READINGS .....................................................................................................................32

3.33

3.34 “STHH:MM” - START LOGGING ........................................................................................................................ 33

“SV” - DISPLAY SOFTWARE VER SION ............................................................................................................. 33

3.35

“TEST” - PERFORM INTERNAL SELF-TESTS .................................................................................................... 33

3.36

“TF” - DISPLAY OR SET TIME FORMA .............................................................................................................. 34

3.37

“TNN/T” – SET THERMISTOR TYPE .................................................................................................................. 35

3.38

“TR” - DISPLAY CURRENT TRAP COUNT ......................................................................................................... 35

3.39

“TR0” - RESET TRAP COUNT ........................................................................................................................... 35

3.40

“VL” – DISPLAY COIN CELL VOLTAGE ........................................................................................................... 35

3.41

“V3” – DISPLAY THE D CELL BATTERY VOLTAGE .......................................................................................... 36

3.42

“V12” – DISPLAY THE EXTERNAL BATTERY VOLTAGE ................................................................................... 36

3.43

“WF” - DISPLAY CURRENT WRAP FORMAT ..................................................................................................... 36

3.44

“X” - TAKE IMMEDIATE READING ................................................................................................................... 37

3.45

4. MAINTENANCE .................................................................................................................................................. 38

4.1

CLEANING.......................................................................................................................................................... 38

BATTERIES ......................................................................................................................................................... 38

4.2

5. TROUBLESHOOTING ........................................................................................................................................ 39

APPENDIX A. SPECIFICATIONS ......................................................................................................................... 40

A.1

MEASUREMENT CAPABILITY ............................................................................................................................ 40

POWER .............................................................................................................................................................. 40

A.2

MEMORY .......................................................................................................................................................... 40

A.3

CLOCK .............................................................................................................................................................. 41

A.4

SERIAL INTERFACE (ALL LC-2X4 MODELS) ...................................................................................................... 41

A.5

RS-485 NETWORK ............................................................................................................................................ 41

A.6

VIBRATING WIRE MEASUREMENT .................................................................................................................... 41

A.7

INTERNAL/EXTERNAL TEMPERATURE MEASUREMENT ..................................................................................... 41

A.8

MAIN BATTERY MEASUREMENT ....................................................................................................................... 42

A.9

MULTIPLEXER RELAY ..................................................................................................................................... 42

A.10

APPENDIX B. CONNECTOR PINOUTS .............................................................................................................. 43

B.1

TRANSDUCER CABLE CONNECTIONS................................................................................................................. 43

RS-232 CONNECTOR PINOUT (8002-4-1) .......................................................................................................... 43

B.2

USB CONNECTOR PINOUT (8002-4-2) .............................................................................................................. 44

B.3

RS-485 CONNECTOR PINOUT (OPTIONAL, 8002-4-3) ........................................................................................ 44

B.4

APPENDIX C. DATA FILE TRANSFER TO A WINDOWS PC ........................................................................ 45

C.1

DOWNLOADING DATA USING LOGVIEW ........................................................................................................... 45

DOWNLOADING DATA USING HYPERTERM INAL (OR EQUIVALENT) .................................................................. 46

C.2

APPENDIX D. SAMPLE DATA FILE ................................................................................................................... 49

D.1

SAMPLE RAW DATA FILE .................................................................................................................................. 49

APPENDIX E. THERMISTOR TEMPERATURE DERIVATION ..................................................................... 50

APPENDIX F. NETWORKING .............................................................................................................................. 53

DESCRIPTION ..................................................................................................................................................... 53

F.1

EXAMPLE OF A FOUR-DATALOGGER NETWORKING SESSION ............................................................................ 53

F.2

APPENDIX G. LITHIUM COIN CELL ................................................................................................................. 55

G.1

DESCRIPTION .................................................................................................................................................... 55

REPLACEMENT PROCEDURE .............................................................................................................................. 55

G.2

APPENDIX H. MODEL 8032-27 AND LOAD CELL WIRING .......................................................................... 57

APPENDIX I. BATTERY REPLACEMENT INSTRUCTIONS FOR UNITS MANUFACTURED BEFORE

SEPTEMBER 2018 ................................................................................................................................................... 58

FIGURES

FIGURE 1 - BATTERY DETAIL......................................................................................................................................... 4

FIGURE 2 - SELECT WORKSPACE NAME ......................................................................................................................... 6

FIGURE 3 - SELECT WORKSPACE FOLDER ...................................................................................................................... 6

FIGURE 4 - LOGVIEW MAIN WINDOW ........................................................................................................................... 7

FIGURE 5 - LOGVIEW MAIN WINDOW WITH NEW PROJECT ............................................................................................ 8

FIGURE 6 - LOGVIEW CONTEXT MENU .......................................................................................................................... 9

FIGURE 7 - DATALOGGER SETTINGS, CONNECTION OPTIONS ........................................................................................ 9

FIGURE 8 - DATALOGGER HIGHLIGHTED, NOT CONNECTED .........................................................................................10

FIGURE 9 - DATALOGGER CONNECTION MISMATCH .....................................................................................................11

FIGURE 10 - DATALOGGER CONNECTED .......................................................................................................................11

FIGURE 11 - PC INTERNAL COM PORT .........................................................................................................................12

FIGURE 12 - DEVICE MANAGER PORTS LIST .................................................................................................................12

FIGURE 13 - HYPERTERMINAL CONNECTION DESCRIPTION ..........................................................................................13

FIGURE 14 - COM PORT SELECTION .............................................................................................................................13

FIGURE 15 - COM PORT SETTINGS ...............................................................................................................................14

FIGURE 16 - ORDER OF ARRAY USAGE .........................................................................................................................19

FIGURE 17 - LOGVIEW COLLECT DATA BUTTON ..........................................................................................................45

FIGURE 18 - DATA COLLECTION PROGRESS BAR ..........................................................................................................45

FIGURE 19 - DATA COLLECTION COMPLETE MESSAGE.................................................................................................46

FIGURE 20 – HYPERTERMINAL CONNECTION DESCRIPTION .........................................................................................46

FIGURE 21 - HYPERTERMINAL CONNECTION SELECTION .............................................................................................46

FIGURE 22 - HYPERTERMINAL COM PORT SETTINGS ..................................................................................................47

FIGURE 23 - HYPERTERMINAL TRANSFER MENU .........................................................................................................47

FIGURE 24 - SPECIFY DATA CAPTURE FILE ..................................................................................................................48

FIGURE 25 - HYPERTERMINAL/DATALOGGER COMMUNICATION .................................................................................48

FIGURE 26 - MODEL 8032-27 JUMPER WIRE ASSEMBLY ..............................................................................................57

FIGURE 27 - BATTERY INSTALLATION DETAIL .............................................................................................................58

TABLES

TABLE 1 - TRANSDUCER CABLE CONNECTIONS ............................................................................................................. 3

TABLE 2 - VIBR ATING WIRE GAGE TYPES ....................................................................................................................22

TABLE 3 - GAGE TYPE DESCRIPTIONS ..........................................................................................................................23

TABLE 4 - ENGINEERING UNITS MULTIPLICATION FACTORS ........................................................................................23

TABLE 5 - LOGARITHMIC INTERVALS LIST ...................................................................................................................25

TABLE 6 - S COMMAND INFORMATION .........................................................................................................................31

TABLE 7 - SS COMMAND INFORMATION .......................................................................................................................31

TABLE 8 - TEST MENU INFORMATION .........................................................................................................................34

TABLE 9 - APPROXIMATE OPERATING TIMES ...............................................................................................................38

TABLE 10 - TRANSDUCER CABLE CONNECTIONS ..........................................................................................................43

TABLE 11 - RS-232 CONNECTOR PINOUT .....................................................................................................................43

TABLE 12 - USB CONNECTOR PINOUT .........................................................................................................................44

TABLE 13 - RS-485 CONNECTOR PINOUT .....................................................................................................................44

TABLE 14 - STANDARD THERMISTOR RESISTANCE VERSUS TEMPERATURE .................................................................50

TABLE 15 - BR55KA822J THERMISTOR RESISTANCE VERSUS TEMPERATURE .............................................................51

TABLE 16 - 103JL1A THERMISTOR RESISTANCE VERSUS TEMPERATURE ....................................................................52

TABLE 17 - COMMON CONDUCTOR CHART ..................................................................................................................57

TABLE 18 - MULTIPLEXER BOARD WIRING ..................................................................................................................57

EQUATIONS

EQUATION 1 - DISPLAYED GAGE READING USING LINEAR CONVERSION .....................................................................21

EQUATION 2 - DISPLAYED GAGE READING USING POLYNOMIAL CONVERSION ............................................................22

EQUATION 3 - DIGITS CALCULATION USING LINEAR CONVERSION ..............................................................................23

EQUATION 4 - DIGITS CALCULATION USING POLYNOMIAL CONVERSION .....................................................................23

EQUATION 5 - CONVERT THERMISTOR RESISTANCE TO TEMPERATURE .......................................................................50

EQUATION 6 - CONVERT THERMISTOR, TYPE BR55KA822J, RESISTANCE TO TEMPERATURE .....................................51

EQUATION 7 - CONVERT THERMISTOR, TYPE 103JL1A, RESISTANCE TO TEMPERATURE .............................................52

1

1. INTRODUCTION

Model 8002-4, LC-2x4, 4-Channel Datalogger is a low cost, battery powered, easy to use

measurement instrument, designed to read up to four vibrating wire sensors equipped with

thermistors.

The 320K standard memory provides storage for 10666 data arrays. Each array consists of an

optional datalogger ID string (16 characters maximum), a timestamp consisting of the year, date

(Julian day or month/day format), time (hhmm or hours/minutes format) and seconds when the

reading was taken. Also included in the data is the internal 3V (or external 12V) battery voltage,

the datalogger temperature, the vibrating wire readings, the transducer temperature and the Array

number.

Internal math is calculated using 32-bit floating point notation (IEEE). Math operations on the

instrument readings, such as application of zero readings, gage factors (or calibration factors)

and offsets when using a linear conversion technique or polynomial coefficients when using the

polynomial conversion, provide outputs directly in engineering units. The dataloggers internal

configuration is defined through communication with a computer using the supplied RS-232 or

USB (or optional RS-485) interface cable. The datalogger is configured and monitored using

LogView, a Geokon proprietary Graphic User Interface (GUI) software application (See Section

2.5). The datalogger can also be configured and monitored via text-based commands with any

standard terminal emulator software, such as Microsoft Windows HyperTerminal™ (see Section

3).

The communication method for each model of the LC-2x4 is described below

8002-4-1: Communication with the LC-2x4 is implemented via the host computer’s RS-232

COM port. See Section 2.5.6 for further information.

8002-4-2: Communication with the LC-2x4 is implemented via the host computer’s USB 2.0

port. When connected to a computer via the USB port, the LC-2x4 appears to the

computer as a “virtual” COM port. The LC-2x4 datalogger also receives all of its

operating power from the computer, thus extending the internal 3V (or external

12V) battery life. When disconnected from the USB port, the datalogger

automatically switches to the internal 3V (or external 12V) battery pack. See

Section 2.5.7 for further information.

8002-4-3: Communication with the LC-2x4 is implemented via RS-485. This allows for

long communication cables (up to 4000’) between the host computer and the LC2x4. The ability to network two or more LC-2x4 dataloggers together is also

available with this communication option. See Section 2.5.8 and Appendix F

Networking for further information.

All data, both readings and configuration, are stored in non-volatile EEPROM with a typical

storage life of 10 years (minimum). The internal temperature compensated real-time clock, used

to provide timekeeping and triggering of readings, is accurate to approximately two minutes per

year. The comma delineated ASCII output format allows for easy importing into popular

spreadsheet programs such as Lotus 1-2-3 or Microsoft Excel. See Appendix D for sample data

files.

2

2. GETTING STARTED

The following equipment will arrive with the Model LC-2x4 datalogger:

(If any accessories are missing or damaged, please contact the factory.)

• Set of two alkaline D cell batteries.

• Set of four desiccant packs packaged with the batteries.

• Accessories:

Shipped with the 8002-4-1: Part #8002-10-RS232 comprising: a USB to RS-232 serial

adapter cable, a RS-232 Communication Cable (DB-9F to 10-pin Bendix Male), a #3

Phillips head screwdriver, and a 3/32" flat head screw driver.

Shipped with the 8002-4-2: Part #8002-10-USB comprising: USB Communication

Cable (USB-A to 10-pin Bendix Male) a #3 Phillips head screwdriver, and a 3/32" flat

head screw driver.

Shipped with the 8002-4-3: USB Communication Cable (USB-A to 10-pin Bendix

Male), RS-485 Interface for PC, RS-485 patch cord

2.1 Transducer Installation

2.1.1 Cable Gland Models (8002-4-1, 8002-4-2, 8002-4-3)

1) Open the datalogger by unscrewing the four captive screws on the front of the

enclosure. Make sure that no dirt, water or other contaminants are allowed to

enter the enclosure.

2) Loosen the nuts on the cable fittings and remove the white plastic dowels.

3) Thread the transducer cables through the cable fittings.

4) Connect the cable wires to the datalogger’s 5-pin internal terminal blocks, located on

the Multiplexer circuit board. (NOTE: The multiplexer board is mounted on the

right side of the enclosure. Do not connect any transducer cables to the terminal

block located on the battery board.) Wire each conductor of the cable into the

correct position in the terminal block by pressing down on the corresponding orange

tab at the back, inserting the conductor, and then releasing the orange tab. Refer to

Table 1 for transducer wiring information. (See also Appendix B.)

3

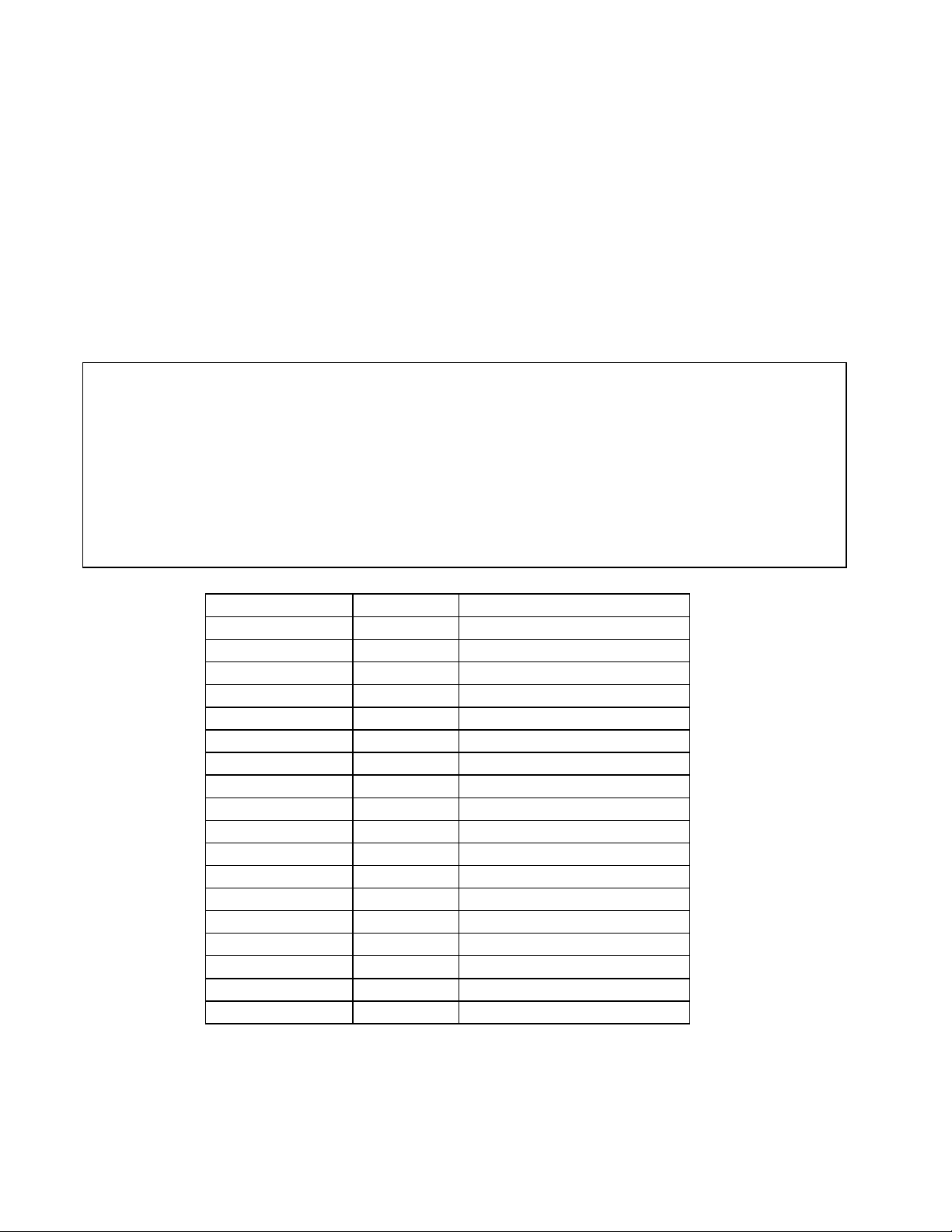

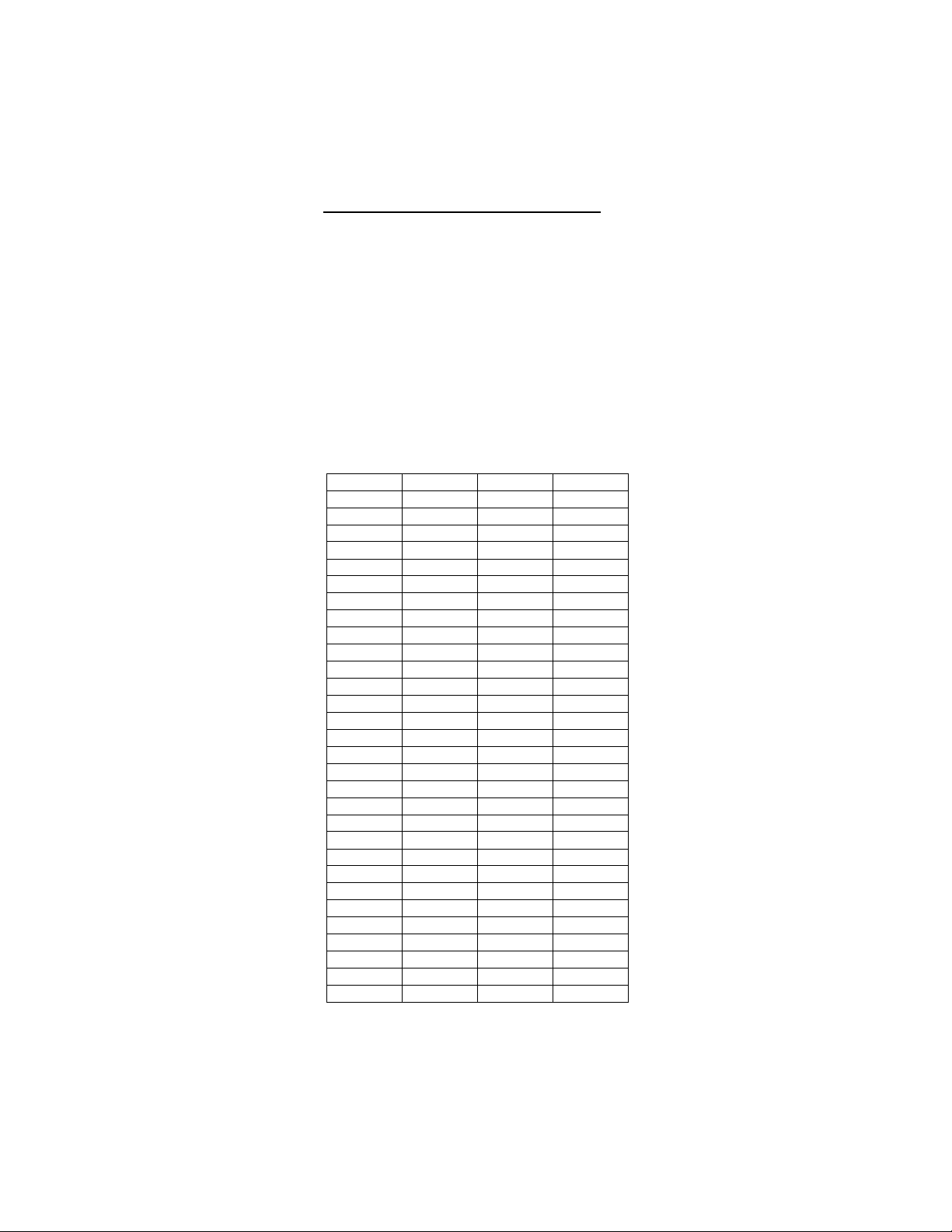

Cable

Color

VW1+

1

Vibrating Wire +

RED

VW1-

1

Vibrating Wire -

BLACK

TH1+

1

Thermistor +

WHITE

TH1-

1

Thermistor -

GREEN

Analog Ground

(shield)

BARE

WIRE

VW2+

2

Vibrating Wire +

RED

VW2-

2

Vibrating Wire -

BLACK

TH2+

2

Thermistor +

WHITE

TH2-

2

Thermistor -

GREEN

Analog Ground

(shield)

BARE

WIRE

VW3+

3

Vibrating Wire +

RED

VW3-

3

Vibrating Wire -

BLACK

TH3+

3

Thermistor +

WHITE

TH3-

3

Thermistor -

GREEN

Analog Ground

(shield)

BARE

WIRE

VW4+

4

Vibrating Wire +

RED

VW4-

4

Vibrating Wire -

BLACK

TH4+

4

Thermistor +

WHITE

TH4-

4

Thermistor -

GREEN

Analog Ground

(shield)

BARE

WIRE

Terminal

Block Position

SHLD1 1

SHLD2 2

SHLD3 3

Channel

Number

Description

Wire

SHLD4 4

5) Tighten the nuts on the cable fittings so that they securely grip the cables. This must

be done to ensure that water does not enter the enclosure. (Beware of

overtightening, which may damage the plastic threads.)

2.1.2 10-pin Bulkhead Models (8002-4A-1, 8002-4A-2, 8002-4A-3)

Transducers are attached to the datalogger with 10-pin Bulkhead connectors. Align the

grooves on the transducer connector (male), with the connector on the unit (female). Push

the connector into place and then twist the outer ring of the male connector until it locks.

Table 1 - Transducer Cable Connections

4

2.2 Battery Installation

Install the batteries as follows:

(For units manufactured prior to September 2018, refer to Appendix I.)

1) Open the device by unscrewing the four captive screws on the front of the enclosure. Make

sure that no dirt, water or other contaminants are allowed to enter the enclosure.

2) Install the batteries by aligning the positive (+) side of the D cells with the left side of the

battery holder. Push the batteries straight down into the holder.

Figure 1 - Battery Detail

3) The battery select switch (located to the right of the battery holder) is set to “Alkaline” at the

factory. If using lithium batteries, move the switch to the “Lithium” position.

2.3 Accessories

After the batteries have been installed:

1) Remove the desiccant packs from the plastic seal top bag they were shipped in and place

them inside the enclosure.

2) Reinstall the cover. Ensure that the rubber gasket clean and properly seated in the groove on

the underside of the cover. Tighten the screws a little at a time, working in a diagonal pattern.

Make sure the cover seals tightly and evenly.

2.4 Earth Ground Installation

The LC-2x4 provides lightning protection in the form of gas tube surge arrestors. In order for

these components to divert the energy from a lightning strike safely to ground, a good solid

electrical connection to earth ground needs to be made. A grounding rod should be driven (or

other suitable attachment to earth utilized) to ground the system and provide a path to earth in the

event of a lightning strike. A 6' to 8' copper stake with appropriate large gauge wire (12 AWG or

larger) connected to the LC-2x4 enclosure is suggested. The stake should be driven as close to

the datalogger as possible, and to a depth of at least one meter (three feet). A copper grounding

lug is supplied on the exterior of the LC-2x4 enclosure to provide connection to this wire from

the grounding rod.

5

2.5 Software Installation and Setup

LogView is Graphical User Interface (GUI) software is used to communicate with the datalogger

using a personal computer running a Microsoft Windows® operating system. Other general

purpose communication programs (e.g., Windows HyperTerminal™) can also be used to

communicate with the Model LC-2x4 via text-based commands. The LogView and USB drivers

install program can be downloaded at www.geokon.com/software.

Perform the following steps to install LogView software for each computer that will connect to

an LC-2x4. These instructions are for computers running Windows XP. The installation

procedure is very similar for computers running Windows7, Windows 2000 and Windows 98.

This installation procedure needs to be performed only once for each computer that will run

LogView to communicate with an LC-2x4 datalogger.

NOTE: The USB drivers are only required for LC-2x4 models 8002-4-2 and the 8002-5 RS-485

Interface

Make sure that the two 1.5-volt D cell alkaline batteries are installed in the datalogger (See

Section 2.2, “Battery Installation” for instructions) and that the LC-2x4 datalogger is not

connected to the computer at this time.

2.5.1 LogView Installation

1) Using Windows Explorer, navigate to the extracted downloaded files and double

click on the file “start.bat” to start the install process.

2) Click “ >” when the Welcome window appears.

3) When the Choose Install Location window appears, choose a folder for the

LogView installation then click “Next>”.

4) When the Choose Start Menu Folder window appears, choose an appropriate

folder (default is Geokon) then click “Install”.

5) Click “Next >” when the Java Installation Complete window appears.

6) Click “Finish” when the Completing the LogView Setup Wizard window appears.

2.5.2 Launching LogView

Launching LogView can be accomplished two different ways. Double clicking on the

desktop icon:

Or via the Windows Start button: “Programs → Geokon → LogView”

6

2.5.3 LogView Workspaces

When opening LogView for the first time, the user will be prompted to create a

workspace name (see Figure 2). The workspace name can be any combination of letters

and numbers and, ideally, will be descriptive in nature. See the LogView User’s Guide

for more information on workspaces.

Figure 2 - Select Workspace Name

Once the workspace name has been selected, clicking on “Ok” causes LogView to

prompt the user to choose or create a folder where all the workspace elements will be

stored (see Figure 3). The folder location can be entered directly, e.g.,

C:\Workspaces\East Coast or the Browse button can be used to navigate to a folder

location or to create a new folder (see Figure 3). This workspace location will be stored in

the LogView configuration for subsequent application access. Once workspaces are

created, future user access is always by name.

Figure 3 - Select Workspace Folder

If no other is specified, a default folder path is displayed based on the system default

workspace path combined with the new workspace name. After the folder path has been

specified, either the default or user selected, clicking on “Ok” will display the main

window of LogView (see Figure 4). On the left-hand side of the main window is the

Project Explorer displaying the newly created workspace. The user can now add new

project(s), datalogger(s) and sensor configurations to the workspace by right-clicking on

the workspace and using the menu tools.

7

Figure 4 - LogView Main Window

2.5.4 Adding Projects to LogView Workspaces

Right-clicking on the “PRODUCTION” workspace brings up a context sensitive menu

that allows the user to add projects to this workspace (using the “New→Project” menu

selection). Select a name that makes sense for the real-world project this program will be

used for. In this example “TestLoggers” was chosen as the project name (see Figure 5

below)

8

Figure 5 - LogView Main Window with new project

2.5.5 Adding Dataloggers to LogView Projects

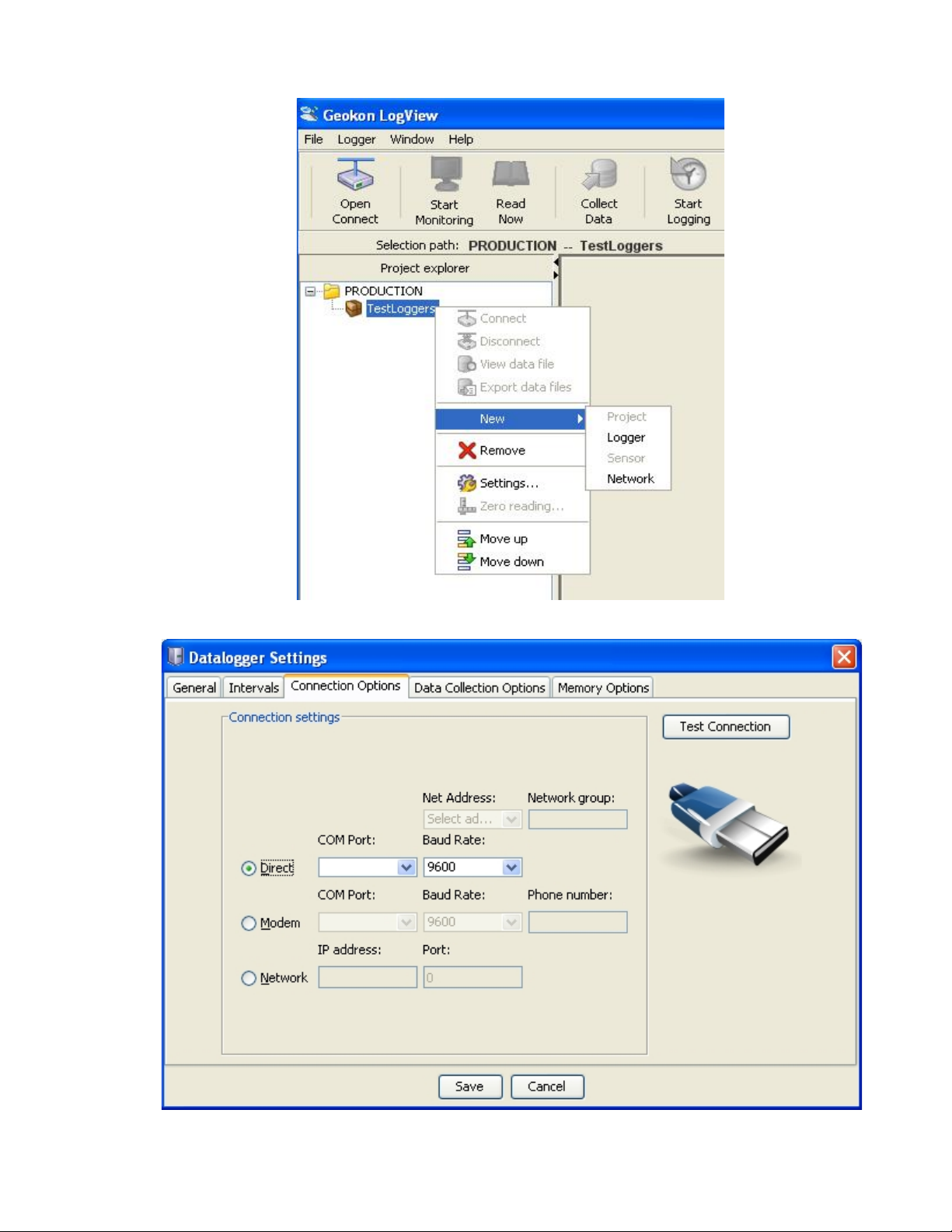

Right-clicking on the “TestLoggers” project brings up a context sensitive menu (see

Figure 6) that allows users to add dataloggers to their projects. Selecting New→Logger

from the context menu causes the “Datalogger Settings” dialog to be displayed. Like

Workspaces and Projects, Dataloggers can be assigned a unique human-readable name. For

this example, “MyLogger” was chosen for the Datalogger name. For a complete

description of all datalogger settings please see the LogView Online Help section on

Datalogger Settings. For connection purposes, the relevant tab in this dialog is

“Connection Options” (see Figure 7).

After physically connecting to a PC, all LC-2x4 dataloggers require a COM port to be

identified in the “Connection Options”. Starting with firmware revision 3.1.X, LC-2x4

dataloggers can communicate at baud rates of 9600 and 115,200. Before this revision the

datalogger baud rate was 9600 only; for these dataloggers, the default setting should not be

changed (See Figure 7).

9

Figure 6 - LogView Context Menu

Figure 7 - Datalogger Settings, Connection Options

10

2.5.6 LC-2x4 Connection (8002-4-1, RS-232)

Connect the supplied LC-2x4 RS-232 Communications cable (S-8001-6) to the COM port

of the LC-2x4 datalogger. The protective cap on the datalogger COM connector is

removed by pushing in and turning. Plug the DB-9 end of the RS-232 Communications

cable into the host computer’s RS-232 port (either internal or external via a USB to Serial

converter). Proceed to Section 2.5.9, Connecting to a Datalogger with LogView.

2.5.7 LC-2x4 Connection (8002-4-2, USB)

Connect the supplied LC-2x4 USB Communications cable (COM-109) to the USB port of

the LC-2 datalogger. The protective cap on the datalogger USB connector is removed by

pushing in and turning. Plug the USB-A end of the USB cable into an available USB-2.0

port on the host computer.

NOTE: On certain PCs with operating systems older than XP, Service Pack 3, the 80024-2 may require the installation of a driver to properly communicate with the PC. If the

PC does not recognize the datalogger’s internal USB to serial converter then the driver

may need to be installed by executing the program, CDMv2_xxxx, from the LogView

Install folder. Proceed to Section 2.5.9, Connecting to a Datalogger with LogView.

2.5.8 LC-2x4 Connection 8002-4-3 (RS_485)

Make the COM port connection per Section 2.5.6 (RS-232) or 2.4.7 (USB), and then refer

to Appendix F: Networking to establish communications.

Figure 8 - Datalogger Highlighted, Not Connected

11

2.5.9 Connecting to a Datalogger with LogView

1) With a Datalogger profile configured and selected in the Project Explorer (see Figure

8), click on the “Open Connect” button on the LogView Toolbar.

2) When connecting to a new Datalogger for the first time, the message below (see Figure

9) may be displayed after a few seconds. This is normal and is only an indication that

the datalogger does not match the configuration created in the Project Explorer. Click

on “Continue” to finish connecting to the datalogger.

3) Click on the “Upload Settings” button on the LogView Toolbar to synchronize the

datalogger with the LogView configuration (see Figure 10).

4) LogView is now connected and configured correctly for the LC-2x4 datalogger. Sensors

can now be added to the datalogger in a similar fashion as adding Dataloggers to

Projects. Sensor settings are accessed via the context menu from the Project Explorer.

5) Always upload the new settings to the datalogger after changing its configuration in

LogView.

Figure 9 - Datalogger Connection Mismatch

Figure 10 - Datalogger Connected

12

2.5.10 Determining COM Port Numbers

When connecting an 8002-4-1 datalogger to a PC with an internal serial port(s) the COM

Port number that LogView requires is usually COM1 or COM2 but, occasionally may be

COM3 if the PC has more than one internal serial port. Figure 11 below illustrates that the

PC has two serial ports, one internal (COM1) and the other via a USB to serial converter

(COM13).

Figure 11 - PC Internal COM Port

When connecting an 8002-4-2 datalogger to a PC the COM Port number LogView requires

can be any number and depends on how many other devices are attached to the PC like,

internal serial ports and Bluetooth devices. Figure 12 below illustrates that the PC has three

serial ports, one internal (COM1) and the other two via USB to serial converters (COM13

and COM3). One way to determine which COM port an 8002-4-2 datalogger is attached to

is to disconnect the cable and see which COM device disappears from the Device Manager

Ports list.

Figure 12 - Device Manager Ports List

In this case, COM3 is actually the 8002-4-2 datalogger and not a universally available

serial port.

13

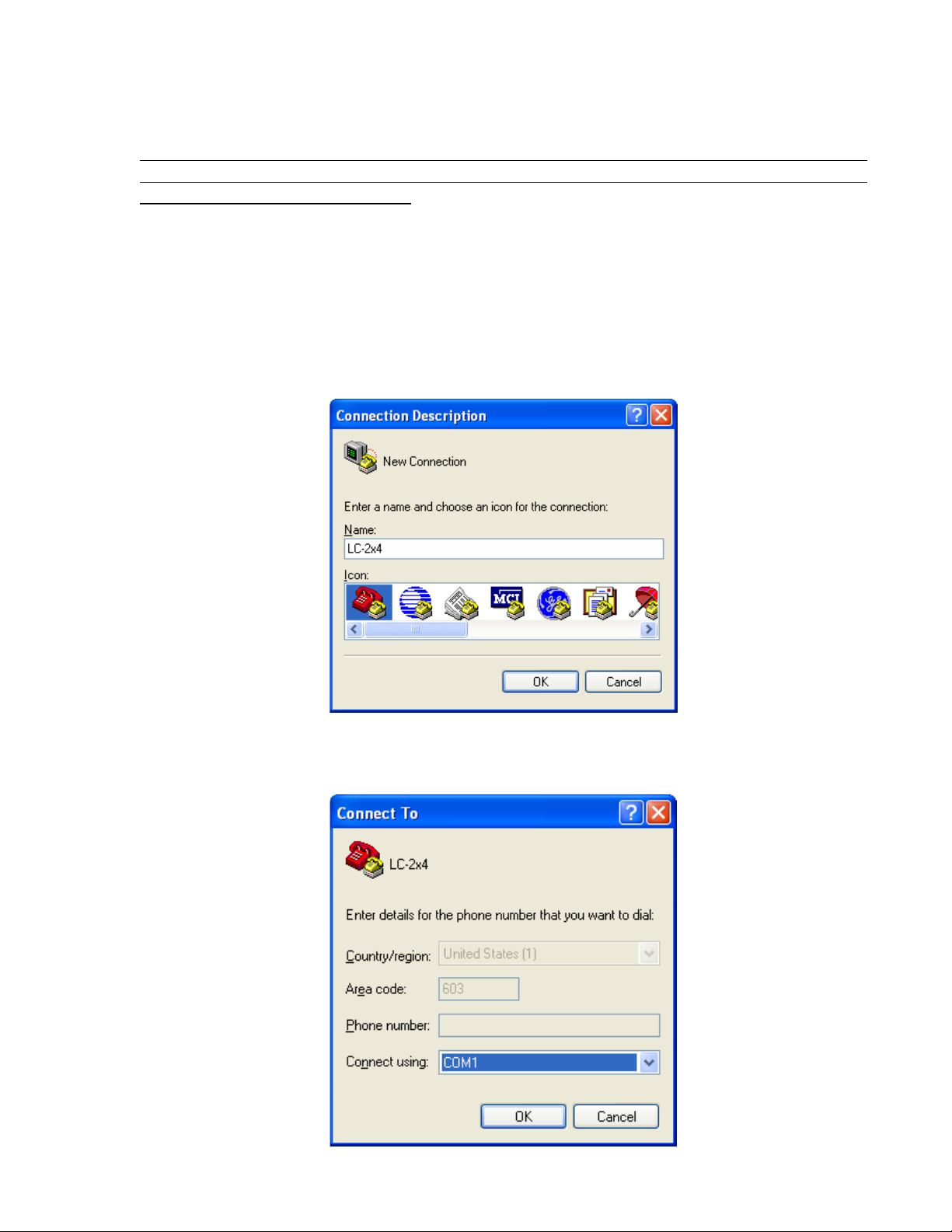

2.6 Communication Setup Example Using HyperTerminal

NOTE: If using a 8002-4-2 USB LC-2x4, it is important that the LC-2x4 first be connected to the

computer’s USB port before attempting to communicate so that the LC-2x4 can be recognized by

the computer as a virtual COM port.

Proceed with the following steps to connect with the datalogger using a terminal emulator

program such as Microsoft Windows HyperTerminal™:

1) Launch HyperTerminal (Start → All Programs → Accessories → Communications → HyperTerminal). If

running under Vista or newer, contact Geokon for Geokon’s Terminal Window Software.

2) Enter a name for the New Connection and click OK (see Figure 13):

Figure 13 - HyperTerminal Connection Description

3) In the Connect Using window, select the appropriate COM port (see Figure 14):

Figure 14 - COM Port Selection

14

4) In the COM Properties window, configure the COM port (see Figure 15):

Figure 15 - COM Port Settings

8002-4-1 (RS-232): Configure the COM port (typically COM1 or COM2) as 9600 Bits per

second, 8 Data bits, no Parity, 1 Stop bit, no Flow control.

8002-4-2 (USB): Configure the new COM port that is added when the LC-2x4 is connected as

9600 Bits per second, 8 Data bits, no Parity, 1 Stop bit, no Flow control.

5) Click Apply then OK.

6) Press <ENTER> <ENTER> to wake the datalogger from sleep. The datalogger returns the

power up prompt:

Hello. Press "?" for Help.

*

Note: If no characters are received in 15 seconds the datalogger (non-networked)

will return to its low power sleep mode. Press <ENTER> <ENTER> to wake it

again.

Note: When network commands are enabled and RS-485 is being used, the address

must be sent before the respective datalogger will respond. See Sections 3.21 thru

3.25 for additional information.

15

1) Type ? <ENTER> to display the Help list. See Section 3 for detailed information on all the

commands listed. Note: All commands must be entered in capital letters.

*?

Command Description

-----------------------------------------------C View current Clock

CSmm/dd/yy/hh:mm:ss Clock Set

DEFAULT Load factory DEFAULT gage settings

DF Date Format(0=julian,1=month,day)

DL Display DataLogger type

Dnnnnn Display nnnnn arrays from pointer

E End communications and go to sleep

Gnn/c/tt/szzzzzz/sffffff/soooooo

(or Gnn/c/tt/saaaaaa/sbbbbbb/scccccc)

Gage information, where;

nn = Channel #

c = Conversion Type(L/P)

tt = Gage Type

For Linear (L) Conversion:

szzzzzz = zero reading with sign

sffffff = gage factor with sign

soooooo = offset with sign

For Polynomial (P) Conversion:

saaaaaa = polynomial coefficient A with sign

sbbbbbb = polynomial coefficient B with sign

scccccc = polynomial coefficient C with sign

IDdddddddddddddddd View current ID,set to dddddddddddddddd

Ln/lllll/iii View Log intervals/change n interval

lllll = length

iii = iterations of interval

LD,LE Log intervals Disable, Enable

M,MD,ME Monitor status, Disable, Enable

MXS Display Multiplexer Setup

MX# Select Multiplexer Configuration(4,16)

N Display Next time to read

NAddd Network Address (1-256)

NS,ND,NE Network Status, Disable, Enable

Pnnnnn Position array pointer to nnnnn

R Reset memory

RESET RESET processor

S,SS Datalogger Status, System Status

SCnnnnn View SCan interval/enter nnnnn interval

SPhh:mm StoP logging, hh:mm = stop time

SR Synchronize Readings(0=not synch'd,1=synch'd)

SThh:mm STart logging, hh:mm = start time

16

SV Software Version

TEST System Test

TF Time Format (0 = hhmm, 1 = hh,mm)

Tnn/t Thermistor information, where;

nn = Channel #

t = Thermistor Type

0=standard

1 = high temp BR55A822J

2 = high temp 103JL1A)

TR,TR0 display TRap count, zero TRap count

VL display Lithium cell Voltage

V3 display 3V Battery Voltage

V12 display 12V Battery Voltage

WFn Wrap Format(0=don't wrap memory,1=wrap memory)

X Single Reading - NOT stored

All of these commands are executed by typing with the correct syntax and pressing <ENTER>.

If the command has not been entered correctly, the datalogger will respond with an asterisk only.

For example:

*L7/100/255

*

The datalogger will respond to correctly entered commands by displaying the modified values.

The purpose and syntax of each of these commands are discussed in the following sections.

17

3. COMMAND LIST

3.1 “BRnnn”- Set or Display the Current Baud Rate

This command is not displayed in the help text (?<ENTER>). Displays or sets the current baud

rate. Valid numbers for “nnn” are 9 (9600 baud) or 115 (115,200 baud). The example below

changes the baud rate to 9600 with no confirmation.

*BR9

3.2 “C” - Display Current Clock Settings

Displays the current datalogger real-time clock settings. The CS command section explains how

to adjust the clock settings.

*C

Date: 02/21/07 Time: 10:43:08

*

3.3 “CSmm/dd/yy/hh:mm:ss” - Set the Internal Clock

Set the datalogger’s internal real time clock; mm represents the month, dd the day of the month,

yy the year, hh the hours, mm the minutes, and ss the seconds. Illegal combinations will be

ignored (e.g., CS02/30/07 or CS///12:60). Fields that are left blank will not be changed (e.g.,

CS//07 to only change the year).

*CS///10:45:00

Date: 02/21/07 Time: 10:45:00

*

Note: If logging is currently started and the clock is changed, a restart of the scan interval or log

interval table will occur.

3.4 “DEFAULT” – Load Factory Default Settings

The DEFAULT command will reload the datalogger’s channel and gage settings to the factory

default settings, along with the reading synchronization and memory wrap settings. This results

in:

All channels Enabled

All Gage Types set to 1

All Zero Readings set to 0.00000

All Gage Factors set to 1.00000

All Gage Offsets set to 0.00000

All channels use linear conversion

Scan interval = 10S

All readings synchronized to the top of the hour

18

Memory will wrap when full and continue logging

All Thermistors set to standard temperature

*DEFAULT

This will load all channels with factory default gage settings!

Are you sure(Y/N)?Y

All channels restored to factory default gage settings.

3.5 “DF” - Display or Set Date Format

This setting determines how the date information will be displayed in the array when the monitor

mode is active or arrays are displayed from memory. Entering DF displays the current date

format. Entering DF0 sets the date format to julian. Entering DF1 sets the date format to

month,day. The default date format display is Julian (decimal) day.

*DF

Date format is julian.

*DF1

Date format is month,day.

*DF0

Date format is julian.

3.6 “DL” – Display Current Mode

Displays the current datalogger mode setting.

*DL

LC-2x4

3.7 “Dnnnn” - Display Arrays Forward from User Position

Use the D command to display arrays forward from the User Position for verification or

collection. The updated memory pointers are displayed by this command.

*P1

MS:3146 OP:3147 UP:1

*D5

2007,11,23,17,52,43,3.10,25.51,9039.950,-999999.0,-999999.0,-999999.0,23.2,-99.0,

-99.0,-99.0,1

2007,11,23,17,53,43,3.10,24.77,9040.149,-999999.0,-999999.0,-999999.0,23.2,-99.0,

-99.0,-99.0,2

2007,11,23,17,54,43,2.97,24.42,9040.319,-999999.0,-999999.0,-999999.0,23.2,-99.0,

-99.0,-99.0,3

2007,11,23,17,55,43,2.98,24.22,9039.622,-999999.0,-999999.0,-999999.0,23.1,-99.0,

-99.0,-99.0,4

19

1

10666

2007,11,23,17,56,43,2.98,23.96,9038.542,-999999.0,-999999.0,-999999.0,22.7,-99.0,

-99.0,-99.0,5

MS:3146 OP:3147 UP:6*

MS represents the Memory Status of the datalogger. This number indicates how many arrays

have been written to memory. In this example, MS:3146 indicates that 3146 out of 10666 arrays

have been written to memory. OP:3147 indicates that the next memory location to be written to

is location 3147. UP:1 indicates that the memory location currently being pointed to (via the P

command) is memory location one. Use the D command to display arrays forward from the User

Position. In this case, D5 displays the arrays stored at memory locations 1, 2, 3, 4, and 5, and

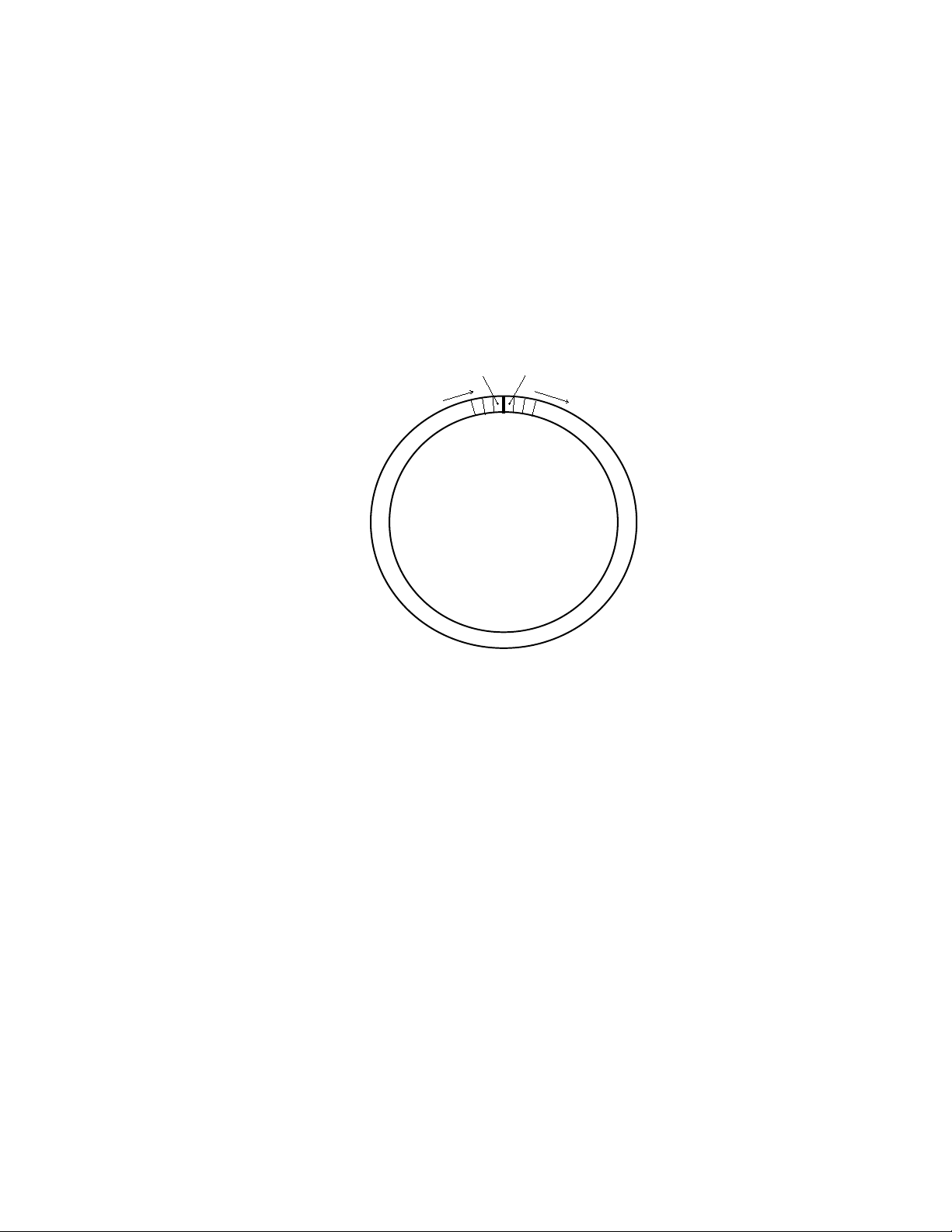

leaves the memory pointer at memory location 6. Figure 16 illustrates the ring memory scheme.

Figure 16 - Order of Array Usage

OP represents the Output Position that the next array will be written to.

UP represents the User Position. This value is updated by D and P commands. The user can

display arrays from this position or re-position to another array.

The format is comma delineated ASCII, identical to that displayed when the Monitor mode is

active. See Appendix D for a sample data file. See Appendix C in regards using the D command

to collect data. When the array display is finished the memory pointers are displayed.

3.8 “E” - Low Power Sleep Mode

Returns the datalogger to its low power sleep mode (readings continue to be logged and

displayed in this mode). This command should always be used when finished communicating

with the datalogger to ensure the lowest power consumption. However, the datalogger (non-

networked) will enter sleep mode regardless if no command is received in a period of

approximately 15 seconds.

To return from the low power operating mode press <ENTER> <ENTER>. The datalogger

responds:

20

Hello. Press "?" for Help.

*

Note: When network commands are enabled the address must be sent before the respective

datalogger will respond. See Sections 3.21, 3.23, and 3.24 for additional information.

3.9 “Gnn/c/tt/szzzzzz/sffffff/soooooo” or “Gnn/c/tt/saaaaaa/sbbbbbb/scccccc” – Gage Settings

The G command is used to set up each of the four datalogger channels. All of the transducer

parameters, including the type of conversion (linear or polynomial) and whether a channel is

enabled or disabled are set with this command.

Refer to Table 2 and Table 3 for a description of each gage type.

The syntax for this command is:

Linear Conversion:

Gnn/c/t/szzzzzz/sffffff/soooooo

Where:

nn = Channel # (Valid entries are 1, 2, 3, and 4 for the LC-2x4)

c = Conversion Type(L/P) where L=Linear and P=Polynomial

t = Gage Type:

0: Channel Disabled (will display “---“)

1: VW Gage Type 1

2: VW Gage Type 2

3: VW Gage Type 3

4: VW Gage Type 4

5: VW Gage Type 5

6: VW Gage Type 6

szzzzzz = zero reading with sign

sffffff = gage factor with sign

soooooo = offset with sign

Example: To setup Channel 1 as a model 4000 VW Strain Gage with a Zero Reading of 490

digits, a Gage Factor of –0.0015 and a Gage Offset of zero, enter:

G1/L/3/490/-0.0015/0 <ENTER>

The LC-2x4 will return:

CH 1: ENABLED

GT: 3 ZR: 490.0000 GF: -0.00150 GO: 0.00000

*Note: If selecting Gage Type 0 to disable the channel, the LC-2x4 will only return “*”. Use the

MXS command (Section 3.18) to view the disabled channels.

When using linear conversion (L) of the instrument reading, the G command is used to select the

gage type and enter the gage zero reading, gage factor, and gage offset.

Linear Conversion is described further as follows:

21

szzzzzz represents the zero reading for the transducer being read, sffffff represents the multiplier

NOTE: It is possible that a new datalogger might be used with an older sensor or vice versa and because of

(calibration or gage factor) that will be applied to the reading to convert to engineering units and

soooooo is the offset that will be applied to the gage reading. The zero reading, gage factor and

offset can be entered with a sign and decimal point. The maximum number of digits, including

sign and decimal point is 15. The entered value will display to a maximum of five places to the

right of the decimal point.

For all vibrating wire instruments (Gage Types 1-6), manufactured after November 2, 2011 and

for all dataloggers (8002-4-X) with a firmware revision of 3.1.X and up, the basic formula for

calculation of displayed and stored values is as follows:

Display = ((CurrentReading - ZeroReading) × Multiplier) + Offset

Equation 1 - Displayed Gage Reading using Linear Conversion

equation differences the output might be negative. As of LogView version V2.1.1.X, an additional sensor

configuration parameter is now required, allowing LogView to compensate for old versus new

sensor/datalogger combinations. This new parameter: Output Calculation, determines whether the sensor

was calibrated using the formula: G x (R

available from the calibration certificate supplied with each sensor. Please see the LogView User’s Guide or

the online help section, “Sensor Settings” available while running LogView.

NOTE: In Equation 1 (above), the “CurrentReading” is frequently referred to as R1 while the

“ZeroReading” is referred to as R0

Polynomial Conversion:

Gnn/c/tt/saaaaaa/sbbbbbb/scccccc

Where:

nn = Channel # (Valid entries are 1, 2, 3, and 4 for the LC-2x4)

c = Conversion Type(L/P)

t = Gage Type:

0: Channel Disabled (will display “---“)

1: VW Gage Type 1

2: VW Gage Type 2

3: VW Gage Type 3

4: VW Gage Type 4

5: VW Gage Type 5

6: VW Gage Type 6

saaaaaa = polynomial coefficient A with sign

sbbbbbb = polynomial coefficient B with sign

scccccc = polynomial coefficient C with sign

When using polynomial conversion (P), the G command is used to select the gage type and enter

the three polynomial coefficients, A, B and C.

Polynomial Conversion is described further as follows:

– R1) or G x (R1 – R0). As with the gage factor, this information is

0

22

Geokon Model

Gage Type

Description

4000 3 Strain Gage

4100 1 Strain Gage

4200 3 Strain Gage

4204 6 Strain Gage

4202/421X

1

Strain Gage

4300BX

1

BX Borehole Stressmeter

4300EX

5

EX Borehole Stressmeter

4300NX

1

NX Borehole Stressmeter

4400

1

Embedment Jointmeter

4420 1 Crackmeter

4450

1

Displacement Transducer

4500 1 Piezometer

4600/4651/4675

1

Settlement Systems

4700

1

Temperature Transducer

4800

1

Pressure Cell

4850

1

Low Pressure Piezometer

4900 1 Load Cell

4910/4911/4912

1

Load Bolts

saaaa represents polynomial coefficient A, sbbbb represents polynomial coefficient B and scccc

polynomial coefficient C. The polynomial coefficients can be entered with a sign and decimal

point. The maximum number of digits, including sign and decimal point is 15. The entered value

will display to a maximum of five places to the right of the decimal point.

For the vibrating wire instruments (Gage Types 1-6), the basic formula for calculation of

displayed and stored values is:

Display = (CurrentReading2 × A) + (CurrentReading × B) + C

Equation 2 - Displayed Gage Reading using Polynomial Conversion

NOTE: When using the Polynomial conversion method, the default reading units for a vibrating wire instrument is

the frequency squared multiplied by 10

when A is entered as “0”, B is “1” and C is “0”. However, typical calibration units for vibrating wire instruments are

frequency squared multiplied by 10

units multiply the A coefficient by 1,000,000 and the B coefficient by 1000. The A and B coefficients can be

found on the supplied calibration certificate. The C coefficient should be calculated based on an actual field

reading. The above multiplication is only necessary if the datalogger is being set up via text commands (see Section

2.6) AND the gage conversion is set for polynomial. When using LogView to set up the datalogger configuration,

the multiplication is performed by LogView. Refer to the appropriate sensor manual for more information on how to

calculate the C coefficient.

-6

. For example, an instrument reading 3000Hz will output a value of “9.000”

-3

. To adjust for this discrepancy between LC-2 expected units and calibration

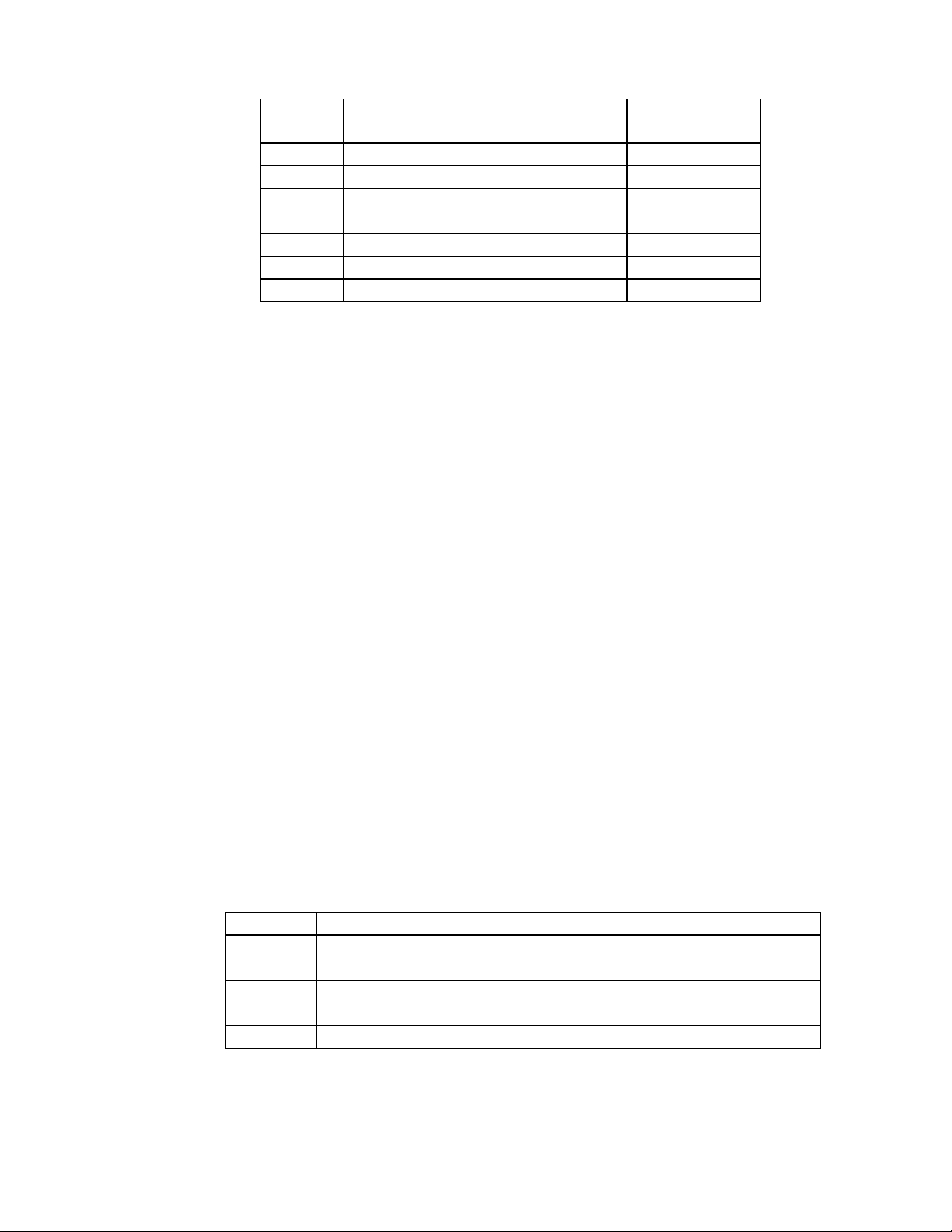

Table 2 - Vibrating Wire Gage Types

23

Type

Measurement

Type

Description

Output

Units

Linear Range

Polynomial

Range

0

Channel Disabled

1

Vibrating Wire

Middle frequency sweep, 1400-3500 Hz

Digits

1960 to 12250

1.960 to 12.250

2

Vibrating Wire

High frequency sweep, 2800-4500 Hz

Digits

7840 to 20250

7.840 to 20.250

3

Vibrating Wire

Very low frequency sweep, 400-1200 Hz

Digits

160 to 1440

0.160 to 1.440

4

Vibrating Wire

Low frequency sweep, 1200-2800 Hz

Digits

1440 to 7840

1.440 to 7.840

5

Vibrating Wire

Very high frequency sweep, 2500-4500 Hz

Digits

6250 to 20250

6.250 to 20.250

6

Vibrating Wire

Low frequency sweep, 800-1600 Hz

Digits

640 to 2560

0.640 to 2.560

psi 1 .036127

.43275

.0014223

1.4223

.49116

.019337

14.696

.014503

14.5039

.14503

145.03

"H2O

27.730 1 12

.039372

39.372

13.596

.53525

406.78

.40147

401.47

4.0147

4016.1

'H2O

2.3108

.08333

1

.003281

3.281

1.133

.044604

33.8983

.033456

33.4558

.3346

334.6

mm H20

704.32

25.399

304.788

1

1000

345.32

13.595

10332

10.197

10197

101.97

101970

m H20

.70432

.025399

.304788

.001 1 .34532

.013595

10.332

.010197

10.197

.10197

101.97

"HG

2.036

.073552

.882624

.0028959

2.8959

1

.03937

29.920

.029529

29.529

.2953

295.3

mm HG

51.706

1.8683

22.4196

.073558

73.558

25.4 1 760

.75008

750.08

7.5008

7500.8

atm

.06805

.0024583

.0294996

.0000968

.0968

.03342

.0013158

1

.0009869

.98692

.009869

9.869

mbar

68.947

2.4908

29.8896

.098068

98.068

33.863

1.3332

1013.2

1

1000

10

10000

bar

.068947

.0024908

.0298896

.0000981

.098068

.033863

.001333

1.0132

.001 1 .01

10

kPa

6.8947

.24908

2.98896

.0098068

9.8068

3.3863

.13332

101.320

.1

100 1 1000

MPa

.006895

.000249

.002988

.00000981

.009807

.003386

.000133

.101320

.0001

.1

.001

1

Table 3 - Gage Type Descriptions

The “Digits” calculation for the Vibrating Wire transducer output when using linear conversion

is based on this equation:

Digits = frequency2 × 10

-3

Equation 3 - Digits Calculation using Linear Conversion

The “Digits” calculation for the Vibrating Wire transducer output when using polynomial

conversion is based on this equation:

Digits = frequency2 × 10

-6

Equation 4 - Digits Calculation using Polynomial Conversion

Frequency, in the above equations, represents the resonant frequency of vibration of the wire in

the transducer (in Hertz) as determined by the datalogger.

To convert calibration factors (pressure transducers are usually psi per digit) to other engineering

units consult Table 4.

NOTE: In LogView Sensor Settings, when output units are set different than inputs units, a

conversion factor (see Table 4) is automatically applied to the gage factor of each sensor. See the

LogView User’s Guide for more information on Sensor Settings.

From →

To

↓

psi

"H2O

'H2O

mm H20

m H20

"HG

mm HG

atm

mbar

bar

kPa

MPa

Table 4 - Engineering Units Multiplication Factors

24

3.10 “IDdddddddddddddddd” - Display or Set Datalogger ID

The ID is a 16-character string that can be used to identify a datalogger and the data that is

transmitted by it. If an ID is entered it will be transmitted as the first element in each array of

data. For example:

*ID

Datalogger ID:

*ID

Datalogger ID:

*IDDatalogger#1

Datalogger ID:Datalogger#1

*ST

Logging started.

Datalogger#1,2007,11,25,11,25,16,2.92,20.93,9.020,

-999999.0,-999999.0,-999999.0,22.0,-99.0,-99.0,-99.0,1

Datalogger#1,2007,11,25,11,25,21,2.92,20.95,9.061,

-999999.0,-999999.0,-999999.0,22.0,-99.0,-99.0,-99.0,2

Datalogger#1,2007,11,25,11,25,26,2.92,21.04,9.045,

-999999.0,-999999.0,-999999.0,22.0,-99.0,-99.0,-99.0,3

Datalogger#1,2007,11,25,11,25,31,2.92,21.09,9.014,

-999999.0,-999999.0,-999999.0,22.0,-99.0,-99.0,-99.0,4

To clear the ID enter a <SPACE> character as the ID. When the ID is cleared the arrays from the

logger will display beginning with the year. To display the current ID enter ID <ENTER>.

3.11 “L” - Display Log Intervals

Displays all six log intervals.

*L

Log Intervals List

-----------------------------------------------Interval #1 Length: 10 Iterations: 100

Interval #2 Length: 20 Iterations: 90

Interval #3 Length: 30 Iterations: 80

Interval #4 Length: 40 Iterations: 70

Interval #5 Length: 50 Iterations: 60

Interval #6 Length: 60 Iterations: 50

*

This command has no effect on the current interval (scan or log). If logging is started and log

intervals are enabled the iterations value will be followed by the number of readings left at that

interval. For example:

25

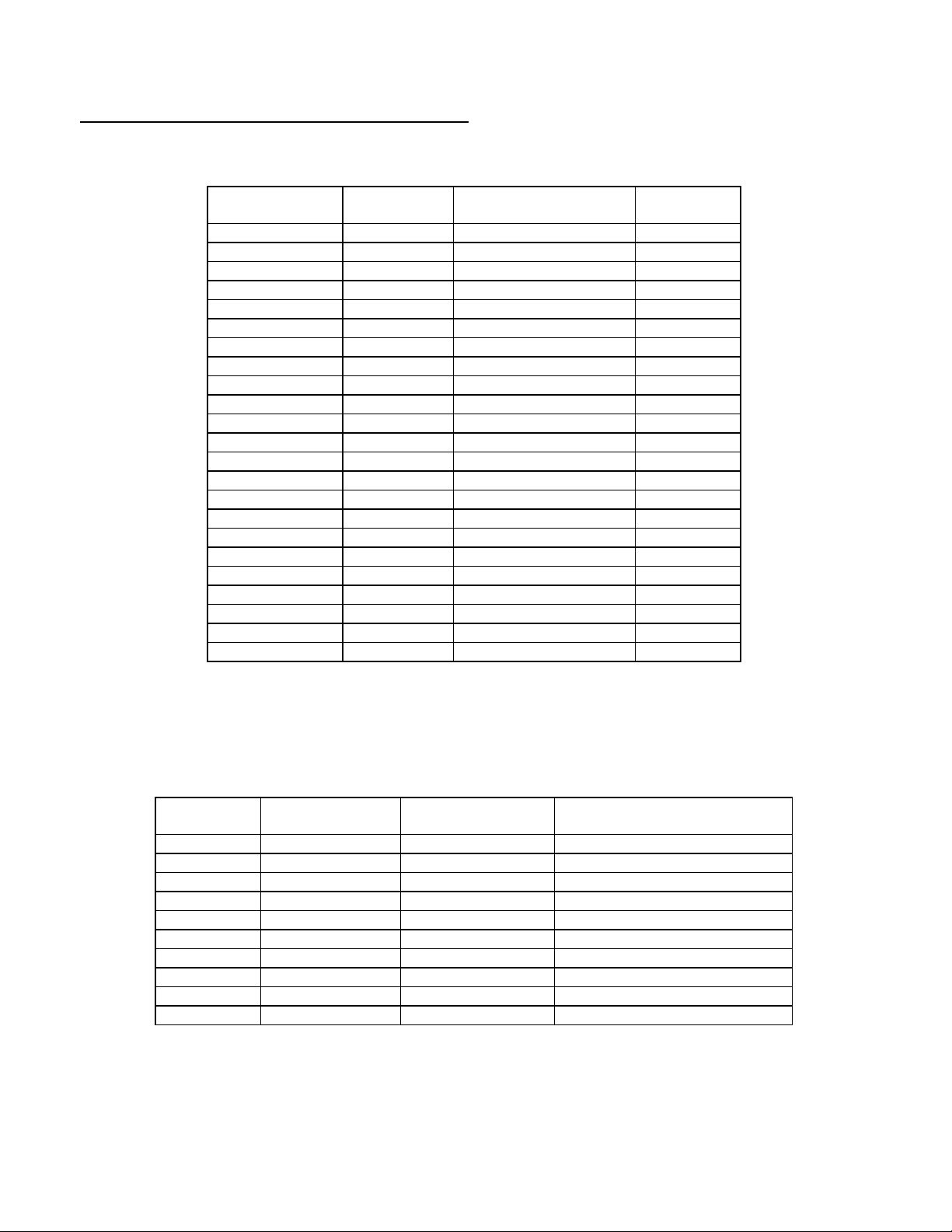

Interva

l

Length

Iterations

Elapsed Time

1

10 seconds

6

1 minute

2

30 seconds

20

10 minutes

3

60 seconds

100

100 minutes

4

300 seconds

200

1000 minutes

5

2400 seconds

250

10000 minutes

6

3600 seconds

0

endless

*L

Log Intervals List

-----------------------------------------------Interval #1 Length: 10 Iterations: 100/96

Interval #2 Length: 20 Iterations: 90/90

Interval #3 Length: 30 Iterations: 80/80

Interval #4 Length: 40 Iterations: 70/70

Interval #5 Length: 50 Iterations: 60/60

Interval #6 Length: 60 Iterations: 50/50

*

The above list indicates that there are 96 iterations of interval #1 left before interval #2 begins

execution. See Section 3.12 to modify intervals.

3.12 “Ln/lllll/iii” - Define Length and Iteration of Interval

Define the length and iteration of any interval in the list; n refers to the number of the interval

(#1-#6), lllll is the length (3-86400), and iii is the iterations (0-255), or the number of readings

that will be taken at that interval. If 0 is entered for the iteration value that interval will execute

indefinitely. Illegal entries will be ignored (e.g., L7/10/100 or L1/1000/500). If the entry

is correct the modified interval will display.

*L1/100/0

Interval #1 Length: 100 Iterations: 0

*

If log intervals are enabled and logging was started, any change to the interval list will

result in a restart of the table!

Table 5 lists possible logarithmic interval lengths and iterations. Any combination of lengths and

iterations is permissible.

Table 5 - Logarithmic Intervals List

26

3.13 “LD” - Disable Log Intervals

If logging is started (ST command) it will continue based on the scan interval entry (SC

command).

*LD

Log intervals disabled.

*Datalogger#1,2007,11,25,11,41,17,2.92,20.63,9.055,

-999999.0,-999999.0,-999999.0,22.5,-99.0,-99.0,-99.0,549

*

3.14 “LE” - Enable Log Intervals

If logging is started (ST command) it will continue based on the interval lengths and iterations of

the log list (SC command).

*LE

Log intervals enabled.

*Datalogger#1,2007,11,25,11,42,56,2.92,21.51,9.042,

-999999.0,-999999.0,-999999.0,22.5,-99.0,-99.0,-99.0,622

3.15 “M” - Display Current Monitor Mode Setting

The monitor mode will display arrays as they are stored in memory in the course of logging. This

is useful where a test is being conducted and immediate display of logged values would be

helpful. Use the “MD” and “ME” commands (next two sections) to disable or enable the use of

the Monitor mode.

*M

Monitor mode enabled.

*

3.16 “MD” - Disable Monitor Mode

Arrays will not be sent to the host computer as they are logged.

*MD

Monitor mode disabled.

*

3.17 “ME” - Enable Monitor Mode

Arrays will be sent to the host computer as they are logged.

*ME

Monitor mode enabled.

*

27

3.18 “MXS” – Display Multiplexer Status

Displays the Multiplexer Status.

*MXS

LC-2MUX 4-Channel Multiplexer Setup:

CH 1: ENABLED

GT: 3 ZR: 0.00000 GF: 1.00000 GO: 0.00000 TH: 0

CH 2: ENABLED

GT: 1 ZR: 0.00000 GF: 1.00000 GO: 0.00000 TH: 0

CH 3: ENABLED

GT: 1 ZR: 0.00000 GF: 1.00000 GO: 0.00000 TH: 0

CH 4: ENABLED

GT: 1 ZR: 0.00000 GF: 1.00000 GO: 0.00000 TH: 0

*

3.19 “MXn” – Set the Maximum Number of Channels

Set the maximum number of channels of the multiplexer. Can be set to 4 or 16. Set to 4 by the

factory for all LC-2x4 dataloggers.

*MX4

4 Channel Multiplexer Selected.

*

3.20 “N” - Display Next Measurement Cycle

Displays the next time the datalogger will initiate a measurement cycle. If the start time (ST

command) has been set, this command will display when logging will begin.

*ST12:00

Logging will start at: 12:00:00

*N

Next time to read: 12:00:00

*

28

3.21 “NA” - Display Network Address

Displays the current network address.

*NA

Network address: 1

*

When network recognition is enabled, this number (preceded by the # character) must be entered

for the respective datalogger to respond. The following example illustrates communication with

two different dataloggers on the RS-485 network.

<ENTER>

<ENTER>

#1<ENTER>

Network address: 1

*NA

Network address: 1

*E

<ENTER>

<ENTER>

#2<ENTER>

Network address: 2

*NA

Network address: 2

*E

3.22 “NAddd” - Set Network Address

Sets the current network address to any address between 1 and 256.

*NA10

Network address: 10

*

When network recognition is enabled, this number (preceded by the # character) must be entered

for the respective datalogger to respond. The following example illustrates communication with

two different dataloggers on the RS-485 network.

<ENTER>

<ENTER>

#1<ENTER>

Network address: 1

*NA

Network address: 1

*E

29

<ENTER>

<ENTER>

#10<ENTER>

Network address: 10

*NA

Network address: 10

*E

NOTE: If connected directly to the datalogger via USB and networking is enabled, the

datalogger will respond with the * prompt only.

NOTE: The network address cannot be changed while networked. Direct connect to the

datalogger via USB in order to change the network address.

3.23 “ND” - Network Disable

Disables networking of two or more LC-2x4 dataloggers.

*ND

Network recognition disabled.

3.24 “NE” - Network Enable

Enables networking of two or more LC-2x4 dataloggers.

*NE

Network recognition enabled.

Note: If a networked LC-2x4 is connected via the RS-232 or USB port, connection to the

datalogger can be made directly without the need to enter the correct datalogger address. This

can be helpful if the network address is unknown and the datalogger is network enabled.

3.25 “NS” - Display Network Status

Displays the current network status.

*NS

Network recognition disabled.

*

Or;

*NS

Network recognition enabled.

*

30

3.26 “Pnnnn” - Set User Position Memory Pointer

Type P and a number between 1 and 10666 to position the pointer. Arrays can then be displayed

(D command) from the new position. The updated pointers will display after entering a valid

position.

*P1

MS:3200 OP:1567 UP:1

*

3.27 “R” - Reset Memory Pointers

Reset memory pointers to default settings. Gage and interval settings, as well as the real-time

clock settings, are not affected by this command. User will be asked to verify before executing.

Press Y to continue, any other key to abort.

*R

Are you sure(Y/N)?Y

Memory cleared.

*

Note: This command does not erase memory. If the need arises to recover data that was

previously taken, take one or more readings and then position the memory pointers via the P and

D commands to recover previously taken readings

3.28 “RESET” - Reboot the LC-2 Microprocessor

All stored readings and settings, as well as the ID and real-time clock settings are not affected by

this command.

*RESET

Resetting...

RESET COMPLETE

*

3.29 “S” – Display Status

Displays the datalogger Status.

*S

MS:1004 OP:1005 UP:1004

4 Channel Multiplexer Selected.

Scan interval: 15 second(s).

Logging stopped.

Log intervals disabled.

Monitor mode enabled.

*

31

Line

Description

Manual

Sections

1

Status of memory pointers

3.7, 3.26 2 Multiplexer Type

3.18 3 Scan interval setting

3.30 4 Start/Stop status

3.32, 3.34

5

Stop time (optional)

3.32 6 Log interval status

3.13, 3.14

7

Monitor mode status

3.15, 3.16, 3.17

Line

Description

1

Trap Count (Communication errors counter)

2

Current network address

3

Current network status

4

Current time format configuration.

5

Current date format configuration.

Table 6 - S Command Information

3.30 “SCnnnnn” - Set Scan Interval

Enter the scan interval, in seconds. Range of entry is 3 to 86400 and is dependent on the number

and type of transducers connected. Only whole numbers are accepted. Typing SC with no value

returns the current setting only

*SC

Scan interval: 60 second(s).

*SC300

Scan interval: 300 second(s).

*

3.31 “SS” - Display System Status

Displays the System Status of the datalogger.

*SS

Trap count: 0

Network address: 1

Network recognition disabled.

Time format is hh,mm.

Date format is month,day.

*

Table 7 - SS Command Information

32

3.32 “SPhh:mm” - Stop Logging

Stop the datalogger logging values; hh is the hour (24-hour format) of the day to stop and mm

the minutes. The time entry is optional.

*SC60

Scan interval: 60 second(s).

*ST

Logging started.

Datalogger#1,2007,11,25,14,10,05,2.94,23.99,9.071,---,---,

---,22.9,---,---,---,1

*SP12:00

Logging will start at: 15:13:46

Logging will stop at: 12:00:00

*

Note that when SPhh:mm is issued, the datalogger responds with the time of the next reading

along with the time at which logging will stop.

3.33 “SR” - Synchronize Readings

Synchronize readings to the top of the hour. If enabled (default) via the SR1 command, then all

readings after the first reading will synchronize to the top of the hour:

*SR1

Readings are synchronized to the top of the hour.

*ST

Logging started.

2008,318,1314,41,3.50,24.45,-8961.077,-999999.0,-999999.0,

-8444.892,23.1,-99.0,23.8,23.9,6645

*2008,318,1314,45,3.50,24.57,-8961.276,-999999.0,-999999.0,

-8445.080,23.2,-99.0,23.8,23.9,6646

2008,318,1315,0,3.50,24.86,-8960.023,-999999.0,-999999.0,

-8445.035,23.2,-99.0,23.8,23.9,6647

*SR0

Readings are not synchronized to the top of the hour.

*ST

Logging started.