VANVEX R +

VANVEX RS +

Domestic hot water heat pump

OE04:956-1807

MANUAL

2

3

TABLE OF CONTENTS

Introduction .....................................................................4

1. About the product ...............................................................4

2. Transport, Handling and Delivery .............................................13

3. Positioning .................................................................... 15

4. Water Circuit ..................................................................17

5. Air system .....................................................................21

6. Electric Connections ..........................................................24

7. Control and Operation ........................................................25

8. Maintenance ..................................................................42

9. Disassembly & Decommissioning .............................................45

10. Troubleshooting ...............................................................46

11. Warranty ......................................................................48

12. Declaration of conformity ....................................................50

13. Product and installer information ............................................51

4

INTRODUCTION

The aim of this manual is to give information, instructions and warnings on the heat

pump water heater. The manual is to be used by installers and plumbers as well as by

end users, since it contains important safety indications.

The manual is a part of the heat pump water heater and it is to be conserved with care,

since it contains important installation and maintenance instructions that can be useful to assure a long life time and an efficient operation.

1. ABOUT THE PRODUCT

The product is a heat pump water heater or also domestic hot water heat pump

(DHWHP) that has been designed according to EU directives. The product is intended

for hot water production for domestic use or for similar applications. The unit has

been designed to be ready for installation.

1.1. Safety precautions

• The product shall be installed, commissioned, repaired only by qualified technicians. Incorrect installation can result in damages of properties and injuries to people and animals.

• The unit shall be disconnected from the power supply when the cover is off.

• The unit shall not be used by children or people with limited physical or mental

capacity.

• Children should be supervised to ensure that they do not play with the appliance.

• Cleaning and maintenance shall not be made by children without supervision.

• Do not place flammable materials in contact or close to the unit.

• The water system and the air system should be installed as stated in the manual.

• When in service, the unit should not be placed in subzero temperature areas.

• When not in service, the unit can be placed in subzero temperature areas, but all the

water in the tank or in the condensate drain should be removed.

• Hot water can cause serious burns if directly connected to the taps. The installation

of a mixing valve is suggested.

• The unit should be used only for its specified use. The manufacturer is not liable for

any damages due to failure to observe this manual.

• Take all the possible precautions to avoid incidents.

• The product contains HFC-R134a.

5

1.2. Technical data

1.2.1. General

The heat pump water heater is composed of a water tank, a refrigerant circuit, a cabinet and a display connected to a control board. The main scope of the appliance is to

heat water stored in a tank.

1.2.2. Operation

The unit is programmed to start heating the water inside the tank when its temperature falls below a predetermined level. The unit stops when the water temperature

reaches a set point that can be regulated by the user. In general, the appliance is

designed to produce enough hot water to cover the need of a household of 4 persons

or more.

There are two ways in which the unit can heat the water:

1) Heat pump operation

In the operation with heat pump, a efrigeration cycle utilizes the operation of a compressor and the extraction of heat from the air to heat the water in the tank. This is

the standard way used to heat the domestic hot water, since it leads to lower electricity consumption, hence also lower running costs.

More information regarding the heat pump operation and the cooling circuit can be

found in paragraph 1.2.3.

2) Electric heater operation

The water is heated using an electric heater. An electric resistance is powered to heat

the water in a safe, fast and flexible way. However, using the electric heater can

become an expensive way to produce hot water. This operation should be used as a

back-up or as integration of the standard operation.

The electric heater is activated in case of:

• Failure of the heat pump operation.

• Too high or too low air temperatures.

• The quantity of hot water produced is not enough.

6

1.2.3. Cooling circuit

As depicted in Figure 1 and 2, the heat pump cycle can be divided in four main processes: compression (1-2), condensation (2-3), expansion (3-4), evaporation (4-1)

described below.

• At the suction of the compressor (1) the superheated gas refrigerant enters the

compressor at low pressure.

• In the compressor, the gas is compressed to a higher pressure and temperature

level (2).

• The gas is first de-superheated and condensed in the condenser, exchanging heat

with water stored in the tank.

• The refrigerant exits the condenser in a subcooled, liquid form (3)

• Through a thermostatic expansion valve the pressure of the refrigerant is lowered

to allow its evaporation at lower temperatures (4).

• The refrigerant is evaporated in the fin-coil heat exchanger that uses forced air as

heat source (1).

• The process goes on until the power supply to the compressor is stopped.

A deeper description of the cooling circuit and all components used for its design can

be found in Figure 3, 4 and 5.

3 2

14

Figure 1 – Heat pump principle Figure 2 – Pressure-Enthalpy diagram

7

Note: The extensive use of the electric heater leads to higher electricity consumption

and it may lead to high electricity bills. The operation with electric heater normally

consumes 3 times more electricity than the operation with heat pump. The energy

released to the condenser (2-3) is, in fact, the sum between the free energy extracted

from the air in the evaporator (1-4) and the energy supplied to the compressor (2-1).

On average, the energy absorbed by the evaporator is more than double of the energy

used to run the compressor.

1.2.4. Safety instructions – Cooling circuit

• Only skilled and trained technicians shall carry out repair and service of the heat

pump circuit.

• Before opening the cooling circuit, discharge the refrigerant to a level that allows

safe working conditions.

• The refrigerant can be toxic if inhaled or if in high concentrations.

• Special attention should be given if the work is carried out with an open flame.

1.2.5. Process and Instrumentation Diagram

Figure 3 – Process and Instrumentation Diagram

8

AA1

XL7

XL6

GQ1

HZ1

RM1

CA1

GQ2

AA2

XL8

XL1

XL2

XL9

XL3

Refrigerant circuit

GQ1: Compressor

GQ2: Fan

RM1: Check valve

EP1: Condenser

EP2: Evaporator

HZ1: Filter drier

QN1: Solenoid valve

QN2: Thermostatic

expansion valve

XL3: Service valve

Water circuit

XL1: Water outlet

XL2: Water inlet

XL4*: Coil top

XL5*: Coil bottom

XL6: Air outlet

XL7: Air inlet

XL8: Condensate outlet

XL9*: Hot water circulation

EP3*: Coil

EB1: Electric heater

FR1: Anode

FN1: Thermal protection

The items with * are only available for Vanvex 260 RS +.

Figure 4 – Design of the cooling circuit and

the main components

9

FR1

FN1

EB1

BT3

EP1

XL4

XL5

Sensors

BT1: Air inlet temperature

BT2: Evaporator temperature

BT3: Tank water temperature

BT4*: Additional temperature

BT5*: Additional temperature

(not included)

BP1: Pressostat

Electric components

AA1: Main printed circuit board

AA2: Display circuit board

WF1: Modbus port

GC1*: Solar 0-3V/10V

QA1*: SG-ready port

GP1*: Additional supply

to pump or damper

KF1*: Wi-Fi

The items with * are optional.

Nomenclature according to standard

IEC 81346-1 and 81346-2.

Figure 5 – Design of tank, condenser and

related components

10

1.2.6. Main Technical Data

The main technical data are collected in the following figures and table.

A

B

C

H

F

G

D3

E2

D1

D2

E1

Figure 6 – Dimensional data

Parameter Unit 190L 260L

Dimensional data

A – Height mm 1610 1960

B mm 385 385

C mm 280 280

D1 mm 180 300

D2 mm 435 670

D3 mm 375 460

E1 mm 285 285

E2 mm 305 305

F – Diameter mm 603 603

G - Diameter mm 160 160

H – Max diameter mm 620 620

Height required for installation mm 1700 2040

Weight dry/wet (with coil) kg 94/284 120/370

Nominal insulation thickness mm 50 50

11

Parameter Unit 190L 260L

Electrical data

Power supply V/Hz 230/50

Fuse A 13 (10)

Electric connections - L1, N, G

Electric heater power W 1500

Cooling and water circuit

Refrigerant type - R134a

Refrigerant quantity g 1200 1280

GWP - 1430

CO2 equivalent ton 1,7 1,8

Cooling circuit - Hermetically sealed

Protection rating - IP21

Water connections - Enameled in ¾ - BSPT (ISO 7-1)

Water connections – Stainless* mm 22 – Compression fittings

Water condensate connection mm Ø19

Nominal insulation thickness mm 50 50

Corrosion protection - Magnesium anode / Stainless steel

Performance data

Outdoor air at 7°C (EN16147)

COP - 3.57 3.69

Heat up time hh:mm 06:28 09:12

Stand-by heat losses W 17 20

Sound power dB(A) 49 49

Indoor air at 20°C (EN16147)

COP - 4,13* 4.20

Heat up time hh:mm 05:15* 07:09

Stand-by heat losses W 17* 21

Sound power dB(A) 55.6 55.6

Volume at 40°C L 247 347

Auxiliary power W 1.61 1.61

*To be subjected to 3rd party test.

12

1.2.7. Fan Curve

Figure 7 – External static pressure vs airflow at different fan speeds.

In order to assure an efficient operation, it is suggested to keep the external pressure

drops below 200 Pa.

Parameter Unit 190L 260L

Airflow

Nominal air flow rate (variable range) m3/h 450 (0-800)

Maximum fan power consumption W 85

Max external static pressure Pa 200

G - Air duct connections mm 160

Minimum volume of room installation m

3

30

Operating limits

Max air temperature °C 40

Min air temperature °C -7

Max water temperature °C 60

Max water pressure MPa 0,6 or 1,0. Check nameplate

13

2. TRANSPORT, HANDLING AND DELIVERY

Immediately upon receipt, the domestic hot water heater pump must be examined to

make sure that it is intact and undamaged. If not, the shipping company must be

informed immediately. The recipient has the responsibility for all the shipments

unless otherwise agreed.

2.1. Delivery Mode

The appliance is delivered without condensate drain tube and the safety equipment

for the water circuit.

2.2. Storage

The unit must be stored and preferably transported upright, free of water and within

its packaging.

Transport and storage may take place at temperatures between -10 °C and +50 °C. If

the unit has been transported or stored at sub-zero temperatures the unit should be

left at room temperatures for 24 hours before commissioning.

2.3. Transport with Forklift

For transport with a forklift, the unit must stand on the associated transport frame.

Always lift the unit slowly. Due to the high center of gravity, the appliance must be

secured against tipping during transportation.

2.4. Unloading the Heat Pump

In order to avoid damages, the unit must be unloaded on a flat surface.

14

2.5. Transport with Trailer

The unit must only be transported on the associated transport frame. This also

applies to transport on stairs.

The unit must be secured against sliding on the trailer.

Water connections etc. shall not be used for transportation purposes.

It should be made sure that the trailer does not damage the cabinet or the

various connections.

Figure 8 - Transport with trailer

2.6 Horizontal transport

When carefully transporting the unit over a short distance to its final location, the unit

can be transported horizontally in its packaging on the dedicated side. If the unit has

been tilted more than 45°, the unit must be left in its normal upright position for at

least 24 hours before it is started.

15

3. POSITIONING

The installation site should be equipped with a power supply of 220-240V and 50 Hz.

The power supply and the hydraulic system must comply with the local regulations.

The unit should be placed vertically, with a maximum inclination of 1°. The unit must be

well balanced and stable on the ground surface. Use the built-in adjustable pads to

level the unit.

The unit must be installed as close as possible to the hydraulic system in order to minimize heat losses in the water pipes. The water pipe outlet should be insulated for the

same reason.

The unit should not be placed in direct contact with the sunlight.

The unit can only be installed in a frost-free room and it should follow the criteria:

• Room temperature between 5°C and 40°C.

• Drain possibility for condensate and floor drain.

• No abnormal dust concentration in the air.

• Solid base (approx. 500 kg / m2).

• It is necessary to ensure that there is sufficient space around the unit for mainte-

nance and service. A clearance of 0.5 m around the unit is recommended.

Ducted unit

In case of a ducted unit, the unit should be

installed as close as possible to the walls in order

to minimize pressure losses in the air ducts.

Not-ducted unit

In case the unit is used without exhaust/extraction air ducts, it should be placed in a room with

the following characteristics:

• The volume of the room should be more than

30 m3.

• The room should be well ventilated.

• There should be no other appliances that need

air to operate.

• The minimum distances described in Figure 9

should be respected.

Figure 9 - Minimum distance from

walls for not-ducted units

16

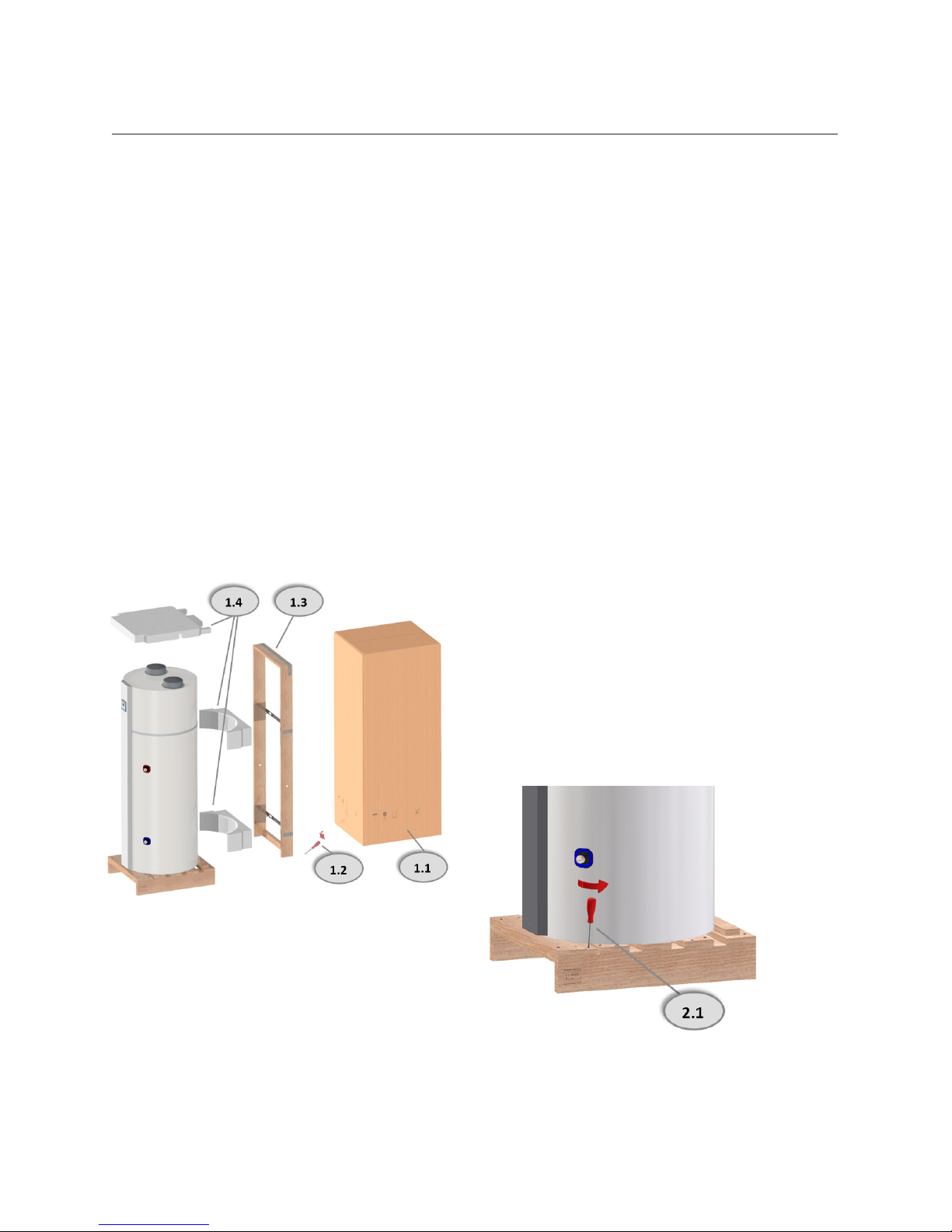

3.1. Set-up sequence

Once the unit is placed in a room with characteristics as specified in the previous

paragraph, then it can be prepared following the sequence described below:

1. Remove the packaging from the pallet.

2. Remove the transport fittings from the pallet.

3. Remove the unit off the pallet and place it on the floor.

4. Adjust the unit vertically by adjusting the feet.

5. Check that the unit has no damages.

6. Set-up the water circuit (See chapter 4) and fill the tank with water.

7. Set-up the air circuit (See chapter 5).

8. Set-up the electric connections (See chapter 6).

When the unit is supplied with electricity, it automatically starts running in its

standard operation according to the factory settings as described in Chapter 7.

Figure 10 - Set-up sequence

17

QN3

QN8

QN7

QN4

QN6

QN5

GP1

RM4

RM3

XL1

XL9

XL2

XL4

XL5

4. WATER CIRCUIT

The water circuit must be installed in accordance with local norms and standards.

The water used must be drinking water.

Material compatibility in the whole system must be ensured. Incorrect material

combinations in the water circuit can lead to damage due to galvanic corrosion. This

requires special attention when using galvanized components and components that

contain copper.

The pipe sizes for on-site installation shall be based on the available water pressure

as well as the expected pressure loss in the pipe system.

As for all pressurized vessels, the heat pump water tank has to have an approved

safety valve (pressure setting depending on local rules and regulations) and a non

return/check valve on the cold water inlet.

The following figure depicts the suggested configuration on the water system, with

the possibility to include a water recirculation circuit. This last connection is only

available for Vanvex 260 RS +.

XL1: Water outlet pipe connection

XL2: Water inlet pipe connection

XL4*: Coil top

XL5*: Coil bottom

XL9*: Water circulation connection

QN3: Shut-off valve water outlet

QN4: Shut-off valve water inlet

QN5: Drain valve

QN6: Safety valve

QN7: Shut-off valve pump inlet

QN8: Shut-off valve pump outlet

RM3: Check valve

RM4: Check valve water circulation

GP1: Water circulation pump

Figure 11 – Diagram of suggested water circuit connections

18

4.1. Water connections

Dirt in the pipe work must be avoided. After installation of the external pipes flush if

required before connection of the domestic hot water heat pump.

If no circulation of water is needed, make sure that the circulation connection is

properly sealed.

When installing the pipes please ensure that the pipe connections are not excessively

stressed. Use a pipe wrench to relax torque forces on the pipe connections.

The water pipe outlet should be insulated to reduce heat losses to the ambient and to

reduce the risk of injuries and burns.

4.2. Location of connecting pipes

Hot water outlet pipe is mounted on the upper connecting branch.

If the unit is equipped with the hot water circulation access, the middle connecting

branch is used for hot water return. Inlet of fresh cold water is mounted on the bottom

connecting branch.

4.3. Connection of condensate drain

While the heat pump is running, condensate will form, which is to be discharged

to the sewage drain via the condensate

drain pipe, Ø 19 mm connection outside.

The quantity of condensate depends on

the humidity, the air flow, and the temperature of the air.

The condensate connecting branch must

be equipped with an air tight water trap

and run to a drain. The water trap must

contain a standing water column of at

least 60 mm.

Neglecting to install a drain trap can lead to damage to the appliance. If the drain trap

is not installed correctly, the product warranty is not valid.

Figure 12 - Condensate drain

19

4.4. S Coil connection (optional)

In the unit there can be an extra heat exchanger installed. In the sensor pocket for the

thermostat sensor, there can also be placed a sensor to control the external connection e.g. oil burner, wood burner etc. The maximum inlet temperature of the heating

coil is 90 °C. If there is risk of inlet temperatures above 90 °C the installer must install

an external device preventing high inlet temperature to the heating coil.

4.5. Safety instructions – Water circuit

• Only drinking water must be used.

• During installation, attention must be paid to the choice of materials and it must be

ensured that chosen materials work together without problems in the entire circuit.

• Special attention must be paid when using galvanized components and components

containing aluminum.

• Safety equipment must be installed to prevent over pressure in the system. Always

use a safety valve with maximum relief pressure according to the unit nameplate

and a stop valve (approved according to heating and plumbing regulations). All pipe

work has to be installed according to plumbing and heating regulations.

• The discharge pipe of the pressure-relief device (safety valve) must be installed

frost free and with a slope away from the device. The pipe must also be left open to

the atmosphere.

• Temperatures above 90 °C in the heating coil may cause excessive pressures in the

cooling circuit.

20

4.6. Leak test

After installation it is necessary to check that the entire water installation is tight.

This is accomplished by performing a water leak test.

4.7. Commissioning of the water circuit

Fill the water tank via the cold water connecting branch. Deaerate the water tank by

opening one of the hot water taps located at the highest level until air no longer

appears at the tapping point.

A few days after the initial setup and start-up, check the installation for leaks in

the water installation or blockage of the condensate drain.

21

5. AIR SYSTEM

The inlet air must not be polluted with aggressive components (ammonia, chlorine

etc.) as components parts of the heat pump unit may be damaged. The air also needs

to be free of dust and other particles.

Inlet and outlet ducts shall be made of rigid smooth pipes to minimize pressure losses.

Please take into account the fan working pressure and the ducts pressure losses during dimensioning of the duct system (see technical data).

The two connections to the heat pump are Ø 160 mm. It is advised to install the air

ducts near the heat pump, levelled or with a slight inlet, in order to avoid ingress of

condensed water from the duct system to the heat pump.

All air ducts should be insulated after they have been installed, in order to reduce heat

loss and noise level. Insulation has to be applied to protect against external condensation on the cold exhaust duct.

It is recommended to mount a flexible connection between the air duct and duct connection to ease future service of the unit.

It is also recommended to install silencer units in between the heat pump unit and the

ventilation system to avoid potential travel of noise from the unit to the ventilation

system.

The unit has been designed to operate with different air ducts configurations:

1) Not-ducted unit, ambient air. The unit extracts heat from the ambient air and

lowers the air temperature of 5-15 °C according to the operating conditions.

Since the air is re-directed to the room, this configuration is particularly interesting during summer periods. This configuration is not suggested for winter

periods, especially if the room in which the appliance is located is heated by

other appliances.

2) Partially ducted unit, ambient air. This configuration is normally preferred to

configuration 1 since the cold air coming out from the unit is directed out of the

house.

3) Ducted unit, external air. This configuration minimizes the temperature

decrease of the installation site, since there is no contact between the air in the

room and the air through the heat pump. It is suggested to place the inlet pipe

22

far from and possibly higher than the outlet pipe, to minimize the recirculation

of cold air into the unit.

4) Ducted unit, exhaust air. This is the configuration that normally minimizes the

electricity consumption of the unit. It is particularly suggested if there is no

cooling demand in the installation site.

Figure 13 – Air ducts configuration

23

The appliance is normally supplied with two air duct connections with a plastic net

with a protective function (Figure 14).

If the appliance is used as ducted unit it is highly suggested to manually remove the

plastic net by using a set of pliers. This operation allows the unit to run more efficiently, since the air pressure losses in the air circuits are minimized.

Figure 14 - Standard connection for use with

ambient air, not ducted units.

Figure 15 - Connection for use with ducted units.

24

N

N

RX

GND(0V)GND(0V)

L

L

TX

FAN

SUPPLY

WIFI

WIFI

11-01-2017 Rev.:C

Wiring ES1028_1 PCB With Hygrostat switch

Hygrostat switch

Resistor 10Kohm 0.5Watt

ES1028_1A

6. ELECTRIC CONNECTIONS

The unit must be supplied with current at 220-240V and 50 Hz.

The unit is supplied with a standard Schuko plug. If local regulations dictates fixed

installation or if the supplied plug does not ensure correct earthing, cut off the

Schuko plug from the power supply cable.

When the unit is connected to the power supply, it will turn on automatically and it will

start its operation automatically.

• The first time that the unit is turned on, it will start its operation according to its

factory settings.

• If some control settings are modified, the unit will start with the same settings at

the previous switch off conditions.

6.1. Electric Diagram

Figure 16 – Wiring diagram

25

7. CONTROL AND OPERATION

7.1. Home view

The unit can be controlled from the control panel described in Figure 17. From the

home view, all the main operational modes, functions, set points and information on

the unit can be accessed.

Figure 17 – Display, control panel

1: Electric heating state (ON/OFF)

2: Main menu (Can be open by pressing )

3: OK/Enter

4: Mode (Change with or )

5: Scroll down

6: Scroll up

7: Return back

8: Information (open with )

9: Temperature set point

10: Heat pump operation (Heat pump, Ventilation, Defrosting)

11: Time

26

The top part of the screen gives information about the unit operation, time and temperature set point. This part is passive and it is changed automatically.

The bottom part of the screen is active, meaning that the icon on the screen contains

other menu items. This part is divided in three menus:

• INFORMATION MENU (8), that can be accessed by pressing ( )

• MODE MENU (4), that can be accessed by pressing ( ) or ( )

• MAIN MENU (2), that can be accessed by pressing ( )

The MAIN MENU is composed of 4 sub menus:

– Temperatures

– Functions

– General

– Installer

The menu items with * are only available for Vanvex 260 RS +.

7.2. Information menu

The information menu can be opened pressing button ( ) from the home view. This

menu gives all the operational information of the unit. The available information are

divided in four groups:

• Temperatures (T)

• Collected data on the unit operation and performance (I)

• The state of the relays of the unit (R)

• The errors and alarms of the unit (Er)

All the information that can be shown in the information menu are described in the following table. All temperatures are in °C.

27

Class Code Menu Item Description

T

T1 T air i The air temperature at the inlet of the unit

T2 T air o The evaporator temperature at the outlet of the unit

T3 T tank t The water temperature at the top of the unit

T4 T tank b* The water temperature at the bottom of the unit

T5 T extra* The temperature measured by the additional sensor

V

V1 Fan % The actual speed of the fan in %.

V2 Input V* The actual input signal in GC1 (0-10V) from the PV or

hygrostat in Volts.

I

I1 HP hr The total amount of hours that the compressor has been

running

I2 EL hr The total amount of hours that the electric heater has

been running

I3 Fan hr The total amount of hours that the fan has been running

I4 T Avg a The average air temperature with operating unit is dis-

played in °C since last Reset All

I5 T Avg e The average evaporator temperature with operating unit in

°C since last Reset All

I6 HP ON The number of START/STOPS for the entire unit life time

since last Reset All

I7 W el The calculated instantaneous electricity consumption in W

since last Reset All

I8 MWh el The total calculated electricity consumption in MWh since

last Reset All

I9 W th The calculated instantaneous heating capacity is displayed

in W

I10 MWh th The total calculated hot water production is displayed in

MWh since last Reset All

I11 EL MWh The electricity consumption of the electric resistance in

MWh since last Reset All

R

R1 Extra* The operation of the extra relay, for example for the

operation of a circulation pump

R2 Defrost The operation of the relay that controls the solenoid valve

for the defrosting function is shown

R3 Fan The fan speed is shown in %

R4 HP The operation of the compressor is shown

R5 EL The electric heater operation is shown

28

7.3. Mode of operation

Different strategies to heat the water can be selected from the main control panel

pressing 5 or 6 (Scroll down or scroll up) from the home view.

The possible modes of operation to choose from are found in the following table:

Figure 18 – Modes of operation

Class Code Menu Item Description

Er

Er1 T1 Error The temperature sensor T1 is out of range

Er2 T2 Error The temperature sensor T2 is out of range

Er3 T3 Error The temperature sensor T3 is out of range. If T3 Error

occurs, the unit does not heat the water in any way

Er4 T4 Error* The temperature sensor T4 is out of range. The error Er4 is

ignored and the unit runs normally

Er5 T5 Error* The temperature sensor T5 is out of range. The error Er5 is

ignored and the unit runs normally

Er6 Err HP The pressure switch opens, when the pressure in the cool-

ing circuit is above the limit of pressure specified on the

high pressure switch

Er7 Err Evap The temperature sensor T2 is above T1 - 2°C for more than

one hour

Er8 Err C Evap The temperature T2 is below - 25°C

Er9 Err H Evap The temperature T2 is above D11 (Evaporator T max)

Er10 Filter Replace filter. The alarm is displayed on the main screen,

but the operation of the unit is not affected.

29

Note: the unit can be turned off switching to HOLIDAY mode.

Code Set point name Description

P1 AUTO The heat pump heats the water when required, normally using the

heat pump operation. The unit starts when the water temperature T3

is more than 5°C below A1 (T AUTO) and it stops when this temperature is reached. If the air temperature is out of the feasible limits,

the water is heated with the electric heater.

P2 ECO The heat pump consumes as low energy as possible. The heat pump

has a lower water temperature set point A2 (T ECO). The heat pump

heats the water to a lower temperature compared to the other

operations.

P3 BOOST The heat pump and the electrical heater operate simultaneously

when possible. The unit starts when the water temperature T3 is

more than 5 °C below A3 (T BOOST) and it stops when this temperature is reached. If A3 (T BOOST) is higher than D33 (T HP max) the

compressor stops when the temperature D33 (T HP max) is reached.

The remaining temperature lift is accomplished with only the

electric heater.

P4 BACKUP This is an emergency mode. When an error occur, preventing the ope-

ration of the heat pump, the water cannot be heated. On the display

the possibility to activate the BACKUP mode is asked to the user.

In BACKUP mode the water is heated up by the electric heater at a

lower temperature than the desired one.

The Legionella control is active in any case.

The unit starts when the water temperature T3 is more than 5 °C

below D12 (BACKUP T) and it stops when this temperature is

reached.

P5 SILENT The fan speed decreases to the minimum in order to minimize the

sound emission of the unit in operation. The unit starts when the water temperature T3 is more than 5 °C below T1 (T AUTO) and it stops

when this temperature is reached.

P6 HOLIDAY The heat pump is turned off and only the LCD display is active. The

heat pump does not start when water heating is required. The compressor is OFF except during LEGIONELLA control in which it can be

activated.

The HOLIDAY mode is connected to the Hot on time function B4 (Hot

on time). After the HOLIDAY period is completed, the unit goes back

to the previous mode of operation.

30

7.4. Main Menu

Entering this menu requires a good understanding of the unit operation.

It is highly recommended to read and well understand the descriptions of the following menu items. Changing some of these set points can have large effects on how the

appliance operate and performs.

The main menu is divided

in four sections:

• Temperatures

• Functions

• General

• Installer

7.4.1. Temperatures

The temperature set points can be changed under the menu point “temperatures”.

Different temperature set points can be adjusted according to the relative mode of

operation. All temperatures are in °C.

Code

Set point

name

Description Range

Factory

setting

A1 T AUTO The temperature level at which the unit heats the

water when the AUTO mode is selected. The unit

starts if the temperature of the water in T3 falls of

5 °C below the set point.

50 - 60 53

A2 T ECO The temperature level at which the unit heats the

water when the ECO mode is selected. The unit

starts if the temperature of the water in T3 falls of

5 °C below the set point.

50 - 55 50

A3 T BOOST The temperature level at which the unit heats the

water when the BOOST mode is selected. The unit

starts if the temperature of the water in T3 falls of

5 °C below the set point.

50 - 65 55

Figure 19 - Main menu

31

7.4.2. Functions

The functions are similar to the modes of operation but they cannot be accessed

directly from the home view and they can vary from unit to unit.

In addition, since SOLAR, FLOOR and COOLING (called extra functions) can not be

used simultaneously, the choice of these functions should be made from the Installer

menu (D26 Extra function). In the function menu, only one of these extra function is

normally shown. The function menu is described in the following table.

Code

Set

point

name

Description Range

Factory

setting

B1

OFF The fan switches off when the heat pump does not run.

OFF/

Single

Speed/

2Speeds

OFF

Single

speed

The fan is always running at a single fixed speed (B2 Fan

speed), both when the heat pump is operating and when it

is not.

2

Speeds

The fan is always in operation but it runs normally at a

higher speed D6 (Fan AUTO Speed) when the heat pump

starts operating and at (B2 Fan speed) when it is not

operating.

B2

Fan

speed

The main fan speed regulation for the ventilation function.

There are three ventilation level that can be selected: LOW

D5 (Min Fan Speed), MEDIUM D4 (Fan medium speed)

HIGH D3 (Max fan speed).

LOW/

MEDIUM/

HIGH

HIGH

B3

Low

Tariff

Standard

The low tariff allows the electric heater and

the heat pump to run only during periods with

low electricity prices, according to the menu

item that regulate the program of the low tariff D17/D18 (Low tariff weekday/weekends).

The unit runs only during pre-defined hours of

the day. If the PV function (B5) is active, this

allows the electric heater and the heat pump

to run outside the low tariff period.

OFF/

STANDARD/

OPTIMAL 1/

OPTIMAL 2

OFF

Optimal 1

This function allows the maximum exploitation of the lower electricity price during the

night periods between 00:00 and 05:00.

Optimal 2

This function allows the maximum exploitation of the lower electricity price during the

night periods between 00:00 and 05:00.

During the day, the unit works according to

Low Tariff periods D17 and D18.

Ventilation

32

Code

Set point

name

Description Range

Factory

setting

B4

Hot on

time

The unit can be programmed to deliver hot water from

1 to 30 days from the moment in which the function

is activated and the HOLIDAY mode is selected. The

unit switches to AUTO MODE in the desired number of

days. If OFF is selected, the function is not active.

OFF/ON OFF

B5

OFF*

The PV function is not active. If this function is activated, the heat pump and the electric heater can start

only if the input voltage in GC1 (0-10V) is higher than

D20/D21 (PV min Voltage HP/EL) for longer than D22

(PV min time).

OFF/

ECO/

STOR

AGE

ECO

PV ECO*

The PV function allows for water heating only with the

heat pump until temperature set point defined by the

MODE of operation is reached.

PV

STORAGE *

The PV function allows for water heating to the

maximum temperature level, giving priority to the

operation of the heat pump if the BOOST or BACK UP

mode is not active. The heat pump operates alone until

the max allowed temperature for the heat pump operation D33 (T HP Max) is reached. The electric heater

operates only from D33 to the maximum allowable

temperature D9 (Water T max).

B6 Solar*

The Solar function allows the water to be heated up by

the solar collector, activating a water pump controlled

by the extra relay (GP1). The pump starts when T5 > T3

+ D24 (Solar DT min). The pump stops if the temperature in the tank goes above D23 (Solar T max) or if T5

is below T3.

OFF/ON OFF

B7 Floor*

The floor heating function activates an external circulation pump. If the temperature at the bottom of the

tank T4 (T water b) is higher than the setting menu D25

(Floor T start) the floor heating function is activated.

If the extra temperature T5 (T Extra) is higher than the

floor heating temperature (B8 T floor) the circulation

pump (Extra relay GP1) stops.

OFF/ON OFF

Photovoltaic

33

7.4.3. General

The general section collects all the standard settings that have little or no effect on

the heat pump operation, exept for the menu item Reset.

Activating the Reset function brings all the set points to the factory settings value.

The set points of the General menu are described in the Table below

Code

Set point

name

Description Range

Factory

setting

B8 Floor T*

The desired floor heating temperature in °C with

hysteresis of 1K.

15 - 40 35

B9 Cooling*

The Cooling function can be activated. See installer

menu D28 (Cooling type).

OFF/ON OFF

B10 Cooling T*

The air temperature set point (°C) below which the

heat pump stops, when the unit is in the Cooling

function.

10 - 30 21

Code

Set point

name

Description Range

Factory

setting

C0 Reset

The set points in the user menu are reset. The

more advanced settings can be reset only from the

installer menu. The information as number of hours

of the compressor and fan cannot be reset.

OFF/ON OFF

C1 Info The software version is displayed. - -

C2 Time The time can be adjusted here. - -

C3 Date The date can be adjusted here. - -

C4 Day The day of the week can be selected. - Monday

C5 Language More languages can be selected. - English

C6 Contrast The contrast of the screen can be adjusted. 0-10 5

34

7.4.4. Installer

The installer menu should be accessed only by qualified personnel. Some of the set

points that can be regulated from this menu can have large effects on the unit performance depending on the type of commissioning and installation. There should be a

proper match between installer set points and type of installation in order to optimize

the performance and lifetime of the unit.

In order to access the Installer Menu, a 4-digits password needs to be entered. The

password is: 2016. All temperatures are expressed in °C.

Code

Set point

name

Description Range

Factory

setting

D0 Reset all

All the set points are reset to original factory settings. Also the Information menu and the installer

set points are modified.

OFF/ON OFF

D1 Errors The alarms of the unit can be checked here. - -

D2

D2.0

Address

Modbus address. The Modbus address can be set

between 1 and 247.

1-247 30

D2.1 Baud

Rate

Modbus baud rate. The Modbus baud rate can be set

between 19200 and 9600.

9600/

19200

19200

D2.2 Parity

Modbus parity. The Modbus parity can be set between Even or Odd or deactivated.

Even/

Odd/

None

Even

D2.3

Write

enable

Modbus modify. If this function is activated, it is

possible to modify the set points kept for development with a data logger.

OFF/ON ON

D3

Fan max

speed

The maximum fan speed (%) can be regulated. This

is the highest limit at which the fan can run both

when the ventilation function is active and when the

heat pump is in standard operation.

0-100

70

(outdoor)

D4

Fan medium speed

The medium fan speed (%) can be adjusted.

0-100

50

(outdoor)

D5

Fan min

speed

The minimum fan speed (%) can be adjusted.

0-100

40

(outdoor)

D6

AUTO

speed

The automatic speed of the fan (%) when the heat

pump is running in AUTO and ECO mode can be

regulated. This is a nominal value while the fan

speed may automatically vary its speed at a higher

level, depending on the operating conditions.

0-100

57

(indoor)/

48

(outdoor)

Modbus

35

Code

Set point

name

Description Range

Factory

setting

D7 Air T min

The minimum air temperature allowed during the

operation of the heat pump can be regulated here. If

T1 is below Air T min the electric heater starts and

it works alone until the set point is reached. (Even if

the air temperature increases in the meanwhile).

(-7) (+10)

-7

D8 Air T max

The maximum air temperature allowed during the

operation of the heat pump can be regulated here.

30-40 40

D9

Water T

max

The maximum allowed temperature in the tank.

55-65 65

D10

Defrosting T

Stop

The temperature of T2 at which the defrosting function stops. The defrosting function is automatic and

it occurs not more often than once every hour.

0-10 4

D11

Evaporator T

max

The maximum evaporator temperature allowed

during the operation of the heat pump can be regulated here. If T2 has a higher temperature than the

set point, then use electric heater. This function is

active 10 minutes after the compressor start.

10-40 30

D12

BACKUP T

The water temperature at which the unit stops the

backup mode with only the electric heater.

0-65 35

D13

Legionella

The legionella function can be activated. The

legionella function does not switch the heat pump

on, but just continues the heat up cycle to a higher

temperature D14 (Legionella T). The legionella

operation works only with the heat pump until 60°C.

The remaining temperature lift is accomplished

with the electric heater alone.

OFF/ON OFF

D14

Legionella T

The legionella temperature set point can be regulated.

60-65 60

D15

Legionella date

The legionella week day can be set Monday/

Sunday

Sunday

36

Code

Set point

name

Description Range

Factory

setting

D16

Forced

operation

The forced operation of the heat pump can be

activated here. The heat pump starts even if there

is not need for hot water. When the maximum

temperature allowed by the heat pump is reached

the unit will stop. This function is to use for testing

purposes. It becomes OFF again after one heat up

cycle is completed.

OFF/ON OFF

D17

Low

Tariff

weekday

The start and stop time of the low electricity tariff

period for weekdays. Three periods can be selected.

0-23

0-23

0-23

0

0

0

D18

Low

Tariff

weekend

The start and stop time of the low electricity tariff

period for weekends. Three periods can be selected.

0-23

0-23

0-23

0

0

0

D19

Light

Saving

Time

Light Saving Time can be deactivated.

OFF/ON ON

D20

PV min

Voltage

HP*

The minimum voltage (V) required to start the HP

when the PV function is active. 0-10 0

D21

PV min

Voltage

EL*

The minimum voltage (V) required to start the

electric heater when the PV function is active. 0-10 0

D22

PV min

time*

The minimum time (minutes) at which the input

voltage from the PV panel should be above the set

point D20/D21 (PV min Voltage HP/EL) in order to

start the electric heater or heat pump when the PV

function is active. D22 also regulates the minimum

heat pump operational time when started by the PV

function.

1-120 15

D23

Solar T

max*

The maximum allowed temperature (°C) in the solar

collector.

55-89 89

D24

Solar DT

min*

The minimum temperature (°C) difference between

solar collector and tank.

1-5 5

D25

Floor T

start*

The temperature (°C) that needs to be in the tank to

allow the floor function to be active with hysteresis

of 1K.

25-45 35

37

Code

Set point

name

Description Range

Factory

setting

D26

Extra

function*

The desired extra function is selected here. The

possible functions are Solar, Floor or Cooling.

Once the function is activated, move to the function menu and adjust the set point as desired.

OFF/

Solar/

Floor/

Cooling

OFF

D27

OFF

The SG ready function can be activated by the

installer here. Three possible modes can be selected. This function allows the start of the heat pump

from an external access (See QA1 in Figure 16).

SG ready is not active if there is not external input

(SG1 OFF, SG2 OFF).

OFF/

SG Boost/

SG Eco/

SG Block

OFF

(SG

BOOST)*

The heat pump and electric heater must start, if

below the max water temperature allowed in the

tank. Both Heat Pump and Electric heater are

forced to operate (SG1 ON and SG2 ON).

(SG

ECO)*

The heat pump operates minimizing

costs, only the heat pump is activated ( SG1 OFF,

SG2 ON).

(SG

BLOCK)*

The unit can be stopped even if there is a need for

hot water (SG1 ON, SG2 OFF).

D28

Cooling

1*

The fan and heat pump run until the additional

temperature T5 placed in the room environment is

below a certain level. The water temperature can

only reach the maximum temperature allowed in

the tank D33 (T HP max). The cooling function activates a three-way damper, which directs the cold

exhaust air to a room with cooling requirements.

The two functions operate the damper in opposite

directions.

Cooling 1 (2). If the T5 is higher than B10 T

Cooling, the extra relay that operates the damper

(GP1) switches ON (OFF).

If the T5 is lower than B10 (T Cooling), the extra

relay that operate the damper (GP1) switches OFF

(ON).

Cooling1/

Cooling2

Cooling

1

Cooling

2*

SG ReadyCooling Type

38

7.5. Defrosting

When the evaporation temperature (T2) falls below 0°C, the evaporator starts to

accumulate ice on its fins. In order to maintain the unit reliable and well performing, an

automatic defrosting operation is activated.

Defrosting can occur between 60 minutes and 120 minutes from the last defrosting

or from the last moment in which the evaporation temperature was above 0°C.

Defrosting can occur with two different strategies according to the conditions of the

inlet air.

Code

Set point

name

Description Range

Factory

setting

D29

OFF* Normal operation.

OFF/

Hygrostat/

Ventilation

Max/

Start-Stop

OFF

Hygrostat*

The fan always runs according to the input signal

in GC1 (0-10V) from an external hygrostat,

CO2-sensor or similar appliances.

1. If the voltage is between 0 - 3.0 V the fan

speed is D5 (Fan min speed).

2. If the voltage is between 3.0 - 8.0 the fan

speed is D4 (Fan medium speed).

3. If the voltage is higher than 8 V the fan

speed is D3 (Fan max speed).

Ventilation

max*

If the ventilation function is already selected,

a signal higher of 2V to GC1 leads to maximum

air flow.

Start/

stop*

If GC1 receives a signal higher than 2V, the unit

operation is stopped.

D30

Filter

timer

The filter function is activated (ON) or deactivated (OFF).

OFF/ON OFF

D31

Filter

timer time

If the filter function is ON then the timer of the

filter can be selected. This set point determines

the number of months after which the filter

alarm is displayed.

0 -12 3

D32

Filter

reset

Once the air filter has been replaced, activate

this function to reset the filter timer.

OFF/ON OFF

D33 T HP max

The maximum water temperature that can be

reached by the heat pump in °C .

50-65 60

External control

39

1) If the air temperature is above 4°C, then the defrosting occurs running both compressor and fan. The fan runs at speed D3 (Fan max speed).

2) If the air temperature is below 4°C, then the defrosting occurs running the compressor and stopping the fan.

Before defrosting is completed the fan stops for a short period to allow the excess

water in the unit to leave the unit from the condensate drain. Defrosting automatically

stops when the temperature of the evaporator (T2) becomes higher than the set point

(D10).

7.6. Photovoltaic Function

The domestic hot water heat pump (DHWHP) can be controlled by a signal from a solar

photovoltaic (PV) converter or an energy meter, either as simple start/stop via a potential free contact or by a variable signal.

Figure 20 represents possible installation configurations with or without energy meter.

Using the variable signal option, a certain output (DC or mA) from the (PV) inverter or

the energy meter corresponds to a given amount of excess power for use in the DHWHP.

This excess power can be used to activate either the electrical immersion heater, the

heat pump (HP) or both.

Figure 20 – PV installation 1: control signal from inverter. PV installation 2: control signal from energy meter.

40

TB1: DC/AC Inverter

BU: Energy meter

E1-2-3: Electric loads

WG1: Heat pump power supply

GC1: Photovoltaic function input signal (0-10 VDC , 0-3 VDC, 4-20 mA).

7.7. Safety fea tures

7.7.1. High pressure switch

In order to ensure that the compressor does not run beyond its operating envelope

there is a built-in high pressure switch which shuts down the compressor when the

pressure in the cooling circuit becomes too high. The pressure switch shuts down the

compressor if the pressure gets higher than 2.0 MPa.

To restart the unit, the power must be switched off and switched on again.

7.7. 2 . Saf et y b re ak er s

In the event of a failure on the electrical immersion heater, the safety breakers will

shut down the unit. If the set value (80°C) is exceeded, the electrical immersion heater

will disconnect. The electrical immersion heater can be reactivated when the temperature is below 80°C.

To do this, the power to the unit must be switched off and the front panel dismantled.

Then the reset buttons in the center of the breakers can be pressed. This must only be

performed by skilled personnel.

Morever, an additional thermal safety breaker switches off the compressor in case

the compressor surface reaches temperatures above 160°C

41

7.7. 3 . A larms

Alarm Meaning Possible reasons Possible solutions

Er1, Er2,

Er3, Er4,

Er5

Temperature

sensors out

of range

The temperature sensor T1, T2, T3,

T4* or T5* is defective or not connected to the PCB

Check that the sensor is

connected to the PCB

Substitute the temperature

sensor

Err HP High

pressure

switch

High pressure in the cooling system Reduce the water

temperature setpoint

Reduce the fan maximum

speed in the installer menu

High pressure switch BP1 is defective

or not connected to the PCB

Substitute component

Er 7 - Err

Evap /

Er9 - Err

H Evap

High

evaporator

temperature

Wrong position of the temperature

sensor

Check that T2 is positioned in

the evaporator

Leakage of refrigerant

Fix leakages and charge

refrigerant

Err C

Evap

Low

evaporation

temperature

Mal-functioning fan Make sure that the fan is

connected to the PCB or

substitute the component

Low air flow Increase the minimum fan

speed in the installer menu

Low air inlet temperature T1 Increase the minimum air

temperature in the installer

menu

Er10 Filter

Change filter Substitute the air filter

42

8. MAINTENANCE

Please observe local rules and regulations regarding potential periodically inspection

of the heat pump by skilled personnel.

8.1. Environmental requirements

When repairing or dismantling the domestic hot water heat pump please follow the

environmental regulations and legal requirements in relation to recycling and disposal

of materials.

8.2. Cooling system and fan

Servicing primarily consists of cleaning of the evaporator if no air filter is installed.

Remove the top plate of the unit. Relocate cables from the top part of the EPS housing. Remove the top part of the EPS housing off the unit. Clean the evaporator and fan

with a brush or a bottle brush.

Be carefull using cleaning spray. The may contain chemicals that can damage EPS

parts. If in doubt, check the spray on a small EPS.

Be careful not to remove balancing weights on the fan wheel during this process, as

this will cause fan imbalance and lead to a higher noise level as well as wear and tear

on the fan.

8.3. Condensation and condensate drain

Together with inspecting and cleaning of the fan, the condensate drain shall be

cleaned of dirt.

Pour some water in the lower half of the EPS part and check if the water flows freely.

If not, then the drain must be cleaned.

43

8.4. Water circulation and water tank

8.4.1. Pressure relief valve

Your installer has installed a pressure relief valve near the cold water connection on

the domestic hot water tank to protect the water tank against excessive pressures

when the domestic water expands during the heating process.

The back pressure valve (check valve), which is installed in front of the pressure relief

valve on the cold water pipe, prevents water from the tank flowing back into the cold

water pipe. Therefore, the pressure in the water tank rises to the maximum setting of

the pressure relief valve and the pressure relief valve opens. The redundant water discharges. If the pressure relief valve did not open, the water tank would burst.

The pressure relief valve must be operated regularly to remove lime deposits and to

verify that it is not blocked. It is tested by pressing the lever/turning the handle on the

pressure relief valve while checking that water discharges. Damages due to a faulty

pressure relief valve are not covered by the warranty.

Please note that water may drip from the discharge pipe of the pressure-relief valve

due to heating of the water.

8.4.2. Anode

In order to prevent corrosion of the enameled hot water tank, a magnesium anode is

installed behind the front panel at the top half of the water tank.

The anode has a life expectancy of approximately 2-5 years depending on the water

quality.

It is recommended to inspect the anode every year.

1) Disconnect the electrical power supply or pull out the power plug.

2) Remove the plastic front cover. This allows access to the anode.

3) Disconnect the wire connection between the anode and the tank (see pictures

below).

4) Insert a multimeter (range mA) between the anode and the tank. Anode current >

0.3 mA: Anode is active and ok. Anode current < 0.3 mA: Anode should be checked

and possibly be replaced.

5) Reconnect the wire connection between the anode and the tank. Close the front

cover and switch on the unit.

44

0.3 mA

Figure 22 – Anode control

Please note that the water has to be heated to operational temperatures at least once

before the test above can be performed.

In order to replace the anode the following should be done:

• Close the cold water inlet.

• Connect a hose to the drain valve so the water from the water tank can run into the

nearest drain.

• Open a hot water tapping point (to avoid vacuum in the water tank).

• When the water level in the tank is below the anode, this can be removed for inspection and replacement.

Check and replacement of anode must only be performed by skilled personnel.

45

9. DISASSEMBLY & DECOMMISSIONING

The following must be done during decommissioning:

• Disconnect the unit from the power mains - i.e. the electrical cables are removed.

• Close the cold water supply and attach a hose to the drain valve, so that water from

the tank can run to the nearest drain.

• Remove the water and heating pipes.

• Remove the air ducts and close all supply and extract air dampers so that no condensation forms in the ducts.

The unit has to be decommissioned in the most environmentally proper manner. When

the product is discarded, please observe the local municipal waste removal regulations.

46

10. TROUBLESHOOTING

In addition check out the following questions before contacting an installer:

• Is the cold water supply open?

• Has the periodic cleaning of evaporator, condensation drain and fan as described in

the maintenance section been followed?

• Has any of the safety features disengaged the heat pump/electrical immersion

heater?

• Has external short-circuiting of terminals disengaged the heat pump?

• Has factory resetting been tested?

• If it is not one of the above errors, please contact:

In the warranty period (0-2 years): The installer, from which the unit was purchased.

After the warranty period (> 2 years): The installer from which the unit was purchased

or partners of the manufacturer.

Please have data from name plate ready (silver plate on the unit).

47

Problem Possible reasons Possible solutions

The product

does not

supply hot

water

The unit is not connected to the

power supply

Make sure the display turns ON

Alarms from the controller stop the

operation of the unit

Check the alarms in the Info menu Er

Low water temperature set points Increase all temperature set points in menu

A Temperatures

Low airflow in evaporator Clean the evaporator and the air ducts

Fan does not work Make sure that the fan is connected to the

PCB or substitute the component.

SG Ready function is active Switch OFF SG Ready function

Themal safety switch FN1 opens

and stops the power supply to the

electric heater

Restore the original conditions of the thermal safety switch FN1.

High sound

emissions

Too high maximum fan speed Reduce the fan maximum speed in the

Installer menu

Activate the SILENT mode

Obstruction of the air ducts. Remove the obstruction

Dirt on fan or evaporator. Clean the evaporator and the fan. Do not

use cleaning spray that can be damage the

EPS housing

Components vibration Make sure all components as compressor

and solenoid valve are well fastened

48

11. DECLARATION OF CONFORMITY

The Declaration of Conformity can be downloaded at www.g

envex.dk

49

12. PRODUCT AND INSTALLER INFORMATION

Installed model:

Serial number:

Accessories:

Installers

Pipe installation

Date:

Company:

Name:

Phone number:

Electrical installation

Date:

Company:

Name:

Phone number:

Commissioning

Date:

Company:

Name:

Phone number:

50

51

OE04:956-1807

KVM-Genvex A/S • Sverigesvej 6 • DK-6100 Haderslev • Tlf.: +45 73 53 27 00 • salg@genvex.dk • genvex.dk

THE AIR WE BREATHE

Genvex –The original Danish Ventilation System

Genvex is a genuine Danish original. We invented the ventilation system

more than 40 years ago, and we are still ahead of the pack when it

comes to development and production of the strongest and most durable

ventilation system.

Our unit is working in thousands of homes providing fresh clean air

– free of pollen, dust and harmful particles. This helps to strengthen

the health of the house and to make the indoor environment healthy

and comfortable for lots of families. At the same time, our system is

an important element when it comes to saving energy in homes and

in society as a whole – in fact you can recover up to 95% of the heat

energy with a Genvex system.

All

Genvex

systems are

rated with

energy label

A

The original Genvex units are

assembled by skilled and

experienced technicians and

have a lifetime that in many cases

is measured in decades. The units

are approved by all applicable

standards and are easy to operate

and service. Last – but not least

all Genvex systems are developed

with focus on compact dimensions

and ease of installation and can be

integrated discreetly in all types of

homes.

We are part of the NIBE Group

– a family of companies that

specialize in supplying hot water,

heating and home comfort to

homeowners worldwide.

Please visit www.genvex.dk to see a list of our distributors

Loading...

Loading...