OPERATING

INSTRUCTIONS

OPTIMA 260 – ECO 190, ECO 375

2

TABLE OF CONTENTS

1. Installation of Optima 100 Design ...............................................................................................................................3

2. Installation of Optima 100 Opus ...................................................................................................................................4

3. Operation ...............................................................................................................................................................................5

4. Data Logger ...........................................................................................................................................................................5

5. Genlog Set Points ................................................................................................................................................................9

6. Function ............................................................................................................................................................................... 16

7. Maintenance .......................................................................................................................................................................17

8. Troubleshooting ................................................................................................................................................................ 18

9. Table of Factory Settings .............................................................................................................................................. 19

3

1. INSTALLATION OF OPTIMA 100 DESIGN

1.1 Installation of the Control Panel

The control panel is designed to be mounted onto

a level wall.

1.2 Installation

Find the installation place for the control panel, mark off

the holes and screw the fixture securely onto the wall.

Use at least 4 screws for securing the panel, two at the

top and two at the bottom.

Obligatory screw

Obligatory screw

Obligatory screw

Obligatory screw

Screw

Screw

Hold up the wall frame against the wall and mark off the

holes for fastening the frame. Drilling of holes, hole size

and suitable screws for fixing the panel all depend on the

wall material.

Place the control panel in the fixtures and tilt it in against

the wall. The four support points in the corners of the

display must touch the wall to keep the display stable.

A

Support

point

Support

point

Support

point

Support

point

Underneath the control panel there is access for the:

A: Terminal block. Connection to main circuit board

Fit a 8 x 0.25 mm

2

low-current cable between the unit and

the control panel. The maximum cable length is 50 m.

The voltage drop for cable lengths over 50 m is too high

and can cause operating errors.

Method of Installation of the Wall Fixture

First screw the fixture securely onto a level wall and then

guide the cable visibly up from below.

Connect the low-current cable to the terminal block.

Check that the cable is connected to the same

numbers at both ends.

(Between the control panel and the main circuit

board in the unit.)

Clip the control panel to the wall fixture by guiding it down

from above, slightly slanting out at the bottom. Finish by

pressing it in at the bottom so that it is flat against the wall.

To disassemble, pull the control panel slightly slanting out

at the bottom and lift up.

Pos. Description

1 Panel housing

2 Front of panel

3 Pressure plate for display

4 Wall fixture

5 Glass for the display

4

2.1 Installation of the Control Panel

The control panel is designed for being mounted to an Opus

type power socket.

2.2 Installation

Find the installation place for the control panel,

connect the wires and click the control panel into place.

Fit a 8 x 0.25 mm2 low-current cable between the

ventilation unit print circuit board and the control panel.

The maximum cable length is 50 m.

The voltage drop for cable lengths over 50 m is too high and

can cause operating errors.

Check that the low-current cable is connected to the same

numbers at both ends. (Between the control panel and the

main circuit board in the unit.)

The key on the left of the control panel is K3, and the key on

the right of the control panel is K5.

2. INSTALLATION OF OPTIMA 100 OPUS

5

4. DATA LOGGER3. OPERATION

Genvex item no. 022031

– USB/Optima communication cable for PC

Data logging equipment

There are two ways to adjust set points and program the

Optima 260 control system.

1. Programming via Genvex Genlog software using a USB

connected to the Optima 260 main circuit board.

2. Programming via Genvex Genlog software and

outputting set points to the SD card. (Use the "save to

SD card" function in the Set Point Management menu.)

Note on method 1

To be able to initiate communication with Optima 260,

use data logger equipment with a 4-pin connector.

Connect the 4-pin connector to the main circuit board

and the USB connector to the PC. These are accessories

that can be purchased directly from Genvex.

Note on method 2

To use method 2 to initialise a Genvex unit with an

Optima 260 control system, we recommend that you

remove the SD card of the main circuit board again after

starting up the unit (start-up and input of data take

approx. 2 minutes) as Optima 260 will input the

preprogrammed data on the SD card every time there

is a power outage. You can replace with advantage the

programming SD card with an empty SD card in order to

take advantage of the automatic data logging feature.

The latest version of the Genvex Genlog software can be

ordered from Genvex by telephone +45 73532700.

1

2

3

4

K3 K5

All Genvex ventilation units with Optima 260 control

system can be operated with an Optima 100 display.

The Optima 100 control system has the following

setup options:

• Fan speed

• Filter alarm

• Reheater activation/deactivation

The control system comes factory-preset, which means that

the unit can be put into operation without changing

the operating settings. The factory setting is only a basic

setting that can be adapted to the operating desires and

demands for the dwelling in question to make it possible to

achieve optimal utilisation and operation for the system.

3.1 Operating and Changing Settings

Optima 100 Design is operated with the K3 and K5 keys.

Optima 100 Opus is operated with the K3 and K5 keys.

The K3 key is used to change fan speed. To turn off the

ventilation unit, press and hold the K3 key for approx.

5 seconds (the unit will shut down after an afterflow period

of approx. 3 minutes).

Note: the "turn off ventilation" feature must first be

enabled in the control system via Genlog.

The K5 key is used to reset the filter alarm (press and hold

for 10 seconds). Individual push of the key activates/

deactivates a possible electric reheater, if mounted.

6

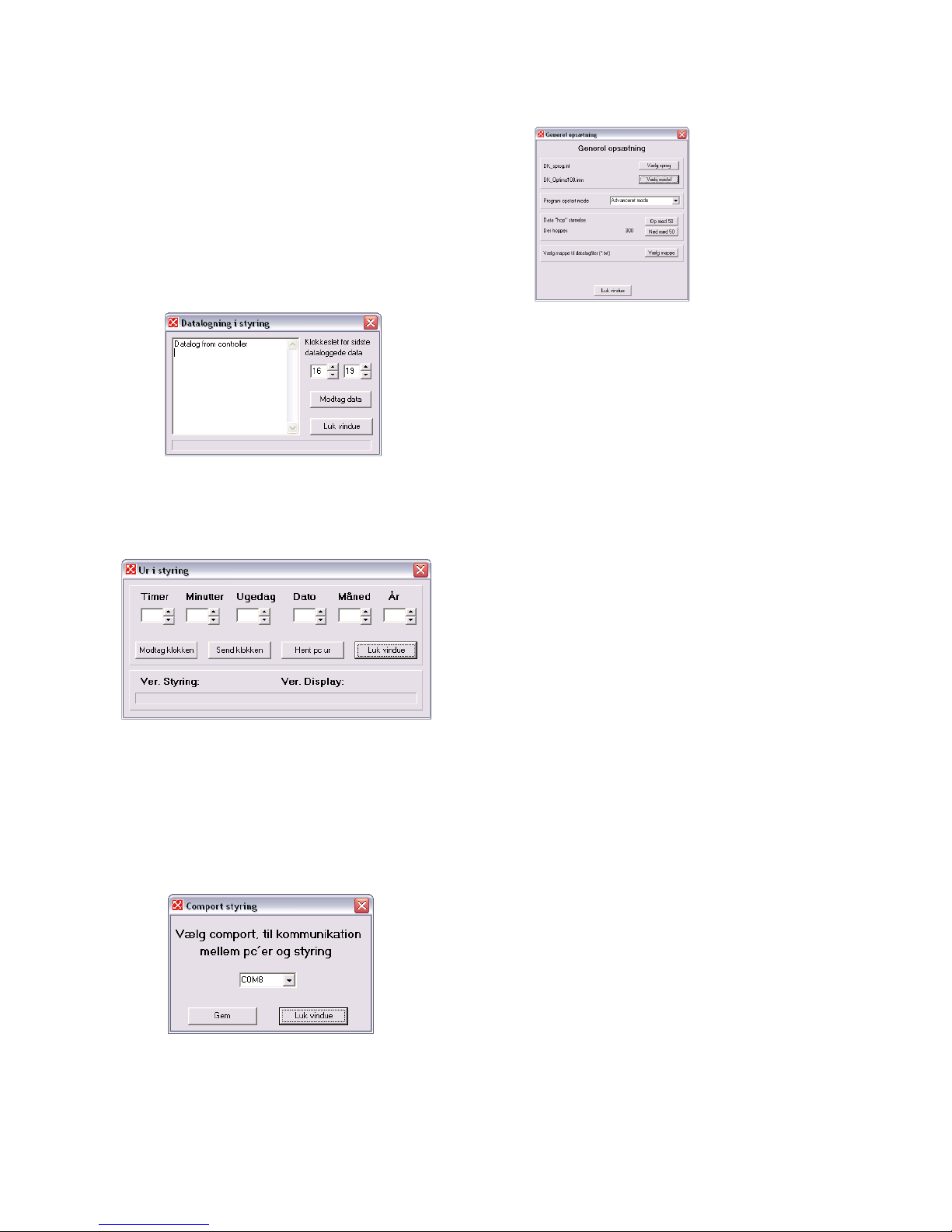

Functional Description of Data Logger

The data logger software is designed for configuring and

monitoring Genvex devices. The data logger can be

connected to all Genvex Optima control systems.

The instructions presuppose a correct and

functioning setup of the software.

The user interface in Genvex Data Logger

The data logger can be used for several different purposes:

Setup of parameters in the control system.

Setup and changes to the clock program in the control system.

Reading of the data logger in the control system for the

past three years.

“Live” logging of the current operation of the device.

Subsequent analysis of the operation of a device.

User interface

The program is structured with the primary image in the

middle of the screen. This is where the graphs that

represent the information collected from the control

system are displayed. The menu line for the various

settings is placed at the top.

Values that are read “here and now” or values that lie below

the read line are displayed on the left side. The red line

appears when you click a random place on the display.

The figures in the left column will then represent all the

values that lie on the line. The colours of the curves in the

logging area correspond to the colours displayed on the

left-hand side. The exact time of logging will be displayed

in the field at the very bottom.

Tip: Click on the clock field to change the field to display

“LOG NO.”. This can be useful if you want to refer to a

certain logging.

There is an area with grey and white lines at the top of the

logging area itself on the screen. These lines will be red if

relay function is active. Hold the mouse cursor over

the line for a moment, and a small help text will appear.

The left y-axis is a scale for temperatures. The right-hand

side of the logging area is the scale for percentages, e.g.

for fan speeds. The x-axis represents the time line.

A logging can contain a good many pages. This is why

there is a page number in the right/left corner next to the

red arrows. To flip between pages, click the red arrows.

Press and hold the left mouse button for a moment over

the red arrow to open a dialogue box. Here you can enter

the page number you want to scroll to.

There is a status menu located at the bottom of the

screen. This line displays the date and time, if the data

logging has started or stopped, the number of data log

files and which control system the software is

configured for (this is changed in “Settings”).

Menus

Files

Retrieve data*

– Retrieves data saved previously on the hard drive (.txt files)

Import of SD card files* – Imports data saved on the

Optima Design control panel (.dal files)

Save data – Saves the current logging

Save window – Saves only the current window

Save data Excel – save the data to comma separated

value file

Print – Prints the current window

Exit – Exits the software

*The data logger works with .txt files, whereas the control panel works

with .dal files.

View

View graphs – Opens a check box. This provides the

opportunity to select or deselect the graphs displayed

on the screen, usually to provide an overview.

7

Zoom – Makes the picture larger or smaller.

View average – Makes it possible to view an average of

the graphs in the selected window.

Functions

Start logging (20 sec.) – Opens a dialogue box for

inputting file name. It can be very advantageous to add

the Optima version to the name, e.g. by writing Opt310 as

part of the name. Then start a new logging from the

control panel. The logging is taken every 20 seconds and

is then displayed on the screen. After a while, the logging

will begin to form an image. If you do not click on the

image to generate the red line, the values on the left side

will refer to the last logging.

Stop logging (20 sec.)

Stops the logging. The display on the screen is saved

automatically.

One logging

Only performs a single logging. Not saved automatically.

Comments on data

Here you can add comments on a logging.

Delete data

Here you can delete data.

High-speed data logging (2 sec.)

Not saved in a file. Used for monitoring only.

Data from Control System

Set points in control system – Opens the following box.

Here it is possible to retrieve all set points from the

microchip or control panel, change them and then export

them back to the microchip or control panel.

Clock/week program in control system – Opens the

following box.

This program makes it easier and clearer to create the

clock program in Optima. Select the day of the week

which will be programmed by clicking on it. The day

selected in the example is Monday. Create the clock

program for Monday by using arrow-up and arrow-down

in the lowermost window, immediately to the left of the

buttons for the weekdays.

Select 1, 2, 3 or 4 underneath fanspeed level. To skip an

item, select 0. To stop the ventilation unit, select 4.

Once the clock program for the selected day has been

created, the day can be copied to the other days by

clicking on the day of the week.

The buttons on the right side of the window are used for

receiving and sending the change times to and from the

control panel and for downloading and saving the clock

program on the hard drive.

“Exit” "closes the window.

8

Data logging in control system (not for systems with SD

card for datalog) – Here you can retrieve the saved logging

in the control panel to the program. Change the time, if

possible, if the time of the last logging deviates from the

selected time. This is done out of consideration for the time

line at the bottom of the screen. This can be relevant, for

example, if the logging is retrieved from a transmitted

loose SD card or the like.

Click on “Receive data” to input the data. Note that this can

take up to 10 minutes. While the data is being loaded,

the control panel and the control system of the device will

not be able to communicate.

Clock in control system – An easy way to set the clock in

the control system.

Settings

Comport control – Here you select the Comport which will

be used for the data logger.

General setup – Here you can choose language,

model as well as folder for the log files.

For instance, it can be a good idea to create a folder for

logs under “Documents” and set up the program to suggest

this folder as default.

General Information

Note that:

• Loggings are not linked to setup. In other words, even if

the loggings are retrieved from the hard drive or the

control panel, they do not necessarily match the selected

control system. You therefore run the risk of analysing a

logging from a Combi, but viewing the values as if they

come from an Energy.

• The software is set up by default in Danish. This can be

changed in “Settings”.

• Certain antivirus programs will regard the log files as

viruses when they are sent by email.

Connection to PC – Optima 260

In order for the Optima 260 to be able to communicate

directly with the Genlog software, use data logger

equipment that can be connected directly to the Optima

260 printed circuit board. For details see page 5.

9

5. GENLOG SET POINTS

Calendar

Use this function to configure the setting for each day of

the week. Each day can be configured to run with different

fan speeds, as required. You can copy the configuration

from one day to another. Here you can choose ON or OFF.

If, for example, there is nobody home for some time, the

daily settings can be turned off and the system will run

according to a manual setting, e.g. level 1.

01 – Calendar

Choose between controlling the system manually or

controlling the speed (air exchange) and temperature

automatically according to a fixed weekday program.

If the menu item is set to OFF, the system will be controlled

manually according to the speed and temperature selected.

If the menu item is set to ON, the system will be controlled

according to the day programs entered in menu items 02 to

08.

Setting option: ON/OFF.

Example: Monday

Up to 10 switching times can be entered for one day.

The times can be entered in a random order. Enter hours

in the first, minutes in the second and speed in the third

column. Use the fourth column to enter the temperature

difference with which the temperature should be lowered.

Example: If the temperature is set to 21°C and you enter –

2.0°C, the system will aim at 19°C.

If the speed has been changed manually with the key under

daily operation, the program will return to the weekday

program once the next switching time has been passed.

Examples of a weekday program:

01 07:30 H3 -0.0

02 09:15 H1 -1.0

03 17:00 H3 -0.0

04 18:00 H2 -0.0

05 23:30 H2 -2.0

It is not necessary to use all switching times. If the line is

marked with 0, the control system will skip it.

Thursday to Sunday:

These days can be filled in individually in the same way as

under the example for Monday.

User menu

01 - Temperature

Set your desired temperature between 10 and 30°C.

Item 19 of the Service menu allows you to choose

between supply air regulation or extract air regulation.

Setting option: between 10 and 30°C.

02 - Preheating

If a preheater is fitted to the outdoor air duct, the set point

must be configured to ON. Enter the desired preheating

temperature in item 20 of the Service Menu. If a refrigerant

device is installed in the supply air duct instead, the set

point must be set to OFF. (It is not possible to control a

preheater and a refrigerant device at the same time).

If both types of optional equipment are installed, the set

point must be configured manually in the spring and in the

autumn. If none of the help functions in item 27 of the

Service Menu are used, help function 4 can be used to

control the additional cooling.

Setting option: ON/OFF.

03 - Reheating

If there is a reheater fitted to the system, you can choose if

the reheater should operate. If the set point is set to OFF,

the heater will not operate, even when this is necessary. If

the set point is set to ON, the heater will start, as required.

It regulates in accordance with the temperature set in item

1 of the User Menu.

Setting option: ON/OFF.

04 - Timer levels 3 and 4

At speeds 3 and 4, the system will automatically reconnect

to speed 2 after the number of hours set in item 17 of the

Service Menu by setting the set point to ON. If the set point

is set to OFF, the system will run at speed 3 or 4 until it is

manually changed to another speed.

Setting option: ON/OFF.

Monday 1

Tuesday 2

Wednesday 3

Thursday 4

Friday 5

Saturday 6

Sunday 7

Weekday

January 1

February 2

March 3

April 4

May 5

June 6

July 7

August 8

September 9

October 10

November 11

December 12

Month

10

05 – Change filter

There is a built-in filter timer which counts how long the

system has been running since the last change of filter.

The set point can be set between 1-12, which corresponds to

12 months. It is recommended that the set point be initially

set to 3, which corresponds to 3 months (if 0 is entered,

the filter timer is off and will not give filter warning).

If the filters are too dirty after the set period, set the set

point to a lower number. If it is not necessary to change the

filters after the configured period, the set point can be set

to a higher number.

When the timer reaches the set value for filter change,

the filter change alarm will flash on the display.

Once the filters are changed, return to the screen with the

daily operating options and press and hold down the filter

indicator key until the diode switches off. The device will

then change back to normal operation.

Setting option: between 1 and 12 months. set point = 0 will

disable the filter timer (Be careful when using this setting –

Genvex disclaims any responsibility for faults in the

ventilation unit caused by a clogged filter).

06 – Humidity control

Here you turn on humidity control. It must be set to ON in

order to be active.

Setting option: ON/OFF.

Service Menu

10 – Level 1 Supply air

Level 1, which is the lowest speed, is usually used when there

is nobody home. Both fans can be configured independently

of each other for all levels so that the air flow in the supply

air and in the extract air is equal, which provides optimal

operation.

The adjustment of the system must be performed with

specialised air measuring equipment and can be done

without using the main regulating damper.

Configuring the air flows without expert advice is not

recommended. Incorrect configuration can lead to major

energy consumption or unpleasant indoor climate.

Setting option: between 0 and 100%.

11 – Level 2 Supply air

Level 2 is the recommended speed of the system for

providing optimal indoor climate. It should be adjusted to the

ventilation requirement of the dwelling.

Setting option: between 0 and 100%.

12 – Levels 3 and 4 Supply air

Level 3 is the highest speed that can be configured.

It is used, e.g. if there are many guests or there is a

lot of activity in the kitchen.

Setting option for level 3: between 0 and 100%.

Factory setting for level 3: 75%.

Level 4 is used mainly in the summer for lowering indoor

temperature. Remember that a higher air exchange rate

increases energy consumption.

Setting option for level 4: Cannot be configured.

13 – Level 1 Extract air

The fan speed is adjusted until the same air flow is achieved

as the supply air on level 1.

Setting option: between 0 and 100%.

14 – Level 2 Extract air

The fan speed is adjusted until the same air flow is achieved

as the supply air on level 2.

Setting option: between 0 and 100%.

15 – Levels 3 and 4 Extract air

The air flow of level 3 is adjusted to the same air flow as the

supply air on levels 3 and 4 (item 12).

Setting option for level 3: between 0 and 100%.

Factory setting for level 3: 75%.

Setting option for level 4: Cannot be configured.

16 – Not relevant

17 – Timer levels 3 and 4

If automatic reconnection is used for speeds 3 or 4, you can

enter how many hours the system should run on level 3 or 4

before it automatically returns to level 2. The set point can

be configured to between 1 and 9 hours.

Setting option: between 1 and 9 hours.

18 – Filter/stop

To ensure that the filters are changed when the filter change

alarm flashes on the screen of the control panel, the set

point can be set to ON. The system will then stop

automatically after 14 days if the filters have not been

changed in

the meantime.

If this precaution is not required, the set point can be set to

OFF and the system will continue to operate.

Setting option: ON/OFF.

11

19 – Method of regulation

There are 2 options:

0. Cannot be used

1. Supply air regulation (T1 sensor)

2. Extract air regulation (T7 sensor)

If the system is used in a dwelling, supply air regulation is

the normal choice. The set point is set to 1. For extract air

regulation, set the set point to 2.

Setting option: between 0 and 2

20 – Preheating

If preheating is set to ON in item 2 of the User Menu,

the set point must be configured to the outdoor air

temperature, at which the preheater should kick in.

Setting option: between -15 and 0°C.

21 – Bypass open

Here you set the temperature at which the bypass should be

100% open. You set a temperature differential, which

means that if you want the bypass to be 100% open at e.g.

23°C and if the set temperature in User Menu item 1 is

20°C, this menu item should be set to 3°C.

The bypass will open, provided that:

1. The extract air temperature is higher than the outdoor

air temperature.

2. The outdoor air temperature is above the set

temperature in Service Menu item 29.

Units with modulating bypass

If the temperature rises by 0.5°C above the temperature

set in User Menu item 1, the bypass damper will begin to

open. The bypass is 100% open when the temperature

reaches the set point in User Menu item 1 + the

temperature differential set in this menu item.

To get a smooth opening of the bypass, the temperature at

which the bypass is fully open should be set to approx. 3 ºC

above the set temperature in Use Menu item 1.

Units with on/off bypass (e.g. ECO190/ECO 375)

The bypass opens when the temperature reaches the set

point in User Menu item 1 + the temperature differential

set in this menu item.

Setting option: between 1 and 10°C.

22 – Regulation water

If a water reheater with a motor-operated valve is installed

in the system, it may be necessary to adjust the regulation

time.

The less regulation time, the faster the motor-operated

valve will regulate.

Setting option: between 1 and 250 seconds.

23 – Regulation electricity

If an electrical preheater or an electrical reheater is

installed, it may be necessary to adjust the regulation time.

Setting option: between 1 and 300 minutes.

24 – Frost reduction

To avoid icing of the counter current heat exchanger,

the supply air flow can be reduced gradually, once the

discharge air temperature after the counter current

heat exchanger has fallen below the set temperature.

This function gradually reduces the supply air

flow until the set value is reached.

Caution: May cause under-pressure in the house!

Setting option: Between 0 and 10 °C. The function is

disabled if set to 0°C.

25 – Frost protection

If a water reheater with motor-operated valve is installed in

the system, a frost protection sensor must be fitted to the

water reheater and the set point must be set to ON.

If no frost protection sensor is installed, the set point must

be set to OFF.

Setting option: ON/OFF.

26 – Frost protection temperature

If frost protection in item 25 is set to ON, the frost

protection temperature must be set to the temperature

where the system should stop and the motor-operated

valve open completely for the flow of hot water.

Setting option: between 0 and 10°C.

12

27 – Help function

This function can be used for the following:

Set point Function

0 The relay is off.

1 The relay is on when the system is running.

This can, e.g. be used to open and close

the outdoor air damper and the discharge

air damper.

2 The relay is on when extra heat is required or

when the circulating pump should run when

heating with water reheating is required.

3 The relay is on when the “Change filter” alarm

is active. This can be used to activate an

external alarm.

4 The relay is on when extra cooling is required.

This function is used if a preheater is also

fitted to the system.

The control can handle an earth heat

exchanger using a damper.

The relay will be on if one of the following two

conditions are met:

• The outdoor temperature, sensor T9, is

lower than the value configured in item 26

(frost protection temperature, typically set

at 5°C).

• The outdoor temperature, sensor T9,

is more than 1° above the temperature

configured in item 1 and 1 ° above the

current room temperature.

Setting option: between 0 and 5.

28 – System stop

Here you choose if it should be possible to stop the system

by pressing the key for speed (K1) in the operating menu for

3-4 seconds. If the set point is OFF, the system cannot be

turned off.

Setting option: ON/OFF

29 – Turn off bypass

To prevent the bypass damper from opening at low outdoor

air temperatures and from blowing cold, unheated air into

the dwelling, use this function to configure the lowest

outdoor air temperature, at which the damper must be

closed. The value is an expression of the greatest

difference that may exist between the temperature

configured in item 1 and the lowest outdoor air

temperature.

Setting option: Between 0 and 20 °C. If 0°C is selected,

the function is turned completely off.

30 – Modbus Mode

See separate description for MODBUS.

Setting option: 0-2.

0 = Modbus OFF

1 = 9600 Baud

2 = 19200 Baud

31 – Modbus Address

See separate description for MODBUS.

Setting option: 1-247.

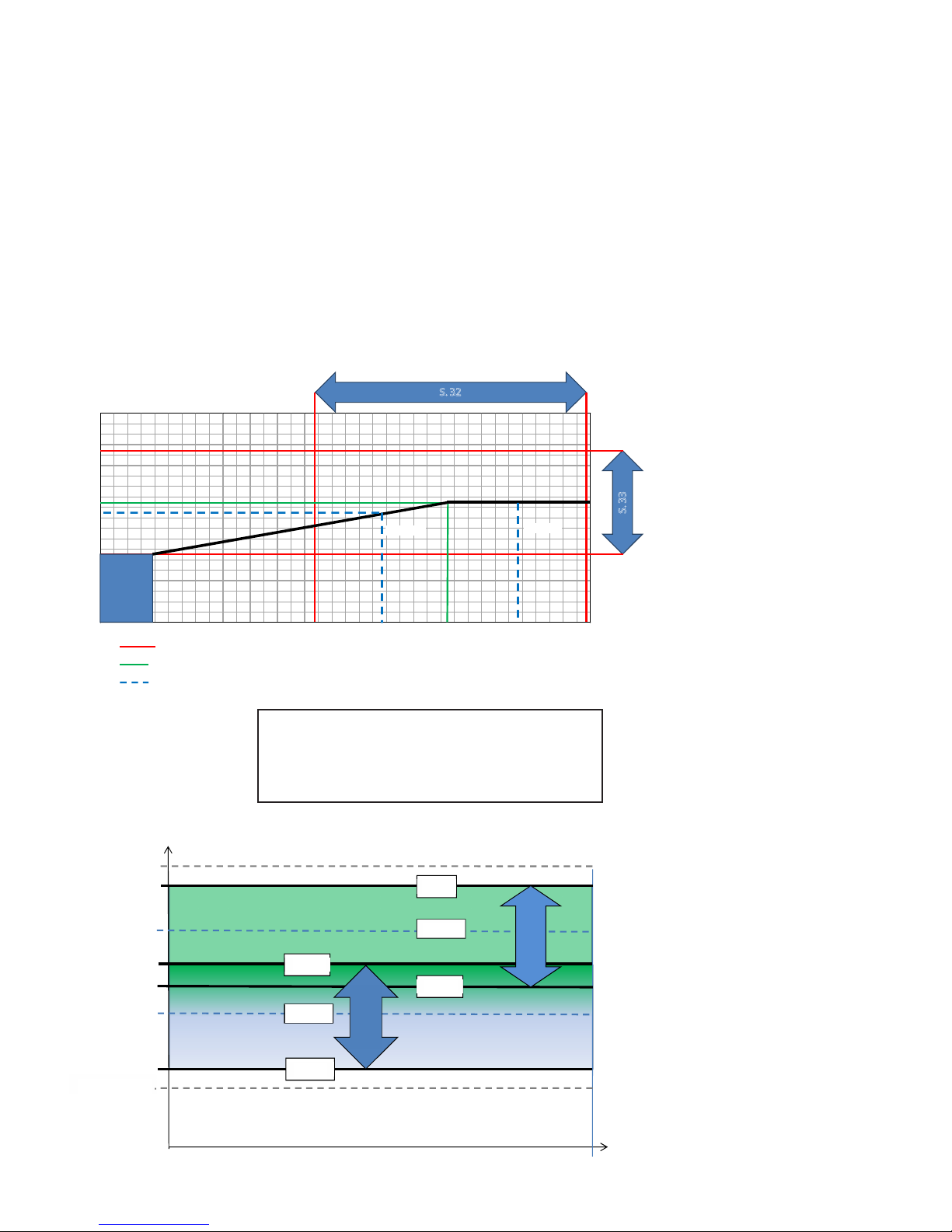

32 – Humidity max. temperature

Setting the end point for outside temperaturecompensation (T3), see the X-axis on the graph.

Setting option: 5-25°C.

33 – Humidity max. value

Setting the end point for outside temperature

compensation, see the Y-axis on the graph (desired max.

humidity value).

Setting option: 35-85%.

34 – Humidity fan speed

Setting of how much the fan speed may differ in relation to

the desired fan speed. See menu items 11, 12, 14 and 15.

Setting option: 5-30%.

Examples

Set point 34 = ± 15%

With a desired fan speed of 3, the fan speed will be able to

fluctuate by ± 15%. Since fan speed 3 is set at 75% in

Service Menu 12 and 15, the fan speed will be max. 90%

and min. 60%.

The same applies to fan speed 2. Since fan speed 2 is set at

50% in Service Menu 11 and 13, the fan speed will be max.

65% and min. 35%.

Fan speed is regulated by ±1% once every 10 min.

Setting option: See item 35

= Grænser

= Standardindstilling

= Eksempler

Eksempel 1

Ved en frisklufttemperatur på 10°C vil værdien for relativ

fugtighed være 55 %.

Eksempel 2

Ved en frisklufttemperatur på 20°C vil værdien for relativ

fugtighed være 60 %.

100%

95

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0 - 10 -9 - 8 -7 -6 -5 - 4 -3 -2 - 1 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

S. 33

S. 32

Pre-

setting

Eks. 1

Eks. 2

RH

Fast

indstilling

Frisklufttemperatur

Trin 3 = 75 %

35 %

65 %

90 %

60 %

±15 %

±15 %

S.34

S.34

Trin 4 = 100 %

Trin 2 = 50 %

Trin 1 = 25 %

13

35 – Humidity regulating frequency

Setting of desired frequency for how often the fan speed

may be changed.

The function is defined as 1% per unit of time.

When humidity regulation is activated, the current

humidity is continuously measured via the integrated

humidity sensor in the ventilation unit, which is placed

in the extract air duct.

Setting option: 1-60 min.

Outside temperature compensation curve

Fan speed

Presetting

E.g., 1

90%

65%

60%

35%

±15%

±15%

= Boundaries

Outdoor air temperature

= Factory setting

= Examples

E.g., 2

Example 1

The RH value at an outdoor air temperature of 10°C is 55%.

Example 2

The RH value at an outdoor air temperature of 20°C is 60%.

RH

Level 4 = 100%

Level 3 = 75%

Level 2 = 50%

Level 1 = 25%

14

36 – Right/Left (only relevant for ECO 190)

NOTE: THIS FUNCTION SHOULD ONLY BE ADJUSTED BY

AN AUTHORISED VENTILATION CONTRACTOR.

ECO 190 is delivered by default in a right-configured

version. If the unit needs to switch to left-configured

design, reconfigure the temperature sensors for this by

setting this function to 1.

Note that you will continue to have to undertake hardware

changes, e.g. proper connection of condensation drain,

tipping of exchangers, moving of humidity sensor. Contact

Genvex if you need more detailed information.

37 – Preheat PI P

P-band for the PI controller for the electrical modulating

preheater.

The P-band controls the amplification of the controller

following a deviation from the set point (speeder)

38 – Preheat PI I

I-band for the PI controller for the electrical modulating

preheater.

The function controls how quickly the controller adapts

to a deviation of the set point (brake).

39 – Preheat Reg

The Preheat Cycle function works, as follows:

E.g. necessary output 50% and cycle = 60 sec means that

the controller will switch the preheater on for 30 sec and

off for 30 sec.

Note: Please refer to your country-specific regulations on

limitations when adjusting this function.

The modulating preheater function refers to the value

adjusted in set point no. 20.

The preheater will try to maintain a steady freish air

temperature according to this set point.

When the modulating preheater is used, the existing

outdoor air temperature sensor (T3), which is built into the

ventilation unit, can be used as reference. No extra

temperature sensor is required.

40 – Reheat offset

Offset for reheater with reference to the set point for the

requested temp on the display (user menu 01).

E.g. requested temp = 20°C

Offset value = 2 reheater aims to maintain a supply

temperature of 18°C

41 – Reheat PI P

P-band for the PI controller for the electrical modulating

reheater.

The P-band controls the amplification of the controller

following a deviation from the set point (speeder).

42 – Reheat PI I

I-band for the PI controller for the electrical modulating

preheater.

The function controls how quickly the controller adapts to a

deviation of the set point (brake).

43 – Reheat Reg

The Reheat Cycle function works, as follows: E.g. necessary

output 50% and cycle = 60 sec means that the controller

will switch the reheater on for 30 sec and off for 30 sec.

Note: Please refer to your country-specific regulations on

limitations when adjusting this function.

The modulating reheater function refers to the value

adjusted in set point no. 40.

The reheater will try to maintain a steady supply air

temperature according to this set point.

When using the modulating reheater, it will be necessary to

replace the inlet air temperature sensor (T1) in the

ventilation unit with a new temperature sensor installed

upstream of the reheater.

44 – Display Model

This is where you choose which external display is selected

together with the Optima 260 control system.

0 = No display

1 = OPT100 Design/OPT100 Opus

2 = Boost button

45 – Boost time 1 (only relevant if a boost button is purchased)

This is where you choose how many minutes of pressing the

boost button will lead to forced operation – when the

button is pressed once

46 – Boost time 2 (only relevant if a boost button is purchased)

This is where you choose how many minutes of pressing the

boost button will lead to forced operation – when the

button is pressed twice

47 – Boost time 3 (only relevant if a boost button is purchased)

This is where you choose how many minutes of pressing the

boost button will lead to forced operation – when the

button is pressed three times

48 – Calendar on/off

This is where you can activate calendar functions. See a

more detailed description under the item "calendar".

15

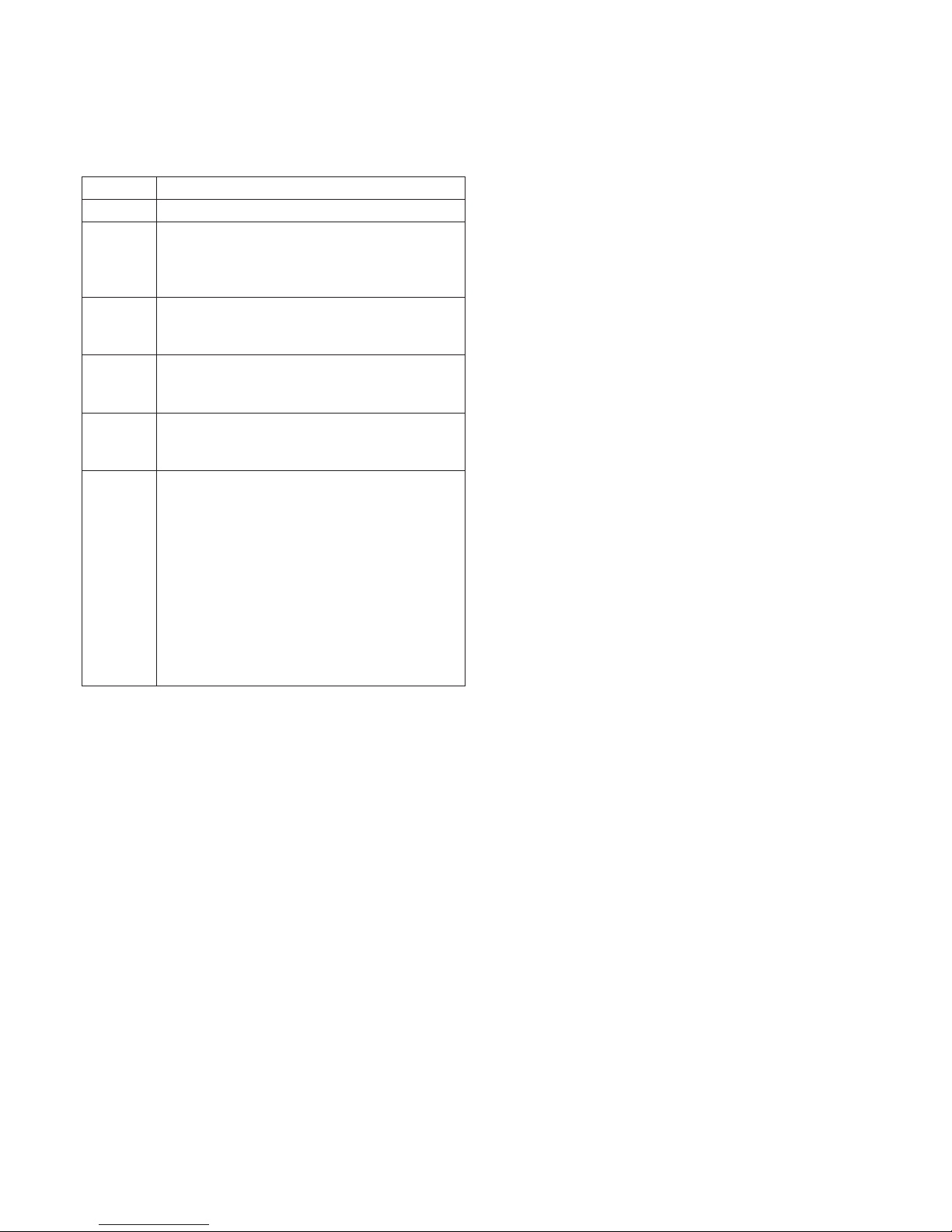

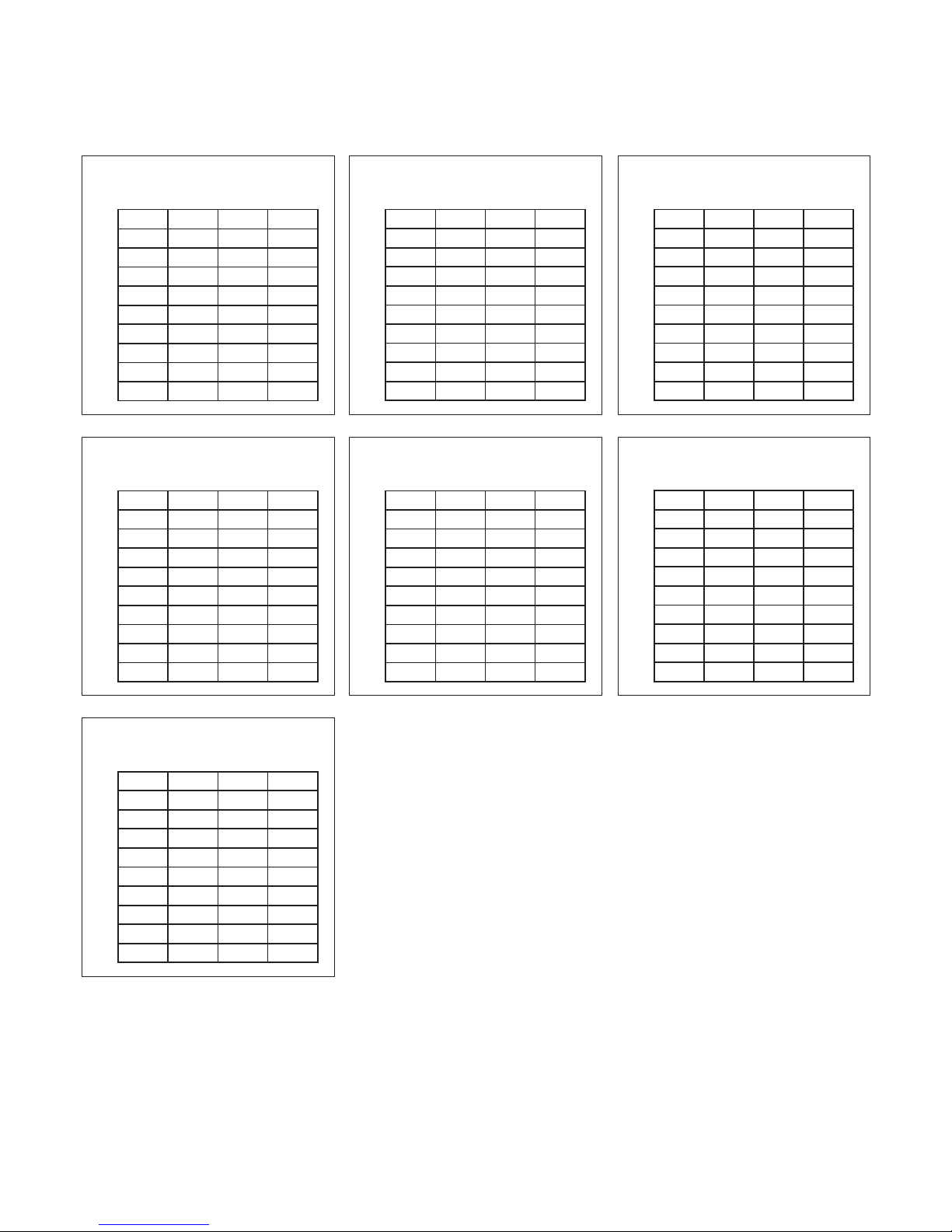

Schedule for week program

Red. T2 = Reduced room temperature (Night set-back)

Hours Minutes Speed Red. T2

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

Monday

Hours Minutes Speed Red. T2

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

Thursday

Hours Minutes Speed Red. T2

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

Sunday

Hours Minutes Speed Red. T2

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

Tuesday

Hours Minutes Speed Red. T2

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

Friday

Hours Minutes Speed Red. T2

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

Wednesday

Hours Minutes Speed Red. T2

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

Saturday

16

6.1 Regulation of Optima 260

Regulation of room temperature

There are 2 methods of regulation – see Service Menu item

19. If supply air regulation has been selected, the controller

will blow in air with the temperature set, provided that a

reheater is fitted to the system. The supply air temperature

is regulated by the supply air sensor, T1.

When using extract air temperature control, we recommend

that the supply air temperature be configured 2-3°C below

the room temperature.

Relay R8

When the system is running at levels 1, 2, 3 or 4, the relay

will be turned on. This function can be used to e.g. control

an optional fresh air damper or the discharge air damper.

6.2 Extra heating and cooling

Water reheating

For systems with water reheaters, the motor-operated

reheater will begin to regulate (PI regulation) when the

temperature has fallen 1°C below the set temperature.

Electrical reheating on/off version

For systems with electrical reheaters, the reheater will

connect when the temperature has fallen 1°C below the set

temperature. If the regulation time is set to, e.g. 3 minutes,

temperature sensor T1 will measure if the temperature is

now above or below the temperature set after 3 minutes.

If the temperature is still below the set temperature,

the reheating will keep running. When the temperature

reaches the set value, the electrical reheater will disconnect.

Electrical reheater (modulating)

As regards systems with a modulating electrical reheater,

the electrical reheater will automatically adapt to changes

in airflow and temperatures maintaining a constant

temperature according to the requested set point.

The controller will be adjusting the electrical output of the

reheater automatically.

Extra cooling

If an extra cooling device is fitted to the system, such a

device will turn on when the bypass motor is open

completely and turn off again when the bypass motor

begins to turn off again.

Systems with an electrical preheater will regulate in the

same way as an electrical reheater.

6. FUNCTION

17

Follow the following instructions to achieve optimal

performance:

Before you open the unit, turn off the power/

pull out the plug and wait until the fans have

stopped completely.

A couple of days after the primary installation, check that

the condensation outlet is working.

Environmental requirements

When repairing or dismantling the unit, statutory

environmental regulations must be observed regarding

recycling and destruction of various materials.

7.1 Unit

Filters

When the alarm flashes in the control panel display, the

filters must be changed. Stop the system using the circuit

breaker of the unit or the circuit breaker on the terminal

board. Open the front cover/filter drawers and remove the

filters. Once the filters are changed, reset the filter timer.

There is a danger of cuts from sharp edges.

The edges must not be damaged.

Vacuum cleaning or using pressurised air on the

filters is not recommended as it can impair filter

performance.

G4 = Standard filter

F5 = Fine filter

F7 = Pollen filter

Condensation drain:

When changing the filter in August/September, before the

outside temperature falls to 5°C, check that the

condensation drain is not blocked by dirt and make sure

that there is water in the water trap. Pour 1 litre of water

into the condensation tray and make sure that it runs off

freely. If the condensation drain does not work, this could

lead to water damage at your home.

Heat exchanger:

Inspect the heat exchanger every year. If it is dirty,

remove it and:

• Alu-exchanger: Wash in lukewarm soapy water and rinse

using a hand shower, if necessary.

• Plastic exchanger: No cleaning with solvents – use only

clean water and carefully remove dust from air intake

surfaces with a household vacuum cleaner.

Fans

Inspect the two fan wheels for dirt every year. If they are

dirty, they can be washed with a brush, bottle cleaner, etc.

Supply air and extract air valves

Clean the valves by wiping them with a dry cloth.

Make sure that the valves do not turn causing changes to

the air volume.

7.2 Alarms

Filter timer

The control has a filter timer to guarantee that the filter is

changed and that optimal operation is achieved. When the

timer reaches the set value, a key will flash in the display

until the filters have been changed.

Once the filters are changed, press and hold down the filter

indicator key until the diode switches off.

7.3 Dismantling/taking the system out of service

Do as follows:

Disconnect the power supply, i.e. the power cables.

Disconnect the condensation outlet and power cables for

any reheaters/preheaters. Disconnect the cables to the

control panel and dismantle ducts.

If the system should be taken out of service, the ducts must

be dismantled to avoid condensed water in the system and

in the ducts. Close all supply air and extract air valves.

7. MAINTENANCE

18

8.1 Safety thermostat in electrical heater

(optional equipment)

If an electrical heater suffers from a fault, the safety

thermostat will disconnect. The heater is equipped with a

fire thermostat that automatically cuts off the power

supply if the temperature exceeds 50°C. If the temperature

falls, the heater automatically re-engages.

As an additional safety measure, there is a built-in thermal

cut-out, which disengages if the temperature exceeds 100°C.

Re-engaging must be done manually.

This does not apply to PTC electrical heaters.

8.2 The system is not running

Unit stopped:

Possible error:

• Fuse in main board has blown, no power to unit

• One of the fuses on the circuit board of the unit has blown

• Loose wire, no power to unit

• Loose wire between unit and control panel

• Faulty or incorrectly set week program

• Filter timer has switched the system off

Condensed water is leaking from the unit

Possible error:

• Condensation outlet blocked by dirt

• The condensation outlet is not adequately protected

against freezing at low outdoor temperatures.

8.3 Air faults

No supply air:

Possible error:

• Faulty supply air fan

• Clogged supply air filter

• Clogged outdoor air grill due to dirt and leaves during the

fall and snow and ice during the winter.

• Fuse on the circuit board has blown

• The unit is in defrost mode (supply air fan stops)

• Incorrect value set in User Menu item 2

No extract air:

Possible error:

• Faulty extract air fan

• Clogged extract air filter

• Fuse on the circuit board has blown

8. TROUBLESHOOTING

Cold supply air:

Possible error:

• Clogged heat exchanger

• Faulty extract air fan

• Clogged extract air filter

• The electrical reheater is disconnected from the

overheating thermostat (only units with electrical

reheater installed).

• Air in the heating pipes, faulty thermostat/motor valve,

incorrect setting of control panel

19

8. TABLE OF FACTORY SETTINGS

Item Headline Factory setting Configuration area Date Date Date Date

(5.5) 01 Temperature 21°C 10 - 30°C

02 Preheating OFF ON/OFF

03 Reheating OFF ON/OFF

04 Timer levels 3 and 4 OFF ON/OFF

05 Change filter 3 months 1 - 12 months

06 Humidity control OFF ON/OFF

(5.8) 10 Level 1 Supply air 30% 0 - 100%

11 Level 2 Supply air 50% 0 - 100%

12 Level 3 and 4 Supply air 75% 0 - 100%

13 Level 1 Extract air 30% 0 - 100%

14 Level 2 Extract air 50% 0 - 100%

15 Level 3 and 4 Extract air 75% 0 - 100%

16 Not applicable OFF ÷ 5 - 0°C

17 Timer levels 3 and 4 3 hours 1 - 9 hours

18 Filter/stop OFF ON/OFF

19 Method of regulation 2 0 - 2

20 Preheating ÷ 3°C ÷ 15 - 0°C

21 Bypass open 3°C 1 - 10°C

22 Regulation water 20 sec. 1 - 250 sec.

23 Regulation electricity 3 min. 1 - 30 min.

24 Frost reduction 0°C 0 - 10°C

25 Frost protection OFF ON/OFF

26 Frost protection temperature 5°C 0 - 10°C

27 Help functions 0 0 - 5

28 System stop OFF ON/OFF

29 Turn off bypass 4°C 0 - 20°C

30 Modbus Mode 2 0 - 2

31 Modbus Address 1 1 - 247

32 Humidity max. temperature 15°C 5 - 25°C

33 Humidity max. value 60% 35 - 85%

34 Humidity fan speed 15% 5 - 30%

35 Humidity regulating frequency 10 min. 1 - 60 min.

36 Right/Left 0 0-1

37 Preheat PI P 5 1-255

38 Preheat PI I 200 1-255

39 Preheat Reg 40 10-120

40 Reheat offset -2 0-20

41 Reheat PI P 5 1-255

42 Reheat PI I 200 1-255

43 Reheat Reg 40 10-120

44 Display Model 1 0-2

45 Boost time 1 (min) 15 0-250

46 Boost time 2 (min) 30 0-250

47 Boost time 3 (min) 60 0-250

48 Calendar on/off 0 0-1

THE ORIGINAL BREATH OF FRESH AIR

08:116-1702

Genvex – the Original Danish Ventilation System

Genvex is a genuine Danish original. We invented our ventilation system

more than 40 years ago, and we are still ahead of the pack when it comes

to development and production of the strongest and most durable

ventilation systems on the market.

Our units are installed in thousands of Danish homes and deliver fresh,

clean air, which is completely free from pollen, dust and harmful

particles. This helps extend the service life of the house and creates a

healthy and pleasant indoor climate for thousands of people. At the same

time, our system is an important element when it comes to saving energy

at home and in society as a whole – a Genvex system actually allows you

to recover up to 95% of the heat energy.

All

Genvex systems

have energy label

A

An original Genvex system is built

by skilled, experienced technicians

and has a service life that in many

cases is measured in decades.

Our units are approved according to

all applicable standards and are also

easy to operate and service on a

daily basis. Last, but not least, all

Genvex systems are produced with

a focus on compact installation

dimensions and ease of installation

and can be installed discreetly and

beautifully in all types of homes.

We are part of the NIBE Group – a

family of companies specialised in

delivering hot water, heating and

home comfort to homeowners all

over the world.

A list of our dealers is available at www.genvex.dk

KVM-Genvex A/S • Sverigesvej 6 • DK-6100 Haderslev • Tel.: +45 73 53 27 00 • salg@genvex.dk • genvex.dk

Loading...

Loading...