Page 1

GigaPico Next

AutoFocus

Users’ Manual 1.1

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

1

Page 2

Table of contents

1 Introduction ...................................................................................................................... 4

1.1 What is FSO?........................................................................................................... 4

1.2 Why is it important? ............................................................................................... 4

1.3 Optical Free-space Transmission .......................................................................... 6

1.4 Typical applications ................................................................................................ 7

2 Interfaces for the Giga Next AF Series ........................................................................... 8

2.1 1000Mbps TP interface........................................................................................... 8

2.2 1000 Mbps FO interface ......................................................................................... 8

3 Sites of installation ........................................................................................................... 9

3.1 Key factors of operation ......................................................................................... 9

3.2 Preferred installation sites ..................................................................................... 9

3.3 Distance measurement .......................................................................................... 11

3.4 Direct sunshine ...................................................................................................... 11

4 Eye safety ........................................................................................................................ 12

5 The mounting bracket .................................................................................................... 13

5.1 Mounting brackets for the X Series .................................................................... 13

6 System installation ......................................................................................................... 15

6.1 On the table test .................................................................................................... 15

6.1.1 Alignment of the PX0500E1000TP ................................................................... 16

6.1.2 How to use the alignment base ........................................................................... 16

6.1.3 Fine tuning .......................................................................................................... 17

6.2 Meanings of the LCD ............................................................................................ 17

6.3 AF adjusment method .......................................................................................... 18

6.4 Connecting to your Network ................................................................................ 20

6.4.1 PoE 802.3 af connection. ................................................................................... 20

6.4.2 System layout ...................................................................................................... 20

6.4.3 System layout with GEO20 ................................................................................ 21

7 Management ................................................................................................................... 22

7.1 Features .................................................................................................................. 22

Login Screen and password ........................................................................................ 22

Head information screen ............................................................................................. 22

Status info screen ........................................................................................................ 23

Device setup ................................................................................................................ 24

Network Setup ............................................................................................................ 25

SNMP Setup ............................................................................................................. 27

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

2

Page 3

Security ...................................................................................................................... 28

Auto-focus setup (AF) ................................................................................................ 28

Mandatory Management Activation ........................................................................... 30

Firmware update ......................................................................................................... 31

7.2 Network Interface software update ..................................................................... 33

7.2.1 Update cabel........................................................................................................ 35

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

3

Page 4

1 Introduction

1.1 What is FSO?

FSO is free space optics provides point-point broadband communications using

Laser Light as the transmission medium.

FSO is a state of art data communication method which is based on a very old

communication solution. Ancient Chinese developed a protection system against the

Mongol tribes, building watchtowers within the line of site to other towers. And as

soon as the towers saw some hostile sign on the horizon they use they shield to

reflect the sun to the remote towers. In this way the area could be prepared against

the attack in a very short period of time.

In the ancient times for this communication use the mirror

as a transmitter and the sunlight was the light source, and

the receiver was the remote guard’s eye. This basic

signalling method was developed later into up

communication device which used „line coding”. This

allowed the guards to tell the number of enemy, or the

direction they are coming from.

Current FSO systems use a laser-diode as a light source,

and a receptor diode (photo diode) to receive the signals

coming from the laser diode from the transmitter side. But

the basic elements are still the same: line of site between

the communication nodes, and individual line coding. It is all about performance.

GeoDesy FSO offers FSO systems with the highest power budget available on

the market.

1.2 Why is it important?

Because of in the ancient Chinese times, the rain, the fog, or even the cloudy

weather, could impact the operation of the whole system.

In the FSO units, comprising light source and receiver the cloud problem was

solved, but development conditions still can impair

performance. To go throw the rain, the fog, or snow you

need more and more power to be seen from the remote

side. Achievable power levels are limited by a number of

factors including eye safety.

In this way there is no other choice to see more than

„training the eye”. Making the receiver more and more

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

4

Page 5

sensitive to sense delight emitted from the remote side. GeoDesy FSO offers high

transmit power and also very hard receiver sensitivity. These two factors combined

to provide one of the best performing FSO systems on the market today.

To meet the demands for every higher bandwidth, GeoDesy FSO (Europe) Limited

continues to invest heavily in research and development with the newest product line

which offers Gigabit speeds being launched.

This manual describes the GeoDesy FSO Next series of free space laser

transmission system.

The GeoDesy FSO Next product range offers cost effective reliable free space

laser transmission for two Mbps up to 1000 Mbps data to the air, where a clean line

of site is available. It delivers the most effective point-to-point connection between

computer networks or telephone exchanges.

No need for installing cables, no rental costs, no licensing requirements.

Ideal for urban areas or city centres, where the use of these lines are expensive.

Suitable for factories or industrial environments where high noise level can interfere

with the transmitted data. The best choice to make a connection across rivers and

other natural or artificial obstacles, where cable is not available.

The transmission technique used in the GeoDesy FSO devices provides

transparent and wire-speed data transfer with virtually zero latency. Because they

use infrared light as the transmission medium, GeoDesy FSO system do not

require frequency licenses and the transmission is not effected by electro-magnetic

or radio-frequency interference. Basically the GeoDesy FSO link can be

considered as a virtual fibre in the air, which ends in real fibre optic cable at both

ends.

Our product is built using high quality components for operation in even the most

adverse conditions.

Metal housing gives robust, waterproof environment for the electronics.

The shield protects the device from direct sunlight and provides extra air isolation.

The GeoDesy FSO X systems comprise two laser-heads

one at each end. The interface connections are housed in the outdoor unit together

with the PSU of the system.

Best practises were employed in cost engineering throughout the development of

GeoDesy FSO.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

5

Page 6

1.3 Optical Free-space Transmission

The principle used in free space laser transmission is very similar to the one is used

for fibre optic transmission. The difference is while fibre optic devices use electronics

and optics optimized for transmission to the air. Also one can observe to the

similarity in the transmission properties. No galvanic contact, no ground-loops, no

need for surge protection, noise immunity, long distances, high bandwidth.

What makes it unique – and difficult to design – is that it does not require any

transmission medium like fibre or copper, but it has to cope with the dynamically

changing parameters. For instance while the attenuation of an optical fibre is

constant, the attenuation of the atmosphere between the laser units can change

dramatically (depending on the weather conditions).

The laser-heads are usually placed on top of building, where the clean line of site is

guaranteed and the beam cannot be interrupted.

In the head the incoming signal is amplified, encoded, and then drives the laserdiode. The transmitter optics assures the proper beam shape and controls the beam

divergence. The receive optics perceives and directs the transmitter signal to the

photo diode. The diode converts it back into electrical, than it is decoded, amplified

and converted.

There are several things that can influence the quality of transmission. We can

classify those factors into three main groups.

System conditions - transmitting power, transmitter’s wavelength, beam divergence,

receiver optics diameter, receiver sensitivity, parameters of optical system and

casing. These parameters determine the system’s characteristic at a certain

distance and are controlled by system design and factory set up.

Weather conditions - molecular absorption, particle scattering and turbulence. These

elements have great effect on the operational conditions of the system. We do not

have very much influence on them; proper product selection can eliminate the

undesirable effects.

Environmental conditions - building movements, direct sunlight, refractive surfaces.

These are also key factors related to the installation sites and can be controlled by

appropriate site survey and system installation

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

6

Page 7

Corporate

LAN

ISP

1.4 Typical applications

Most typically the GeoDesy FSO Next product are is used to interconnect LANs. The system is protocol transparent, thus other applications also can be taken into

consideration. Appropriate interface converters are needed and system bandwidth

must be matched for that.

Here we collected some circumstances, where the deployment of the GeoDesy

FSO is the most adequate as a cost effective solution.

Those are:

Areas with natural or artificial obstacles

Where cable is actually not an alternative, like

across rivers or railways or in rugged terrain.

Urban

areas

Where only leased lines are available with

limited speed, and high rental cost. With

GeoDesy FSO links you can establish on line

LAN-to-LAN connections.

Industrial areas

Where you have noisy environment with high EMI

or RFI. Factory buildings, airport objects can be

connected through laser link.

ISP connections

Where high

bandwidth is required. ISP’s can offer high-speed links

to their customers or trunks can be established

between ISP’s instead of expensive leased lines.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

7

Page 8

2 Interfaces for the Giga Next AF Series

2.1 1000Mbps TP interface

The GeoDesy FSO Giga Next AF series products are designed to provide

easy-to-use and cost-effective solution for interconnecting Local Area Networks. By

utilizing standard Category 5e cable and using standard IEEE802.3af interface the

deployment of the system is easier than ever before. The transparent and wire

speed data transfer together with virtually zero latency assures the easy integration

of the system in all environments.

The Giga Next AF systems should be considered as repeaters in the network. So

the installation distance between the head and the network device is 100m. The

distance on a back to back site is maximum 5 meters, between the heads without

signal regeneration.

The Giga Next AF systems connecting to the network with two RJ 45 cable which

provides the power required for operation and the data. The system requires IEEE

802.3af Power over Ethernet switch or power injector. The power consumption suits

to the standards described in the standard. Also provides fast and easy connection

for the management system for more details please see the chapters below. The

system is certified Class 1M product, this way 100% eye safe.

2.2 1000 Mbps FO interface

The GeoDesy FSO Giga Next MF system is ready to be upgraded with a Single

or Multi mode SC fiber interface with SX or LX option.

The power is provided via the same cable as in the case of the TP interface

systems.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

8

Page 9

3 Sites of installation

3.1 Key factors of operation

There are four key issues that the site survey has to shed light on. Proper system

operation cannot be guaranteed without satisfying all of the four requirements.

Clear line of sight - The entire optical path between the two ends must be free

of any obstacles. It not only means that one has to see the other side, but other

possible sources of disturbance should also be taken into consideration. For

example there might be turbulence above the roofs and other constructions, and this

can cause fraction or scattering of the beam or snow accumulation on roofs too

close to the beam can influence or even interrupt communication.

Solid mount surface - is the key for long-term operation. Since the diameter of

the beam is limited, it is extremely important to mount the unit on a stable structure

with the possible smallest movement. This way the receiver of the remote unit

cannot get out of the beam due to the movement of the opposite head.

East-West orientation - although the receiver optics are equipped with optical

filters to protect the receiver diode from the effect of undesired light sources, direct

sunshine can cause saturation of the diode. This prevents the system from working

properly for several minutes a day at certain times of the year. In most cases this

effect can be avoided by careful selection of the mounting spot.

In order to comply with the requirements of the successful installation - including the

discussed four key factors and other criteria - the following matters should be taken

into consideration.

3.2 Preferred installation sites

All buildings and constructions have a certain movement of their own. It’s

determined by the structure and material of the building. Metal structures can shift or

twist due to temperature changes. Wooden construction can expand or shrink with

any changes in humidity. Give preference to concrete or brick buildings. On the

other hand high structures like towers, skyscrapers or poles are always subject to

movement. Mount the support frame to walls of the building or near corners, as they

are the most stable spots. Use appropriate consoles for wall mounting. If a stand is

used on the top of

building, secure it directly to the ceiling or to the concrete cornice wherever is

possible. Do not fix stands to insulating materials as they can slowly sink under the

weight of the unit and with temperature changes. Big chimneys and smokestacks

may look stable, but as their inner temperature varies they can also move. Vibration

caused by heavy traffic, trains and elevators etc. may slowly move the system out of

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

9

Page 10

Preferred installation

sites

Pay attention to

Avoid (*)

Concrete wall

Behind window

Soft materials

Brick wall

Old constructs

Chimneys

Microwave towers

Wooden constructs

Metal masts or Frames

Hidden heat isolations,

like Styrofoam

its specified direction. Another important consideration is to provide enough space

for alignment and to have the potential for future maintenance. Consider that the

support frame is usually heavy, so the selected spot should be easily accessible.

(*)

In cases where installations are listed under “AVOID” cannot be avoided than special mounting

accessories to be designed and special installations must be used.

It is not only the building that has to be solid, but the support structure too. Antenna

poles and security camera holders are not suitable for the GeoDesy FSO units.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

10

Page 11

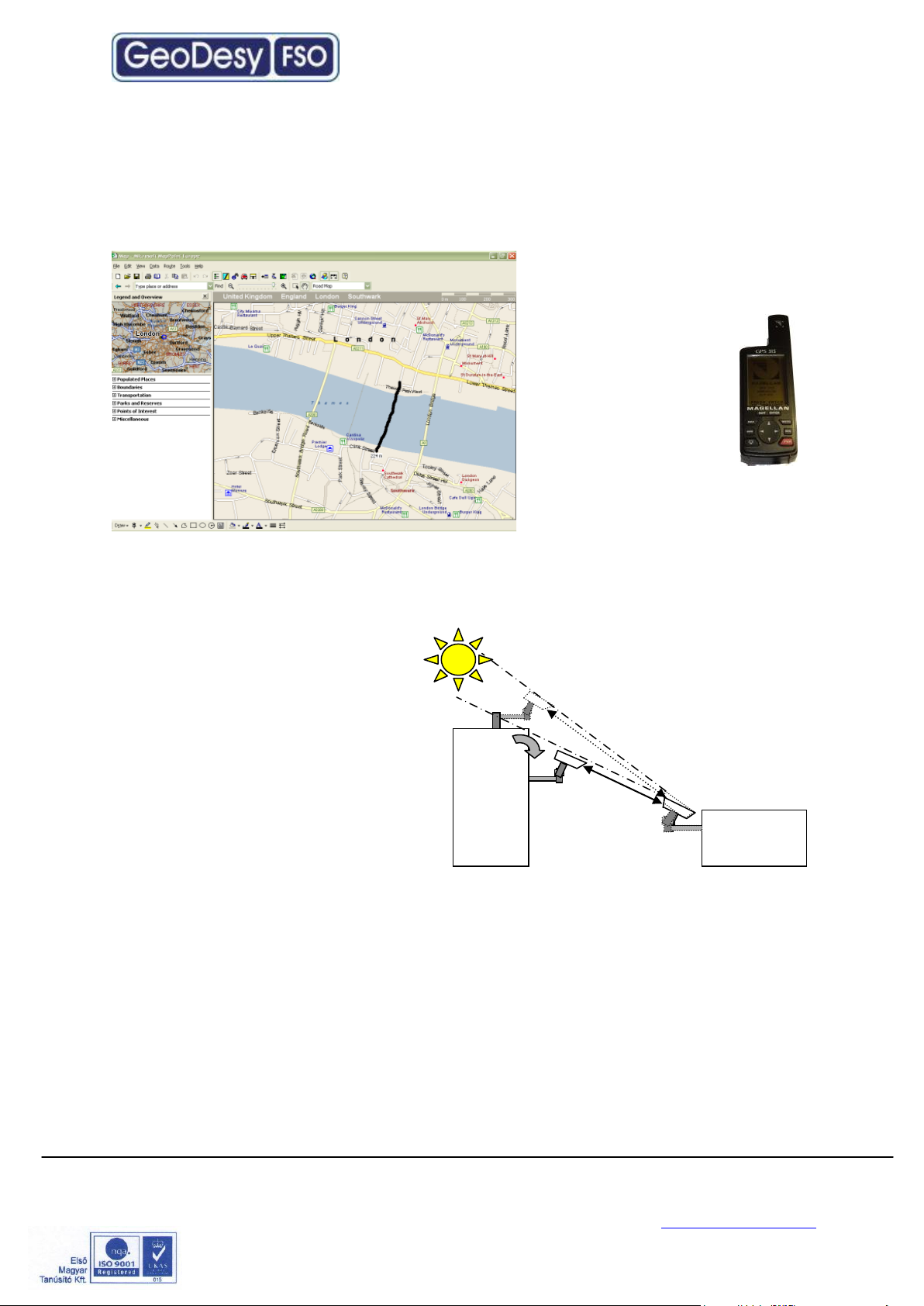

3.3 Distance measurement

Because the units were designed, and calibrated for certain distance operations the

higher distance will decrease the availability. GeoDesy FSO pre-calibrates and pretests every unit shipped to the customer. To ensure that the unit you are about to

buy fits to the needs, the first step

is to measure the distance. The

best way to measure it is by GPS

(Global Positioning

System), these units

are accurate enough to

determine the distance

between two points.

For more details please

refer to the GPS

manufacturer

handbook. Also there are several

other ways to measure the

distance. If you know the exact

address you can use mapping software like MapPoint or Auto route.

3.4 Direct sunshine

To prevent the sun shining directly

into the receiver optics, first one

has to determine the orientation of

the link. Try to avoid East-West

orientation wherever it is possible.

Examine both sides of the link at

sunset and sunrise and find a

position where the sun cannot get

behind any of the heads. Be aware

that the path of the sun is changing

throughout the year.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

11

Page 12

Type : LB P0500E1000TP

S/N : LBH-«s/n»

Input Power : -48VDC IEEE 802.3af compilant

Laser : 1M

Wavelength : 785nm

Manufactured by: GeoDesy FSO 1162 Budapest,

Kondorfa u. 6-8, HUNGARY, Tel.:+36-1-453-7440 Fax.:+36-1-240-3570

www.GeoDesy FSO.com

INVISIBLE LASER RADIATION

DO NOT VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS

CLASS 1M LASER PRODUCT

4 Eye safety

There are no two installation spots of the same kind, the buildings or structures, the

available space and the accessibility of the place will be different in each case.

Nevertheless, as a general rule it is very important to select the installation site so

that nobody can look directly into the transmitter. For this reason place the head

either so high (on the side wall of the building) or so close to the edge of the building

(on a parapet on the rooftop) that no person can approach it accidentally and can

get into the beam path. Set up barriers if necessary and put warning signs at

prominent places.

The laser heads are provided with all labels and hazard warnings required by the

laser standard. There are warning labels on both the left and right side of the

protective cover next to the optical window and there is a warning and an informative

label on the rear side of the laser head.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

12

Page 13

5 The mounting bracket

In the following chapter you will find detailed description of the bracket fastenings.

5.1 Mounting brackets for the X Series

GeoDesy FSO provides the mounting bracket and all the necessary components

for X series units. A simple fixing technique of this bracket can be seen on the

following figure, required tools are as follows:

- drilling machine

- 10 mm wrench

Bracket sizes:

Length: 463mm

Leg Width: 263mm

Head Width: 130mm

Drill size: 10mm wall drilling

Installation steps:

Place the bracket on the wall

Mark the wall with a permanent marker

Use your 10mm wall drill to drill all of the holes into the wall

Clean the holes

Place the wall-plugs into the holes (please note that some times you need to

use hammer to put the wall-plugs into the hole, if you have to please be

careful not to break the wall-plug )

Place the bracket to the wall an line it up to the holes

Put the screws into the wall-plug through the hole on the leg of the bracket

(please see the figure above)

Tighten up the screws

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

13

Page 14

Packet list for the bracket:

3pcs 8x110 screw for bracket fixing

3pcs 8x100 plastic wall-plug for bracket fixing

2pcs M6x90 bolt Head fixing

3pcs M6x25 screw Head fixing

3pcs M6 bolt head fixing

6pcs 6mm spacer bracket and head fixing

6pcs 6mm spring spacer bracket and head fixing

Mounting Hole Patterns

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

14

Page 15

6 System installation

6.1 On the table test

Warning! Do not look either into the transmitter or the receiver optics because at

this distance even the reflected laser beam can be dangerous to your eyes.

Operating the system on much shorter distance than presumed originally can cause

saturation or even permanent damage to the receiver. Always use optical

attenuators for this kind of test.

The on-the-table test needs careful planning and careful use during the test period.

The units should be placed at about 2 m distance from each other with optical

windows facing one another. Put an appropriate optical attenuator (Attenuating foil

or cardboard with several small holes) between the heads. Make all the necessary

connection as described below to connect your network equipment (computer or

protocol analyzer) to the heads and power up the units. Turn ON the PoE injector

and check if the power LED is ON on the head.

You should be able to align the units without any tool and get full received level on

the signal strength LED’s. Make sure that the “Saturation”(OV) indicator is OFF.

Adjust your attenuators if necessary to avoid saturation of the receivers.

Please note that at this short distance, specially the longer distance links can reflect

to the remote site or even to the same head. If you experience full receiving level,

with no traffic throughput, in that case try to move the heads slightly units out of the

reflection zone.

Please also take in consideration that the laser beam is concentrated and in such a

short distance can harm your eyes, every time you test the units on short distance,

do it with extra care. Never look into the sighting device if the remote laser is turned

on. We strongly suggest to double check the power connection before you turn on

the device. Handle the power connection with extra care. Safety first.

After obtaining the desired received level, check the data connection between

devices. Using computers or appropriate testing devices.

On the table tests are perfect for troubleshooting (If there is a transmission problem,

check the status of the connecting devices (e.g. Link signal or cable polarity) and

cables.) in a controlled area. If you experience some problems during the test,

please try to test the connected equipments with a direct connection.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

15

Page 16

6.1.1 Alignment of the PX0500E1000TP

The first step after the unit was placed to

the bracket, and the units facing each other.

On the back of the receiver you can find the

LEDs and LCD screen for the local received

level and the remote received level.

This help will be very useful because as soon as you have received – which is very

easy to achieve – you can see the effect of your local sides movement to the other

side. For further information please check the Meanings of the LCDs chapter.

6.1.2 How to use the alignment

base

1. Loose the Coarse locker on the

horizontal as well as on the

vertical side with a 10mm

spanner

2. Move the head left - right up

down you should use the built in

telescope to lit up a few LEDs on

the remote end.

3. When you have lined the unit up

to a rough position lock the

coarse locker with a 10mm

spanner.

4. Repeat step 1-4 on the remote

end.

5. On the bottom of the unit you can find fine tuning screws one for horizontal

and one for vertical.

6. No tightening is needed on any other screw than the coarse locker.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

16

Page 17

6.1.3 Fine tuning

1. Site A start moving the

laserhead with the horizontal

fine adjustment screw by

looking at the Remote end

received level

2. Using the fine adjustment

screws, lighten as many LEDs

as possible

3. Repeat step 1-2 on Site B.

4. If necessary try step 1-2 on

both sites again.

6.2 Meanings of the LCD

Power: The head is powered up.

RX-OK: Received beam is good for communication.

TP Lk: Copper link between the head and the

Network equipment.

R-LS: The recived signal form the remote end is

modulated and .

RV/TLs: Remote end is visible for the management system and there is TP

connected to remote end – same as TP-Lk but displays it on the remote end.

Please press the button and look at the LCD scren!

1.screen

Loc (local level): Local Received level

Rem (remote level): Remote Sites Received level

Op-optimal

Ov-overload

REM:?FSO Currently on FSO channel searching the Remote side.

REM:?Backup Currently on Backup channel searching the Remote side.

REM:?FSO or Backup Auto Software desides on what to search for.

2.screen

HeadSN: Laser head serial number.

0000001

IP address: default IP address:192.168.100.220 or 192.168.100.221

After factory reset the IP address is always: 192.168.100.221

3.screen 4.screen 5.screen

Temperature -AF mode position manual 000 tech@geodesy.hu

-AF mode auto

Here shows that the auto fucus with is enabled or disabled.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

17

Page 18

6.3 AF adjusment method

What is AF after all? AF stands for Auto Focus. Geodesy FSO Giga Next AF is

equipped with the lates innovation from Geodesy. An automatic focusing control

system. The system is capable of changing its beam divergency depending on the

changes of the environment. In the case if the weather gets bad, the system will

decrease the beam size, to concentrate the distributed beam power, to ensure more

stable operation.

IMPORTANT! Auto focus adjustment does not work if there is no remote level!

Remote connection required for the Auto focus adjustment.

The installation of the Giga Next AF is pretty much the same as the standard system

installation. To make sure that the AF system won’t kick in during the alignment,

ensure that the AF is set to disabled, which is the factory default.

The default settings of the Auto Focus (AF) laser heads is manual mode (disabled).

The factory beam divergence is set for 200m, this way the alignment of the system

will be easy on every installation distance.

Please do not change the setting of the AF laser heads to auto focus when there is

no connection between the two heads.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

18

Page 19

Alignment steps

1. using the crosshair align the units into a roughly aligned position. Please note

that the alignment scope will not be able to provide with a perfect alignment,

this will have to be done using the fine alignment screws referring to the

received level screen on the LCD panel.

2. using the fine adjustment screws on the alignment base set the units to the

highest received level possible. (for further details on how to perform the fine

adjustment refer to 6.2.2 and 6.2.3 chapters)

Default distance setting of all Giga Next AF laser heads for 200m. As you can see in

below sketch, “+25 STEP” equals ~ 2 cm larger laser beam over 100 meters.

For example, if you would like to install the laser heads over 350 meters than you

will need smaller beam size to reach bigger distance (compared to the default

200m), so click on “-100 STEP” which will make the laser beam narrower and will

be proper for 350m. While clicking on the “STEP” buttons please check the remote

received level on the laser head.

Please perform the same operation on the other side.

3. After we have got the proper level, please click on “Save position as default”

button. As you have clicked on the “Save position as default” button the laser

heads will enable the AUTO FOCUS mode (enabled). The equipment will

automatically improve the remote level to the most ideal position.

Note: Geodesy FSO shall not be responsible for any failures from improper handling

of the device. If any other screw than the coarse lockers or the fine adjustment is

moved, might decrease the stability of the installation.

Trick for the reliable alignment

Please note that the beam has a powerfull ring on the side of the head and easily can be set to this ring but this is far not as big

for further help. Or contact GeoDesy FSO technical support.

as the core part of the beam. So every time you have an

alignment please make sure that when you see the maximum

LED s or a relativly high received level. Keep on moving to

determine where the core part of the beam is. This can be

done easily by looking at the received level you will see that

the received level moves up then it will start move down than

up again. During this time you just had the head moving into

one direction. If you have any doubt on how to do the alignment please contact your distributor

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

19

Page 20

1. Orange/White

TX+

2. Orange

TX

3. Green/White

RX+

4. Blue

+VIN

5. Blue/White

+VIN

6. Green

RX-

7. Brown/White

-VIN

6.4 Connecting to your Network

6.4.1 PoE 802.3 af connection.

BOX1.1(FO)

6.4.2 System layout

BOX1.0(FO)

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

20

Page 21

6.4.3 System layout with GEO20

Beside the GeoDesy laser equipment (buckup) you can only use GeoDesy’s GEO20

Radio equipment. In the case of using a different backup solution, could cause

undesired operation. Please referr to support@geodesy-fso.com for more

inforamation about the compatibility.

BOX 1.0(FO)

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

21

Page 22

7 Management

7.1 Features

The Inband network-monitoring unit is a newly developed highly featured monitoring

for GeoDesy FSO manufactured laser links. This high quality equipment allows the

user to monitor the link statuses such as detector voltage transmitter status, and

many other features of the Laser link. Nevertheless, this chapter is intended to

describe the usage of this network monitoring, and its connection and relationship

with the GeoDesy FSO laserheads.

Login Screen and password

The GeoDesy FSO unit arrives with preset values. Such

as user name and password. We strongly recommend

you to change the password after the unit was installed.

The default username is admin, and the password is

admin. If you forget your password contact technical

support to receive your fail-safe password.

Head information screen

The head information screen is the main navigation panel through this screen you

will be able to navigate into the submenu, of the monitoring system.

Device Name: displays the name of the device. Individually can be changed

Total Uptime: Diplays the elapsed time from the last boot of the device

IP address: Displays the IP(Internet Protocol) address of the device which must be a

unique identifier in the network.

Managed head: displays the managed head type.

Head Serial Number: This is the head serial number and during the Activation

process we will ask for this number.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

22

Page 23

Status info screen

Clicking on the Device Setup you will enter the main status information screen,

which will give you good summarized information of the device, such as status

information of the transmitters, detector level, or temperature values.

Laser ON: Transmitter transmitts

Temperature: ambient temperature inside the device. These units were designed for

extreme conditions and should not have any problems under -20C to 70C. In fact the

unit is emitting some heat so the temperature displayed is not the air temperature

outside the head. For example the temperature can be -10C outside but in the

device it wont go below -1 or -2. The value will display error depeding on the setting

was done device setup. There is no default value for this setting, only a suggested

value, which is 60C.

Detector level: shows the local heads received level. In volts, the maximum is 7 volts

and the minimum is 0.2 volts. The value will display error depeding on the setting

was done device setup.

Remote Detector level: this value is dispalyed form reception of the remote head.

The maximum is 7 volts and the minimum is 0.2 volts.

TP_Link: displays that there is connection over the TP cable.

FSO Link: displays that there is valid signal received from the remote end.

Remote is visible: this status information is a good information about the connection

over the two laserheads if this status is OK that means that there is data transferred

over the link.

Remote TP Link: shows that whether the remote end is connected into the switch

and the TP interface is available.

PSU: The PSU of the device is sending the OK signal.

RX OK: this information is showing that the receiver is enabled. It basically means

that there is valid signal with necessary strenght is received in the local end.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

23

Page 24

Device setup

The device setup screen leads you to the main monitoring options. Here the alarms

can be set and main information about the Laser head.

Device name: uniqe identifier of

the device

Managed head: Type of the

laserhead

Temperature alert level: when the temperature reach this value, the alarm will be

triggered.

Auto recovery time: It determines the time before the heads start the recovery

process in the case of link disconnection.

Motherboard Serial number: Mainboard serial number inside the head (Not the same

as the Head Serial Number)

Motherboard Firmware version: This is the version number of the Firmware For the

update procedure please referr to the Firmware update section.

Head Serial number: Serial number of the unit. Should be the same number as the

one on the back of the unit. If the number is missing or not match up with the one on

the back, during activation this is the number you will have to let the support know.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

24

Page 25

Software version: software of the laser head.

NPASW SW version: Network Port Auto SWitchover version.

GBIC-compatibility mode:On or OFF.

If there are two connectors under the laser head them the GBIC-compatibility mode

should be ON (the is GBIC-module in it) but if there are 3 or 4 them the GBICcompatibility modeshould be OFF (the is NPASW module it).

Network Setup

Clicking on the IP Setup link you can have access to the Ethernet module of the

system, this will make easy access to the IP number and/or port settings. These

settings are sensitive setting and some of them cannot be restored by the user.

Please always do the changes with extra care! If you have doubt in any step, do not

hesitate to contact the technical support of the manufacturer website for further

information.

Local IP: the IP address of the local

device can be set in this box. If the IP

address is set retype it to your browser.

Enter only valid IP addresses, if you forget the IP address, you will have to turn to

our support and in some cases return the device for reseting the IP address. Please

always do the IP change with care.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

25

Page 26

Subnet mask: you can set the subnet

mask of the local device.

Default gateway: The default getway

setting for the local device.

Auto MDI/MDI-X: this enables the Auto

setting for the MDI/MDI-X, some old

switch types might report

incompatibility here it can be switched

off. (Auto MDI/MDI-X can be turned off

even in the Xs systems)

Remote IP:This will tell this device what

the IP address of the remote device is.

This setting wont change the remote

units IP address, this just identify the remote device for the local device. If the IP

address is not valid all diplays will go error and the display of the remote sites

received level on the laserhead will be disabled!

SWAP: swaps the local and the remote IP address. This function will require a swap

on the remote end to make the entire system working. If this function is used restart

the system.

NPASW mode: Network Port Auto SWitchover

FSO: Transmition throgh FSO.

Backup: Backup channel (FSO disabled)

Auto: If NPASW mode is Auto then the actual channel chosen by the software

is ON.(FSO or backup)

NPASW time limit: Minimum time needed to switch from back up to FSO(minimum 2

seconds)

NPASW treshold LOW:switches to backup

NPASW treshold HIGH:switches to FSO

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

26

Page 27

SNMP Setup

One of the main features of the device is the SNMP(Simple Network Monitoring

Protocol). The SNMP settings can be set on this page.

Trap address: The IP address of the SNMP trap over the network.

Trap events in the system you have

possibility to setup three different trap

event.

For further details on the trap event see

Trap event list chapter of this book. In this section there are the settings of the

SNMP Agent.

SNMP trap address: IP address of the

SNMP tarp computer

Read Community and Read Write

community To the setup of the Read

and the Read-Write community, the

preset value is public

Agent UDP Port the SNMP agent UDP

port number (1…1000) the preset value

is 162

Trap UDP Port: the SNMP trap UDP

port number (1…1000) the preset value

is 161

Traps:

The Laserhead is sending two different traps:

LaserHeadAlarm (OID: 1.3.6.1.4.1.17857.0.1201) This trap will be sent after any

of the alarms will go on (for alarm setting please see chapter 5.4)

LaserHeadAlarmCancel (OID: 1.3.6.1.4.1.17857.0.1202) After the alarm goes off

this trap will be sent

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

27

Page 28

Security

On the security section you can set the username and the password for the unit. If

you have forget the usernam and/or the password please contact The technical

support.

MGM Trusted-host filtering: Here you can adjust two addresses wehre you can till in

from which computer with you reach the MGM! To adjust you will hove to adjust a

filter.

Filter adjust:

Off: Turned off.

IP: Only see the IP address.

MAC: Only see the MAC address

IP+MAC: Either IP or MAC address should be equal to the adjusted.

IP&MAC: Both IP and MAC addresses should be equal to the adjusted.

Auto-focus setup (AF)

Automatic divergence corrections:

Enabled (auto): adjust beam size to the best level according to the remote level.

Disabled (manual): It disables the automatic adjustment routine, and lets the user

adjust the beam size by using the „STEP” buttons.

Last activity: which the AF (auto focus) has done.

idle: AF was not active..

setting default: saves the standard settings.

moving default: return to default settings.

moving to open: opens to widest beam.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

28

Page 29

increasing remote load: the AF adjusts the laser beam to increase remote level.

decreasing remote load: the AF adjusts the laser beam to decrease remote level.

optimizing remote load: the AF adjusts the laser beam to optimal remote level.

Manual focus control: After setting the Manual Focus controls you can adjust the

manual focus by clicking on the „STEP” buttons. You can increase the beam size, by

clicking on the plus numbers or you can decrease it by clicking on the minus. The

amount of the increase or the decrease depends on the number of steps .

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

29

Page 30

Mandatory Management Activation

Thank you for buying our product. Please read this note carefully. From software

version (3.2.1218/R090x)!

The product you have bought has fully functional management software, which has

limitation only in time. The unit activation request should be sent to

activation@geodesy-fso.com. And the activation code will be issued, later and sent

to the email address give, or can be accessed from your local distributor.

After 90 days if the system was not activated the data transmission will be

degraded!

Activation process:

1. Login to the devices through a web browser using the

IP:192.168.100.220,192.168.100.221

2. Default login name:admin and password:admin

3. Click on Evaluation period

4. Click on Get a key

5. Fill in the table and click on send

6. We will return the activation key

Limitations:

- All Next-Series(100MB/s) limitation course 1-60 days unlimited, for 61-80 days

10MB/s, for 81-90 days 1MB/s, beyond 90 days 100KB/s (MGM-Option).

- All GigaNext-Series(1000 MB/s) will be limited after the 90th day, when the whole

bandwidth will be blocked, except the management system.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

30

Page 31

Firmware update

The firmware update has the following steps:

Run FTP client

Log-in to the Laser-head

Copy Geodesy_FWUpdate_Vxx.sys over

Log in the laserhead

Click on update

Wait 50-60 seconds

Restart the laserhead

Run FTP client

FTP client setup

IP address: the IP address of the device (192.168.100.220 or 192.168.100.221 as a

factory default ) or the IP address you gave to the system earlier – same as the IP

address for the Web management.

User name: same as for the web management (default admin)

Password: same as for the web management (default admin)

If you have passive mode please turn it off, otherwise the system will not connect.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

31

Page 32

copy the file over to the Laserhead

Log off the FTP server

Now the Update button will be active

Click on update and the update process will start it takes upto 60 seconds. The

LEDs on the back of the device will go off than lit one after the other.

Make sure that the system power is fixed and the power will not go off during the

update process. If the LEDs froze, wait 2-3 minutes before unplugging the power

cable, and repluging again.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

32

Page 33

7.2 Network Interface software update

1. Connect the RJ11 and RS232 cable (update cabel)

between the laser head and the PC.

2. Enter into the management of the laser head and into the device info.

4.Click on the „Update” button.

5.Click on OK button.

6. Start the Total Commander program and start PIC32.exe program.

7. Choose COM1 port.

8.Click ont the Connect button.

9.Click on Erase button.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

33

Page 34

10. Click on Load Hex File button

and then choose the attached .HEX

file (new software)

11.Click on the Program button.

12.Click on Run application button:

the laser head will restart with the

new software.

13. Click on the Disconnect button and close the program.

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

34

Page 35

7.2.1 Update cabel

GeoDesy Kft. Telefon: 06-1-481-2050

Fax.: 06-1-481-2049

E-mail: info@geodesy-fso.com

http://www.geodesy-fso.com

35

Loading...

Loading...